Abstract

In this study, corncob acid hydrolysate was used as a substrate for bacterial cellulose (BC) production by Gluconacetobacter xylinus. After 2 weeks’ static fermentation, a BC yield of 4 g/L could be obtained. Both effects of medium composition and fermentation condition on the BC production were evaluated. Most extra substrates (carbon and nitrogen sources) except mannitol, butyric acid, and levulinic acid showed no effect on the improvement of BC yield. Fermentation condition including fermentation mode, inoculation concentration, and initial pH showed certain influence on the BC yield and thus should be well controlled. The analysis by field emission scanning electron microscope (FE-SEM), Fourier transform infrared spectroscopy (FTIR), and X-ray diffraction (XRD) showed that the BC sample had obvious nano-network structure, clear functional groups that were found in cellulose, and relatively high crystallinity and crystallinity index value. Moreover, the BC sample had great water-holding capacity. Overall, corncob acid hydrolysate could be one promising substrate for BC production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose (BC), synthesized by various bacteria, has great potential in the application on many fields such as materials, food, medicine, etc. [1]. Many factors can influence the BC productivity, and fermentation substrate cost is a significant one. In order to reduce its production cost, different substrates such as molasses [2], konjac powder hydrolysate [3], various fruit juices [4], etc. were utilized for BC production.

Compared with these low-cost substrates, lignocellulosic biomass has great potential for BC production due to its great availability and renewable characteristics [5]. After hydrolysis, the hydrolysates of lignocellulosic biomass can be used for the production of ethanol [6], butanol [7], single cell oils [8], and other products. To utilize lignocellulosic hydrolysates for BC production, the capacity of strain to metabolize xylose is critical, but the xylose-assimilated BC-producing strains are few [9].

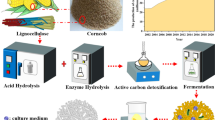

Recently, some studies continued to find out suitable microorganisms to accumulate BC on lignocellulosic hydrolysates, and the possibility of using lignocellulosic hydrolysates for BC production has been proven [10, 11]. Among different lignocellulosic biomass, corncob is a potential one for industrialization due to its advantages such as ease for hydrolysis, high sugar concentration of hydrolysate, wide culture area, etc. [12]. Although corncob acid hydrolysate has been used for the production of many chemical products [8], no work used it as substrate for BC production. Thus, for the first time, the possibility of using corncob acid hydrolysate as a substrate for BC production was evaluated in this work. To make this bioconversion more efficient, the effect of medium composition and fermentation condition on the BC production by G. xylinus was evaluated. Besides, the structure of BC samples obtained on corncob acid hydrolysate was analyzed by field emission scanning electron microscope (FE-SEM), Fourier transform infrared spectroscopy (FTIR), and X-ray diffraction (XRD). At the same time, the water-holding capacity of BC samples was measured.

Methods and Materials

Preparation of Corncob Acid Hydrolysate

Corncob acid hydrolysate was kindly denoted by Zhongke New Energy Co., Ltd (Ying-Kou, China). According to Zhongke New Energy Co., Ltd, the resulted hydrolysate was detoxified by overliming and absorption according to the previous work [13]. The diluted detoxified corncob acid hydrolysate (sugar concentration was about 25 g/L) was used as substrate for BC fermentation.

Microorganism, Medium, and Fermentation

Gluconacetobacter xylinus CH001 (Laboratory of Energy and Biochemical Engineering, Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences) was used as the microorganism for BC production in this work.

The pre-culture was performed on pre-cultivation medium (g/L, mannitol 25, peptone 5, yeast extract 3) at 28 °C and 150 rpm for 48 h. Then, seed culture was translated into the corncob acid hydrolysate. Then, the static fermentation was carried out at 28 °C for certain days.

Effect of Medium Composition on the BC Production by G. xylinus

Five kinds of carbon sources, namely arabinose, fructose, glucose, sucrose, and mannitol with concentrations of 3 g/L were added individually into corncob acid hydrolysate to evaluate their effect as extra substrate on BC production by G. xylinus.

When considering the effect of extra nitrogen sources on BC production by G. xylinus, different nitrogen sources including yeast extract, peptone, beef extract, ammonium acetate, ammonium chloride, and ammonium sulfate, were added into the corncob acid hydrolysate individually with concentrations of 2 g/L, and the BC fermentation was carried out, respectively.

To measure the added organic acids to the BC yield of G. xylinus, four kinds of organic acids (formic acid, acetic acid, butyric acid, and levulinic acid) were added into the corncob acid hydrolysate individually with concentrations of 3 g/L, and the BC fermentation was carried out respectively.

Effect of Fermentation Condition on the BC Production by G. xylinus

To evaluate the fermentation mode on the BC production by G. xylinus, both static and agitated fermentation were carried out. The fermentation condition was the same: inoculum concentration 8 %, initial pH 6.0, cultural temperature 28 °C. The speed of agitated fermentation was 150 rpm.

To measure the effect of initial pH value on the BC production by G. xylinus, seven different initial pH values ranging from 4.0 to 7.0 were used for various corncob acid hydrolysates medium. All the BC static fermentation was kept at 28 °C, and the inoculum concentration was 8 %.

To study the effect of inoculum concentration and seed age on BC production by G. xylinus, five inoculum concentrations (4, 6, 8, 10, and 12 %) and three seed ages (24, 48, 72 h) were applied to culture G. xylinus. All the BC fermentation was kept at 28 °C, and the initial pH value was 6.0.

Analytical Methods

After fermentation, the fermentation broth and BC were separated by vacuum filtration. Then, the BC was treated by 1.5 % (w/v) NaOH at 80 °C for 2 h. After that, the BC was repeatedly washed by distilled water. Finally, the BC was dried to constant weight at 80 °C and weighed. Sugar concentration was measured by DNS method [14].

The morphologies of oven-dried BC samples were observed by a Hitachi S-4800 high-resolution field emission scanning electron microscope (FE-SEM, Hitachi, Japan) operated at 2.0 kV and 10 μA. To measure the functional structure of BC samples, the Fourier transform infrared spectroscopy (FTIR) was carried out in the range of 400 to 4000 cm−1 wavelength with a Perkin-Elmer Spectrum One FTIR spectrometer (US). Structure, size, and percentage of crystals of BC samples were analyzed by D/max-RA X-ray diffractometer (Rigaku, Japan) with Cu Kα radiation (λ = 0.154 nm) operated at 40 kV and 100 mA. Samples were scanned from 5 to 50° (2θ range) at a scan speed of 0.008°/step. The crystal size of cellulose and crystallinity index (CI) was determined according to previous researches [15, 16].

To determine the water-holding capacity, firstly, water on the surface of wet BC was absorbed carefully by absorbent paper and the weight of BC was recorded as M0. After drying at 105 °C to constant weight, the weight of dried BC was recorded as M1. The water-holding capacity was defined as (M0 − M1)/M1. To measure the water release rate, the BC sample was placed at room temperature and then its weight (M2) was recorded at different time intervals, and the water weight in BC samples was defined as M2 − M1.

Results and Discussion

Basic Phenomenon of BC Production by G. xylinus on Corncob Acid Hydrolysate

The original corncob acid hydrolysate offered by Zhongke New Energy Co. Ltd contained about 50 g/L reducing sugars. After detoxification, the corncob acid hydrolysate without adding nitrogen sources or other trace elements was used for BC production. Usually, too high initial sugar concentration is not suitable for BC production [1]. Thus, the initial sugar concentration was not higher than 25 g/L in many studies [3, 10]. Thus, in this work, the corncob hydrolysate was diluted for 50 %, and the initial sugar concentration for BC production was about 25 g/L.

Then, the BC fermentation was carried out on the diluted corncob acid hydrolysate (Fig. 1). Overall, the fermentation period was about 2 weeks. After 1 day of fermentation, no obvious mycelium or BC shape could be observed in the flask containing medium. The BC concentration could hardly be detected at this period. As the fermentation went on, a clear film-like BC material was observed at the bottom of the flask. On the other hand, the sugar consumption by G. xylinus was slow during the first 3 days’ fermentation. Obviously, compared with other traditional fermentation processes such as ethanol fermentation [6] or lipid fermentation [12], the lag phase for BC fermentation is much longer. The BC pellicle was formed on the surface of the medium after 4 days’ fermentation. After that, the BC pellicle on the surface of corncob acid hydrolysate became thicker as the fermentation went on. Also, the sugar consumption by G. xylinus increased accordingly. Finally, the BC yield on the corncob acid hydrolysate was about 4 g/L.

It is worth noting that the BC yield of G. xylinus on corncob hydrolysate was not stable, and with different batches, the BC yield varied from 1.0 to 4.5 g/L. Obviously, this phenomenon is different from other traditional dynamic fermentation [12]. It is possible that the static fermentation make the metabolism especially sugar utilization of G. xylinus become changeable and finally affect the final BC yield. However, corncob acid hydrolysate was still proven to be the potential substrate for BC fermentation.

Effect of Medium Composition on BC Production by G. xylinus

In the past decades, medium composition such as carbon source, nitrogen source, and some extra materials was considered as one important factor that influence the BC yield of G. xylinus [1, 17]. In this study, various carbon sources (sugars and mannitol), nitrogen sources, and organic acids were added into corncob acid hydrolysate individually to measure their effect on BC production by G. xylinus.

As shown in Fig. 2a, all sugars tested (glucose, fructose, arabinose, sucrose) could not improve the BC yield of G. xylinus. Specially, the existence of arabinose and sucrose had obvious negative effect on the BC production. It is possible that arabinose and sucrose were not the suitable carbon sources for BC fermentation by G. xylinus, or the existence of these sugars would inhibit the utilization of other sugars in corncob hydrolysate. Interestingly, adding mannitol showed small stimulation on BC production by G. xylinus, suggesting it is a suitable substrate for BC production. However, considering the cost of mannitol, it is not necessary to add this carbon source for the BC production by G. xylinus on corncob acid hydrolysate.

In spite that N element does not exist in the BC products (mainly cellulose), adding extra nitrogen source might be beneficial for the growth of G. xylinus and thus improve its BC yield. In this study, some extra nitrogen sources including organic ones (yeast extract, peptone, and beef extract) and inorganic ones (ammonium acetate, ammonium chloride, and ammonium sulfate) were added individually to measure their effect on BC production by G. xylinus (Fig. 2b). Interestingly, both organic and inorganic nitrogen sources showed no beneficial effect on BC yield of G. xylinus. It is possible that one optimal C/N ratio existing for the BC production by G. xylinus and thus more nitrogen sources in corncob hydrolysate would show a negative influence on its BC yield.

In many studies, adding organic acids into medium could improve BC yield of G. xylinus [18]. In our previous work, acetic acid also showed beneficial effect on both xylose utilization and BC production of G. xylinus [19]. Usually, short-chain fatty acids such as formic acid, acetic acid, butyric acid, and levulinic acid were found in lignocellulosic hydrolysates [5, 12]. To measure their effect on BC production, these acids were added individually into corncob acid hydrolysate for BC fermentation. As shown in Fig. 2c, acetic acid showed a surprisingly negative effect on BC yield of G. xylinus, possibly due to the influence of corncob acid hydrolysate environment. On the other hand, butyric acid and levulinic acid showed small stimulating effect on BC production by G. xylinus. This stimulating effect was related to the acid concentration, e.g., when levulinic acid concentration was higher than 3 g/L, it would show negative effect on the BC yield of G. xylinus (data not shown). Interestingly, formic acid showed extremely serious inhibition on BC production by G. xylinus, suggesting that it has fatal influence on the metabolism of G. xylinus.

Overall, some extra substrates such as mannitol, butyric acid, and levulinic acid could have small improvement on BC yield of G. xylinus, but considering their cost, there is no need to add these materials into corncob hydrolysate.

Effect of Fermentation Condition on BC Production by G. xylinus

In many studies, fermentation condition showed certain influence on BC fermentation [1, 17]. In this study, the factors such as fermentation mode, inoculation concentration, and initial pH were chosen to evaluate their effect on BC production by G. xylinus.

Traditionally, both static and agitated fermentation modes could be used for BC production [1]. Usually, static fermentation generates BC membrane, and agitated fermentation produces BC granule. The difference of static and agitated fermentation of on corncob acid hydrolysate is shown in Table 1. Obviously, the shape of BC samples obtained by agitated fermentation was clustered while a BC membrane was generated after static fermentation (Fig. 3). Overall, the BC yield obtained by agitated fermentation was much lower than that by static mode.

Inoculation concentration shows a certain influence on fermentation. Too low inoculation concentration might affect the growth of G. xylinus, but a too high one would prevent the BC accumulation. In this study, 4–12 % inoculation concentration was applied (Fig. 4a). When the inoculation concentration was low (4 %), no BC products were detected after fermentation. When the inoculation concentration was higher, the BC yield varied little after fermentation. Overall, 10 % is optimal for BC production by G. xylinus. Besides inoculation concentration, inoculation seed age would also influence the BC yield of G. xylinus. In this work, the optimal seed age was 48 h, longer or shorter seed age would decrease the BC yield of G. xylinus (data not shown).

It is worth noting that some kinds of organic acids are present in lignocellulosic hydrolysates that might influence the fermentation process [20]. Specially, BC fermentation is usually one biological process that would generate some acidic materials that might lead to the decrease of pH value. Thus, the effect of initial pH value on BC production by G. xylinus on corncob acid hydrolysate was evaluated. As shown in Fig. 4b, obviously, a low initial pH value (pH <5.5) was not beneficial for the BC production by G. xylinus that the BC dry weight got after fermentation decreased as the initial pH value to be lower. This again showed that acidic environment was unfavorable for the growth and product accumulation of G. xylinus. After fermentation, the final pH value was not always lower than initial pH value, indicating that the corncob acid hydrolysate has some buffer capacity. As that acid material is secreted during the BC fermentation, the buffer capacity of corncob acid hydrolysate is beneficial for BC production. When the initial pH value was higher than 5.5, the effect of initial pH value on the BC production by G. xylinus was not obvious. Overall, the optimal initial pH value for BC production was 6.5.

Structure and Water-Holding Capacity of BC Samples Obtained from Corncob Acid Hydrolysate

After static fermentation, the morphology and structure of final product BC membrane was analyzed by FE-SEM, FT-IR, and XRD.

In SEM image (Fig. 5), the BC was shown as a porous network containing various nanoscale fibers. The size of most fibers in BC network was ranged from 10 to 80 nm. This structure is similar to our previous study obtained on synthetic medium [19].

The functional groups of BC samples obtained from corncob acid hydrolysate were analyzed by FT-IR with wavelength range from 400 to 4000 cm−1. As shown in Fig. 6a, the characteristic bands of cellulose (type I) synthesized on the corncob acid hydrolysate appeared at 3349 and 3246 cm−1 for the stretching vibration of hydroxyl groups (–OH), at 2897 cm−1 for the asymmetric stretching vibration of methylene (–CH2–), at 2854 cm−1 for the symmetric stretching vibration of methyl (–CH3), at 1428 cm−1 for the asymmetric deformation vibration of methyl and methylene, at 1061 cm−1 for C–O–C and C–O–H stretching vibration of sugar ring, and at 897 cm−1 for γ (COC) in plane, symmetric stretching [21]. Overall, the functional groups detected were in good accordance to that of cellulose.

The XRD result of BC samples obtained from the corncob acid hydrolysate was shown in Fig. 6b. The peaks at 2θ angles of 14.6, 16.8, and 22.8° corresponded to the (1Ī0), (110), and (200) crystal planes, respectively, showing that both products were cellulose I. The crystals size (Å) of (1Ī0), (110), and (200) crystal planes were 72.56, 184.28, and 61.44, respectively. In addition, a stronger diffraction peak intensity means a smaller crystal size as for these three crystal planes. Overall, the crystallinity and crystallinity index (CI) of the BC sample obtained from corncob acid hydrolysate were 95.2 and 93.8 %, respectively.

Besides structure, the water-holding capacity of BC samples was further measured. Generally, 1 g BC samples (dry weight) obtained from corncob acid hydrolysate could absorb 112.16 ± 0.25 g water. This great water-holding capacity of BC shows its great potential as water-absorbing material. More specially, the water release rate was measured in a long period, and it is required more than 40 h to lose all the water absorbed in BC membrane (Fig. 7), further suggesting its potential as a water-absorbing material.

To make this material have more water-holding capacity and more suitable for industrial application, modification with chemical or biological methods could be applied. Moreover, besides water-holding capacity and water release rate, other related key index of BC and its modified material such as water absorption rate, porosity, rehydration capacity, etc. need to be further investigated in our ongoing work.

Conclusion

Detoxified corncob acid hydrolysate is proven to be one potential alternative substrate for BC production by G. xylinus. The extra materials inducing carbon sources, nitrogen sources, or organic acids is not necessary for this bioconversion. Fermentation condition showed a certain influence on the BC yield and thus should be well controlled. Overall, the BC sample obtained in this study had obvious nano-network structure, clear functional groups found in cellulose and relatively high crystallinity and CI value by analysis of FE-SEM, FT-IR, and XRD.

References

Chawla, P. R., Bajaj, I. B., Survase, S. A., & Singhal, R. S. (2009). Food Technology and Biotechnology, 47, 107–124.

Bae, S., & Shoda, M. (2004). Biotechnology Progress, 20, 1366–1371.

Hong, F., & Qiu, K. (2008). Carbohydrate Polymers, 72, 545–549.

Kurosumi, A., Sasaki, C., Yamashita, Y., & Nakamura, Y. (2009). Carbohydrate Polymers, 76, 333–335.

Palmqvist, E., & Hahn-Hagerdal, B. (2000). Bioresource Technology, 74, 25–33.

Cardona, C. A., Quintero, J. A., & Paz, I. C. (2010). Bioresource Technology, 101, 4754–4766.

Qureshi, N., Saha, B. C., Dien, B., Hector, R. E., & Cotta, M. A. (2010). Biomass and Bioenergy, 34, 559–565.

Huang, C., Chen, X. F., Xiong, L., Chen, X. D., & Ma, L. L. (2012). Bioresource Technology, 110, 711–714.

Ishihara, M., Matsunaga, M., Hayashi, N., & Tisler, V. (2002). Enzyme and Microbial Technology, 31, 986–991.

Hong, F., Zhu, Y. X., Yang, G., & Yang, X. X. (2011). Journal of Chemical Technology and Biotechnology, 86, 675–680.

Dahman, Y., Jayasuriya, K. E., & Kalis, M. (2010). Applied Biochemistry and Biotechnology, 162, 1647–1659.

Chen, X. F., Huang, C., Xiong, L. L., Chen, X. D., & Ma, L. L. (2012). Biotechnology Letters, 34, 1025–1028.

Huang, C., Wu, H., Li, R. F., & Zong, M. H. (2012). New Biotechnology, 29, 372–378.

Miller, G. (1959). Analytical Chemistry, 31, 426–428.

Shezad, O., Khan, S., Khan, T., & Park, J. K. (2010). Carbohydrate Polymers, 82, 173–180.

Cheng, K. C., Catchmark, J. M., & Demirci, A. (2009). Cellulose, 16, 1033–1045.

Sani, A., & Dahman, Y. (2010). Journal of Chemical Technology and Biotechnology, 85, 151–164.

Toda, K., Asakura, T., Fukaya, M., Entani, E., & Kawamura, Y. (1997). Journal of Fermentation and Bioengineering, 84, 228–231.

Yang, X. Y., Huang, C., Guo, H. J., Xiong, L., Luo, J., Wang, B., Chen, X. F., Lin, X. Q., & Chen, X. D. (2014). Indian Journal of Microbiology, 54, 268–273.

Almeida, J., Modig, T., Petersson, A., Hahn-Hagerdal, B., Liden, G., & Gorwa-Grauslund, M. (2007). Journal of Chemical Technology and Biotechnology, 82, 340–349.

Park, J. K., Jung, J. Y., & Park, Y. H. (2003). Biotechnological Letters, 25, 2055–2059.

Acknowledgments

The authors acknowledge the financial support of the Science and Technology Project of Guangdong Province (2013B010403020), National Natural Science Foundation of China (51303181), the Support Plan Project of National Science and Technology (2012BAD32B07), the Project of Jiangsu Province Science and Technology (BE2013083), and Foundation of Director of Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences (y407pb1001, y107rf1001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, C., Yang, XY., Xiong, L. et al. Utilization of Corncob Acid Hydrolysate for Bacterial Cellulose Production by Gluconacetobacter xylinus . Appl Biochem Biotechnol 175, 1678–1688 (2015). https://doi.org/10.1007/s12010-014-1407-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1407-z