Abstract

Neem tree (Azadirachta indica) cell suspension culture is an alternative for the production of limonoids for insect control that overcomes limitations related to the supply of neem seeds. To establish conditions for cell growth and azadiracthin-related limonoid production, the effect of different sucrose concentrations, nitrate and phosphate in Murashige and Skoog (MS) medium, and the addition of one precursor and three elicitors was evaluated in shake flasks. The process was scaled up to a 3-l stirred tank bioreactor in one- and two-stage batch cultivation. In shake flasks, more than fivefold increase in the production of limonoids with the modified MS medium was observed (increase from 0.77 to 4.52 mg limonoids/g dry cell weight, DCW), while an increase of more than fourfold was achieved by adding the elicitors chitosan, salicylic acid, and jasmonic acid together (increase from 1.03 to 4.32 mg limonoids/g DCW). In the bioreactor, the volumetric production of limonoids was increased more than threefold with a two-stage culture in day 18 (13.82 mg limonoids/l in control single-stage process and 41.44 mg/l in two-stage process). The cultivation and operating mode of the bioreactor reported in this study may be adapted and used in optimization and process plant development for production of insect antifeedant limonoids with A. indica cell suspension cultures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of chemical pesticides in agriculture has caused serious ecological and health problems worldwide [1]. The production of environmentally friendly biopesticides has been proposed as a solution to this problem [2]. One of the most recognized botanical biopesticides is obtained from limonoids produced by neem tree. Currently, this biopesticide is produced by extraction from the tree seeds, but this process has disadvantages such as contamination with fungi and heterogeneity in the content of limonoids due to genetic, climatic, and geographical variations [3, 4]. To overcome these problems, several researchers have implemented the production of limonoids from plant cell suspension and hairy root cultures in bioreactors [5–7]. Different strategies of hairy root cultures have been developed recently [8–10]; however, in bioprocess, the stirred tank bioreactor is considered one of the best options since it presents less technical difficulties in the scale-up process and has good adaptability of the existing industrial technology. Moreover, agitated bioreactors are highly effective for proper mixing and oxygenation of cell suspensions and prevent formation of large cell aggregates [11].

Azadirachtin is a high-value secondary metabolite obtained from Azadirachta indica, which is commercially used as a broad-spectrum biopesticide. Ever since its discovery and isolation, research on this compound has increased and, recently, systems to increase azadirachtin production have been developed [5, 12]. However, azadirachtin is not the only limonoid found in A. indica that represents a powerful natural pesticide; other related limonoids as nimbin, salannin, and isonimbinolide are active against several species of insects [13]. Efforts in recent years have focused on optimizing the culture medium composition, modifying nutritional requirements of cells and studying the supply of precursor and elicitor molecules that enhance cell growth and production of secondary metabolites [14]. Particularly, the supply of biotic and abiotic exogenous elicitors represents a promising strategy for enhancing the production of high-value plant compounds. The effect of elicitors may vary from one plant species to another, so there is no universal effect of a particular elicitor on different plants or cell cultures [15]. Thus, the proper selection of elicitors for each cell culture is required in order to enhance product yield. Furthermore, considering the complexity of the biosynthesis of several compounds from A. indica, there is the possibility that a synergistic effect of different elicitors enhance their production in cell suspension cultures.

The aim of this work was to establish a suitable two-stage bioreactor process to enhance growth and production of limonoids with A. indica cultures. Therefore, the use and modification of several components in the culture medium (nitrate, phosphate, sucrose, precursor, and elicitors) were evaluated in shake flasks. Once the culture media for growing and production of limonoids was defined, the process was scaled up to a 3-l stirred tank bioreactor operated in batch mode with one and two stages.

Materials and Methods

Development of Callus and Cell Suspension Culture

Callus culture was developed from A. indica seed kernels obtained from Cotové agricultural center of Universidad Nacional de Colombia in Santa Fe de Antioquia. Calli were cultured on MS medium, with sucrose 30 g/l, indolebutyric acid (IBA) 2 mg/l, benzil amino purine (BAP) 1 mg/l, pH 5.8, Phytagel 2 g/l, 25 °C, and darkness. Suspension culture was initiated from friable callus in 100 ml of MS medium liquid and incubated in 500-ml shake flasks under dark conditions in an orbital shaker at 110 rpm. Sub-culture to fresh media was done after a 10-day incubation period. Periodically, Evans blue dye was used to measure cell viability in optical microscopy on the basis of its penetration into non-viable cells.

Dry Cell Weight Estimation, Extraction, and Limonoids Analysis

For dry cell weight (DCW) estimation, cell samples were harvested from shake flasks and bioreactor; fresh cells were collected by vacuum filtration and dried until constant dry cell weight (24 h at 60 °C). For bioassays, lyophilized biomass was extracted with ethanol (3 × 10 ml) 95 % and sonication (1 g cells/10 ml) for 30 min. For extraction of limonoids, the same protocol was followed but methanol was used instead. The methanolic extract was evaporated under vacuum below 40 °C and partitioned with 1 ml sodium chloride (1 % w/v), 10 ml water, and dichloromethane (3 × 10 ml). Final dry extract was dissolved in methanol and analyzed by high-performance liquid chromatography (Agilent technologies, USA HP1100); a LichroCART 125-4 LiChrosper 100 RP-18 C-18 column (125 mm length × 4.6 mm diameter) was used as stationary phase. The mobile phase flow rate was 1 ml/min, and the composition was controlled by a gradient of acetonitrile/water starting at 35:65, increasing to 45:55 after 10 min, to 70:30 after 11 min, and returning to 35:65 after 14 min. Volume injection was 50 μl and the absorbance of limonoids was measured at 213 nm by a Diode Array Detector. Limonoid peaks in the samples were compared with standard azadirachtin (Sigma, USA; catalogue no. A-7430) [16]. Peaks with similar absorption spectrum but at different absorption time and with a single maximum between 200 and 213 nm were considered as limonoids related to azadirachtin [17].

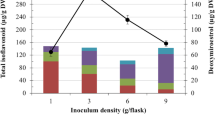

With the purpose of increasing biomass and production of limonoids with insect antifeedant activity, some previously reported culture media that stimulate cell growth or azadirachtin production were evaluated in shake flasks; so, conventional MS medium with source of nitrate and phosphate—NH4NO3 1.65 g/l, KNO3 1.90 g/l, KH2PO4 0.17 g/l [18]—and A. indica MS modified medium with source of nitrate and phosphate—NH4NO3 0 g/l, KNO3 5.7 g/l, KH2PO4 0.094 g/l [19]—were studied. Effects of different sucrose concentrations (25, 37, 45, and 60 g/l), addition of sodium acetate 0.1 g/l as precursor on day 0, and effects of the elicitors salicylic acid (SA) 137.3 mg/l, jasmonic acid (JA) 2.9 mg/l, and chitosan (CH) 16.5 mg/l added on day 8 of cultivation were also evaluated at concentrations previously reported by Prakash and Srivastava [20]. Cell suspensions were cultured in 250-ml shake flasks, inoculum 5 g DCW/l, and 50 ml of working volume. Flasks were harvested after 15 days and analyzed for DCW and limonoid content.

Two-Stage Bioreactor Process

A. indica cell culture in a two-stage process was carried out in a 3-l bioreactor (Applikon, ez-Control) with 2 l of working volume, equipped with an internal filter cell separator, an impeller of six pitched-blades, a turbine rotating at 400 rpm, and a porous stainless steel air diffuser. Culture was maintained at 25 °C under dark conditions, and pH was controlled at 5.8 with NaOH 0.25 M addition. The culture media selected in shake flasks was used in the two-stage bioreactor process. The cultivation started as a batch for 15 days with MSx1.5 medium, sucrose 45 g/l, sodium acetate 0.1 g/l, and 30 % of dissolved oxygen tension. After 15 days, 1 l of culture medium was drained retaining cells in the bioreactor and 1 l of concentrated modified medium was added together with elicitors to reach the desired concentrations in the bioreactor (sucrose 60 g/l, SA 137.3 mg/l, JA 2.9 mg/l, CH 16.5 mg/l). In the second stage, the dissolved oxygen tension was increased to 80 % in order to stimulate limonoid production [17].

Bioassays

Choice feeding bioassays were conducted to evaluate cell culture extracts using larvae of Spodoptera frugiperda. The antifeedant index (AI) of ethanolic extracts obtained from freeze-dried biomass of cell culture was calculated [16]. Second instar larvae were placed in petri dishes containing a layer of agar 1 % w/v and two discs of corn leaves (Zea mays) with an area of 2.25 cm2 each one. Discs were taken from freshly cut corn plantlets grown in lab. One disc was treated with 50 μl of ethanolic extract and a parallel disc was treated with an equivalent volume of vehicle (95 % ethanol without extract) for use as negative control. The affected areas were measured with image analysis software (ImageJ), and AI was calculated with areas consumed (AC) from leaf discs [16, 21, 22]:

Statistical Analysis

Experiments in shake flasks and bioassays were performed in triplicate; in the bioreactor, experiments were performed in duplicate and the samples were analyzed two times. One-way analysis of variance (ANOVA) and Tukey HSD (test for post-ANOVA) were used for multiple group comparisons. Treated and control groups were compared with Student’s t test. Graphs containing errors bars show the mean ± the standard error of the mean. p < 0.05 was considered statistically significant.

Results and Discussion

Selection of Culture Media for Biomass and Production of Limonoids

Effect of Sucrose Concentration

A proportional relationship between sucrose concentration and biomass production has been reported for cell suspension culture and hairy root cultures of A. indica [23, 24]. Also, it is known that sucrose concentrations higher than 60 g/l have an inhibitory effect on the specific growth rate [25]. In the present study, significantly higher biomass production was obtained with sucrose 45 g/l (25.57 ± 1.63 g DCW/l) and sucrose 60 g/l (27.93 ± 2.38 g DCW/l) after 15 days, as compared with sucrose 25 g/l (15.74 ± 0.66 g DCW/l) and sucrose 37 g/l (20.68 ± 0.84 g DCW/l). In addition, no statistically significant differences were found when using 45 and 60 g/l sucrose concentration (Fig. 1a).

Despite the positive effect of sucrose concentration on A. indica cell growth, the study of its effect regarding azadirachtin production has shown contradictory results. In cell suspension cultures, Sujanya et al. [23] did not observe a significant increase in azadirachtin production when comparing two different sucrose concentrations using MS medium. On the other hand, in callus cultures, Wewetzer [26] found that azadirachtin production was three times higher on media supplemented with 15 g/l sucrose as compared with 30 g/l sucrose; however, he concluded that abundant sucrose in culture media was not a limiting factor in the production of azadirachtin. In the present study, the different sucrose concentrations evaluated did not show significant improvement in the production of limonoids, which supports the results reported in the literature (Fig. 1b).

Effect of Nitrate and Phosphate Concentration

Cell growth and secondary metabolites production are strongly influenced by modification of carbon source, phosphate level, and ratios of nitrate/ammonium, carbon/nitrogen, and phytohormones in cell culture media [27]. Therefore, it is common to improve cell growth and azadirachtin production by modifying one or several components of MS basal medium [19, 23, 27]. In the present study, the conventional MS medium and a modified medium were evaluated. After 15 days, an increase in biomass was observed with the use of the modified medium: 15.13 ± 0.62 versus 18.16 ± 0.84 g DCW/l, MS medium versus modified medium (p = 0.04) (Fig. 2a). Also, an increase in the production of limonoids was found: 0.77 ± 0.24 versus 4.52 ± 1.21 mg/g DCW, MS medium versus modified medium (p = 0.006) (Fig. 2b). The decrease in phosphate concentration in modified medium could influence increase in production of limonoids [19, 27].

a Effect of nitrate and phosphate concentration on dry cell weight in A. indica cell culture. b Effect of nitrate and phosphate concentration on production of limonoids. MS medium contains as nitrate and phosphate NH4NO3 1.65 g/l, KNO3 1.9 g/l, and KH2PO4 0.17 g/l, and modified medium contains NH4NO3 0 g/l, KNO3 5.7 g/l, and KH2PO4 0.094 g/l. *p < 0.05 versus control; **p < 0.01 versus control

Effect of Sodium Acetate

The addition of precursors to the media in order to increase the production of secondary metabolites in plant cell cultures has been reported [28–30]. In the present study, when the precursor sodium acetate 0.1 g/l was added on day 0, a significant increase in production of limonoids was observed (0.15 ± 0.07 vs. 1.22 ± 0.14 mg/g DCW, control vs. treatment, p = 0.022) (Fig. 3b). No significant increase in cell growth was observed after 15-day culture (Fig. 3a). Prakash and Srivastava [28] found that azadirachtin content was higher when sodium acetate was used; moreover, cell growth increased slightly in their investigation. Differences in production between this study and Prakash and Srivastava [28] could be mainly due to the cell line and the culture medium used in their experiments.

Prakash et al. [31] showed the importance of developing a suitable cell line for high biomass and azadirachtin production from seeds with high azadirachtin content. Also, by the use of optimized media during the experiments, it is possible to increase azadirachtin production [19]. Increase in azadirachtin production and other secondary metabolites such as limonoids can be attributed to high levels of acetyl coenzyme A as result of sodium acetate feeding. Sodium acetate is transformed to acetic acid and acetyl coenzyme A in sequence after entering the cells, which could promote the tricarboxilic acid cycle and energy metabolism. Hence, life activities of cells could be enhanced, which may lead to improved production of secondary metabolites [32].

Effect of Chitosan, Salicylic Acid, and Jasmonic Acid

When chitosan, salicylic acid, and jasmonic acid were added as elicitors to the culture medium on day 8, an approximately fivefold increase in production of limonoids was observed after 15-day culture (Fig. 4). The highest production of limonoids was obtained when elicitors were added together to culture medium (0.92 ± 0.07 vs. 4.47 ± 1.6 mg/g DCW, control vs. treatment, p = 0.049). DCW was not affected by the presence of elicitors (Fig. 5). Similar results have been reported by Prakash and Srivastava [20], where a synergistic effect of these elicitors resulted in fivefold higher azadirachtin production. Other studies related to elicitation in hairy root cultures have also found great enhancement in azadirachtin production. Srivastava and Srivastava [5] studied different abiotic stress inducers (Ag+, Hg+2, Co+2, Cu+2) and signal molecules (methyl jasmonate and salicylic acid) and found that salicylic acid enhanced the azadirachtin yield in hairy root cultures to the maximum (up to 4.95 mg/g). On the other hand, with addition of biotic elicitor, Satdive [33] enhanced the production of azadirachtin by approximately fivefold (0.074 % DW), while signal compounds such as jasmonic acid and salicylic acid showed an approximately sixfold (0.095 % DW) and ninefold (0.14 % DW) enhancement.

Two-Stage Bioreactor Process

The necessity of a two-stage process for production of limonoids in suspension cultures of A. indica has been reported. Compared with the single-stage process, by the manipulation of major nutrients, an almost twofold increase in the volumetric productivity of limonoids has been achieved using two-stage process in shake flasks [27]. Also, other studies have shown that the use of elicitors in culture medium and the increase of oxygen supply in bioreactors enhance azadirachtin and production of limonoids [17, 28]. In the present study, the two-stage bioreactor process permitted using two different culture media selected in shake flasks for growth and production of limonoids. More than three fold increase in the limonoid volumetric production compared with the control single-stage process was observed. The highest production of limonoids was obtained on day 18, 72 h after addition of elicitors (13.82 vs. 41.44 ± 3.30 mg/l, control single-stage process vs. two-stage process) (Fig. 6d). On days 16 and 21 (24 and 96 h after addition of elicitors), production was slightly lower.

Comparison of two-stage process (triangles) and control single-stage process (dots) for kinetics of A. indica in a 3-l stirred tank bioreactor. a Cell viability, b dry cell weight, c sugars consumption, d production of limonoids. The arrow indicates the end of first stage and the start of second stage

The effect of addition of elicitors (chitosan, salicylic acid, and jasmonic acid) supports results previously reported, where a synergistic effect of these elicitors resulted in fivefold higher azadirachtin production [20]. In statistical elicitor optimization studies, Prakash and Srivastava [20] evaluated the effect of incubation time of elicitors on azadirachtin production and found the maximum production between 48 and 72 h of incubation. Less azadirachtin production was achieved after 24 and 96 h of incubation. In contrast to the work of Prakash and Srivastava [28], who added the elicitors to the bioreactor after 8 days of culture, the second-stage process was initiated and elicitors were added on day 15 in order to accumulate more biomass in bioreactor and increase the limonoid volumetric production.

Cell viability decreased in the two-stage process compared with control single-stage process, but biomass increased and production of limonoids was more than threefold higher (Fig. 6). Also, a threefold increase in methanolic extract production was observed (2.27 ± 0.19 vs. 6.85 ± 0.66 g/l, control single-stage process vs. two-stage process) (data not shown); this increase in methanolic extract is important because it is the basis for a bioinsecticide formulation.

In a two-stage bioreactor process, the possible stress induced by elicitors and the oxidative stress caused by the increase of dissolved oxygen tension from 30 to 80 % could cause the cells to shift their primary metabolism toward the production of secondary metabolites such as terpenoids and limonoids [17].

After 18 days of two-stage bioreactor process, the highest production of limonoids obtained was 41.44 mg/l. This value represents eight azadirachtin-related limonoids by its UV spectrum, with a maximum absorption peak between 200 and 210 nm. This yield exceeds the values of production of limonoids different from azadirachtin reported in literature; after 14 days of bioreactor cultivation, Orozco-Sánchez [17] produced 5.3 ± 1.8 mg limonoids/l when OTRmax was increased from 6.21 to 6.21 kg O2 m3 day−1; on the other hand, the highest production of limonoids reached by Raval et al. [27] was 4.5 mg/l in a shake flask two-stage process. Other studies focus only on azadirachtin and do not consider azadirachtin-related limonoids with insect antifeedant activity [28].

Prakash and Srivastava [25] observed dry biomass reduction with A. indica cells in a 3-l bioreactor operated in batch mode when culture featured complete consumption of glucose and phosphate on day 10. In the present study, sugars were almost completely consumed on day 11 in the control single-stage process with MS medium and sucrose 30 g/l (Fig. 6c); however, in the two-stage process, no substrate depletion was observed and total sugar concentration did not exceed the reported inhibitory sucrose concentration of 60 g/l [25]. Prakash and Srivastava [7] reported good cell growth and sugar consumption when feeding a cell retention bioreactor; however, in the present study, little sugar consumption was observed in production stage, probably because of the decrease in cell viability due to the stress induced by elicitors and the increase of dissolved oxygen tension. Perhaps, cells do not require this quantity of substrate for production of limonoids; at industrial scale, it is important to take this into account since sucrose excess may represent a big difference in the economic feasibility study of a process plant.

In the two-stage bioreactor process, the production of extracellular limonoids oscillated between 0 and 2 mg/l (data not shown). Although this production represents a small percentage of total production of limonoids (less than 5 %), it should not be despised because, even with small amounts of azadirachtin (0.02–5.28 mg/l), an antifeedant effect on S. frugiperda larvae has been reported [16]. The antifeedant effect has been attributed to the presence of other compounds such as nimbin and salannin, which might act independently or synergistically with azadirachtin [13].

Bioassays

Although the antifeedant effect of A. indica extracts has been reported for seeds, calli, shake flasks, and hairy root cultivation [5, 13, 16, 34], to knowledge of the authors, the present study is the first report of antifeedant effect from cell suspension cultured in a two-stage bioreactor process to date. Antifeedant index of 76 % ± 24 in bioreactor and 43 % ± 17 in shake flasks was obtained (Fig. 7b). These results show that it is possible to produce limonoids for biological control of insects with cell culture of A. indica in a stirred tank bioreactor.

The antifeedant index was measured 96 h after applying the treatment. During the bioassay, larvae showed greater preference to consume the control leaf discs. Although only one application of the extract was performed, the repellent effect prevailed during the entire assay, in some cases, in lower proportion than at the beginning of the experiment.

Conclusions

In this paper, a suitable two-stage bioreactor process that enhances the production of limonoids in A. indica cultures was presented. Several limonoids related to azadirachtin were taken into account; in fact, in some cases, azadirachtin was not present at all and a good antifeedant effect on S. frugiperda larvae was observed anyway. Significantly higher biomass production was obtained with sucrose 45 g/l (25.57 ± 1.63 g DCW/l) and sucrose 60 g/l (27.93 ± 2.38 g DCW/l) after 15 days, compared with sucrose 25 g/l (15.74 ± 0.66 g DCW/l) and sucrose 37 g/l (20.68 ± 0.84 g DCW/l). More than fivefold increase in the production of limonoids was observed with modified MS medium (0.77 ± 0.24 vs. 4.52 ± 1.21 mg/g DCW, MS medium vs. modified medium), and when sodium acetate and elicitors were added to culture medium. The maximum production of limonoids in shake flask was achieved when elicitors CH, SA, and JA were added together (0.92 ± 0.07 vs. 4.47 ± 1.6 mg/g DCW, control vs. treatment). In order to increase the production of limonoids, it is recommended to use the modified MS medium and the precursor sodium acetate, as well as adding to culture medium the elicitors CH, SA, and JA combined. It is important to consider that elicitors affect cell viability and should only be used at the end of the exponential phase of growth. Moreover, the greatest effect of elicitors on the production of limonoids occurs about 48 h after they are supplied. With the medium modifications and the two-stage bioreactor process proposed in the present study, it was possible to stimulate cell growth or production of secondary metabolites. Thereby, in bioreactor, the production of limonoids was increased more than threefold on day 18 (13.82 mg limonoids/l in control single-stage process vs. 41.44 mg/l in two-stage process). The production of methanolic extract was increased. Besides, ethanolic extracts obtained from bioreactor and shake flask cultures showed repellent effect on S. frugiperda, establishing the basis for a bioinsecticide production with plant cell suspension culture at industrial scale. In future investigations, it would be interesting to study the hydrodynamic and oxidative stress involved in the production of limonoids in bioreactor.

References

Aktar, M. W., Sengupta, D., & Chowdhury, A. (2009). Impact of pesticides use in agriculture: their benefits and hazards. Interdisciplinary Toxicology, 2(1), 1–12. doi:10.2478/v10102-009-0001-7.

Boeke, S. J., Boersma, M. G., Alink, G. M., Van Loon, J. J. A., Van Huis, A., Dicke, M., & Rietjens, I. M. C. M. (2004). Safety evaluation of neem (Azadirachta indica) derived pesticides. Journal of Ethnopharmacology, 94(1), 25–41. doi:10.1016/j.jep.2004.05.011.

Sidhu, O. P., Kumar, V., & Behl, H. M. (2003). Variability in Neem (Azadirachta indica) with respect to azadirachtin content. Journal of Agricultural and Food Chemistry, 51(4), 910–915.

Prakash, G., Bhojwani, S. S., & Srivastava, A. K. (2002). Production of azadirachtin from plant tissue culture: state of the art and future prospects. Biotechnology and Bioprocess Engineering, 7(4), 185–193. doi:10.1007/BF02932968.

Srivastava, S., & Srivastava, A. K. (2013). Production of the biopesticide azadirachtin by hairy root cultivation of Azadirachta indica in liquid-phase bioreactors. Applied Biochemistry and Biotechnology, 171(6), 1351–1361.

Srivastava, S., & Srivastava, A. K. (2014). Effect of elicitors and precursors on azadirachtin production in hairy root culture of Azadirachta indica. Applied Biochemistry and Biotechnology, 172(4), 2286–2297. doi:10.1007/s12010-013-0664-6.

Prakash, G., & Srivastava, A. K. (2008). Production of biopesticides in an in situ cell retention bioreactor. Applied Biochemistry and Biotechnology, 151(2-3), 307–318. doi:10.1007/s12010-008-8191-6.

Srivastava, S., & Srivastava, A. K. (2012). Azadirachtin production by hairy root cultivation of Azadirachta indica in a modified stirred tank reactor. Bioprocess and Biosystems Engineering, 35(9), 1549–1553. doi:10.1007/s00449-012-0745-x.

Srivastava, S., & Srivastava, A. K. (2012). In vitro azadirachtin production by hairy root cultivation of Azadirachta indica in nutrient mist bioreactor. Applied Biochemistry and Biotechnology, 166(2), 365–378. doi:10.1007/s12010-011-9430-9.

Srivastava, S., & Srivastava, A. K. (2012). Strategies to overcome oxygen transfer limitations during hairy root cultivation of Azadiracta indica for enhanced azadirachtin production. Applied Biochemistry and Biotechnology, 167(6), 1818–1830. doi:10.1007/s12010-011-9531-5.

Prakash, G., & Srivastava, A. K. (2007). Azadirachtin production in stirred tank reactors by Azadirachta indica suspension culture. Process Biochemistry, 42(1), 93–97. doi:10.1016/j.procbio.2006.06.020.

Singh, M., & Chaturvedi, R. (2013). Sustainable production of azadirachtin from differentiated in vitro cell lines of neem (Azadirachta indica A. Juss.). AoB Plants, 5, plt034–plt034. doi:10.1093/aobpla/plt034.

Simmonds, M. S. J., Jarvis, A. P., Johnson, S., Jones, G. R., & Morgan, E. D. (2004). Comparison of anti-feedant and insecticidal activity of nimbin and salannin photo-oxidation products with neem (Azadirachta indica) limonoids. Pest Management Science, 60(5), 459–464.

Linden, J. C., Haigh, J. R., Mirjalili, N., & Phisaphalong, M. (2001). Gas concentration effects on secondary metabolite production by plant cell cultures. Advances in Biochemical Engineering/Biotechnology, 72, 27–62. Retrieved from http://www.ncbi.nlm.nih.gov/pubmed/11729755

Radman, R., Saez, T., Bucke, C., & Keshavarz, T. (2003). Elicitation of plants and microbial cell systems. Biotechnology and Applied Biochemistry, 37(1), 91. doi:10.1042/BA20020118.

Capataz-Tafur, J., Orozco-Sánchez, F., Vergara-Ruiz, R., & Hoyos-Sánchez, R. (2007). Antifeedant effect of cell suspension extracts of Azadirachta indica on Spodoptera frugiperda J. E. Smith under laboratory conditions. Revista Facultad Nacional de Agronomía, Medellín, 60(1), 3703–3715. Retrieved from http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0304-28472007000100006&lng=en&nrm=iso&tlng=es

Orozco-Sánchez, F. (2009). Efecto de la oferta oxígeno sobre el crecimiento y la producción de terpenoides con células de Azadirachta indica en un biorreactor. Yautepec, México, PhD thesis Instituto Politécnico Nacional. Retrieved from http://itzamna.bnct.ipn.mx:8080/dspace/bitstream/123456789/5725/1/EFECTOFERTA.pdf.

Murashige, T., & Skoog, F. (1962). A revised medium for rapid growth and bio assays with tobacco tissue cultures. Physiologia Plantarum, 15(3), 473–497. doi:10.1111/j.1399-3054.1962.tb08052.x.

Prakash, G., & Srivastava, A. K. (2005). Statistical media optimization for cell growth and azadirachtin production in Azadirachta indica (A. Juss) suspension cultures. Process Biochemistry, 40(12), 3795–3800.

Prakash, G., & Srivastava, A. K. (2008). Statistical elicitor optimization studies for the enhancement of azadirachtin production in bioreactor Azadirachta indica cell cultivation. Biochemical Engineering Journal, 40(2), 218–226.

Kearney, M.-L., Allan, E. J., Hooker, J. E., & Mordue (Luntz), A. J. (1994). Antifeedant effects of in vitro culture extracts of the neem tree, Azadirachta indica against the desert locust (Schistocerca gregaria (Forskål)). Plant Cell, Tissue and Organ Culture, 37(1), 67–71. doi:10.1007/BF00048119.

Blaney, W. M., Simmonds, M. S. J., Ley, S. V., Anderson, J. C., & Toogood, P. L. (1990). Antifeedant effects of azadirachtin and structurally related compounds on lepidopterous larvae. Entomologia Experimentalis et Applicata, 55(2), 149–160. doi:10.1111/j.1570-7458.1990.tb01358.x.

Sujanya, S., Devi, B. P., & Sai, I. (2008). In vitro production of azadirachtin from cell suspension cultures of Azadirachta indica. Journal of Biosciences, 33(1), 113–20. Retrieved from http://www.ncbi.nlm.nih.gov/pubmed/18376076

Srivastava, S., & Srivastava, A. K. (2011). Statistical medium optimization for enhanced azadirachtin production in hairy root culture of Azadirachta indica. In Vitro Cellular & Developmental Biology - Plant, 48(1), 73–84. doi:10.1007/s11627-011-9395-y.

Prakash, G., & Srivastava, A. K. (2006). Modeling of azadirachtin production by Azadirachta indica and its use for feed forward optimization studies. Biochemical Engineering Journal, 29(1-2), 62–68.

Wewetzer, A. (1998). Callus cultures of Azadirachta indica and their potential for the production of Azadirachtin. Phytoparasitica, 26(1), 47–52. doi:10.1007/BF02981265.

Raval, K. N., Hellwig, S., Prakash, G., Ramos-Plasencia, A., Srivastava, A., & Büchs, J. (2003). Necessity of a two-stage process for the production of azadirachtin-related limonoids in suspension cultures of Azadirachta indica. Journal of Bioscience and Bioengineering, 96(1), 16–22. Retrieved from http://www.ncbi.nlm.nih.gov/pubmed/16233477

Prakash, G., & Srivastava, A. K. (2011). Integrated yield and productivity enhancement strategy for biotechnological production of azadirachtin by suspension culture of Azadirachta Indica. Asia-Pacific Journal of Chemical Engineering, (July 2010), 129–137. doi:10.1002/apj

Whitmer, S., Canel, C., Hallard, D., Gonçalves, C., & Verpoorte, R. (1998). Influence of precursor availability on alkaloid accumulation by transgenic cell line of Catharanthus roseus. Plant Physiology, 116(2), 853–857.

Shinde, A. N., Malpathak, N., & Fulzele, D. P. (2009). Optimized production of isoflavones in cell cultures of Psoralea corylifolia L. Using elicitation and precursor feeding. Biotechnology and Bioprocess Engineering, 14(5), 612–618. doi:10.1007/s12257-008-0316-9.

Prakash, G., Emmannuel, C. J. S. K., & Srivastava, A. K. (2005). Variability of azadirachtin in Azarirachta indica (neem) and batch kinetics studies of cell suspension culture. Biotechnology and Bioprocess Engineering, 10(3), 198–204. doi:10.1007/BF02932013.

Dongping, L., Dexiu, Z., Yan, H., & Qiao, Z. (2001). The effect of precursor feeding on flavonoids biosynthesis in cell suspension cultures of Saussurea medusa. Acta Botanica Yunnanica, 23(4), 497–503. Retrieved from http://europepmc.org/abstract/CBA/353936

Satdive, R. K., Fulzele, D. P., & Eapen, S. (2007). Enhanced production of azadirachtin by hairy root cultures of Azadirachta indica A. Juss by elicitation and media optimization. Journal of Biotechnology, 128(2), 281–289. doi:10.1016/j.jbiotec.2006.10.009.

Zypman, S., Ziv, M., & Applebaum, S. W. (2001). Production of desert locust feeding deterrents from in vitro cultured neem (Azadirachta indica). Phytoparasitica, 29(4), 284–291. doi:10.1007/BF02981844.

Acknowledgments

This work was partially financed by the Departamento Administrativo de Ciencia, Tecnología e Innovación (Colciencias grants 1118-521-28952) and Programa Jóvenes Investigadores e innovadores Colciencias (566-2011).

Conflict of Interest

The authors declare that they have no conflict of interest.

Authorship Contributions

A. Vásquez-Rivera participated in programming experiments, acquisition, analysis and interpretation of data, and writing the manuscript. D. Chicaiza-Finley participated in experiments and data acquisition. R.A. Hoyos participated in writing the manuscript. F. Orozco-Sánchez participated in the study conception and design, drafted and revised the manuscript, and approved the final version to be submitted.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vásquez-Rivera, A., Chicaiza-Finley, D., Hoyos, R.A. et al. Production of Limonoids with Insect Antifeedant Activity in a Two-Stage Bioreactor Process with Cell Suspension Culture of Azadirachta indica . Appl Biochem Biotechnol 177, 334–345 (2015). https://doi.org/10.1007/s12010-015-1745-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1745-5