Abstract

α-l-Rhamnosidases have wide application in the field of biotechnology for derhamnosylation of many natural glycosides. In this study, an α-l-rhamnosidase-producing strain, Aspergillus niger CCTCC M 2018240, was isolated from decayed orange peels, and the gene encoding α-l-rhamnosidase was successfully expressed in Pichia pastoris GS115. Three-dimensional structure simulation indicates the enzyme is a member of glycoside hydrolase 78 family. The optimal recombinant strain GS115/pPIC9K-rha-14 exhibited an enzyme activity of 0.47 U/mL when cultured in shaking flasks, and the recombinant α-l-rhamnosidase hydrolyzed α-1,2 and α-1,6 glycosidic bonds in naringin and rutin, respectively, thus generating prunin and isoquercitrin, respectively. Through high density-induced fermentation based on a glycerol feeding strategy in a 3-L bioreactor, the enzyme activity reached 46.87 U/mL after 7 days of methanol incubation, which was approximately 99 times higher than that produced in shaking flasks. This process offers a simple and effective approach for the large-scale production of α-l-rhamnosidase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

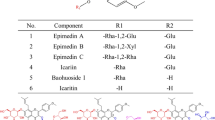

α-l-Rhamnosidase (EC 3.2.1.40) is a member of glycosyl hydrolases, which can specifically hydrolyze the terminal l-rhamnose residues in many natural glycosides, such as rutin, naringin, hesperidin, and terpene glycosides [1]. Based on the CAZy database (http://www.cazy.org/), α-l-rhamnosidases are categorized into four families of glycoside hydrolase, GH13, 28, 78, and GH106, based on the similarity of sequences. Because of their substrate specificity, α-l-rhamnosidases have important applications in food and pharmaceutical fields, such as citrus fruit debitterizing [2], wine aroma enhancement [3], enzymatic preparation of l-rhamnose, pruning, and isoquercitrin [4,5,6], and analysis of the structure of glycolipids, glycosides, and polysaccharides in plant and bacteria [7].

α-l-Rhamnosidases are widely located in plants, animal tissues, yeast, bacteria, and fungi but are obtained mainly by fermentation of microorganisms and seldom from plants and animal tissues. Many wild strains have been shown to produce the enzymes (Table 1), but the enzyme activity in wild strains is generally below 0.2 U/mL, and the enzymatic characteristics depend on the source. Aspergillus sp. is considered a good candidate for producing α-l-rhamnosidases and is followed by bacteria. α-l-Rhamnosidase is generally produced as a mixture with β-d-glucosidase, termed naringinase or hesperidinase [26]. To achieve highly pure α-l-rhamnosidase without β-d-glucosidase activity, complex separation methods with multiple steps are needed, thus resulting in a low recovery rate and high cost [10, 22, 24]. Moreover, α-l-rhamnosidase is an induction enzyme, and the induction is regulated by carbon source metabolism during fermentation, thus hindering enzyme production. Therefore, traditional fermentation for α-l-rhamnosidase production cannot meet the increasing demand of its wide range applications. Recombinant α-l-rhamnosidases are being pursued, but nowadays, only three commercial recombinant α-l-rhamnosidases from prokaryotes are provided by Megazyme (Bray, Ireland) and Prozomix (Haltwhistle, UK). The price of the recombinant α-l-rhamnosidase E-RHAMS (1500 U/mL) from Megazyme (Bray, Ireland) is high at 3000 U/158 € (http://www.cazy.org/). This expense is prohibitive for large-scale applications. Recently, some α-l-rhamnosidases, which belong to GH78 family, have been successfully expressed in Escherichia coli, Saccharomyces cerevisiae, and Pichia pastoris (Table 2). Among which, the enzymes expressed in E. coli and P. pastoris respectively from Bacillus sp. GL1 and Aspergillus terreus CCF 3059 achieved the highest activity. In this study, in contrast to the α-l-rhamnosidase from A. terreus CCF 3059, an Aspergillus niger CCTCC M 2018240 able to secrete naringinase was isolated from decayed orange peels, and the α-l-rhamnosidase gene (rha) was cloned and expressed in P. pastoris GS115. The resultant α-l-rhamnosidase (Rha) was confirmed as a member of the GH78 family. Moreover, the recombinant Rha was optimized for production in a 3-L bioreactor, and its activity in hydrolysis of rutin and naringin was also investigated for the potential values in food and pharmaceutical industries.

Materials and Methods

Hosts, Vectors, and Culture Conditions

The clone vector pMD19-T was bought from TaKaRa (Beijing, China) and utilized for the clone of α-l-rhamnosidase gene rha via the polymerase chain reaction (PCR). The host strain used for plasmid transformation is E. coli JM109. Luria-Bertani medium plates (5 g/L yeast extract, 10 g/L tryptone, 10 g/L NaCl, 20 g/L agar, and containing 50 μg/mL kanamycin or 100 μg/mL ampicillin) were used to screen E. coli JM109 recombinants. P. pastoris GS115 (Shybio, Shanghai, China) was used to express Rha.

Low sugar naringin agar plates (5 g/L MgSO4·7H2O, 5 g/L KCl, 10 g/L K2HPO4, 10 g/L sucrose, 0.1 g/L FeSO4·7H2O, 2.5 g/L naringin, and 20 g/L agar, native pH) were used for screening α-L-rhamnosidase-producing strains which were able to utilize naringin. The selected strains from the above agar plates were cultivated in a fermentation medium (1.5 g/L KH2PO4, 0.5 g/L MgSO4·7H2O, 0.09 g/L ZnSO4·7H2O, 0.1 g/L CaCl2, 4 g/L (NH4)2SO4, 20 g/L sucrose, 1 g/L yeast extract, 2 g/L soybean powder, 2 g/L peptone, and 6 g/L naringin, pH 6.0). Czapek-Dox medium plates (0.5 g/L KCl, 0.5 g/L MgSO4·7H2O, 0.01 g/L FeSO4·7H2O, 1 g/L K2HPO4, 3 g/L NaNO3, 30 g/L sucrose, and 20 g/L agar) were used for the isolation of fungi. YPD medium (10 g/L yeast extract, 20 g/L tryptone, and 20 g/L dextrose) or BMGY/BMMY medium (10 g/L yeast extract, 20 g/L tryptone, 13.4 g/L yeast nitrogen base with no amino acids, 4 × 10−6 g/L biotin, 100 mM potassium phosphate buffer, and 10 g/L glycerol or 0.5% (v/v) methanol) was used to culture P. pastoris GS115. MD medium plates (13.4 g/L yeast nitrogen base with no amino acids, 4 × 10−6 g/L biotin, 20 g/L dextrose, and 20 g/L agar) were used for yeast recombinant screening.

Screening and Identification of an α-l-Rhamnosidase-Producing Strain

Orange peels were buried in soil at 31° 28′ N and 120° 38′ E for about 15 cm for 5 days in the summer. The decayed orange peels were rotated in distilled physiological saline for 30 min at 30 °C and 220 r/min. Serial dilutions of the suspension were spread over low sugar naringin plates at 30 °C for 5 days, then 10 mL 90% diethylene glycol was added to the plates. The strains with clear zones around colonies were picked and inoculated in shaking flasks in an incubator for 4 days at 30 °C and 220 r/min.

The isolate was performed on Czapek-Dox medium plates at 28 °C for 4 days, and the genome was extracted by utilizing a Rapid Fungi Genomic DNA Isolation Kit (Sangon, Shanghai, China). The ITS sequence was amplified by PCR using the fungi universal primers [41]. The obtained DNA fragments were purified by utilizing a SanPrep Column PCR Product Purification Kit (Generay, Shanghai, China) and sequenced by Sangon (Shanghai, China), then the ITS sequence was submitted to the NCBI database to determine the species of the isolate used the BLASTn tool.

Cloning the α-l-Rhamnosidase Gene from A. niger CCTCC M 2018240

A. niger CCTCC M 2018240 was kept on potato dextrose agar (PDA) slants at 4 °C. One milliliter of spore suspension from the agar slant (after the spore density had reached an absorbance of 0.2 at 600 nm wavelength) was poured into PDA culture in shaking flasks and cultured at 30 °C and 220 r/min. After 2 days of culture, the mycelia were collected and washed, dried, and then powdered with liquid nitrogen.

Total RNA was extracted from A. niger CCTCC M 2018240 by using a Spin Column Fungal Total RNA Purification Kit (Sangon, Shanghai, China) according to the manufacturer’s instructions. Then, by using the total RNA as a templet, the first strand cDNA was obtained by using a RayScript cDNA Synthesis Kit (Generay, Shanghai, China). The rha was amplified by PCR using the degenerate primers F1 (forward, 5′-ATGTGGTCTTCCTGGCTGCTG-3′) and R1 (reverse, 5′-CTAATTATTACTCAACTTCCACTTTCCACCCTGC-3′), which were designed by the sequence α-l-rhamnosidase A mRNA of A. niger CBS 513.88 (XM_001389049.1). The obtained rha gene was purified and connected with the pMD19-T vector (pMD19-T-rha) and transferred into E. coli JM109. The obtained positive recombinant plasmid pMD19-T-rha was verified through sequence determination by GENEWIZ (Suzhou, China).

Sequence Analysis of Gene and Amino Acids of α-l-Rhamnosidase

The NCBI blastp tool was used to analyze the homology of deductive amino acid sequence of Rha. The initial sequence alignment was made used the ClustalW server (https://www.genome.jp/tools-bin/clustalw) and then displayed by using the ESPript 3.0 server (http://espript.ibcp.fr/ESPript/ESPript/index.php). The SWISS-MODEL server (https://swissmodel.expasy.org/) was used for constructing the tertiary structure of Rha [42]. The Ramachandran plot (http://servicesn.mbi.ucla.edu/PROCHECK/) was used to check the quality of the model [2].

Construction of Recombinant P. pastoris

The Rha gene rha was amplified through PCR using the designed primers F2 (forward, 5′-gctgaagcttacgtagaattcGTGCCCTACGAGGAGTACATCC-3′) and R2 (reverse, 5′-ttaattcgcggccgccctaggCTAATTATTACTCAACTTCCACTTTCCAC-3′), containing EcoR I and Avr II sites (underlined), respectively, with the recombinant plasmid (pMD19-T-rha) as a template. The plasmid pPIC9K was digested by EcoR I and Avr II, then the rha gene and pPIC9K vector were ligated by seamless cloning using a ClonExpress II One Step Cloning Kit (Vazyme, Nanjing, China) and transferred into E. coli JM109. Then, the positive recombinants were screened using the Colony PCR method.

The recombinant vector pPIC9K-rha with Sal I was linearized (TaKaRa, Dalian, China) and then transferred into P. pastoris GS115 using electroporation in a 0.2-cm cuvette, according to the parameters 1,500 V, 200 Ω, and 25 μF.

Recombinant Screening and Shaking Flask Culture

The recombinants obtained on MD plates were transformed to YPD agar plates containing 0.5–4.0 mg/mL of Geneticin (G418) to screen multi-copy recombinants.

Single colonies of P. pastoris recombinants with high G418 (Yuanye, Shanghai, China) resistance were picked and inoculated into BMGY medium in 250-mL shaking flasks inoculated at 30 °C and 220 r/min. When the optical density of the cell suspensions reached 2.0–4.0 at a 600-nm wavelength, the recombinant P. pastoris strains were collected and transferred into BMMY medium in 250-mL shaking flasks inoculated at 30 °C and 220 r/min to produce α-l-rhamnosidase. Meanwhile, methanol was added to reach 0.5% (v/v) every 24 h for the production of α-l-rhamnosidase. The enzyme activity of the expressed α-l-rhamnosidase was assayed after 5–7 days of cultivation, and the highest enzyme activity of recombinant was chosen for high cell density culture in a 3-L bioreactor.

Fed-Batch Fermentation

The optimal recombinant was obtained and inoculated into 100 mL of YPD medium in a 500-mL shaking flask and inoculated at 30 °C, 220 r/min for 24 h, and afterwards transferred into a 3-L bioreactor (Bailun Bio, Shanghai, China) with 0.9 L of BSM medium (26.7 mL/L 85% H3PO4, 0.93 g/L CaSO4·2H2O, 18.2 g/L K2SO4, 14.9 g/L MgSO4·7H2O, 4.13 g/L KOH, 40 g/L glycerol, and 4.35 mL/L Pichia trace mineral 1 (PTM1) solution (6 g/L CuSO4·5H2O, 0.08 g/L KI, 3 g/L MnSO4·H2O, 0.2 g/L Na2MoO4·2H2O, 0.02 g/L H3BO3, 0.5 g/L CoCl2, 20 g/L ZnCl2, 65 g/L FeSO4·7H2O, 0.25 g/L biotin, and 5.0 mL/L concentrated H2SO4). Fifty percent (w/v) glycerol containing 12 mL/L PTM1 solution was used to increase the biomass of P. pastoris GS115 and 100% methanol comprising 12 mL/L PTM1 was added for the production of Rha.

During the entire fermentation process, the pH of the medium was controlled at 5.5 by using 25% ammonium hydroxide, meanwhile, maintaining the dissolved oxygen (DO) level between 15% and 20% saturation by regulating the airflow rate (3–5 L/min) and the stirring rate (400–800 r/min). During the batch phase, the temperature was maintained at 30 °C and the glycerol used as the sole carbon source. When DO rapidly increased, indicating the glycerol was consumed in the medium, 50% (w/v) glycerol was fed to increase the cell biomass. After the OD600 reached 150 or 250, glycerol feeding was stopped, and a starvation cultivation period of 0.5–1 h was used to deplete the glycerol. Then, 100% methanol comprising 12 mL/L PTM1 was fed to induce the production of Rha; meanwhile, the temperature was reduced to 28 °C. In the methanol induction phase, the airflow rate was controlled at 3–5 L/min (2.5–3.5 VVM). The methanol was pulse-added in 24-h intervals at a starting rate of 1.0 mL/L/h of 100% methanol comprising 12 mL/L PTM1, the feeding rate raised 1.0 mL/L/h an hour, and reached 6.0 mL/L/h after 6 h of induction. Then, the feeding rate of 6.0 mL/L/h was maintained. After induction of 70 h approximately, the feeding rate was decreased to 4.0 mL/L/h and maintained for the rest of the fermentation to keep the AOX1 promoter induced. Samples were taken at regular times and the biomass, Rha activity, and total protein concentration were determined. Each condition was measured three times.

Enzyme Activity Assays

p-Nitrophenyl-α-l-rhamnopyranoside (pNPR) was used as a substrate for the assay of Rha. Fifty microliters of 4 mM pNPR and 400 μL of 50 mM citric acid buffer (pH 5.0) were mixed and 50 μL of crude enzymes was added to start the reaction, which was performed at 50 °C for 1 min and stopped by adding 1.0 mL of 1.0 M Na2CO3. The p-nitrophenol (p-NP) released was detected by spectrophotometry at 400 nm.

One unit of enzyme activity (U) was defined as the amount of enzyme that released 1 μmol of p-NP per minute under the conditions described above.

Protein Concentration Determination and SDS-PAGE Analysis

Determination of protein concentration used the reported method [43]. The molecular weight and homogeneity of Rha were evaluated by SDS-PAGE analysis through a previously reported method [44].

Hydrolysis of Naringin and Rutin

The total reaction volume was 5 mL, containing 4.9 mL of 0.1 M citric acid buffer (pH 4.0) with naringin or rutin (1 g/L) suspended in the buffer, and 10 μL of enzyme solution (40 U/mL) was added to start the reaction and performed at 50 °C for 3 min and stopped by heating to 100 °C for 5 min. The reaction solution was centrifuged at 12,000 r/min for 5 min and the supernatant was filtered by using a 0.22-μm membrane and analyzed through liquid chromatography-mass spectrometry (LC-MS) with a Waters MALDI SYNAPT MS.

Results and Discussion

Isolation of an α-l-Rhamnosidase Production Strain

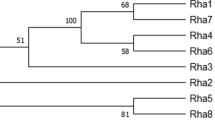

Approximately 28 strains were isolated from the low sugar naringin agar plates. Among which, 24 strains produced clear zones around the strains (Fig. S1). The strain termed no. 7 had a maximum enzyme activity of 0.1 U/mL after 4 days of fermentation and was chosen for further studies (Fig. S2). The morphology of the strain was observed as shown in Fig. S3a. It initially exhibited white fluff, and black spores became visible the next day; subsequently, the black spores increased, and the strain became larger and continued to grow. The conidiophore was slender, and the tops of the hyphae were connected with spherical conidial heads, which had a large number of spores (Figs. S3b and S3c), characteristics typical of Aspergillus cell morphology. Furthermore, the obtained 598 bp ITS sequence (Fig. S4) of strain no. 7 was blasted in the NCBI database (https://www.ncbi.nlm.nih.gov/) and was found to have 100% identity with A. niger CMXY25845, A. niger CMXY2362, A. niger PHCT-FS11, and A. niger JC-A3, which has 99.83% identity with Aspergillus awamori SRRC 332, Aspergillus welwitschiae CBS 139.54, and Aspergillus lacticoffeatus CBS 101883, it also has 94.99% and 95.84% identity with Aspergillus tubingensis DGY03 and A. tubingensis YLAC-3, respectively. Therefore, strain no. 7 was identified as A. niger and deposited in China Center for Type Culture Collection (CCTCC No. M 2018240).

Sequence Analysis of Rha from A. niger M 2018240

The rha gene from A. niger CCTCC M 2018240 (GenBank Accession No. MH779610) was 1971 bp at full length, and the sequence encoded a protein of 656 amino acid residues. A comparison of the rha cDNA sequence and its genomic rha sequence revealed the presence of an intron at 1102–1147 bp. The deduced amino acid sequence of Rha was consistent with that of the hypothetical protein from A. niger ATCC 1015 (EHA26552.1) and had high identity (95–99%) with the α-l-rhamnosidases from Aspergillus. Scanning with NCBI-BLAST revealed 99%, 98%, and 98% identity with the sequences from A. niger CBS 513.88 (XP_001389086.1), A. kawachii (BAF98236.1), and A. luchuensis CBS 106.47 (OJZ92413.1), respectively. When comparing the amino acid sequence of α-l-rhamnosidase r-Rha1 in A. niger JMU-TS528 with the amino acid of α-l-rhamnosidase Rha in A. niger CCTCC M 2018240 [39], we found that r-Rha1 has 655 amino acids and Rha has 656 amino acids. Moreover, the sequence of Rha has 96% identity with the sequence of r-Rha1. The Rha sequence had 86%, 70%, and 66% identity with the sequences from Aspergillus ibericus CBS 121593 (RAL02489.1), Aspergillus oryzae (OOO09775.1), and Penicillium chrysogenum (BAU37009.1), respectively. However, it showed less than 50% identity with the sequences from bacteria (Table S1). These results showed that Rha was a typical α-l-rhamnosidase from Aspergillus.

To date, the crystal structures of four Rhas, in the GH78 family, have been determined [45,46,47,48]. Comparison with three of these amino acid alignments (Fig. 1) indicated that Rha from A. niger M 2018240 has the same residues of Asp567, Trp576, Asp579, Trp684, Glu841, and His862, which are conserved in the GH78 family α-l-rhamnosidases and are crucial for enzyme catalysis [45, 46]. This result suggested that Rha belonged to the GH78 family α-l-rhamnosidases. Furthermore, the tertiary structure of Rha was also constructed with the SWISS-MODEL server, by using the α-l-rhamnosidase RhaB from Bacillus sp. GL1 as a template. The model (Fig. 2a) showed that Rha contains an (α/α)6-barrel structure consistent with the structures of GH78 family Rhas from Bacillus sp. GL1 [45], Streptomyces avermitilis NBRC 14893 [48], and Klebsiella oxytoca KCTC 1686 [47]. These findings further indicated that Rha belonged to the GH78 family, because the (α/α)6-barrel structure is the catalytic module of GH78 family enzymes [48]. According to the results of the Ramachandran plot (Fig. 2b), 98.4% of the amino residues distributed in the core and allowed regions, thus indicating that the tertiary structure model was valid.

Sequence alignment of Rha with GH78 family α-l-rhamnosidases. Sequence alignment of Rha from A. niger CCTCC M 201840 with GH78 family α-l-rhamnosidases by using ClustalW and the BoxShade 3.21 server. RhaB (accession no. BAB62315.1), KoRha (accession no. AEX05711.1), and BtRha78A (accession no. AAO76108.1) from Bacillus sp. GL1, Klebsiella michiganensis KCTC 1686, and Bacteroides thetaiotaomicron VPI-5482 are shown. The identical and similar amino acid residues are highlighted with red and yellow, respectively. The residues listed with rectangles are conserved

Construction of Recombinant P. pastoris GS115 for α-l-Rhamnosidase Production

The recombinant vector pPIC9K-rha was identified by double enzyme digestion (Fig. S5), and then the positive pPIC9K-rha was linearized by Sal I and transferred into P. pastoris GS115. To obtain multi-copy recombinants, we further selected the recombinants grown on MD agar plates containing various concentrations of G418 (Geneticin, 0.5–4.0 mg/mL). One hundred ninety-eight colonies grew on the MD plates, and four of them, GS115/pPIC9K-rha-4, GS115/pPIC9K-rha-9, GS115/pPIC9K-rha-10, and GS115/pPIC9K-rha-14, which grew on the YPD plates containing 4.0 mg/mL of G418 were cultivated in shaking flasks containing BMMY medium for further determination of Rha activity. After 7 days of methanol induction, the recombinant GS115/pPIC9K-rha-14 exhibited the highest Rha activity of 0.47 U/mL and specific activity of 0.57 U/mg (Fig. 3a, b). The Rha activity of GS115/pPIC9K-rha-14 was 3.13 times higher than that of the wild strain A. niger CCTCC M 2018240.

Moreover, SDS-PAGE analysis of Rha showed the molecular weight was approximately 100 kDa (Fig. 4), which was similar to the molecular mass of the enzymes in Bifidobacterium dentium (100 kDa) [32], Clostridium stercorarium (98 kDa) [49], the thermophilic bacterium PRI-1686 (104 kDa for RhmA and 107 kDa for RhmB) [50], Penicillium griseoroseum MTCC-9224 (97 kDa) [23], and Aspergillus nidulans (102 kDa) [17].

Hydrolysis of Naringin and Rutin by Recombinant Rha

Hydrolysis of naringin and rutin by the recombinant Rha was investigated. The hydrolysates were detected by LC-MS. As shown in Fig. 5, the [M+H]+ ion peaks at 581.25, 165.10, and 435.17 m/z in the mass spectrum represented naringin, l-rhamnose, and prunin, respectively. The hydrolysis results for rutin are shown in Fig. 6. Rutin, l-rhamnose, and isoquercitrin were determined with [M+H]+ ion peaks at 611.22, 165.11, and 465.15 in the mass spectrum, respectively. These results indicated that Rha from A. niger CCTCC M 2018240 was capable of hydrolyzing naringin and rutin, in which the l-rhamnose residue connected with the β-d-glucoside by α-1,2 and α-1,6 glycosidic linkages, respectively. Moreover, its hydrolysis rate was 70% approximately when 130 g/L of rutin was hydrolyzed within 1 h (Fig. S6). The high conversion rate indicated that Rha from A. niger CCTCC M 2018240 could be applied in bioengineering field with great potential of progress, such as preparation of l-rhamnose, isoquercitrin, and prunin.

Production of Recombinant Rha by Fed-Batch Fermentation

To enhance Rha production by the recombinant strain GS115/pPIC9K-rha-14, a high density-induced fermentation-based feeding strategy was used with a 3-L fermenter. As shown in Fig. 7a, when the cell density (OD600) reached approximately 150 with glycerol feeding, methanol was added to induce Rha expression, and the maximum Rha activity, total protein concentration, and cell density reached 40.37 U/mL, 6.84 g/L, and 1023, respectively, after fermentation for 169 h. These values were approximately 85.9, 12, and 31 times higher than those in shaking flasks (Fig. 3). When the induction cell density changed to approximately 250 (Fig. 7b), the maximum Rha activity, total protein concentration, and cell density reached 46.87 U/mL, 7.64 g/L, and 1215, respectively, which were approximately 99.72, 13.4, and 36 times higher than those in shaking flasks. Compared with the induction cell density at 150, the highest α-l-rhamnosidase activity, total protein concentration, and OD600 increased by 16.1%, 11.7%, and 18.77%, respectively. These results suggested that cell density and induction were very important for enhancing the expression of the target protein.

Interestingly, the Rha-specific activity obtained through high density fermentation was approximately 6.13 U/mg, which was more than 10 times greater than that obtained through shaking flask fermentation (0.57 U/mg in Fig. 3). This result indicated that high density-induced fermentation not only improved the concentration of protein but also improved the expression of Rha in cells. Gerstorferová et al [36] cloned the gene of α-l-rhamnosidase from A. terreus CCF 3059 and expressed it in P. pastoris KM71H (MutS) and found that the maximum activity reached 9 U/mL after 6 days of induction in shaking flasks. Markošová et al [37] repeated the fermentation process and found that after 3 days of induction, the maximum activity only reached 5 U/mL, and when fermentation was up-scaled in 3-L bioreactors by using two methanol pulses before continuous feeding, the maximum activity reached 322 U/mL after 501 h of fermentation, representing the highest previously reported activity. Here, through high density batch fermentation of 169 h, the Rha activity was greatly improved but was lower than that of P. pastoris KM71H (MutS), thus suggesting that Rha activity and the fermentation process could be further improved.

Conclusions

α-l-Rhamnosidases of the GH78 family can specifically hydrolyze the α-l-rhamnoside residues in the terminal of many glycosides and thus have important application value in the food and beverage processing and pharmaceutical industries [6, 39]. In this study, an α-l-rhamnosidase, a member of the GH78 family, was isolated from A. niger CCTCC M 2018240. We used the plasmid pPIC9K to express the α-l-rhamnosidase gene in P. pastoris GS115. The maximum enzyme activity of the recombinant strain GS115/pPIC9K-rha-14 was 0.47 U/mL in shaking flasks. With a strategy of high density-induced fermentation, the maximum enzyme activity reached 46.87 U/mL in a 3-L fermenter, with the activity 99.72 times higher than that in shaking flasks. Analysis of the hydrolysis of rutin and naringin showed that only l-rhamnose residues were cleaved. Moreover, its hydrolysis rate was 70% approximately when 130 g/L of rutin was hydrolyzed within 1 h (Fig. S6), thus indicating that the enzyme is a potential biocatalyst for the preparation of l-rhamnose, isoquercitrin, or prunin.

References

Yadav, V., Yadav, P. K., Yadav, S., & Yadav, K. D. S. (2010). α-L-Rhamnosidase: a review. Process Biochemistry, 45(8), 1226–1235.

Li, L. J., Wu, Z. Y., Yu, Y., Zhang, L. J., Zhu, Y. B., Ni, H., & Chen, F. (2018). Development and characterization of an α-L-rhamnosidase mutant with improved thermostability and a higher efficiency for debittering orange juice. Food Chemistry, 245, 1070–1078.

Gallego, M. V., Piñaga, F., Ramón, D., & Vallés, S. (2010). Purification and characterization of an α-L-rhamnosidase from Aspergillus terreus of interest in winemaking. Journal of Food Science, 66, 204–209.

Meiwes, J., Wullbrandt, D., & Giani, C. (1997). Alpha-L-Rhamnosidase for obtaining rhamnose, a process for its preparation and its use. US Patent 5468625.

Zhang, R., Zhang, B. L., Xie, T., Li, G. C., Tuo, Y., & Xiang, Y. T. (2015). Biotransformation of rutin to isoquercitrin using recombinant α-L-rhamnosidase from Bifidobacterium breve. Biotechnology Letters, 37(6), 1257–1264.

Ni, H., Xiao, A. F., Cai, H. N., Chen, F., You, Q., & Lu, Y. Z. (2012). Purification and characterization of Aspergillus niger α-L-rhamnosidase for the biotransformation of naringin to prunin. African Journal of Microbiology Research, 6, 5276–5284.

Davies, G. J., Gloster, T. M., & Henrissat, B. (2005). Recent structural insights into the expanding world of carbohydrate-active enzymes. Current Opinion in Structural Biology, 15(6), 637–645.

Jang, I. S., & Kim, D. H. (1996). Purification and characterization of α-L-rhamnosidase from Bacteroides JY-6, a human intestinal bacterium. Biological & Pharmaceutical Bulletin, 19(12), 1546–1549.

Miake, F., Satho, T., Takesue, H., Yanagida, F., Kashige, N., & Watanabe, K. (2000). Purification and characterization of intracellular α-L-rhamnosidase from Pseudomonas paucimobilis FP2001. Archives of Microbiology, 173(1), 65–70.

Park, S. Y., Kim, J. H., & Kim, D. H. (2005). Purification and characterization of quercitrin-hydrolyzing α-L-rhamnosidase from Fusobacterium K-60, a human intestinal bacterium. Journal of Microbiology and Biotechnology, 15, 519–524.

Orrillo, A. G., Ledesma, P., Delgado, O. D., Spagna, G., & Breccia, J. D. (2007). Cold-active α-L-rhamnosidase from psychrotolerant bacteria isolated from a sub-Antarctic ecosystem. Enzyme and Microbial Technology, 40(2), 236–241.

Puri, M., & Kaur, A. (2010). Molecular identification of Staphylococcus xylosus MAK2, a new α-L-rhamnosidase producer. World Journal of Microbiology and Biotechnology, 26(6), 963–968.

Alvarenga, A. E., Romero, C. M., & Castro, G. R. (2013). A novel α-L-rhamnosidase with potential applications in citrus juice industry and in winemaking. European Food Research and Technology, 237(6), 977–985.

Yanai, T., & Sato, M. (2000). Purification and characterization of α-L-rhamnosidase from Pichia angusta X349. Bioscience, Biotechnology, and Biochemistry, 64(10), 2179–2185.

Rodríguez, M. E., Lopes, C. A., Valles, S., & Caballero, A. C. (2010). Characterization of α-rhamnosidase activity from a Patagonian Pichia guilliermondii wine strain. Journal of Applied Microbiology, 109(6), 2206–2213.

Singh, P., Sahota, P. P., Bhadra, F., & Singh, R. K. (2015). Optimization, production and scale up of debittered kinnow beverage by α-L-rhamnosidase producing yeast. Emirates Journal of Food and Agriculture, 27(7), 548–555.

Manzanares, P., Orejas, M., Ibañez, E., Vallés, S., & Ramón, D. (2000). Purification and characterization of an α-L-rhamnosidase from Aspergillus nidulans. Letters in Applied Microbiology, 31(3), 198–202.

Yadav, V., Yadav, S., Yadava, S., & Yadav, K. D. S. (2011). α-L-Rhamnosidase from Aspergillus flavus MTCC-9606 isolated from lemon fruit peel. International Journal of Food Science and Technology, 46(2), 350–357.

Ge, L., Xie, J. C., Wu, T., Zhang, S. S., Zhao, L. G., Ding, G., Wang, Z. Z., & Xiao, W. (2017). Purification and characterisation of a novel α-L-rhamnosidase exhibiting transglycosylating activity from Aspergillus oryzae. International Journal of Food Science and Technology, 52(12), 2596–2603.

Rajal, V. B., Cid, A. G., Ellenrieder, G., & Cuevas, C. M. (2009). Production, partial purification and characterization of α-L-rhamnosidase from Penicillium ulaiense. World Journal of Microbiology and Biotechnology, 25(6), 1025–1033.

Yadav, S., Yadav, V., Yadav, S., & Yadav, K. D. S. (2012). Purification, characterisation and application of α-L-rhamnosidase from Penicillium citrinum MTCC-8897. International Journal of Food Science and Technology, 47(2), 290–298.

Yadav, S., Yadava, S., & Yadav, K. D. S. (2013). Purification and characterization of α-L-rhamnosidase from Penicillium corylopholum MTCC-2011. Process Biochemistry, 48(9), 1348–1354.

Yadav, S., Yadava, S., & Yadav, K. D. S. (2017). α-L-rhamnosidase selective for rutin to isoquercitrin transformation from Penicillium griseoroseum MTCC-9224. Bioorganic Chemistry, 70, 222–228.

Rojas, N. L., Voget, C. E., Hours, R. A., & Cavalitto, S. F. (2011). Purification and characterization of a novel alkaline α-L-rhamnosidase produced by Acrostalagmus luteo albus. Journal of Industrial Microbiology & Biotechnology, 38(9), 1515–1522.

Feng, B., Hu, W., Ma, B. P., Wang, Y. Z., Huang, H. Z., Wang, S. Q., & Qian, X. H. (2007). Purification, characterization, and substrate specificity of a glucoamylase with steroidal saponin-rhamnosidase activity from Curvularia lunata. Applied Microbiology and Biotechnology, 76(6), 1329–1338.

Zhu, Y. P., Jia, H. Y., Xi, M. L., Xu, L. Y., Wu, S. M., & Li, X. T. (2017). Purification and characterization of a naringinase from a newly isolated strain of Bacillus amyloliquefaciens 11568 suitable for the transformation of flavonoids. Food Chemistry, 214, 39–46.

Zverlov, V. V., Hertel, C., Bronnenmeier, K., Hroch, A., Kellermann, J., & Schwarz, W. H. (2000). The thermostable α-L-rhamnosidase RamA of Clostridium stercorarium: biochemical characterization and primary structure of a bacterial α-L-rhamnoside hydrolase, a new type of inverting glycoside hydrolase. Molecular Microbiology, 35(1), 173–179.

Hashimoto, W., Miyake, O., Nankai, H., & Murata, K. (2003). Molecular identification of an α-L-rhamnosidase from Bacillus sp. strain GL1 as an enzyme involved in complete metabolism of gellan. Archives of Biochemistry and Biophysics, 415(2), 235–244.

Birgisson, H., Hreggvidsson, G. O., Fridjónsson, O. H., Mort, A., Kristjánsson, J. K., & Mattiasson, B. (2004). Two new thermostable α-L-rhamnosidases from a novel thermophilic bacterium. Enzyme and Microbial Technology, 34(6), 561–571.

Beekwilder, J., Marcozzi, D., Vecchi, S., Vos, R. D., Janssen, P., Francke, C., Vlieg, J. V. H., & Hall, R. D. (2009). Characterization of rhamnosidases from Lactobacillus plantarum and Lactobacillus acidophilus. Applied and Environmental Microbiology, 75(11), 3447–3454.

Ichinose, H., Fujimoto, Z., & Kaneko, S. (2013). Characterization of an α-L-rhamnosidase from Streptomyces avermitilis. Bioscience, Biotechnology, and Biochemistry, 77(1), 213–216.

Bang, S. H., Hyun, Y. J., Shim, J., Hong, S. W., & Kim, D. H. (2015). Metabolism of rutin and poncirin by human intestinal microbiota and cloning of their metabolizing α-L-rhamnosidase from Bifidobacterium dentium. Journal of Microbiology and Biotechnology, 25(1), 18–25.

Wu, T., Pei, J. J., Ge, L., Wang, Z. Z., Ding, G., Xiao, W., & Zhao, L. G. (2018). Characterization of a α-L-rhamnosidase from Bacteroides thetaiotaomicron with high catalytic efficiency of epimedin C. Bioorganic Chemistry, 81, 461–467.

Manzanares, P., Orejas, M., Gil, J. V., Graaff, L. H., Visser, J., & Ramón, D. (2003). Construction of a genetically modified wine yeast strain expressing the Aspergillus aculeatus rhaA gene, encoding an α-L-Rhamnosidase of enological interest. Applied and Environmental Microbiology, 69(12), 7558–7562.

Koseki, T., Mese, Y., Nishibori, N., Masaki, K., Fujii, T., Handa, T., Yamane, Y., Shiono, Y., Murayama, T., & Iefuji, H. (2008). Characterization of an α-L-rhamnosidase from Aspergillus kawachii and its gene. Applied Microbiology and Biotechnology, 80(6), 1007–1013.

Gerstorferová, D., Fliedrová, B., Halada, P., Marhol, P., Křen, V., & Weignerováa, L. (2012). Recombinant α-L-rhamnosidase from Aspergillus terreus in selective trimming of rutin. Process Biochemistry, 47(5), 828–835.

Markošová, K., Weignerová, L., Rosenberg, M., Křen, V., & Rebroš, M. (2015). Upscale of recombinant α-L-rhamnosidase production by Pichia pastoris MutS strain. Frontiers in Microbiology, 6, 1140.

Liu, Q., Lu, L. L., & Xiao, M. (2012). Cell surface engineering of α-L-rhamnosidase for naringin hydrolysis. Bioresource Technology, 123, 144–149.

Li, L. J., Yu, Y., Zhang, X., Jiang, Z. D., Zhu, Y. B., Xiao, A. F., Ni, H., & Chen, F. (2016). Expression and biochemical characterization of recombinant α-L-rhamnosidase r-Rha1 from Aspergillus niger JMU-TS528. International Journal of Biological Macromolecules, 85, 391–399.

Ishikawa, M., Shiono, Y., & Koseki, T. (2017). Biochemical characterization of Aspergillus oryzae recombinant α-L-rhamnosidase expressed in Pichia pastoris. Journal of Bioscience and Bioengineering, 124(6), 630–634.

Chen, Y. Y., Prior, B. A., Shi, G. Y., & Wang, Z. X. (2011). A rapid PCR-based approach for molecular identification of filamentous fungi. Journal of Microbiology, 49(4), 675–679.

Arnold, K., Bordoli, L., Kopp, J., & Schwede, T. (2006). The SWISS-MODEL workspace: A web-based environment for protein structure homology modelling. Bioinformatics, 22(2), 195–201.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72(1-2), 248–254.

Lambin, P., Rochu, D., & Fine, J. M. (1976). A new method for determination of molecular weights of proteins by electrophoresis across a sodium dodecyl sulfate (SDS)-polyacrylamide gradient gel. Analytical Biochemistry, 74(2), 567–575.

Cui, Z., Maruyama, Y., Mikami, B., Hashimoto, W., & Murata, K. (2007). Crystal structure of glycoside hydrolase family 78 α-L-rhamnosidase from Bacillus sp. GL1. Journal of Molecular Biology, 374(2), 384–398.

Li, B. C., Ji, Y. R., Li, Y. Q., & Ding, G. B. (2018). Characterization of a glycoside hydrolase family 78 α-L-rhamnosidase from Bacteroides thetaiotaomicron VPI-5482 and identification of functional residues. 3 Biotech, 8(2), 120.

O’Neill, E. C., Stevenson, C. E. M., Paterson, M. J., Rejzek, M., Chauvin, A. L., Lawson, D. M., & Field, R. A. (2015). Crystal structure of a novel two domain GH78 family α-rhamnosidase from Klebsiella oxytoca with rhamnose bound. Proteins, 83(9), 1742–1749.

Fujimoto, Z., Jackson, A., Michikawa, M., Maehara, T., Momma, M., Henrissat, B., Gilbert, H. J., & Kaneko, S. (2013). The structure of a Streptomyces avermitilis α-L-rhamnosidase reveals a novel carbohydrate-binding module CBM67 within the six-domain arrangement. The Journal of Biological Chemistry, 288(17), 12376–12385.

Puri, M., Kaur, A., Schwarz, W. H., Singh, S., & Kennedy, J. F. (2011). Molecular characterization and enzymatic hydrolysis of naringin extracted from kinnow peel waste. International Journal of Biological Macromolecules, 48(1), 58–62.

Birgisson, H., Fridjonsson, O., Bahranimougeot, F. K., Hreggvidsson, G. O., Kristjansson, J. K., & Mattiasson, B. (2004). A new thermostable α-L-arabinofuranosidase from a novel thermophilic bacterium. Biotechnology Letters, 26(17), 1347–1351.

Funding

The authors are grateful to the financial supports from the National First-class Discipline Program of Light Industry Technology and Engineering (Grant No. LITE2018-04) and the Topnotch Academic Programs Project of Jiangsu Higher Education Institutions (TAPP).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 556 kb)

Rights and permissions

About this article

Cite this article

Wang, D., Zheng, P. & Chen, P. Production of a Recombinant α-l-Rhamnosidase from Aspergillus niger CCTCC M 2018240 in Pichia pastoris. Appl Biochem Biotechnol 189, 1020–1037 (2019). https://doi.org/10.1007/s12010-019-03020-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03020-2