Abstract

Transient expression of foreign genes by Agrobacterium infiltration is a versatile technique that can be used as a rapid tool for functional protein production in plants. A reproducible protocol of large-scale production of foreign proteins via the novel plant transient expression system in Pisum sativum L. was established in our study. Non-detached plants from soil-independent culture were used as the target organ, and vacuum infiltrating mediated by Agrobacterium tumefaciens harboring green fluorescent protein (GFP) gene was performed. Step-by-step optimization was performed and showed that the quality of plant material as well as agro-infiltration conditions were the major factors influencing the gene expression. Monitoring the transient GFP expression daily, the highest expression level was achieved on the 8th day post-infiltration. Evidence of anti-acidic fibroblast growth factor-single chain variable fragment (anti-aFGF-scFv) gene expression in pea seedling was also achieved using agro-mediated vacuum infiltration system. Our work proves that the system is suitable for the largescale production of pharmaceutical proteins. The in planta infiltration system described here provides a powerful tool to explore easily gene expression in Pisum sativum L. avoiding tissue culture steps and the labor-intensive generation of transgenic plants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Quite a number of new therapeutic proteins have been identified with the development and advance in biomedical research and the application of genomics to human health. The prokaryotic expression system is one of the important expression platforms for therapeutic proteins and other medical protein products (Sebastian et al. 2013; Akbari et al. 2015). However, utilizing traditional bioreactors to produce therapeutic proteins is faced with high costs or potential contamination with pathogens (Krishnan et al. 2012). Alternatively, plants are considered as attractive carriers to produce medicinal proteins (Hamid et al. 2015). Plant systems could effectively synthesize and accurately process the recombinant protein to guarantee the correct protein conformation and the biological functions. As bioreactors, the genetic and protein synthesis machineries of plants are utilized to produce heterologous proteins of interest, which can be purified. It is currently an important aspect in the biotechnology field. There are several advantages like low cost, easy purification, and flexible expression strategy in using plants for medical protein production.

Transformation systems based on the Ti plasmid of Agrobacterium tumefaciens have become the major tool for the transfer of foreign genes into plants for gene expression. Mainly two methods, namely, stable transformation and transient expression systems are widely accepted approaches for foreign protein expression. However, stable transformation system is a labor-intensive and time-consuming task that can take months to achieve, even in the most rapidly produced model plants (Orzaez et al. 2006; Leckie and Stewart 2011). Transient expression system is widely used in exogenous protein expression due to simple operation and short experiment period (Olivier et al. 2003). Also, the transient expression methods are capable of producing higher levels of the recombinant proteins than permanent modifications, because many copies of the recombinant genes are active in each plant cell (Giritch et al. 2006).

A combination of the transient expression methods is called magnifection (Gleba et al. 2014). Magnifection involves using modified plant virus vectors to modify Agrobacterium strains that are, in turn, allowed to infect the crop plant in a mild vacuum (Gleba et al. 2005). The combined use of plant virus vectors and Agrobacterium results in a large number of recombinant RNA virus particles entering the plant cells. High levels of recombinant proteins were produced by these recombinant RNA viruses epigenetically within a few days. Vacuum infiltration of whole plants with dilute suspensions of Agrobacteria carrying T-DNAs encoding RNA replicons was involved in the process of magnifection. The bacteria provide infection and systematic movement throughout the plant, while the viral vector provides short-distance spread, amplification, and high-level expression (Lico et al. 2008).

Pea (Pisum sativum L.) is one of the most important vegetable crops distributed worldwide. Both the appropriate proportion (starch 20–50 %, protein 20–30 %, sugars 4–10 %) and the ignored amounts of deleterious compounds, like lectins or protease inhibitors, make pea a fair source of animal and human nutrition (Barillot et al. 2014). The improvement of quantity and quality in plant bioreactors requires efficient transformation protocols and well-established procedures for plant regeneration. Since the first report of genetic manipulation in pea (Andre and Jacosen 1990), DNA transfer technology has been applied to several other pea species to produce transgenic plants by Agrobacterium-mediated transformation (Andre and Jacosen 1990) or by particle bombardment (Warkentin et al. 1992).

In the present report, we describe the development of magnifection using Pisum sativum L. whole seedlings for foreign gene expression. The magnifection system was optimized by exploring the conditions of Agrobacterium infection, pea seed germination time, concentration of surfactant, pea variety selection using the green fluorescent protein (GFP). Furthermore, first evidence of anti-acidic fibroblast growth factor-single chain variable fragment (anti-aFGF-scFv) gene expression in pea seedling was also achieved using the platform. Additionally, the target protein (scFv) was proven to be effective to combine with its antigen (aFGF). The newly established seedling transient expression system in Pisum sativum L. was considered as an effective and promising method for large-scale production of plant-derived medical proteins.

Materials and methods

Materials

Seeds of Pisum sativum L. were purchased from Agricultural High-Tech Research and Development Co., Ltd., Jilin, China. Plasmids pCAPE2-GFP and pCAPE2-Ev (empty vector) were provided by Dr. Constantin from the Danish Academy of Agricultural Sciences. pCAPE2-scFv was constructed in our lab. Agrobacterium GV3101 was used for transformation. Protein Purification Kit Ni–NTA Agarose (25 mL) was purchased from Promega; 1 mL Ni–NTA (prepacked gravity column) was purchased from Sangon Biotech (Shanghai) Co., Ltd.; Plant internal antibody (Rubisco large subunit) was purchased from Ximeijie Technology Co., Ltd.

pCAPE2-scFv construction

The scFv gene fragment was first PCR-amplified from pET-28a (+)-scFv using a forward primer P1 (5′-CATGCCATGGGCGACATCCAGATGACCCAGTCTC-3′) that contained 6 his-tag, enzyme digestion site Nco I, and a reverse primer P2 (5′-GGAATTCTTAATGGTGATGATGATGATGTGAGGAGACGGTGACCGT-3′) that fused with enzyme digestion site of EcoR I. The full gene fragment (approximately 741 bp) was then inserted into the cloning sites of pCAPE2 cDNA to form pCAPE2-scFv which was then introduced into Agrobacterium strain GV3101.

The establishment of foreign protein transient expression system in pea seedlings

Pea seed treatment

The pea seeds were soaked in clean water for 12 h and covered in wet cotton and kept at 25 °C in dark for 36–48 h to enable sprouting. The seedlings with 2–3 cm radicle and 0.5-cm cotyledons (Fig. 1a) were selected for vacuum infection. The Agrobacteria were infiltrated into the root and leaf tissues of pea plants after vacuum infiltration.

Pea seedling cultivation

Pea seeds were cleaned with sterilized water for 3 times and transferred into 55 °C-water bath for 20 min, and then left in room temperature overnight. Next day, seeds were cleaned with warm water (35–40 °C) and kept in 25 °C-incubator for germination. Seeds were cleaned once a day. Germination was stopped after roots and cotyledon appeared, probably 36–48 h later. The Agrobacterium GV3101 containing the respective plasmids pCAPE2-Ev, pCAPE2-GFP, and pCAPE2-scFv were cultivated in the LB liquid medium and shaked at 28 °C for 18–24 h. The Agrobacteria were collected by centrifuging at 4 °C, 5000 rpm for 10 min; the infection buffer (pH 5.6) contained 100 μM acetosyringone, 10 mM NaCl, 1.75 mM CaCl2; and 0.25 % Tween-20 was used to resuspend the bacteria and kept at room temperature for 1.5 h. The germinated pea seeds were immersed into Agrobacterium suspension for 1–5 min under 0.08 MPa vacuum pressures to penetrate the Agrobacterium into the pea seedling. Rectangular seedling dish (42 cm × 28 cm × 8 cm) with a perforated bottom was used to culture the seedlings. The seedling dish was covered with 10 layers of fully wetted cotton cloth at the bottom and an 8-layer blotting paper over the seedling. Afterward, the dishes with the seedlings were transferred into the incubator.

After infection, pea seeds were cultured at 28 °C in dark for 1 day, and then cultured in the light and temperature cycle for 25 °C 14 h light, 18 °C/10 h dark for 3 days. Pea sprouts were harvested at 6–8 days. The cultivation of pea seedlings was kept watered twice a day to ensure water supply. Four days after inoculation (dai), 100 ppm of nutrient (N:P:K = 20:10:20) was sprayed every day. Pea sprout cultivation process was shown in Fig. 2.

Young stem and leaf infected by Agrobacterium were harvested at 8–10 days and transferred into liquid nitrogen for 5 min, stored at −70 °C for soluble protein extraction. Residual pea plants after harvesting, cotton and absorbent paper were disposed environmental-friendly; seedling dish was reused after disinfection treatment; incubator and culture room were sterilized by UV lamp irradiation to prevent plant virus leakage.

Optimization of foreign protein production in transient expression system

Vacuum infection optimization. Vacuum pressure was set up to 0.02, 0.04, 0.06, and 0.08 MPa, respectively. Infection conditions were set to 60 s, once; 60 s, twice; and 60 s, 3 times. A hundred seeds were used for each setting. Different seed-germination age was selected for improving the expression system efficiency. The 24 h (root length: 1.5–2.0 cm, cotyledons were not appeared) and 48 h (root length: 2–3 cm, cotyledon was appeared) germination age were selected for infection. The infection buffer was used to suspend the bacterium. Two different surfactants were used for treatment: 0.01 % Silwet-77, 0.25 % Tween-20, with no surfactant treatment as control. The 0.08 MPa, 60 s twice of vacuum infection was performed. GFP expression was observed under UV lamp, and the statistical results were collected.

The influence of Agrobacterium infection on pea sprout growth

Sprouts economic yield means per unit area of edible stem and leaf weight. Since the foreign protein mainly expressed in stem and leaf of pea plants, thereby, the economic yield is taken as a measure index of protein yield in pea plants. Sprouts economic yield at different time points: 4, 6, 8, 10, 12 days was determined between Agrobacterium-infected and non-infected plants.

Evaluation of the expression system by GFP

As evaluation of the system, the Agrobacterium-contained pCAPE2-GFP plasmid was transformed into pea germinated seeds. The GFP expression was visualized using a 100-W, long-wave UV lamp.

Gene expression identification by RT-PCR

The total RNA was isolated from plants infected by GV3101-pCAPE2-Ev, GV3101-pCAPE2-GFP, GV3101-pCAPE2-scFv, and wild-type materials separately with the RNAgents® Total RNA Isolation System (Promega). First strand cDNA was synthesized using avian myeloblastosis virus (AMV) reverse transcriptase (Promega); the cDNA of GFP and scFv was then amplified by PCR. PCR products were separated on a 1 % agarose gel and visualized by ethidium bromide staining. PCR system: 95 °C 4 min, 95 °C 60 s, 52 °C 50 s, 72 °C 60 s, 35 cycle; 72 °C 10 min. Actin was used as the reference gene. All the primer sequences are listed in Table 1.

Western-blot analysis

The GV3101-pCAPE2-Ev, GV3101-pCAPE2-GFP, and GV3101-pCAPE2-scFv infected plants were frozen in liquid nitrogen and pulverized. The powder was stirred in extraction buffer (20 mM PBS buffer pH 7.4, containing 0.6 M NaCl), and centrifuged at 13,000×g for 20 min at 4 °C. The supernatants were analyzed by 15 % SDS-PAGE, and then transferred to nitrocellulose membranes for immune-blotting. The recombinant protein was visualized by chemiluminescent detection (The SuperSignal West Pico Trial Kit, PIERCE). The protein extracts from GV3101-pCAPE2-Ev infected plants were used as negative control. Rabbit antibody (Rubisco L.) was used as the first antibody, and HRP-marked goat anti-rabbit IgG was used as the second antibody.

Determination of GFP amount in pea plants by ELISA

The total soluble proteins were extracted by grinding the infiltrated plants (0.5 g fresh weight) in liquid nitrogen. The powder was homogenized with 1.0-mL bicarbonate buffer (15-mM Na2CO3, 35-mM NaHCO3, pH 9.6), centrifuged, and the supernatant concentration was determined by Bradford’s method (Bradford 1976) with bovine serum albumin as a standard. The different protein amount of scFv purified from Escherichia coli and GFP from commercialized product was added into the 96-well polystyrene plate to get the OD 570 nm protein standard curve. The amount of scFv and GFP protein from pCAPE2-scFv and pCAPE2-GFP infected plants was assessed by ELISA according to the protein standard curve.

scFv protein activity analysis by ELISA

The 96-well polystyrene plate was coated with 100 µL of 10 µg/mL aFGF solution in carbonate buffer (pH 9.6). After blocking with 10 % (w/v) instant milk/PBS, 100 µL of series dilution of scFv expressed in Pisum sativum L. plants were added, followed by incubation at 37 °C for 1 h. After washing with PBS containing 0.05 % Tween-20, 100 µL of diluted anti-scFv sera was added, followed by incubation at 37 °C for 1 h. After washing with PBS containing 0.05 % Tween-20, 100 µL of HRP-conjugated sheep anti-mouse IgG antibodies was added, followed by incubation at 37 °C for 1 h. After washing, peroxidase reaction was carried out using o-phenylenediamine (OPD) and hydrogen peroxide as the substrate at room temperature for 20 min. The reaction was terminated by adding 50 µL of 2 M H2SO4, and the absorbance at 570 nm was measured with microplate reader.

Statistical analysis

At least three independent experiments were carried out in each case. Statistical analysis was performed using Student’s t test and MANOVA. Differences were considered to be significant at P < 0.05.

Results

Expression vectors construction

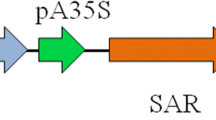

The scheme of recombinant vectors pCAPE2-GFP and pCAPE2-scFv is presented in Fig. 3. According to the scheme, the scFv gene fragment was first PCR-amplified from pET-28a (+)-scFv using a forward primer P1 that contained 6 his-tag, enzyme digestion site Nco I, and a reverse primer P2 that fused with enzyme digestion site of EcoR I (Fig. 3a). The full gene fragment (approximately 741 bp) was then inserted into the cloning sites of pCAPE2 cDNA to form a pCAPE2-scFv. The expression vector was identified by PCR (Fig. 3b) and enzyme digestion (Fig. 3c). After sequencing, the proper recombinant vector was then transferred into Agrobacterium strain GV3101.

Construction of pCAPE2-scFv. a The scheme of recombinant vectors pCAPE2-GFP and pCAPE2-scFv. LB left border; RB right border; 35SP CaMv35S promoter; CP coat protein (involved both in virion assembly and virus movement); scFv 741-bp scFv insert. Arrow foreign gene promoter. b Identification of pCAPE2-scFv recombinant vector by PCR. M DL2000 marker, 1 pET-28a-scFv plasmid, 2 negative control, 3, 4 positive constructions. c Identification of pCAPE2-scFv digested by Nco I, EcoR I; 1 empty vector; 2–5 constructions by two enzyme digestion

Effection of Agrobacterium infection-mediated vacuum pressure on pea plant growth

Radicle and embryo of pea plants were obvious of water-immersed shape after Agrobacterium infection (Fig. 4a). There was no obvious virus symptoms observed at the early stage of the sprout growth. However, stunted growth, shorter internode and plant height were observed on the 6th day after Agrobacterium infection (Fig. 4a). At later growth stage, leaf crinkle and small amount of mottled green were appeared, but no necrotic disease spot or wither phenomenon was present. Soluble protein content was decreased as the enhanced bacterium concentration. Soluble protein content was 25.8 mg/g (fresh weight) when the bacterium OD value was reached to 1.2, of which 22 % was reduced compared to the control (Fig. 4b). To further explore the affection of Agrobacterium infection on pea plant growth and development, economic yield, and soluble protein content, the two main factors affecting the foreign protein recovery yield were determined. The highest economic yield was reached to 2.82 kg/m2 at 8th day in non-Agrobacterium infected sample, whereas 2.35 kg/m2 economic yield (17 % reduced) was obtained on the 10th day in Agrobacterium-infected plants. Results showed that the economic yield was reduced in the Agrobacterium-infection pea plants (Fig. 4c).

Effect of Agrobacterium infection in pea plants. a Comparison of Agrobacterium-infected and non-infected plant growth condition. Left Agrobacterium infected, right Agrobacterium non-infected, pictures shown here are 6th days after Agrobacterium inoculation (bar 20 mm). b Variation of soluble protein content affected by Agrobacterium infection. cVariation of economic yield affected by Agrobacterium infection. Asterisks indicate significant differences using Student’s t test. (*P < 0.05)

GFP expression

GFP expression was observed on the 4th day mainly in shoots after GV3101-pCAPE2-GFP infiltration (Fig. 5b). As the plant growth, GFP expression was spread from the main stem to petioles, leaf veins, and young leaves gradually (Fig. 5c, d). In the next few days, the virus infection scope was expanded systemically. GFP fluorescence intensity was increased to peak at 8–10th days after infiltration (Fig. 5e). Afterward, GFP fluorescence intensity was reduced gradually (Fig. 5f).

Optimization of foreign protein yield in transient expression system in pea plants

Different seed germination time was studied to obtain the highest transformation efficiency. The seeds germinated for 24 and 48 h were selected for the Agrobacterium-mediated GFP transformation. GFP was spread to the leaves in 48 h-germinated seeds (Fig. 6c), whereas GFP was present only in stem in 24 h-germinated seeds at 6 dai (Fig. 6b). Statistical data revealed that GFP expression efficiency in 48 h-germinated seeds (80 %) was higher than that in 24 h-germinated seeds (74 %). Also, the peak value appeared time was 2 days earlier in 48 h-germinated seeds compared with the 24 h-germinated seeds (Fig. 6d). The results implied that expanding the surface area of germinated seeds could promote the infection efficiency.

Optimization of GFP transient expression system in pea plants. a–d The influence of seed germination time on GFP transformation efficiency. a Uninfected plants; b 24 h-germinated seeds; c 48 h-germinated seeds (bar 5 mm), pictures shown here ware 4th days after Agrobacterium inoculation; e Influence of vacuum infection on GFP transformation efficiency; f The influence of surfactants on GFP transformation efficiency. Asterisks indicate significant differences using Student’s t test (*P < 0.05)

The infection conditions of different vacuum pressure and time were optimized to enhance GFP transformation efficiency. The results showed that GFP expression efficiency was increased significantly with the enhanced vacuum pressure. The highest expression efficiency was reached at 0.08 MPa. Under 0.02–0.06 MPa, GFP expression efficiency was increased gradually with the enhanced infection times (Fig. 6e). However, under the 0.08 MPa, GFP expression efficiency under 2 × 60 s infection mode was higher than the 3 × 60 s infection mode. Finally, two surfactants Tween-20 and Silwet-77 were used to evaluate their affection on GFP transformation efficiency. The data showed that GFP expression efficiency using the Tween-20 and Silwet-77 was significantly higher than the control (Fig. 6f).

GFP identification under different infection means

The amount of GFP gene expression was compared between leaf injection (Fig. 7a, lane 2) and germinated seeds vacuum infection (Fig. 7a, lanes 3, 4). Western blot, in a further way, confirmed the RNA expression. Both RNA and protein expression results showed that no differences were observed for the two methods (Fig. 7b, lanes 4, 5). However, compared with the traditional leaf injection, vacuum infection was much easier to operate and large-scale protein production could be realized.

GFP expression comparison in two methods. a RT-PCR analysis for gene expression. M DL2000 marker; lane 1 wild type plant; lane 2 GV3101-pCAPE2-GFP infiltrated by leaf injection; lanes 3, 4 GV3101-pCAPE2-GFP infiltrated by vacuum infection. b Western blot analysis for GFP expression. M marker; lane 1 commercial purified protein of GFP; lane 2 total soluble protein from Agrobacterium (GV3101-pCAPE2-Ev); lane 3 total soluble protein from uninfected plants; lane 4 plant protein from GV3101-pCAPE2-GFP injection leaf; lane 5 plant protein from GV3101-pCAPE2-GFP vacuum infection plant [Rabbit source Rubisco subunits (Rubisco L.) antibody was used as reference]

Determination of GFP amount in pea plants by ELISA

Total soluble proteins in pea plants were reached to 27 mg/g using coomassie brilliant blue G250 method. While GFP protein was accounted to 1.2 % of the total soluble protein, which meant 324 mg GFP protein was expressed in 1 kg pea fresh plants approximately.

Transient expression of aFGF-scFv in pea plants

The plant total RNA and protein were extracted from pea plants at 8 dai. The scFv mRNA accumulation was detected in plants infected by GV3101-pCAPE2-scFv but not the plants infected by empty vector GV3101-pCAPE2-Ev (Fig. 8, lanes 3–5). For Western blot analysis, the protein was transferred to the membrane and hybridized with the anti-his tag monoclonal antibody. The band of 30 kDa was detected clearly (Fig. 8b, lanes 4–6). The result showed that the scFv was effectively expressed in GV3101-pCAPE2-scFv infected plants by vacuum infiltration.

Identification of scFv expression by RT-PCR and Western blot. a Identification of scFv expression by RT-PCR. M DL2000 DNA marker; lane 1 wild-type plants; lane 2 GV3101-pCAPE2-Ev infected plants; lanes 3–5 GV3101-pCAPE2-scFv infected plants. b Identification of scFv expression by Western blot. M marker; lane 1 positive control (scFv purified from Prokaryotic cells); lane 2 total soluble protein from GV3101-pCAPE2-Ev infected plants; lane 3 total soluble protein from wild type plants; lanes 4–6: total soluble protein from GV3101-pCAPE2-scFv infected plant via vacuum infection

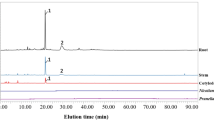

Determination of scFv amount in pea plants by ELISA

The amount of scFv proteins from GV3101-pCAPE2-scFv infected plants was assessed by ELISA according to the protein standard curve. The scFv was yielded to 0.1 % of the plant total soluble proteins according to triplicate identification.

The activity analysis of scFv

The scFv activity was determined by ELISA with extracted total proteins. Different concentrations were set up to verify the binding activity with its antigen aFGF. Based on the results of ELISA assays, the scFv expressed in plants was of a fair binding activity with its antigen aFGF (Fig. 9).

The analysis of scFv binding activity to its antigen aFGF. The 96-well polystyrene plate was coated with aFGF solution, 100 µL of series dilution of scFv expressed in pea plants was added. Control-1 Anti-scFv sera; control-2 HRP-conjugated sheep anti-mouse IgG antibody; control-3 total protein from uninfected plants. The absorbance at 570 nm was measured with microplate reader. Asterisks indicate significant differences using Student’s t test (*P < 0.05)

Discussion

Plants offer a great potential as production system for recombinant proteins. One approach to produce foreign proteins in plants is to generate stable transgenic plant lines. However, this is a time-consuming and labor-intensive process. An alternative expression strategy to transgenic plants is the use of Agrobacterium infiltration mediated by leaf injection and vacuum infection. Agrobacterium vacuum infiltration was first used in tobacco leaf to express foreign protein in vitro (Gleba et al. 2005; Ferraro et al. 2008). However, leaf culture in vitro is complex and susceptible to the influence of environmental conditions which leads to different expression level of foreign protein and cannot play its maximum advantage of vacuum infection. Moreover, the use of detached leaves (Amar et al. 2013) did not provide possible monitoring of target infiltrated tissue during days and weeks of plant development. For this reason, we suggest adopting in planta infiltration system that could give us a better outlook of plant gene expression. Therefore, instead of the leaf injection which is time-consuming and low efficiency, transient expression of foreign proteins in Pisum sativum L. whole seedlings via vacuum infection was established in our study. Our system, characterized for its high efficiency, low cost, and environmentally harmonious, has built a fair basis for the large-scale production of recombinant proteins.

Using leguminous plants as bioreactor could effectively avoid the interference of nicotine from Solanaceae plant in foreign protein purification. Also, to solve the problem of safety and large-scale production for transient expression system, vacuum infiltration of germinating seeds and soil-independent cultivation technology have been established in our pea seedlings transient expression system. The exogenous protein was expressed and controlled in the whole plant under the soil-less cultivation mode. While previously described methods rely on the use of detached leaves and/or in vitro materials which require aseptic handling during culture and infiltration process (Santos-Rosa et al. 2008; Bertazzon et al. 2012), our work focuses on Agrobacterium infiltration mediated by vacuum infection for whole seedling plants. This work allows us to perform the functional genomic research in conditions closer to normal plant growth environment. More importantly, waste materials were easy to handle which effectively prevents the spread of the virus and improves the safety of heterologous protein expression.

The newly established system was soil-independent, and the seedlings were cultured directly after Agrobacterium-mediated vacuum infection. The protein expression was under the control for the whole progress. GFP gene expression was recorded on the 4th day after pea early browning virus (PEBV)-mediated protein expression in the bud of Pisum sativum L. The protein expression level was reached to the maximum on the 8–10th day which was in agreement with the previous report in tobacco plants (Yang et al. 2008; Liu and Ma 2007), but the soluble protein content was obviously higher than that in tobacco plant. The growth cycle of the pea plant was approximately 10 days, and the product could be easily harvested in a short time. The foreign protein content was pretty high as evaluated by GFP fluorescence intensity which implied that the pea seedling materials may be a promising system for foreign protein expression.

In our study, the factors including condition of vacuum infiltration, seed germination time, the surfactant application, and plant varieties were selected and optimized to enhance the foreign protein expression efficiency. GFP expression efficiency could be increased by the enhanced vacuum pressure within 0.06 MPa. Under low vacuum pressure, GFP expression efficiency could be improved by increasing the infiltration times, whereas the increased infiltration time would lead to harm to the newly geminated seeds under high vacuum pressure (0.08 MPa).

Susceptible ability of seeds with different germination time to plant virus is different. Foreign protein expression efficiency could be enhanced by appropriately extending the seed germination time which increased the biomass and obtained more virus infection. Also, GFP expression efficiency was increased by the surfactant application of Tween-20 and Silwet-77 significantly. These data were in accordance with the Brian’s et al. (Brian et al. 2009) report. It is well known that the magnifection provides relatively inexpensive process due to the speed of production and high yield of recombinant protein that simplifies purification (Gleba et al. 2005). Our work, in a further way, optimized the magnifection system, and the GFP protein could reach to 324 mg/kg of fresh pea. Therefore, the foreign protein absolute content was higher than the previous report (Jia et al. 2003) due to the increase in the soluble protein content.

In recent years, genetic engineering drugs based on single chain variable fragment (scFv) have received promising development in malignant tumor molecular target therapy applications (Malpiedi et al. 2013; Khalissa et al. 2009). Compared with the conventional monoclonal antibody drug, single chain variable fragment antibodies play an important role in tumor target therapy due to their advantages, such as small molecular weight, strong penetrability, low immunogenicity, and easy recombinant production (Holliger and Hudson 2005; Weisser and Hall 2009).

Acidic fibroblast growth factor (aFGF) is an important member in the fibroblast growth factor family (Powers et al. 2000). Research shows that overexpression of aFGF has been observed in prostate cancer (Barritault 1993), bladder cancer (Cronaueer et al. 1997), kidney cancer (Nanus and Motzer 1993), breast cancer, and other tumor cells. aFGF plays an important role in the process of tumor occurrence and metastasis which indicates that aFGF has been taken as the potential new target for tumor targeting therapy. In our work, anti-aFGF-scFv protein was successfully harvested on the 8th day of post-inoculation in pea plants. The yield of scFv was reached to 0.1 % of the plant total soluble proteins. With the same system as described in this study, scFv expression is lower than GFP. Possible reasons were analyzed. In one respect, the scFv expression was estimated by ELISA indirectly. The standard curve of scFv was produced using the purified protein from prokaryotic expression system. Low threshold value of the standard curve due to the low protein activity results in the lower scFv content estimated in the sample. In other respect, the invasion of plant virus carrying exogenous gene may cause the plant defense responses and produce gene silencing (Ye et al. 2003; Liu et al. 2015). It is also one of the important reasons why heterologous protein expression decreased in plant. Though the estimated expression level was low, the scFv protein expressed in plants was of a fair binding activity with its antigen aFGF. Additional work is required to be performed to identify whether the scFv protein could inhibit the tumor proliferation.

Anyhow, our work proves that the system is suitable for the large-scale production of pharmaceutical proteins. A series of advantages were included in our system: Soil-independent, easy virus control, environmental-friendly operation, uniform culture condition, short growth cycle, and large-scale production. These characteristics make this system a promising and potential method and source for recombinant protein production.

References

Akbari V, Mir Mohammad Sadeghi H, Dehkordi JA, Chou PC, Abedi D (2015) Optimization of a single-chain antibody fragment overexpression in Escherichia coli using response surface methodology. Res Pharm Sci 10(1):65–73

Amar AB, Cobanov P, Mliki A, Buchholz G, Reustle G (2013) In planta agro-infiltration system for transient gene expression in grapevine (Vitis spp.). Acta Physiol Plant. doi:10.1007/s11738-013-1348-0

Andre DK, Jacosen HJ (1990) Agrobacterium tumefaciens mediated transformation of Pisum. Sativum L. using binary and cointegrate vectors plant cell reports. Plant Cell Rep 9:276–279

Barillot R, Combes D, Pineau S, Huynh P, Escobar-Gutiérrez AJ (2014) Comparison of the morphogenesis of three genotypes of pea (Pisum sativum) grown in pure stands and wheat-based intercrops. AoB Plants. doi:10.1093/aobpla/plu006

Barritault D (1993) Increased immune detection of acidic fibroblast growth factor in bladder cancer detectable in urine. Urol 150(11):26–30

Bertazzon N, Raiola A, Castiglioni C, Gardiman M, Angelini E, Borgo M, Ferrari S (2012) Transient silencing of the grapevine gene VvPGIP1 by agroinfiltration with a construct for RNA interference. Plant Cell Rep 31:133–143

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Brian JG, Masaaki F, Valentina M (2009) Transient protein expression in three Pisum sativum (green pea) varieties. Biotechnol J 4:230–237

Cronaueer MV, Hittmair A, Eder IE (1997) Basic fibroblast growth factor levels in cancer cells and in sera of patients suffering from proliferative disorders of the prostate. Prostate 31:223–233

Ferraro G, Becher ML, Angel SO (2008) Efficient expression of a Tox-oplasma gon-dii dense granule Gra4 antigen in tobacco leaves. Exp Parasitol 120:118–122

Giritch A, Marillonnet S, Engler C, van Eldik G, Botterman J, Klimyuk V, Gleba Y (2006) Rapid high-yield expression of full-size IgG antibodies in plants coinfected with noncompeting viral vectors. Proc Natl Acad Sci USA 103(40):14701–14706

Gleba Y, Klimyuk V, Marillonnet S (2005a) Magnifection—a new platform for expressing recombinant vaccines in plants. Vaccine 23(17–18):2042–2048

Gleba Y, Klimyμk V, Marillonnet S (2005b) Magnifection—a new platform for expressing recombinant vaccines in plants. Vaccine 23:2042–2048

Gleba YY, Tuse D, Giritch A (2014) Plant viral vectors for delivery by Agrobacterium. Plant Viral Vectors 375:155

Hamid RH, Mojgan B, Hossein V, Jaleh B, Bahram K, Hossein NM (2015) Cloning and expression of TNF related apoptosis inducing ligand in Nicotiana tabacum. Iran J Pharm Res 14(1):189–201

Holliger P, Hudson PJ (2005) Engineered antibody fragments and the rise of single domains. Nat Biotechnol 23(9):1126–1136

Jia HG, Pang YQ, Fang RX (2003) Agroinoculation as a simple way to deliver a tobacco mosaic virus-based expression vector. Acta Bot Sin 45(7):770–773

Khalissa D, Shi HL, Li L, Zhu XJ (2009) Nanobodies-the new concept in antibody engineering. A J Biotechnol 8(12):2645–2652

Krishnan S, Chuvappumkal JB, Mookambeswaran A (2012) Recovery of active anti TNF-a ScFv through matrix-assisted refolding of bacterial inclusion bodies using CIM monolithic support. J Chromatogr B 891–892:90–93

Leckie BM, Stewart CN (2011) Agroinfiltration as a technique for rapid assays for evaluating candidate insect resistance transgenes in plants. Plant Cell Rep 30:325–334

Lico C, Chen Q, Santi L (2008) Viral vectors for production of recombinant proteins in plants. J Cell Physiol 216(2):366–377

Liu JY, Ma PD, Sun Y (2007) Expression of human acidic fibroblast growth factor in Nicotiana benthamiana with potato virus X-based binary vector. Biotechnol Appl Biol 48:143–147

Liu F, Wang XD, Zhao YY, Li YJ, Liu YC, Sun J (2015) Silencing the HaAK gene by transgenic plant-mediated RNAi impairs larval growth of Helicoverpa armigera. Int J Biol Sci 11(1):67–74

Malpiedi LP, Díaz CA, Nerli BB, Pessoa JA (2013) Single-chain antibody fragments: purification methodologies. Process Biochem 48:1242–1251

Nanus DM, Schmitz-Drager BJ, Motzer RJ (1993) Expression of basic fibroblast growth factor in primary human renal tumors: correlation with poor survival. Natl Cancer Inst 85:1597–1599

Olivier V, Susana R, Pere M, David B (2003) Retracted: an enhanced transient expression system in plants based on suppression of gene silencing by the p19 protein of tomato bushy stunt virus. Plant J 33:949–956

Orzaez D, Mirabel S, Wieland WH, Granell A (2006) Agroinjection of tomato fruits: a tool for rapid functional analysis of transgenes directly in fruit. Plant Physiol 140:3–11

Powers CJ, McLeskey SW, Wellstein A (2000) Fibroblast growth factors, their receptors and signaling Endocr. Relat Cancer 3:165–197

Santos-Rosa M, Potaraud A, Merdinoglu D, Mestre P (2008) Development of a transient expression system in grapevine via agro-infiltration. Plant Cell Rep 27:1053–1063

Sebastian M, Torsten M, Stefanie B (2013) Production of single chain fragment variable (scFv) antibodies in Escherichia coli using the LEXTM bioreactor. J Biotechnol 163:105–111

Warkentin TD, Jordan MC, Hobbs SLA (1992) Effect of promoter-leader sequences on transient reporter gene expression in particle bombarded pea (Pisum sativum L.) tissues. Plant Sci 87:171–177

Weisser NE, Hall JC (2009) Applications of single-chain variable fragment antibodies in therapeutics and diagnostics. Biotechnol Adv 27(4):502–520

Yang L, Wang H, Liu J, Li L, Fan Y, Wang X, Song Y, Sun S, Wang L, Zhu X, Wang X (2008) A simple and effective system for foreign gene expression in plants via root absorption of agrobacterial suspension. J Biotechnol 134(3–4):320–324

Ye K, Malinina L, Patel DJ (2003) Recognition of small interfering RNA by a viral suppressor of RNA silencing. Nature 426(6968):874–878

Acknowledgments

We would like to express deep thanks to the Tianjin Natural Science Foundation (13JCYBJC37600), Hebei Province Natural Science Foundation (C2014202256), Hebei Province Human Resources and Social Security Foundation (C201400308) and Jilin Province Natural Science Foundation (20140101151JC) for financial supports.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Liang Li and Xiufeng Wang are co-first author.

Rights and permissions

About this article

Cite this article

Li, L., Wang, X., Yang, L. et al. Large-scale production of foreign proteins via the novel plant transient expression system in Pisum sativum L.. Plant Biotechnol Rep 10, 207–217 (2016). https://doi.org/10.1007/s11816-016-0397-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11816-016-0397-4