Abstract

This study aimed to reveal the structural characterization and functional properties of microbial EPS-NOC219 material produced by the Enterococcus faecalis NOC219 strain with high EPS yield isolated from yogurt, with simultaneously, demonstrating the potential of this EPS for future industrial applications. According to the results of the analyses made for this aim, it was determined that the NOC219 strain contains the epsB, p-gtf-epsEFG, and p-gtf-P1 genes. In addition, it was also revealed that the EPS-NOC219 structure is expressed by the epsB, p-gtf-epsEFG, and p-gtf-P1 genes and has a heteropolymeric feature consisting of glucose, galactose, and fructose units. According to the results of the analyses made for this aim, it was determined that the EPS-NOC219 structure, which was produced from the NOC219 strain containing the epsB, p-gtf-epsEFG, and p-gtf-P1 genes, had a heteropolymeric structure consisting of glucose, galactose, and fructose units. On the other hand, it was shown that this structure had a thickener property, high heat stability exhibited a pseudoplastic flow behavior, and had a high melting point. This showed that the EPS-NOC219 had high heat stability and could be used as a thickener in heat treatment processes. In addition, it was revealed that it is suitable for plasticized biofilm production. On the other hand, the bioavailability of this structure was demonstrated with its high antioxidant activity (55.84%) against DPPH radicals and high antibiofilm activity against Escherichia coli (77.83%) and Listeria monocytogenes (72.14%) pathogens. These results suggest that the EPS-NOC219 structure may be an alternative natural resource for many industries as it has strong physicochemical properties and a healthy food-grade adjunct.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, one of the most striking issues in the food industry is the microbial metabolites produced by microorganisms in the microbiota of fermented foods [1]. One of these microbial metabolites is exopolysaccharide (EPS), which has a high-molecular-weight natural-carbohydrate polymer structure [2]. EPS structures are used for different functions in many areas such as textiles, food, medicine, and pharmaceuticals. It is known that especially when EPS is used in the food industry, it can affect a food’s technological and functional properties [3]. For example, some EPS structures have physicochemical properties such as thickener, emulsifier, and stabilizer [4, 5]. On the other hand, some EPSs have bioactive effects such as antibacterial, antiviral, antidiabetic, antitumor, antioxidant, anti-inflammatory, anti-hypoglycemic, hypocholesterolemic antihypertensive, cholesterol-lowering, gastro-protective, and prebiotic properties [6,7,8]. EPS structures even affect the sensory properties of food [3]. EPS-producing microorganisms in the food industry commonly belong to the lactic acid bacteria (LAB) species [9]. LAB-derived EPSs are natural, non-toxic, bio-products with diverse chemical structures and biological activities [3]. Therefore, although LAB-EPS structures are a very popular research topic, research on them is still insufficient.

Bacteria of the genus Enterococcus belong to the LAB group and are generally known as low-grade pathogens. However, their role as primary pathogens remains in question [10]. Some strains of this genus, especially some of the Enterococcus faecalis strains, do not show pathogenicity [11]. They have even been found to have potential health-promoting benefits such as antidiabetic, antimicrobial, antioxidant, and proteolytic activities, along with probiotic characteristics [2, 12]. One of these properties is EPS production. In the literature, the discoveries of a few types of EPS produced by some Enterococcus faecalis strains have been documented [4]. However, the number of those gaining industrial importance with significant market appeal is limited, especially regarding their use as biomaterials. In addition, the high EPS production yield of some Enterococcus faecalis strains reveals the necessity of bringing the EPSs produced by these strains to the industry.

This study aimed to reveal the structure and biological properties of microbial EPS material produced by an E. faecalis strain with high EPS yield isolated from “yogurt,” simultaneously, demonstrating the potential of this EPS for future industrial applications.

Materials and Methods

Materials

In this study, an isolate that codes NOC-219 was used as material. This isolate was isolated from 15 artisanal yogurt samples produced and consumed by the local people living in Samsun province of Turkey. The NOC-219 isolate was selected as the highest-yielding EPS-producing strain among the 325 indigenous LAB isolates from the traditional yogurt in Ondokuz Mayis University, Department of Food Engineering, Biotechnology Laboratory. The other materials were purchased the analytical grade chemicals and reagents from Sigma-Aldrich Co. (USA) and Supelco Co. (USA), and the microbial growth mediums from Merck Co. (Germany).

Selection and Identification of EPS-Producing Isolate

The 325 indigenous LAB isolates were isolated using the previously described methodology [13] from the yogurt samples. Colonies with mucoid phenotype were selectively picked and subcultured in modified MRS-sucrose agar, which contains 40 g/L sucrose instead of glucose 20 g/L [14]. Among LAB isolates producing EPS, the NOC219 isolate, which produced the maximum amount of EPS, was chosen for further analysis.

The selected isolate was identified using 16S rRNA gene sequencing. For this, primer 27F (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1491R (5′-ACGGCTACCTTGTTACGACTT-3′) were used to amplify the 1.5 kb 16S rRNA gene of the NOC219 isolate. PCR reaction was performed with the following program: 95 °C for 15 min, followed by 35 cycles 95 °C for 1 min, 55 °C for 1 min, 72 °C for 3 min, and 72 °C for 10 min final extension. Subsequently, the amplicons were sequenced by Macrogen Inc. (Amsterdam, Netherlands). The similarity was determined with the NCBI database (97–100%).

Determination of EPS Genes of NOC219 Strain

The eps genes in the genome of this isolate were identified with PCR using specific primer pairs. The target gene regions were epsA (putative transcriptional regulator), lev (levansucrase) and gtf (glucansucrase), epsB (putative polymerization and chain length determination protein gene), and p-gtf (putative priming glycosyltransferase gene), representing genes required for the production of homopolymeric and heteropolymeric EPS, respectively. Table 1 shows the primers, the target amplicon lengths [13, 15], and the PCR conditions.

Determination of Potential Probiotic Properties of NOC219 Strain

Resistance to Simulated Gastric Medium and Intestinal Medium Tests

First, 18-h active cell culture of the NOC219 strain was centrifuged. Subsequently, the cell pellet was collected and washed. The viable pellet cells were re-suspended in the simulated gastric medium (PBS solution containing 0.3% pepsin pH 2.0, Sigma-Aldrich) by filtration (filter membrane 0.22 mm), which contained about 8 log CFU/mL. On the other hand, for the resistance test to the simulated intestinal medium, a similarly prepared pellet of the NOC219 strain was re-suspended in the simulated gastric medium (PBS solution containing 0.5% bile salt (w/v), 0.2% pancreatin (Sigma-Aldrich) (w/v), 0.1% trypsin (w/v) pH 8.0, Sigma-Aldrich) by filtration (0.22 mm) [16, 17].

The media were incubated at 37 °C at 100 pm. For the cell viability test in gastric medium, samples were taken at 0, 60, and 120 min. For cell viability tests in medium intestinal resistance, tests were taken at 0, 120, and 240 min for cell viability. MRS agar was seeded, and after 48 h of incubation at 37 °C, the results were determined as CFU/mL.

Hemolytic Activity and Antibiotic Susceptibility Tests

The NOC219 strain was streaked in Columbia Blood agar plates (Merck, Germany), which contained 5% defibrinated sheep blood. After incubation (48 h, 37 °C), the hemolytic activity was determined by observation of a clear zone of hydrolysis around the colonies (β-hemolysis), partial hydrolysis, and greenish zone (α-hemolysis), or no reaction (Ɣ-hemolysis).

Broth culture of the NOC219 strain (18 h, 37 °C, adjusted to 0.5 McFarland (8 log CFU/mL)) was cultivated on an MRS agar sterile petri dish with the spread plate method and allowed to dry for 15 min. Afterward, commercially available different antibiotics (metronidazole, ampicillin, erythromycin, amoxicillin, vancomycin, and tetracycline) disks (Bioanalyse, Turkey) were placed upwards and pressed on the agar plates. After incubation at 37 °C for 24 h, the presence of a zone of inhibition around the disks was noted as resistance [18].

Production and Purification of EPS from NOC219 Strain

EPS production and purification processes were carried out by minor modifying the previously reported method [19]. Briefly, the E. faecalis NOC219 was grown in a modified MRS-sucrose broth medium in 1 L final volume on a shaker with a speed of 150 rpm at 37 °C for 48 h aerobically. The fermentation medium was adjusted to pH 6 every 6 h using 3 M NaOH. Subsequently, the fermented broth was centrifuged at 10,000×g at 4 °C for 30 min, and the pellet and supernatant parts were separated. The cell-free supernatant was subjected to purification. For the purification, an equal volume of cold ethanol was added to this supernatant and kept at 4 °C overnight for EPS to precipitate. Afterward, the precipitated EPS was collected, some distilled water was added to it, and dissolved. This solution was added to two times the volume of cold ethanol and kept at 4 °C overnight. Subsequently, EPS was separated from the supernatant by re-centrifugation. For the removal of compounds that may be found other than the crude EPS obtained. It was dissolved in pure water and dialyzed (12–14 kDa) for 3 days, and then 10% trichloroacetic acid solution was added and kept at 4 °C overnight. Finally, pure EPS precipitated by centrifugation was obtained. It was lyophilized and stored at −80 °C for further studies.

Determination of Monosaccharide Composition of EPS

The freeze-dried EPS solution prepared at a concentration of 20 mg/mL was taken from 1000 μL EPS solution, 800 μL was taken, and 218 μL of 72% formic acid was added, and kept in a water bath at 95 °C for 2 h. It was then neutralized by adding 500 µL of 5 M KOH, centrifuged at 12,000 ×g for 5 min, and filtered through a filter (0.45 μm), was determined by HPLC analysis using a CARBOsep CHO-682 Pb Column (Chrom-tech, 7.8 mm ID × 300 mm, USA) and RID-10 (a refractive index detector) with a mobile phase of H2O, using glucose, galactose, fructose, and rhamnose standards. The flow rate is 0.7 mL/min and the column temperature is at 25 °C [1].

Determination of Functional Groups of EPS by FTIR Analysis

The major structural groups of the EPS were detected using Fourier transform infrared spectroscopy (ATR-FTIR, Perkin Elmer, Spectrum-Two, USA). For this, 1 mg of lyophilized exopolysaccharide was taken and mixed homogeneously with 100 mg of KBr powder. A disk was pressed into a pellet by using a hydraulic press, and the resulting disk was subjected to FTIR spectral measurement in the range of 4000–400 cm−1 wavelength. The obtained peaks were evaluated [7, 20]. FTIR spectrum was determined in transmission mode, and the number of scans was 32. The infrared spectral resolution was 4 cm−1.

Differential Scanning Calorimeter (DSC) Analysis of EPS

The thermal property of the EPS was determined using differential scanning calorimetry (DSC 8000, PerkinElmer, Shelton, CT, USA). It was weighed 5 mg from the EPS to aluminum pans and sealed. Then, the sample was analyzed by applying a heating rate of 10 °C/min in the temperature range of 10–450 °C in a nitrogen gas atmosphere and using an empty pan as a reference [9].

Rheological Analysis of EPS

An aqueous solution of EPS (4%) was prepared at a pH value of 6.0. Rheological measurements of this solution were carried out using an air-controlled rheometer (Anton Paar, MCR-302, Germany). The cone plate (C35/2ºTi L; 17.5 mm diameter, 2° cone angle, 0.1 mm gap) with plate-controlled temperature (4 °C) was employed to perform the following test.

Determination of Steady Shear Flow Behavior Property of EPS

A shear rate range (\(\dot{\gamma }\)) of 0.1 1/s to 100 1/s was used in steady shear property measurement. Herschel-Bulkley’s model was employed to describe the flow behavior of EPS. The value at a shear rate of 50 1/s was shown as an apparent viscosity value (ƞ50) [21].

Herschel-Bulkley model:

- τ 0 :

-

shear stress (Pa)

- K :

-

consistency coefficient (Pa sn)

- ẏ:

-

shear rate (s−1)

- ẏ:

-

flow behavior index

Temperature-Dependent Flow Behavior of EPS

The change in viscosity of EPS (η) was analyzed as a function of temperature from 10 to 80 °C. The temperature ramp rate was 3 °C/min at a constant shear rate of 20 1/s. The activation energy of flow was calculated according to the Arrhenius equation:

Arrhenius model:

- η :

-

shear stress (Pa/s)

- η 0 e :

-

frequency factor

- E α :

-

activation energy (J/mol)

- R :

-

universal gas constant

- T :

-

temperature (°K)

Determination of Dynamic Shear Flow Behavior Property of EPS

Amplitude sweep test was applied at the frequency (0.1 Hz) at 4 °C, at between 0.001 and 10 Pa. Frequency sweep test was performed at 4 °C for 120 s at various frequencies ranging from 0.1 to 100 Hz (0.628–628.3 rad/s, 0.1 Pa) to evaluate viscoelastic behavior of EPS at constant strain within the linear viscoelastic region (less than 1%). The obtained elastic or storage modulus (G′) and viscous or loss modulus (G″) values were calculated as a function of frequency (Hz).

Scanning Electron Microscopy (SEM) Analysis of EPS

The microstructure of the EPS sample was determined using a scanning electron microscope (SEM; JEOL, Tokyo, Japan). The sample was fixed to the SEM stubs with double-sided tape and coated with a layer of gold-palladium coating ~10 nm thick. Then, the samples were observed at 500, 1000, and 2500 magnitudes at 10 kV [22, 23].

Antibiofilm and Antioxidant Activities of EPS

This test was performed against Bacillus subtilis (NRRL-B209), Escherichia coli (ATCC-25922), Listeria monocytogenes (ATCC-7644), and Staphylococcus aureus (ATCC-33862) pathogenic bacteria. Firstly, active cultures (at 37 °C 18 h) of pathogenic microorganisms were prepared. One hundred eighty microliters of nutrient broth, 10 μL of active pathogenic culture, and 10 μL of the EPS solution (0.4 mg/mL) were added to the wells of a microtiter plate, and it was incubated for 18 h at 37 °C [24]. After the plate was gently washed with PBS buffer (pH 7.2), crystal violet (0.2 %) was added to it, and it was incubated for 15 min. After washing the plate with distilled water, 100 μL of acetic acid (30 %, v/v) was added to each well. The absorbance was taken at 570 nm, and biofilm inhibition was measured by the equation: Antibiofilm activity (%) = (ODcontrol − ODsample/ODcontrol) × 100 [25].

Antioxidant activity was determined using 1,1-diphenyl-2-picrylhydrazyl (DPPH•) radical [26]. Briefly, 2 mL of EPS solution (4 mg/mL) was mixed with 4 mL 0.1 mM DPPH• solution. Then the mixture was placed for 30 min, and the absorbance was determined at 517 nm. The result was calculated by the equation as follows: Scavenging activity (%) = (1 − (Asample − Ablank)/Acontrol) × 100.

Statistical Analysis

All analyses were measured at least three times. One-way ANOVA was performed to determine the significance (P < 0.05) of differences between the data with Duncan’s multiple comparison test.

Results and Discussions

Identification and Potential Probiotic Properties of NOC219 Strain

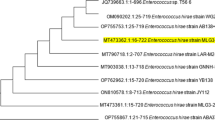

The taxonomic position of the NOC219 strain selected for secreting the most EPS was identified by biochemical and 16S rRNA gene sequencing analysis. The strain showed positive for gram staining, glucose utilization, and Voges-Proskauer tests and negative for methyl red, and gelatin hydrolysis, hemolytic activity (γ-hemolytic). On the other hand, the 16S rRNA gene sequence of this strain NOC219 showed a high degree (99.79%) of similarity with the type strain E. faecalis ATCC 19433T (Fig. 1) and was named Enterococcus faecalis NOC219. Also, its gene sequence was deposited to GenBank (OM982617).

When examined in terms of potential probiotic properties, after 2 h of incubation in the prepared simulated gastric medium, the E. faecalis NOC219 strain decreased from 9.02 ± 0.23 to 7.48 ± 0.52 log CFU/mL, showing a 1.54 log CFU/mL reduction. As for tolerance to the simulated intestinal medium, it decreased from 8.96 ± 0.34 to 7.73 ± 0.14 log CFU/mL, showing a 1.18 log CFU/mL reduction in the simulated intestinal medium (Table 2A). Although the decrease in the viability of the strain is significant in both gastric and intestinal environments, it was determined that the strain had good tolerance to both environments and had probiotic potential, since the numbers of these environments were 6 logs and above after the applied treatment [27]. In some studies in the literature [12, 28], it was determined that some E. faecalis strains with potential probiotic properties showed similar tolerance. Furthermore, as another probiotic property condition, it was determined that the E. faecalis NOC219 strain showed high susceptibility to the ampicillin, erythromycin, amoxicillin, and tetracycline antibiotics with disk diameters of 47.02 ± 0.26, 41.34 ± 0.27 (P > 0.05), 30.25 ± 0.09, and 24.17 ± 0.13 mm (P < 0.05), respectively.

In accordance with these results, the E. faecalis NOC219 strain was determined to have potential probiotic properties such as high antimicrobial activity, no antibiotic resistance, and resistance to gastric and intestinal environments (resistances to low pH, bile salts, and digestive enzymes).

Molecular Detection of EPS Genes in NOC219 Strain

The EPS production characteristic properties of yogurt isolates at strain levels of different species were determined with the previously described methodology [19], and strains were selected for further screening of the eps genes [13, 29]. The target genes for the detection of the eps genes were gtf (glucansucrase), lev (levansucrase) and epsA (putative transcriptional regulator), epsB (putative polymerization and chain length determination protein gene), and p-gtf (putative priming glycosyltransferase gene) representing genes required for the production of homopolymeric and heteropolymeric EPS, respectively, and PCR conditions and primers used for the detection of the target genes were described elsewhere [15].

According to the screening results of EPS genes, it was revealed that the NOC219 strain harbored the epsB, p-gtf-epsEFG, and p-gtf-P1 genes (Table 2B, Fig. 2A). For the heteropolymeric EPS production, an eps gene cluster harboring epsA, epsB, and epsD-epsE genes as well as other genes is required [30], whereas a single gene is described as gtf or ftf is responsible for homopolymeric glucan or fructan type, respectively [15]. This was a molecular indication that heteropolymeric EPS could be synthesized by the NOC219 strain. In a study [31], it was determined that the EPS-MS79 structure, which was produced from an Enterococcus faecium (MS79) strain, was composed of the three monosaccharides arabinose, mannose, and glucose, and therefore, it was a heteropolymeric structure. However, different strains of the same species are known to produce EPSs with different structures. For example, EPSs produced by E. faecium WEFA23 [32] and E. faecium MC13 [33] differ from each other. Moreover, the monosaccharide composition has a significant influence on the functionalities of the exopolysaccharide [34]. Therefore, EPSs produced by new strains should be examined in detail. Besides, several factors, including medium and fermentation conditions as well as genetic factors, affect the EPS production levels of a LAB strain. The monosaccharide composition of EPS examined in the present study was mentioned below.

Production and Purification of EPS from NOC219 Strain

The E. faecalis NOC219 strain exhibited probiotic characteristics and produced an EPS yield of 564.62 ± 0.15 mg/L. This structure was named EPS-NOC219. Yields of EPS structures produced by LAB differ depending on the type of strain, growth conditions, carbon source, initial pH, culture medium, incubation temperature, and inoculum size [33]. In the literature, it was observed that the EPS yields of EPS-producer LAB strains varied considerably. It was reported that the EPS yields were 13.20 g/L of the EPS from Leuconostoc mesenteroides S81 [9], 28.82 g/L of the EPS from Lactobacillus fermentum CFR 2195 [33], and 7.47 g/L of the EPS from Enterococcus faecium MC13 [33] belonging to the same species as in this study. However, it was determined as the EPS yields were 429.4 mg/L of the EPS from Lactobacillus plantarum ZDY2013 [36], 130 mg/L of the EPS from Enterococcus faecium WEFA23 [32], and 355 mg/L of the EPS from Enterococcus faecium K1 [28]. According to the results, it was observed that the EPS yield of the strain in the presented study was higher than many strains belonging to the same species.

Monosaccharide Composition of EPS-NOC219

The monosaccharide components of the EPS-NOC219 carried out after acid hydrolysis of it were examined by HPLC. The results showed that the EPS-NOC219 was a heteropolymer consisting of glucose (4.43 mg/g), galactose (3.25 mg/g), and fructose (0.10 mg/g) in comparison with respective standards (Fig. 2B). Previous studies suggested the heteropolysaccharide-EPS production from the various strains of the E. faecium, including E. faecium MS79 [31], E. faecium WEFA23 [32], and E. faecium MC13 [33]. However, homopolysaccharide-EPS produced by a different strain of the same species, such as E. faecium MC-5 [24], were also determined. In the study, the relative molar ratio of these sugar monomers in the EPS-NOC219 was 44.3:32.5:1. The main monosaccharides were glucose and galactose, while fructose also was present in very low concentrations. Here, it was thought that galactose was converted from glucose by the UDP-glucose 4-epimerase of the Enterococcus faecium NOC219 strain via the Leloir pathway [37] as a result of the use of sucrose. Besides, if this strain was grown in a medium containing lactose and sucrose together, it is also predicted that it will probably produce lactosucrose, a prebiotic [38]. It is known that the monosaccharide composition of an EPS has a significant influence on its functional properties (antioxidant antiviral and anticoagulant properties, prebiotic effect) [34]. The results supported the view that this EPS structure may be prebiotic and determined the path for further work.

Functional Groups of EPS-NOC219

The functional groups of EPS-NOC219 were determined by FTIR analysis. Figure 3A shows the FTIR spectra of EPS-NOC219. The polysaccharide showed high absorbance in the region 1200–1000 cm−1, which was within the so-called fingerprint region (below 2000 cm−1 and spectral regions corresponding to polysaccharides are between 890 and 1175 cm−1) [39]. This region is dominated by ring vibrations overlapped with stretching vibrations of (C–OH) side groups and the (C–O–C) glycosidic bond vibration [40]. Therefore, the strongest absorption band at 1012.51 cm−1 has indicated that the substance is a polysaccharide and suggests that the monosaccharide in it has a pyranose ring [41]. Similarly, the absorption at 1146.76 cm−1 was dominated by glycosidic linkage υ(C–O–C)-stretching vibration. It is known that characteristic anomeric region absorption bands in carbohydrates at about 898 cm−1 for β-anomer and about 845 cm−1 for an α-anomer form of the pyranoid ring [20, 42]. In the IR spectra, the characteristic absorption at 844.56 cm−1 indicated α-anomeric configuration in the EPS-NOC219. The absorption at 912.05 cm−1 indicated that the EPS-NOC219 had β-glycopyranosidic linkages.

As for the other important absorption bands, the few weak peaks at ~1407.95 cm−1 were characteristic of the carboxyl groups (C=O) (1444–1400 cm−1) or carboxylate (COO−), indicating that EPS-NOC219 is not an acidic polysaccharide. Besides, the peak at the 1000–1125 cm−1 range, which showed the presence of guluronic acid and mannuronic acid [43], was not determined in a way that supports it. Also, there was no peak around 1700–1775 cm−1, suggesting that neither glucuronic acid nor diacyl ester was present [7]. As for the peak at 2902.12 cm−1, it was due to C–H stretching vibration [44], and the peak observed at 2985.42 cm−1 between 2860 and 2990 cm−1 was associated with the methyl groups as well as the C–H stretching vibration. Finally, a wide peak observed at 3326.82 cm−1 (between 3044 and 36,127 cm−1) corresponded to the hydroxyl groups of polysaccharides, suggesting that this polymer was a polysaccharide. The FTIR spectrums of EPSs produced by some E. faecium strains [25, 28, 45] are relatively different compared with the present EPS-NOC219. This suggests that these EPS have different characteristics.

Thermal Property of EPS-NOC219

The thermal transitions of the EPS-NOC219 were determined by the DSC analysis. DSC thermogram of EPS exhibited distinct endothermic peaks at 255.91 °C, 296.87 °C, and 320.30 °C, respectively (Fig. 3B). The sharp and distinct peak observed at 296.87 °C has exhibited the melting point (Tm) of the EPS-NOC219. To the best of our knowledge, this is one of the highest records observed for the melting point of EPSs as previous reports showed the melting point of different EPSs ranging between 53.04 and 178.4 °C [28, 33, 43, 46]. However, high melting points were detected in a limited number of studies. In a study by [25], the melting point of the EPS-DU10 produced by E. faecalis DU10 was determined as 270 °C. In addition, in a study by İspirli et al. [1], the melting point of glucan-E81 produced by Lactobacillus reuteri E81 was determined as around 290 °C, and in another study by [47], the melting point of glucan-KX57763 produced by Enterococcus hirae KX57763 was determined as around 296.67 °C. It is suggested that the EPS, which had a relatively higher melting temperature, possessed a stronger ability to retain water [26]. Besides, it is known that differences in the thermal behavior of EPS may be due to the molecular configuration of the biopolymer, and the polymer degradation at higher temperatures may be associated with the higher molecular weight of EPS [24]. Therefore, this EPS structure can give important advantages to be used in different food systems, especially in thermally processed food systems.

Rheological Behaviors of EPS-NOC219

Steady Shear Property

Aqueous EPS-NOC219 solutions (4%, w/w) were loaded in the cone geometry. To the best of our knowledge, only one study has been available about rheological information on EPS produced by E. faecium [31]. Therefore, the rheological results of the present study are quite important. The results were shown in Fig. 4A. According to this, the aqueous EPS-NOC219 was shown a pseudoplastic flow behavior in which the viscosity decreased with increasing share rates, at a constant temperature (+4 °C), and it was described by a Herschel-Bulkley model. The flow behavior of EPS-NOC219 coincided with that previously described for the EPS structures produced from Enterobacter A47 [48], Leuconostoc carnosum CUPV411 [49], and E. faecium MS79, a strain of the same species as the microorganism in the present study; however, it was known that in the literature, the microbial suspensions of a strain of Bacillus cereus were exhibited a different flow behavior such as dilatant [50]. It is known that hydrodynamic forces generated during the shear can have led to the breakdown of the structural units and the physical networks in the chain structure of EPS structures [51]. Therefore, the shear-thinning data presented suggest that the EPS studied would be very suitable to improve the texture or palatability of food products. Besides, the apparent viscosity (ƞ) of the EPS sample was determined as 186 mPas at a 50 s−1 shear rate because the 50 s−1 is an appropriate estimation of oral shear rate for food samples [52].

Dynamic Shear Property

As for viscoelastic properties of the EPS-NOC219, the variations of elastic (storage module; G′) and viscous (loss module; G″) moduli of the EPS sample with frequency were shown in Fig. 4B. Storage modulus represents the energy stored in the structure of the material and is a measure of its elasticity; loss modulus represents the viscous part in the material’s structure where energy is lost due to deformation and frictions. Since such rheological tests are linear rheological tests, a safe linear viscoelastic region scanning was performed that would not damage the sample structure. The linear viscoelastic region of this EPS sample was determined in the range of selected as less than 1% strain.

Both moduli were seen to increase continuously with the frequency. The variation of G′ and G′ modulus with frequency implied that, as the frequency increases, the viscoelastic behavior changes from being dominated by viscous properties (G″ > G′ at lower frequencies) to being dominated by elastic properties (G′ > G″ at higher frequencies). The G′ and G″ curves intersect (G′ = G″) at a frequency, usually called the cross-over frequency. This frequency marks the transition from liquid-like behavior to solid-like behavior. Thus, the polymers can be characterized by the frequency at G′ = G″, denoted as the cross-over time of the system, and the plateau value of G′ at high frequencies (tan delta δ < 1.0) [53].

In the present study, as seen in Fig. 4B, G′ was lower than G″ at the frequencies < 9.03 Hz (except at higher frequencies, where a cross-over is perceived at an angular frequency of about 9.03 Hz) for the aqueous EPS-NOC219 solutions, which means the vicious character of the aqueous EPS-NOC219 solutions was dominant rather than elastic character, and hence, this sample can be described as having a liquid-like behavior at low frequency (tan delta δ > 1.0). Also, this result concurs with those reported by Han et al. [54], Ayyash et al. [31], and Antunes et al. [48] who recorded higher G″ than G′ of EPS-JD2, EPS-M41, and EPS-A47, respectively. This indicates that the EPS-NOC219 could be suitable as a thickener. In general, both moduli of the solution increased alongside with frequency increase; G′ was greater than G″ at frequency > 9.034 Hz (w: 56.76 rad/s). Therefore, the viscoelastic behavior of the sample changed to being dominated by elastic properties.

On the other hand, G′ values of the EPS-NOC219 solution obtained were higher than that of EPS structures studied by Ayyash et al. [31, 46] and Benhouna et al. [55]. This indicates that the EPS-NOC219 more stable and homogeneous structure according to the EPS structures mentioned.

Temperature-Dependent Behavior

The temperature was an important factor affecting the rheological properties of an EPS structure. The apparent viscosity of this EPS solution was dramatically decreased with increasing temperature (Fig. 4C). This suggested that the thickening properties of the EPS solution declined with increasing temperature. This was mainly caused by the decreased molecular flexibility under lower temperatures [56]. The initial temperature of the decrease was about 20 °C (17.11 °C). This result means that the thermal energy after 20 °C is sufficient to break up the polymer structure. The finding suggests that the present EPS-NOC219 is not suitable for high thermal processes. Also, the activation energy of the EPS-NOC219 solution calculated by the Arrhenius equation was 32.58 kJ/mol. On the other hand, in a study on the EPS of a strain of the same species conducted by Ayyash et al. [31], it was detected that the EPS-M41 solution with CaCl2 pH 6.0 among the EPS solution prepared with different salt types and pH values had the highest activation energy of 10.68 kJ/mol. Similarly, in a study by Xu et al. [56], the activation energy of EPS-3 produced from Streptococcus thermophiles S3 was determined as 7.34 kJ/mol. This information shows that the stability of the EPS-NOC219 in the presented study against temperature increase is higher according to the EPS structure mentioned. The activation energy is related to the chain flexibility in the solution. The relatively high activation energy for EPS indicated more inter- and intra-molecular interactions between polysaccharide chains in the investigated concentration [57].

Microstructure of EPS-NOC219

Scanning electron microscopy (SEM) analysis of the macromolecules helps to correlate the known physical properties of this material with its microstructural properties. In the present study, the EPS-NOC219 was determined by the surface morphology and the microstructure of it by SEM images at 500×, 1000×, and 2500× as can be seen in SEM images (Fig. 5A). It is seen that the EPS-NOC219 has two types of structures: a layer-like, compact and closed structure and a spherical granular, compact and smooth structure. It is known that studies suggested that smooth surfaces of EPS are counted as a favorable characteristic for making plasticized biofilms of EPS, and the consistent polymeric matrix is presumed to give mechanical stability to such biofilms [58]. On the other hand, colonization of microbiota on abiotic and biotic surfaces through biofilm in the intestine may impart various health benefits. Therefore, these results may be important in food applications, as they affect the physicochemical properties and rheological properties of food.

Antibiofilm and Antioxidant Capacities of EPS-NOC219

Antibiofilm and antioxidant tests were carried out to examine the bioactive properties of this structure. According to the results (Fig. 5B), the EPS-NOC219 structure showed a pretty good effect with 55.84% antioxidant activity. In a study [45], the EPS produced from Enterococcus faecium (BDU7) strain showed similar results with the same amount of it in the present study. Also, the result is very close to the antioxidant effect (<50%) of phenolic compounds in some fruits (cantaloupe, nectarine, avocado, etc.) [59]. The EC50 value of this EPS was nearly 3.5–4 mg/mL and had a lower effect than the antioxidant capacity of levan S81 from Leuc. mesenteroides S81 with an EC50 value of 1.7 mg/mL [9].

As for the antibiofilm results, the EPS-NOC219 showed the highest activities against E. coli (77.83%) and L. monocytogenes (72.14%) (P < 0.05), then they were followed by S. aureus (59.05%) (P < 0.05) and B. subtilis (48.96%) (P < 0.05). EPS structures may be causing these inhibitions by competitively preventing nutrient uptakes or inhibiting cell wall reactions.

These results may expand the range of properties of the EPS structure. In other words, while improving the structural properties of a product to which EPS is added, its bioactive effect may also increase. This double effect shows that the functionality of the EPS-NOC219 material obtained is versatile.

Conclusion

In this study, the EPS-NOC219 obtained from the E. faecium NOC219 strain, which is a high-yield EPS producer, was investigated in terms of structural and functional properties. In addition, the expression of genes related to EPS production of this strain was also determined. The EPS-NOC219 was revealed to be a heteropolymer composed of glucose, galactose, and fructose units, and the fact that the producer strain harbors the epsB, p-gtf-epsEFG, and p-gtf-P1 genes, required for the production of heteropolymeric-EPS. The EPS-NOC219 structure had a high melting point, exhibited a pseudoplastic flow behavior, and the viscous character of its aqueous solution was more dominant than its elastic character. This indicated that the EPS-NOC219 had high heat stability and could also be used as a thickener in heat treatment processes. Additionally, this EPS was determined to be suitable for making plasticized biofilms. On the other hand, the EPS-NOC219 has shown high antioxidant activity against DPPH radicals and high antibiofilm activity against the E. coli and L. monocytogenes pathogen strains. This situation has revealed its bioavailability. In addition, the probiotic potential of the producer strain was determined. The results have revealed that the EPS-NOC219 structure can be a good alternative natural resource that can be used in foods from a structural and functional point of view, as it has strong physicochemical properties in addition to a healthy food grade.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

İspirli, H., Sagdic, O., Yılmaz, M. T., & Dertli, E. (2019). Physicochemical characterisation of an α-glucan from Lactobacillus reuteri E81 as a potential exopolysaccharide suitable for food applications. Process Biochemistry, 79, 91–96. https://doi.org/10.1016/j.procbio.2018.12.015

Rahnama Vosough, P., Habibi Najafi, M. B., Edalatian Dovom, M. R., Javadmanesh, A. Mayo, B. (2021). Evaluation of antioxidant, antibacterial and cytotoxicity activities of exopolysaccharide from Enterococcus strains isolated from traditional Iranian Kishk. Journal of Food Measurement and Characterization, 1-10. https://doi.org/10.1007/s11694-021-01092-5.

Bibi, A., Xiong, Y., Rajoka, M. S. R., Mehwish, H. M., Radicetti, E., Umair, M., Shoukat, M., Khan, M. K. I., & Aadil, R. M. (2021). Recent advances in the production of exopolysaccharide (EPS) from Lactobacillus spp and its application in the food industry: A review. Sustainability, 13(22), 12429. https://doi.org/10.3390/su132212429

Choudhuri, I., Khanra, K., Pariya, P., Maity, G. N., Mondal, S., Pati, B. R., & Bhattacharyya, N. (2020). Structural characterization of an exopolysaccharide isolated from Enterococcus faecalis, and study on its antioxidant activity, and cytotoxicity against HeLa cells. Current Microbiology, 77(10), 3125–3135. https://doi.org/10.1007/s00284-020-02130-z

Hussain, A., Zia, K. M., Tabasum, S., Noreen, A., Ali, M., Iqbal, R., & Zuber, M. (2017). Blends and composites of exopolysaccharides; properties and applications: A review. International Journal of Biological Macromolecules, 94, 10–27. https://doi.org/10.1016/j.ijbiomac.2016.09.104

Saadat, Y. R., Khosroushahi, A. Y., & Gargari, B. P. (2019). A comprehensive review of anticancer, immunomodulatory and health beneficial effects of the lactic acid bacteria exopolysaccharides. Carbohydrate Polymers, 217, 79–89. https://doi.org/10.1016/j.carbpol.2019.04.025

Xu, Y., Cui, Y., Wang, X., Yue, F., Shan, Y., Liu, B., ... & Lü, X. (2019). Purification, characterization and bioactivity of exopolysaccharides produced by Lactobacillus plantarum KX041. International Journal of Biological Macromolecules, 128, 480-492. https://doi.org/10.1016/j.ijbiomac.2019.01.117.

Nag, M., Lahiri, D., Sarkar, T., Ghosh, S., Dey, A., Edinur, H. A., Pati, S., & Ray, R. R. (2021). Microbial fabrication of nanomaterial and its role in disintegration of exopolymeric matrices of biofilm. Frontiers in Chemistry, 9, 690590. https://doi.org/10.3389/fchem.2021

Taylan, O., Yilmaz, M. T., & Dertli, E. (2019). Partial characterization of a levan type exopolysaccharide (EPS) produced by Leuconostoc mesenteroides showing immunostimulatory and antioxidant activities. International Journal of Biological Macromolecules, 136, 436–444. https://doi.org/10.1016/j.ijbiomac.2019.06.078

Giraffa, G. (2002). Enterococci from foods. FEMS Microbiology Reviews, 26(2), 163–171. https://doi.org/10.1111/j.1574-6976.2002.tb00608.x

Baccouri, O., Boukerb, A. M., Farhat, L. B., Zébré, A., Zimmermann, K., Domann, E., ... & Connil, N. (2019). Probiotic potential and safety evaluation of Enterococcus faecalis OB14 and OB15, isolated from traditional Tunisian testouri cheese and rigouta, using physiological and genomic analysis. Frontiers in Microbiology, 10, 881. https://doi.org/10.3389/fmicb.2019.00881.

AlKalbani, N. S., Turner, M. S., & Ayyash, M. M. (2019). Isolation, identification, and potential probiotic characterization of isolated lactic acid bacteria and in vitro investigation of the cytotoxicity, antioxidant, and antidiabetic activities in fermented sausage. Microbial Cell Factories, 18(1), 1–12. https://doi.org/10.1186/s12934-019-1239-1

Dertli, E., Mercan, E., Arıcı, M., Yılmaz, M. T., & Sağdıç, O. (2016). Characterisation of lactic acid bacteria from Turkish sourdough and determination of their exopolysaccharide (EPS) production characteristics. LWT-Food Science and Technology, 71, 116–124. https://doi.org/10.1016/j.lwt.2016.03.030

Bounaix, M. S., Gabriel, V., Morel, S., Robert, H., Rabier, P., Remaud-Simeon, M., ... & Fontagne-Faucher, C. (2009). Biodiversity of exopolysaccharides produced from sucrose by sourdough lactic acid bacteria. Journal of Agricultural and Food Chemistry, 57(22), 10889-10897. https://doi.org/10.1021/jf902068t.

Palomba, S., Cavella, S., Torrieri, E., Piccolo, A., Mazzei, P., Blaiotta, G., ... & Pepe, O. (2012). Polyphasic screening, homopolysaccharide composition, and viscoelastic behavior of wheat sourdough from a Leuconostoc lactis and Lactobacillus curvatus exopolysaccharide-producing starter culture. Applied and Environmental Microbiology, 78(8), 2737-2747. https://doi.org/10.1128/AEM.07302-11.

Missaoui, J., Saidane, D., Mzoughi, R. Minervini, F. (2019). Fermented seeds (“Zgougou”) from aleppo pine as a novel source of potentially probiotic lactic acid bacteria. Microorganisms 7(12). https://doi.org/10.3390/microorganisms712070.

Qureshi, N., Gu, Q., & Li, P. (2020). Whole genome sequence analysis and in vitro probiotic characteristics of a Lactobacillus strain Lactobacillus paracasei ZFM54. Journal of Applied Microbiology, 129(2), 422–433. https://doi.org/10.1111/jam.14627

Plessas, S., Nouska, C., Karapetsas, A., Kazakos, S., Alexopoulos, A., Mantzourani, I., Chondrou, P., Fournomiti, M., Galanis, A., & Bezirtzoglou, E. (2017). Isolation, characterization and evaluation of the probiotic potential of a novel Lactobacillus strain isolated from Feta-type cheese. Food Chemistry, 226, 102–108. https://doi.org/10.1016/j.foodchem.2017.01.052

Dertli, E., Colquhoun, I. J., Gunning, A. P., Bongaerts, R. J., Le Gall, G., Bonev, B. B., ... & Narbad, A. (2013). Structure and biosynthesis of two exopolysaccharides produced by Lactobacillus johnsonii FI9785. Journal of Biological Chemistry, 288(44), 31938-31951. https://doi.org/10.1074/jbc.M113.507418.

Ye, L., Zhang, J., Yang, Y., Zhou, S., Liu, Y., Tang, Q., ... & Pan, Y. (2009). Structural characterisation of a heteropolysaccharide by NMR spectra. Food Chemistry, 112(4), 962-966. https://doi.org/10.1016/j.foodchem.2008.07.017.

Yilmaz, M. T., Tatlisu, N. B., Toker, O. S., Karaman, S., Dertli, E., Sagdic, O., & Arici, M. (2014). Steady, dynamic and creep rheological analysis as a novel approach to detect honey adulteration by fructose and saccharose syrups: Correlations with HPLC-RID results. Food Research International, 64, 634–646. https://doi.org/10.1016/j.foodres.2014.07.009

Feng, F., Zhou, Q., Yang, Y., Zhao, F., Du, R., Han, Y., & Zhou, Z. (2019). Structural characterization of glucan produced by Lactobacillus sake L-7 from sausage. Transactions of Tianjin University, 25(1), 78–84. https://doi.org/10.1007/s12209-018-0150-x

İspirli, H., Özmen, D., Yılmaz, M. T., Sağdıç, O., & Dertli, E. (2020). Impact of glucan type exopolysaccharide (EPS) production on technological characteristics of sourdough bread. Food Control, 107, 106812. https://doi.org/10.1016/j.foodcont.2019.106812

Tilwani, Y. M., Lakra, A. K., Domdi, L., Yadav, S., Jha, N., & Arul, V. (2021). Optimization and physicochemical characterization of low molecular levan from Enterococcus faecium MC-5 having potential biological activities. Process Biochemistry. https://doi.org/10.1016/j.procbio.2021.08.021

Venkatesh, P., Balraj, M., Ayyanna, R., Ankaiah, D., & Arul, V. (2016). Physicochemical and biosorption properties of novel exopolysaccharide produced by Enterococcus faecalis. LWT-Food Science and Technology, 68, 606–614. https://doi.org/10.1016/j.lwt.2016.01.005

Wang, X., Shao, C., Liu, L., Guo, X., Xu, Y., & Lü, X. (2017). Optimization, partial characterization and antioxidant activity of an exopolysaccharide from Lactobacillus plantarum KX041. International journal of biological macromolecules, 103, 1173–1184. https://doi.org/10.1016/j.ijbiomac.2017.05.118

Aljasir, S. F., & D’Amico, D. J. (2021). Probiotic potential of commercial dairy-associated protective cultures: In vitro and in vivo protection against Listeria monocytogenes infection. Food Research International, 149, 110699. https://doi.org/10.1016/j.foodres.2021.110699

Bhat, B., & Bajaj, B. K. (2019). Hypocholesterolemic potential and bioactivity spectrum of an exopolysaccharide from a probiotic isolate Lactobacillus paracasei M7. Bioactive Carbohydrates and Dietary Fibre, 19, 100191. https://doi.org/10.1016/j.bcdf.2019.100191

Dertli, E., Toker, O. S., Durak, M. Z., Yilmaz, M. T., Tatlısu, N. B., Sagdic, O., & Cankurt, H. (2016). Development of a fermented ice-cream as influenced by in situ exopolysaccharide production: Rheological, molecular, microstructural and sensory characterization. Carbohydrate Polymers, 136, 427–440. https://doi.org/10.1016/j.carbpol.2015.08.047

Horn, N., Wegmann, U., Dertli, E., Mulholland, F., Collins, S. R., Waldron, K. W., ... & Narbad, A. (2013). Spontaneous mutation reveals influence of exopolysaccharide on Lactobacillus johnsonii surface characteristics. PloS one, 8(3), e59957. https://doi.org/10.1371/journal.pone.0059957.

Ayyash, M., Stathopoulos, C., Abu-Jdayil, B., Esposito, G., Baig, M., Turner, M. S., ... & Osaili, T. (2020a). Exopolysaccharide produced by potential probiotic Enterococcus faecium MS79: Characterization, bioactivities and rheological properties influenced by salt and pH. LWT, 131, 109741. https://doi.org/10.1016/j.lwt.2020.109741.

Jia, K., Tao, X., Liu, Z., Zhan, H., He, W., Zhang, Z., ... & Wei, H. (2019). Characterization of novel exopolysaccharide of Enterococcus faecium WEFA23 from infant and demonstration of its in vitro biological properties. International Journal of Biological Macromolecules, 128, 710-717. https://doi.org/10.1016/j.ijbiomac.2018.12.245.

Kanmani, P., Suganya, K., Yuvaraj, N., Pattukumar, V., Paari, K. A., & Arul, V. (2013). Synthesis and functional characterization of antibiofilm exopolysaccharide produced by Enterococcus faecium MC13 isolated from the gut of fish. Applied Biochemistry and Biotechnology, 169(3), 1001–1015. https://doi.org/10.1007/s12010-012-0074-1

Zhou, Y., Cui, Y., & Qu, X. (2019). Exopolysaccharides of lactic acid bacteria: Structure, bioactivity and associations: A review. Carbohydrate polymers, 207, 317–332. https://doi.org/10.1016/j.carbpol.2018.11.093

Yadav, V., Prappulla, S. G., Jha, A., & Poonia, A. (2011). A novel exopolysaccharide from probiotic Lactobacillus fermentum CFR 2195: Production, purification and characterization. Biotechnol Bioinf Bioeng, 1(4), 415–421.

Zhang, Z., Liu, Z., Tao, X., & Wei, H. (2016). Characterization and sulfated modification of an exopolysaccharide from Lactobacillus plantarum ZDY2013 and its biological activities. Carbohydrate Polymers, 153, 25–33. https://doi.org/10.1016/j.carbpol.2016.07.084

Sanchez-Herrero, J. F., Bernabeu, M., Prieto, A., Hüttener, M., & Juárez, A. (2020). Gene duplications in the genomes of staphylococci and enterococci. Frontiers in Molecular Biosciences, 7, 160. https://doi.org/10.3389/fmolb.2020.00160

Duarte, L. S., da Natividade Schöffer, J., Lorenzoni, A. S. G., Rodrigues, R. C., Rodrigues, E., & Hertz, P. F. (2017). A new bioprocess for the production of prebiotic lactosucrose by an immobilized β-galactosidase. Process Biochemistry, 55, 96–103. https://doi.org/10.1016/j.procbio.2017.01.015

Ghosh, S., Lahiri, D., Nag, M., Dey, A., Sarkar, T., Biswas, R., ... & Ray, R. R. (2022). Analysis of antibiofilm activities of bioactive compounds from honeyweed (Leonurus sibiricus) against P. aeruginosa: An in vitro and in silico approach. Applied Biochemistry and Biotechnology, 1-17. https://doi.org/10.1007/s12010-021-03797-1.

Wang, J., Zhao, X., Tian, Z., Yang, Y., & Yang, Z. (2015). Characterization of an exopolysaccharide produced by Lactobacillus plantarum YW11 isolated from Tibet Kefir. Carbohydrate polymers, 125, 16–25. https://doi.org/10.1016/j.carbpol.2015.03.003

Sheng, J., Yu, F., Xin, Z., Zhao, L., Zhu, X., & Hu, Q. (2007). Preparation, identification and their antitumor activities in vitro of polysaccharides from Chlorella pyrenoidosa. Food Chemistry, 105(2), 533–539. https://doi.org/10.1016/j.foodchem.2007.04.018

Kacurakova, M., Capek, P., Sasinkova, V., Wellner, N., & Ebringerova, A. (2000). FT-IR study of plant cell wall model compounds: Pectic polysaccharides and hemicelluloses. Carbohydrate Polymers, 43(2), 195–203. https://doi.org/10.1016/S0144-8617(00)00151-X

Wang, Y., Li, C., Liu, P., Ahmed, Z., Xiao, P., & Bai, X. (2010). Physical characterization of exopolysaccharide produced by Lactobacillus plantarum KF5 isolated from Tibet Kefir. Carbohydrate Polymers, 82(3), 895–903. https://doi.org/10.1016/j.carbpol.2010.06.013

Pan, D., & Mei, X. (2010). Antioxidant activity of an exopolysaccharide purified from Lactococcus lactis subsp lactis 12. Carbohydrate Polymers, 80(3), 908–914. https://doi.org/10.1016/j.carbpol.2010.01.005

Abdhul, K., Ganesh, M., Shanmughapriya, S., Kanagavel, M., Anbarasu, K., & Natarajaseenivasan, K. (2014). Antioxidant activity of exopolysaccharide from probiotic strain Enterococcus faecium (BDU7) from Ngari. International Journal of Biological Macromolecules, 70, 450–454. https://doi.org/10.1016/j.ijbiomac.2014.07.026

Ayyash, M., Abu-Jdayil, B., Olaimat, A., Esposito, G., Itsaranuwat, P., Osaili, T., ... & Liu, S. Q. (2020a). Physicochemical, bioactive and rheological properties of an exopolysaccharide produced by a probiotic Pediococcus pentosaceus M41. Carbohydrate Polymers, 229, 115462. https://doi.org/10.1016/j.carbpol.2019.115462.

Jayamanohar, J., Devi, P. B., Kavitake, D., Rajendran, S., Priyadarisini, V. B., & Shetty, P. H. (2018). Characterization of α-D-glucan produced by a probiont Enterococcus hirae KX577639 from feces of south Indian Irula tribals. International Journal of Biological Macromolecules, 118, 1667–1675. https://doi.org/10.1016/j.ijbiomac.2018.07.015

Antunes, S., Freitas, F., Alves, V. D., Grandfils, C., & Reis, M. A. (2015). Conversion of cheese whey into a fucose-and glucuronic acid-rich extracellular polysaccharide by Enterobacter A47. Journal of Biotechnology, 210, 1–7. https://doi.org/10.1016/j.jbiotec.2015.05.013

Llamas-Arriba, M. G., Puertas, A. I., Prieto, A., López, P., Cobos, M., Miranda, J. I., ... & Dueñas, M. T. (2019). Characterization of dextrans produced by Lactobacillus mali CUPV271 and Leuconostoc carnosum CUPV411. Food Hydrocolloids, 89, 613-622. https://doi.org/10.1016/j.foodhyd.2018.10.053.

Al-Asheh, S., Abu-Jdayil, B., Abunasser, N., & Barakat, A. (2002). Rheological characteristics of microbial suspensions of Pseudomonas aeruginosa and Bacillus cereus. International Journal of Biological Macromolecules, 30(2), 67–74. https://doi.org/10.1016/S0141-8130(02)00006-5

Zarour, K., Llamas, M. G., Prieto, A., Ruas-Madiedo, P., Dueñas, M. T., de Palencia, P. F., ... & Lopez, P. (2017). Rheology and bioactivity of high molecular weight dextrans synthesised by lactic acid bacteria. Carbohydrate Polymers, 174, 646-657. https://doi.org/10.1016/j.carbpol.2017.06.113.

Cichero, J. A., Steele, C., Duivestein, J., Clavé, P., Chen, J., Kayashita, J., ... & Murray, J. (2013). The need for international terminology and definitions for texture-modified foods and thickened liquids used in dysphagia management: Foundations of a global initiative. Current physical medicine and rehabilitation reports, 1(4), 280-291. https://doi.org/10.1007/s40141-013-0024-z.

Lambo-Fodje, A. M., Leeman, M., Wahlund, K. G., Nyman, M., Öste, R., & Larsson, H. (2007). Molar mass and rheological characterisation of an exopolysaccharide from Pediococcus damnosus 2.6. Carbohydrate Polymers, 68(3), 577–586. https://doi.org/10.1016/j.carbpol.2006.06.037

Han, M., Du, C., Xu, Z. Y., Qian, H., & Zhang, W. G. (2016). Rheological properties of phosphorylated exopolysaccharide produced by Sporidiobolus pararoseus JD-2. International Journal of Biological Macromolecules, 88, 603–613. https://doi.org/10.1016/j.ijbiomac.2016.04.035

Benhouna, I. S., Heumann, A., Rieu, A., Guzzo, J., Kihal, M., Bettache, G., ... & Weidmann, S. (2019). Exopolysaccharide produced by Weissella confusa: Chemical characterisation, rheology and bioactivity. International Dairy Journal, 90, 88-94. https://doi.org/10.1016/j.idairyj.2018.11.006.

Xu, Z., Guo, Q., Zhang, H., Wu, Y., Hang, X., & Ai, L. (2018). Exopolysaccharide produced by Streptococcus thermophiles S-3: Molecular, partial structural and rheological properties. Carbohydrate Polymers, 194, 132–138. https://doi.org/10.1016/j.carbpol.2018.04.014

Balaghi, S., Mohammadifar, M. A., Zargaraan, A., Gavlighi, H. A., & Mohammadi, M. (2011). Compositional analysis and rheological characterization of gum tragacanth exudates from six species of Iranian Astragalus. Food Hydrocolloids, 25(7), 1775–1784. https://doi.org/10.1016/j.foodhyd.2011.04.003

Saravanan, C., & Shetty, P. K. H. (2016). Isolation and characterization of exopolysaccharide from Leuconostoc lactis KC117496 isolated from idli batter. International Journal of Biological Macromolecules, 90, 100–106. https://doi.org/10.1016/j.ijbiomac.2015.02.007

Floegel, A., Kim, D. O., Chung, S. J., Koo, S. I., & Chun, O. K. (2011). Comparison of ABTS/DPPH assays to measure antioxidant capacity in popular antioxidant-rich US foods. Journal of Food Composition and Analysis, 24(7), 1043–1048. https://doi.org/10.1016/j.jfca.2011.01.008

Acknowledgements

We would like to thank them for the electron microscope imaging process performed at the Black Sea Advanced Technology Research and Application Center (KITAM)—Ondokuz Mayıs University unit.

Author information

Authors and Affiliations

Contributions

All steps related to the article were conducted by NO.

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• E. faecium NOC219 produce EPS harbors epsB, p-gtf-epsEFG, and p-gtf-P1 genes.

• E. faecium NOC219 produce EPS-NOC219 has probiotic potential.

• EPS-NOC219 structure has a high melting point and a pseudoplastic flow behavior.

• EPS-NOC219 has high heat stability and can use as a thickener in heat treatment processes.

• EPS-NOC219 has high antioxidant activity and high antibiofilm activity.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Özdemir, N. Gene Expression, Structural Characterization, and Functional Properties of Exopolysaccharide Produced from Potential Probiotic Enterococcus faecalis NOC219 Strain. Appl Biochem Biotechnol 195, 6183–6202 (2023). https://doi.org/10.1007/s12010-023-04393-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-023-04393-1