Abstract

Twenty bacterial strains, which are capable of degrading monocrotophos, were isolated from five soil samples collected from agriculture soils in India. The ability of the strains to mineralize monocrotophos was investigated under different culture conditions. A potential strain degrading monocrotophos was selected and named KPA-1. The strain was identified as a Bacillus subtilis on the basis of the results of its cellular morphology, physiological and chemotaxonomic characteristics, and phylogenetic conclusion of 16S ribosomal DNA (rDNA) gene sequences. Organophosphate hydrolase (opdA gene) involved in the initial biodegradation of monocrotophos in KPA-1 was quantitatively expressed, which was a constitutively expressed cytosolic enzyme. RT-qPCR data revealed that KPA-1 harboring opdA gene in an early stage was significantly downregulated from opdA gene in a degradation stage (1.5 fold more) with a p value of 0.0375 (p < 0.05). We have optimized culture conditions for the efficient degradation (94.2 %) of monocrotophos under aerobic conditions. Growth and degradation kinetic studies proved that KPA-1 was able to grow in minimal salt medium containing 1000 ppm monocrotophos as the only carbon source. Hence, KPA-1 culture has a great potential utility for the bioremediation of agriculture soils contaminated with organophosphorus pesticides, particularly monocrotophos.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organophosphorus compounds are used worldwide as insecticides and petroleum additives. It is accounting for an estimated 34 % of worldwide insecticide sales [1]. According to an estimate in India, about 51 % food material is contaminated with pesticide residues of which 20 % is above maximum residue limit prescribed by FAO standards. Agriculture is an important sector of the Indian economy, accounting for 14.62 % of the nation’s gross domestic product [2, 3]. As per the advance estimates released by Central Statistics Office, India, on 7th February, 2013, agriculture and allied sectors are estimated to grow at 1.8 % during 2012–13 as against 3.6 % during the last year [2, 4]. It implies that a significant portion of agricultural production is lost due to attack of pests and diseases which should be prevented using pesticides.

Soil and water contamination systems have been reported from all parts of the world owing to the large-scale use of organophosphorus insecticides in agriculture operation [5]. Thus, it is essential for early detection and subsequent decontamination and detoxification of the polluted environment since organophosphorus compounds possess very high mammalian toxicity. A variety of detoxification methods are employed for the pest resistance, resurgence, and pesticide residues in crop and soil associated with the excessive use of organophosphorus insecticides necessitate. Chemical and physical methods of decontamination convert pesticide compounds from toxic into less toxic states. In few cases, pesticide residues can accumulate in the environment and still as toxic to a range of organisms [6]. Consequently, a complete solution for decontamination and detoxification of organophosphorus insecticides has not yet been attained by those approaches. Bioremediation, in contrast, is an alternate way to remove contaminants from the environment. Microbial bioremediation are highly suitable for total mineralization of organophosphorus insecticides that can be mediated by a typical biochemical pathway existing in many soil bacteria [1, 7, 8].

Several soil bacteria have been isolated and characterized, which can degrade organophosphorus compounds as a source of phosphorus or carbon or both in the fields [9–11]. Monocrotophos (dimethyl (E)-1-methyl-2-(methylcarbamoyl)vinyl phosphate; MCP) are extensively used organophosphorus insecticides against aphides, scale insects, leaf hoppers, mites, and other foliage pests in agricultural operation persisting as soil residue and seeps into ground water [12]. Chlorpyrifos and mancozeb are the most commonly used monocrotophos insecticides, and their consumption in India during 2009–10 was 1815 MT [2, 4]. An extensive study on microbial biodegradation of monocrotophos has been done earlier [13–16]. Monocrotophos are served as a sole source of phosphorus for the growth of Pseudomonas aeruginosa F10B and Clavibacter michiganense subsp. insidiosum SBL 11, which was reported earlier by Singh and Singh (2003) [10]. Monocrotophos degrading bacterium, Paracoccus sp. M-1, was isolated from a sludge collected from the wastewater treatment pool of a pesticide factory [13, 14].

Several genes/enzymes with the ability to degrade monocrotophos have been identified and characterized from many soil bacteria including Arthrobacter atrocyaneus MCM B-425, Bacillus megaterium MCM B-423 [9], and Paracoccus sp. M-1 [13]. Phosphatase and esterase enzymes were proposed to involve in a microbial metabolic pathway of monocrotophos degradation [9]. Organophosphate phosphotriesterase gene from Pseudomonas diminuta has shown a significant homology to a plasmid-borne parathion hydrolase gene from Flavobacterium sp. strain ATCC 27551 [17] and a plasmid-borne phosphotriesterase in P. aeruginosa F10B [10]. The key enzyme involved in the initial biodegradation of monocrotophos in Paracoccus sp. M-1 was a constitutively expressed cytosolic protein [14]. It exhibited high catalytic activity, hydrolyzing a broad range of organophosphates through cleavage of P-O and P-S bonds [18]. The opdA gene in Brevundimonas diminuta was targeted to the periplasmic face of the inner membrane by twin arginine translocation pathway [19].

Monocrotophos degrading gene was sequenced, cloned in different organisms, and altered for better activity and stability [1]. Organophosphate hydrolase (OPH) and organophosphate degrading (opdA) genes identified from Agrobacterium radiobacter were overexpressed and purified earlier [20]. The opdA gene from B. diminuta was cloned and overexpressed in Pseudomonas sp. strain Ind01 [21]. Most recently, a new way for efficient recombinant production of immobilized opdA was also suggested by Blatchford et al. (2012) [22]. Thus, the present study was intended to isolate, identify, and characterize a potential soil bacterium (named as Bacillus subtilis KPA-1) from Indian agriculture soils polluted with monocrotophos. This study was also employed to quantify the KPA-1 harboring opdA gene for monocrotophos degrading efficacy using RT-qPCR approach.

Materials and Methods

Pesticide Description

Technical grade monocrotophos (76 % EC) was used in this study obtained from GSP Crop Science Pvt. Ltd., Ahmadabad, India. It is extensively used in India for aphides, scale insects, leaf hoppers, mites, and other foliage pests in agricultural operations. It is moderately toxic, affecting the human respiratory system. Monocrotophos administered animals has exhibited mild hyperglycemia and dyslipidemia in blood, suggesting that it can be a possible independent and potent environmental cardiovascular risk factor. It is responsible for carcinogenic problems, liver damage, and damage to thyroid cells due to inhibition of acetylcholinesterase activity [23]. It may also cause delayed neurotoxic effects which are not due to acetylcholinesterase inhibition [8]. The chemical structure of monocrotophos and its general characteristics including ecological effects are shown in Supplementary Table 1.

Enrichment and Isolation of Monocrotophos Degrading Soil Bacteria

Five soil samples were collected from vegetables and cotton fields of Gujarat, India which have been exposed to monocrotophos for the past several years. Ten gram of each soil sample was exposed to 100 ppm monocrotophos, mixed very well and kept at 37 ± 2 °C for 5 days. Serial dilutions of 10−1, 10−2, and 10−3 were prepared, and 1-mL aliquots from each dilution inoculated separately on nutrient agar plate containing 100 ppm monocrotophos. Colonies obtained after incubation for 24 h at 37 °C were purified on nutrient agar plates. The purified colonies were transferred step-wise on the nutrient agar plates containing monocrotophos at different concentrations (250, 500, 700, 1000, and 1500 ppm) for obtaining monocrotophos tolerance colonies.

Biodegradation Studies

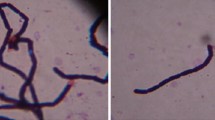

Colonies from agar slant were scrapped in sterile distilled water. One mL of this culture was inoculated in a conical flask containing 100-mL mineral salt medium (MSM, g/L): K2HPO4 1.5, KH2PO4 0.5, MgSO4 0.2, (NH4) 2SO4 0.5, NaCl 0.5, FeSO4 0.02, CaCl2 0.05, pH-7.0 ± 0.3, supplemented with monocrotophos at concentration of 1000 ppm. It was incubated under shaking condition at 150 rpm, at 37 °C for 7 days. Samples were withdrawn every 24 h from flasks and centrifuged (3000 × g) for 15 min at 4 °C. Cell-free supernatant was used for the quantification of residual monocrotophos by high-performance liquid chromatography (HPLC) with WATERS 2489 UV detector using 250 mm × 4.6 mm stainless steel (5 μm) C18 column. Acetonitrile: water (20: 80) was used as a mobile phase at a flow rate of 1 mL/min. MSM amended with 1000 ppm monocrotophos without culture was used as a control. A strain, which is capable of degrading monocrotophos, was selected for further identification, culturing, and expression studies. The shape and morphology of bacterial cells were determined by light microscopy. Biochemical tests were also performed for identification of this strain based on the Bergey’s Manual of Systematic Bacteriology [24].

PCR Amplification of 16S rRNA Gene and Sequencing

Bacterial genomic DNA was isolated from overnight culture by using Xcelgen DNA isolation kit according to the manufacture’s instruction. The isolated DNA was quantified using a NanoDrop 8000 spectrophotometer at 260 and 280 nm. The quality and purity of DNA were examined by agarose (0.8 %, w/v) gel electrophoresis, which was carried out at 80 V for 30 min. The 16S ribosomal RNA (rRNA) gene fragment was amplified from genomic DNA by PCR (Eppendorf Thermal Cycler) using universal primers (8 F: 5′-AGAGTTTGATCCTGGCTCAG-3′ and 1492R: 5′-ACGGTACCTTGTTACGACTT-3′). A reaction mixture for PCR consisted of DNase-RNase free water 7.5 μl, 2× PCR master mix (MBI Fermentas, 1×) 12.5 μl, forward primer (10 pmole/μl) 1.0 μl, reverse primer (10 pmole/μl) 1.0 μl, and DNA sample (30 ng/μl) 3.0 μl. Initial denaturation was performed at 95 °C for 2 min in the first cycle, and final denaturation was at 94 °C for 30 s in 30 cycles. Annealing was set at 55 °C for 30 s and extension at 72 °C for 90 s in 30 cycles and final extension at 72 °C for 10 min in one cycle. To confirm the targeted PCR amplification, 5 μl of PCR product from each tube was mixed with 1 μl of 6× gel loading dye and electrophoresed on 1.2 % agarose gel at constant 5 V/cm for 30 min. The amplified product was visualized as a single compact band of expected size under UV light and documented by gel documentation system (BioRad). Amplified PCR product was purified using Xcelgen Gel extraction kit according to the manufacturer’s protocol. Forward and reverse DNA sequencing reaction of PCR amplicon was carried out with 8 F and 1492R primers using BigDye® Terminator v3.1 Cycle sequencing kit following manufacturer’s instructions on ABI 3730 × l Genetic Analyzer (Applied Biosystems, USA).

Phylogenetic Analysis

Consensus sequence of 16S rDNA gene was used as a template to retrieve the sequence similarity hits from the NCBI database by BLASTn program [25]. The 16S ribosomal DNA (rDNA) gene sequences of related bacteria were selected with a reasonable sequence similarity and separately included in the dataset. The selected sequences in the dataset were clustered by multiple sequence alignment method in the ClustalX 2.0 software [26]. Multiple substitutions in each alignment was corrected and iterated at each step. All positions containing gaps and missing data were eliminated from the dataset. All the aligned sequences were inspected manually and unreliable sequences removed from alignments. Neighbor joining algorithm was used to search homogeneous patterns among all lineages using the MEGA 5.0 software [27] with 1000 bootstraps values. The evolutionary distances were computed using the Kimura 2-parameter method [28] and are in the units of the number of base substitutions per site. The final tree was manually edited and visualized in MEGA software.

Real-Time Quantitative PCR for Expression of opdA Gene

Cultures were grown for 24 and 144 h in MSM supplemented with 1000 ppm of monocrotophos. Total RNA was isolated from cells pellet of sample 0 and 144 h using TRIZOL® Reagent (Life Technologies) as per manufacturer’s protocol. Quantification of total RNA was done using NanoDrop 8000 spectrophotometer. Further, the quality of total RNA was analyzed on 1 % denaturing agarose gel. Complementary DNA (cDNA) was prepared from the total RNA samples using H minus First Strand cDNA synthesis kit (Thermo Scientific) using random hexamer primer as per manufacturer’s instruction. The reaction mixture composed of total RNA template 4 μl, primers 1 μl, DEPC-treated water 7 μl, 5× reaction buffer 4 μl, RiboLock RNase inhibitor (20 U/μl) 1 μl, 10 mM dNTP mix 2 μl, and M-MuLV reverse transcriptase (20 U/μl) 1 μl. After mixing gently, it was centrifuged and incubated for 5 min at 25 °C followed by 60 min at 42 °C. The reaction was terminated by heating at 70 °C for 5 min with temperature at 4 °C.

The prepared cDNA samples were amplified using gene specific primers. LightCycler® Probe Design Software 2.0 was used for designing the primers to 16S rDNA gene (housekeeping) and aryldialkylphosphatase (opdA) gene and then synthesized using Biolytic Dr. Oligo 96/192 synthesizer. The sequences of the 16S rDNA gene primers were 16SF 5′-CAATATTCCCCACTGCTGCC-3′ and 16SR 5′-CACCTAGGCGACGATCCCT-3′ whereas opdA primers were OPDA F 5′-TGTTCCGGTAACCACTCACA-3′ and OPDA R5′-CACTCTCAGAGGGACGAAGG-3′. The reaction mixture composed of nuclease free water 9.0 μl, cDNA 1 μl, primers (10 pmole/μl) 1.0 μl, and 2× PCR master mix (MBI Fermentas) 13 μl. Denaturation and annealing were carried out at 95 and 58 °C for 30 s, respectively. Extension temperature was set as 72 °C for 45 s and final extension was 75 °C for 7 min in 40 cycles. RT-qPCR reaction setup for both genes with two samples was performed in duplicate reaction using LightCycler 480 SYBR Green l Master (2X). Nuclease free water 9.5 μl, cDNA 1 μl, primers (10 pmole/μl) 1 μl, and LightCycler 480 SYBR Green l Master 12.5 μl were included in the reaction mixture. PCR product was electrophoresed along with 100-bp DNA molecular weight marker (Thermo Scientific). Electrophoresis was carried out at 95 V for 30 min.

Growth and Monocrotophos Biodegradation Kinetics

For the degradation kinetic study, the bacterial cell mass (OD600 = 1) was harvested in distilled water from the MSM agar slant amended with 1000 ppm monocrotophos. One mL of this inoculum was then added in MSM supplemented with 1000-ppm monocrotophos and incubated at 37 °C at 150 rpm for 7 days. Various culture conditions including temperature, pH, carbon sources, inoculum size, etc., were examined for the potential degradation of monocrotophos in shake flask. Broth samples were withdrawn at regular interval of 24 h, and residual monocrotophos was analyzed by HPLC under the same operating conditions as stated earlier. Phosphorus released during degradation was measured from the cell-free supernatant by Molybdenum-Vanadate method [29]. For biomass estimation, the broth samples were centrifuged (2739 × g) for 15 min at 4 °C, oven dried at 85 °C, and weighed.

Nucleotide Sequence Accession Numbers

The partial 16S rDNA gene sequence determined in this study has been deposited in the GenBank of NCBI database under accession number KC833048.

Results

Enrichment and Isolation Monocrotophos Degrading Soil Bacteria

We have isolated 20 bacterial isolates by enrichment of five soil samples with monocrotophos (100 ppm) as sole carbon and energy source; out of which, seven isolates could withstand their growth on monocrotophos at concentration of 1000 ppm (Table 1). Notably, KPA-1 reported to show its growth on monocrotophos even at concentration of 1500 ppm. The degradation potential (%) of each isolate was calculated using different concentrations of monocrotophos in MSM medium as shown in Fig. 1. Among seven isolates, the strains KPA-5, KPA-8, and KPA-14 show a maximal degradation (<80 %) of monocrotophos and KPA-1 has reported to show the highest degradation (89.6 %) in this study. Hence, we have chosen KPA-1 as a potential microbial strain for further study.

Identification of Monocrotophos Degrading Strain

The PCR product (16 s rRNA gene) of this strain was sequenced, and then sequence similarity hits searched out for its taxonomic identification using phylogenetic inference. Consensus sequence of 1269-bp 16S rDNA gene was generated from forward and reverse sequence data using aligner software. The culture, which was labelled as KPA-1, was found to be B. subtilis based on nucleotide homology (99 % identity). In the phylogenetic tree, two major clades were generated in which many organisms belonged to the members of Bacillus genus and few of them were Brevibacterium halotolerans, Virgibacillus halodenitrificans, Gracilibacillus dipsosauri (Fig. 2). Five out-group organisms including Salirhabdus euzebyi CVS-14, Listeria monocytogenes EGD-e, Listeria innocua ATCC 33091, Bhargavaea cecembensis DSE10 and Geobacillus kaustophilus G1 have identified to classify the KPA-1 at species level. In the optimized tree, G. kaustophilus G1 served as a recent ancestor to the strain KPA-1. Phylogenetic analysis of this study revealed that KPA-1 was grouped with B. subtilis subsp. subtilis DSM 10, B. subtilis subsp. spizizenii NRRL B-23049, B. vallismortis DSM11031, B. amyloliquefaciens NBRC 15535, and B. atrophaeus JCM9070. Since a strong phylogenetic proximity was found to be with B. subtilis subsp. subtilis DSM 10, KPA-1 was equivalent to B. subtilis subsp. subtilis and finally named as B. subtilis.

Phylogenetic tree based on the 16S rRNA gene sequences of KPA-1 and relating species. Branch lengths are proportional to evolutionary distances. The tree is drawn to scale, with branch lengths measured in the number of substitutions per site. Branches corresponding to partitions reproduced in less than 50 % bootstrap replicates and taxa with same evolutionary distances are collapsed. The sequences with more than 95 % sequence identity are included in the tree. Bootstrap consensus tree inferred from 1000 replicates is taken to represent the evolutionary history of the taxa analyzed. Geobacillus kaustrophilus G1 was served as an out-group organism for optimized tree

Quantitative Expression of opdA Gene by RT-qPCR Data

We have used two samples (24 h, an early stage; 144 h, a degrading stage) for examining the expression of a key gene opdA in KPA-1 culture, which can be responsible for monocrotophos degradation. The results of RNA quantification indicated that the concentration of total RNA at 144-h incubated culture (402 ng/μl) was higher than 24-h incubated culture (264 ng/μl). The quantitative gene expression data derived from opdA messenger RNA (mRNA) revealed a clear response to the presence and absence of opdA in KPA-1. There was clear evidence that B. subtilis KPA-1 harboring opdA gene increased in abundance during the experiments through quantification of opdA gene based on DNA sequence. Contrary to numbers of mRNA transcripts, there was no significant correlation between indicated numbers of gene copies and rates of mineralization (Fig. 3a). We have statistically calculated opdA gene expression ratio and then normalized expression data as shown in Fig.3b and c. RT-qPCR results revealed that B. subtilis KPA-1 harboring opdA gene in an early stage was significantly downregulated from opdA gene in a degradation stage with a p value of 0.0375 (p < 0.05).

Relative quantification by RT-qPCR of mRNA expression levels of opdA gene in B. subtilis KPA-1 exposed to monocrotophos at concentration of 1000 ppm and evaluated at 24 h compared with 144 h and normalized with the expression of a housekeeping gene (16 s rRNA). The relative quantification results were obtained using the REST 2009 program by randomization test with 10,000 permutations (p < 0.05). The graph shows the data of each gene evaluated for each of the times in triplicate and two independent experiments

Melting Curve Profile Analysis

Melting curve profile analyses were performed on RT-qPCR products from KPA-1 harboring opdA DNA (Fig. 4). This is used to validate the presence and quality of a proper PCR product since it represents a separate, confirmatory assay in RT-qPCR analyses using the fluorophore SYBR Green. The different products will exhibit different melting curve profiles depending on nucleotide sequence of the PCR products. On the basis of melting curves of qPCR products from DNA samples, opdA gene in KPA-1 has contained a relatively low, but detectable, background population of KPA-1 harboring the opdA gene even at an early growth stage. It is clear that a peak with a similar temperature profile as the opdA gene from the positive control emerged as time passed. This indicates that KPA-1 harboring opdA gene substantially increased in abundance during monocrotophos degradation. Analysis of the melting curve profiles for mRNA-based PCR products pointed out that there was no detectable opdA transcript at day 0, but its constitutive expression may have occurred at an early stage upon degradation and increased to a certain level to mineralize the monocrotophos in MSM.

Melting curve profiles of RT-qPCR products (different pairs of opdA gene and 16 s rRNA, a housekeeping gene) using DNA and cDNA as templates, sampled at 24 h, an early stage and 144 h, a later stage of monocrotophos biodegradation by B. subtilis KPA-1. The panels display the negative first derivative of temperature versus relative fluorescence units (−d(RFU)/dT) plotted against temperature

Growth and Monocrotophos Biodegradation Kinetics

As a result of biomass estimation, the growth of K15 started after 24 h, reached maximally to 72 h, and continued until 144 h (Fig. 5). Similarly, number of bacterial cells increased continuously from 24 to 144 h. The results of degradation kinetics show that mineralization of monocrotophos started after 24 h, reached a maximum at 120 h, and then declined slowly. There was a steady state condition to be noted between 120 to 144 h for monocrotophos degradation. The highest degradation of monocrotophos was achieved to be 93 % which was coincided with amount of inorganic phosphorus released during growth (data not shown) and also associated with its growth maintenance energy.

Effect of Temperature and pH on Monocrotophos Degradation

We have also observed the growth of KPA-1 at different temperatures and pH in MSM supplemented with 1000 ppm monocrotophos as shown in Fig. 6. It has shown that the monocrotophos degradation increased with increasing temperature from 25 to 40 °C and reached a maximum degradation (94 %) at 35 °C. It declined with increasing temperature from 40 to 50 °C (91–80 %). A steady state of monocrotophos degradation (89 %) was attained in neural to mild alkaline pH as compared to acidic condition. It also noted that at pH 5.0 in the degradation rate of monocrotophos was drastically reduced by KPA-1.

Effect of Inoculum Size and Age on Monocrotophos Degradation

Biodegradation rate of monocrotophos by KPA-1 was raised slightly with increase in inoculum volumes from 1 to 2 mL (Fig. 7). After that, a sharp decrease in monocrotophos degradation rate from 94 to 91.9 % was noted if the inoculum volume further increased from 3 to 5 mL. Monocrotophos degradation was observed as maximum, when 72-h old inoculum was used and the rate was decreased slowly with increase in inoculum age and attained a steady state.

Effect of Additional Carbon Sources on Monocrotophos Degradation

Studies on the suitability of various additional carbon sources for the growth of KPA-1 revealed that although it was shown to utilize all the experimental sources of carbon but the highest monocrotophos degradation (94.2 %) occurred, when glucose and sucrose were used as carbon sources (Fig. 8). A decreasing trend of monocrotophos degradation was observed as glucose sucrose fructose cellobiose cellulose mannose. Overall, all growth and degradation studies revealed that maximum monocrotophos degradation (94.2 %) can be attributed with 72 h of 2 mL culture at 35 °C in MSM supplemented with glucose as an additional carbon source.

Discussion

Over a period of 12–16 days is expected for natural monocrotophos degradation and the process could be expedited through microbial bioremediation [30]. Thus, microorganisms have a great potential in bioremediation of monocrotophos persisting in wastewater or soil [10, 11, 20, 31]. Several of the bacteria interfering in the pesticide degradation processes in natural environments cannot be obtained in a laboratory [8]. However, it is very important for isolation of bacteria that should be used in the cleaning of pesticide-contaminated environments. The genera Paracoccus and Pseudomonas have become the focus of many studies because of their versatile degrading capacity on monocrotophos as sole carbon sources [10, 13, 14, 16, 21, 32]. In the present study, twenty bacterial strains were isolated from five agriculture soil samples collected from the crop and vegetable fields using monocrotophos as a sole carbon source. It can be seen clearly that seven strains may play an important role in degrading monocrotophos at the concentration of 1000 ppm in agriculture soils. One was named KPA-1 that degraded monocrotophos at a higher rate than others and was selected for further study. KPA-1 was a spore-forming, gram-positive, non-motile with a small rod structure. Biochemical assay of it showed positive results for utilization of many carbohydrate sources as sole carbon sources and followed the physiochemical features described for one of the species in Bacillus genus by Bergey’s Manual of Systematic Bacteriology.

Nucleotide sequence of amplified PCR product (16 s rRNA gene) was closely related to the B. subtilis and gave 99 % identity upon similarity search. A phylogenetic tree based on all known representatives of validly described Bacillus species and other related. G. kaustophilus G1 was acted as an out-group organism for phylogenetic classification of KPA-1. Phylogenetic analysis of this study reveals that KPA-1 was taxonomically equivalent to B. subtilis subsp. subtilis. However, an accurate taxonomic classification of this strain at subspecies level is reliable only if we employed the evidence of DNA-DNA hybridization. Although B. megaterium has reported for monocrotophos degradation [31], this is the first report of a strain of B. subtilis degrading monocrotophos.

Evolution can occur very quickly, resulting in microorganisms with new genetic properties which enable them to degrade compounds [10, 17]. More than 30 kinds of degrading plasmid were discovered from natural isolated strains [33], and many key enzymes were encoded by plasmid-borne genes including opdA [10, 17]. Using RT-qPCR approach, we exploited this strain for studying its opdA gene expression on monocrotophos in MSM at different degradation periods. Total RNA concentration of KPA-1 culture in initial degradation time was lower than its concentration in optimal time (144 h). It clearly evidenced the presence of opdA gene in KPA-1 genome and increased in abundance with increasing concentration of monocrotophos. Gene expression rate in terms of normalized expression ratio at optimal degradation stage was increased to the extent of 1.5 fold as compared to initial growth time. The opdA gene that codes for organophosphate hydrolase was initially present in a non-expressed form. Hence, the results of melting curve analysis revealed the KPA-1 harboring opdA gene was expressed to be low at an early growth stage and substantially increased in abundance during monocrotophos degradation in 144-h incubated culture. It suggests that opdA gene was constitutively expressed as a cytosolic enzyme and its expression rate increased to a certain level upon concentration of monocrotophos in MSM, as similar to earlier reports [14, 19–21]. A stable stem loop structure of opdA may also be significantly influenced on its expression levels in KPA-1 [34].

Under aerobic conditions, monocrotophos degradation by KPA-1 was monitored by HPLC for a period of 162 h. The degradation of monocrotophos supported cell growth, indicating that KPA-1 could utilize monocrotophos as a carbon source. The initial biodegradation of monocrotophos occurs under aerobic conditions. Nevertheless, subsequent degradation may proceed even under anaerobic conditions [13]. The results of the growth kinetics have shown little growth during first 24 h, but the growth increased with time in sigmoid fashion. A slow growth during initial period reveals that a bacterium may be greatly stressed in the presence of 1000 ppm monocrotophos. Similarly, higher degradation of pesticide with increased bacterial growth was also reported earlier [35–37]. This rapid degradation of monocrotophos at initial period of incubation suggested that enzyme(s) involved in degradation may be of constitutive nature [14, 19–21]. Since monocrotophos is an organophosphate insecticide, phosphates are released during its degradation [12, 13, 37]. Inorganic phosphate that was released by KPA-1 during degradation was inversely proportional to monocrotophos concentration.

Soil pH, agricultural management, and the concentration of pesticide added are important factors for bacterial use of pesticides as a growth substrate in the environment [5, 8]. Degradation of monocrotophos was found lower in acidic pH whereas neutral to alkaline pH of 9.0 showed increased degradation rate, which was accorded to earlier work [13]. A maximum degradation of monocrotophos and chlorpyrifos was achieved by P. fluorescens, B. subtilis, and Klebsiella sp. at 35 °C [15]. As similar to that, degradation of monocrotophos increased with increase in incubation temperature from 25 to 35 °C in our study. A further increase in temperature up to 50 °C have shown slower degradation rate, which can be explained on the fact that bacterial cells can lose their plasmids (plasmid-borne degradative genes) at higher temperature [17, 38].

Monocrotophos degradation by KPA-1 was greatly accelerated in the presence of an additional carbon source (glucose), suggesting that monocrotophos could be degraded cometabolically in the contaminated soils. Monocrotophos degradation was found as maximum at 2-mL inoculum size of 48-h old and when glucose was used as a carbon source in MSM. It was agreed with previous observations [15, 38, 39]. Microbial degradation of pesticide increases under optimized conditions compared to unoptimized [16]. In our optimized conditions, KPA-1 was able to degrade monocrotophos to the extent of 94.2 %, from MSM containing monocrotophos at the concentration of 1000 ppm, within 144 h, under shake culture condition at 35 °C. It was better than the results obtained for monocrotophos degradation by B. megaterium [31] and P. aeruginosa, and C. michiganense [10].

Generally, N-methylacetoacetamide and O-desmethylmonocrotophose are the main hydrolyzed products in the decomposition of monocrotophos at different ionic conditions [40–43]. In our study, methylamine and CO2 were detected during the growth of KPA-1 strain on monocrotophos as a sole carbon source in the growth medium that may be released from N-methylacetoacetamide under alkaline condition. It was agreed with earlier work done by Bhadbhade et al. [31, 44]. A significant quantity of ammonia was measured as an end product of monocrotophos degradation (data not shown) that can be obtained from methylamine oxidation by methylamine dehydrogenase. Inorganic phosphate, methyl phosphate, and N-methylacetoacetamide are produced from O-desmethylmonocrotophose under acidic condition [43]. N-Hydroxymethyl monocrotophos is also transformed into N-desmethyl monocrotophos, which can be converted into methyl phosphate through dimethyl phosphate by phosphatase activity (see Supplementary Fig. 1). Microbial degradation through hydrolysis of P-O-alkyl and P-O-aryl bonds is considered the most significant step in detoxification [45]. Therefore, the release of phosphates in the medium indicated that the strain KPA-1 is capable of degrading monocrotophos and releasing phosphates as a result of monocrotophos degradation. The release of phosphates due to degradation of monocrotophos with respect to time showed an increase in phosphatase activity with simultaneous increase in soluble phosphate. This strain also released CO2 as an end product (see Supplementary Fig. 2), suggesting that monocrotophos was mineralized to CO2 in accordance with earlier report (see review in ref. 1).

Aryldialkylphosphatase (EC 3.1.8.1) or organophosphorus hydrolase is a key enzyme that hydrolyses aryl dialkyl phosphate into dialkyl phosphate and aryl-alcohol with intermediate reactions. Aryl-alcohol is reduced to aryl-aldehyde by NAD-dependent aryl-alcohol dehydrogenase. Aryl-aldehyde is further converted to benzoic acid, which is consecutively metabolized as oxaloacetate and pyruvate in the tricarboxylic acid cycle. Hence, the results of monocrotophos degradation kinetics and opdA gene expression state well correlated with its growth kinetics due to utilization of monocrotophos by the strain KPA-1 as sole source of phosphorus and additional energy sources (carbon and nitrogen) during the growth period.

Conclusion

Overall results of this study proved that this is the first report on a B. subtilis KPA-1 that can be used successfully for the removal of monocrotophos to the extent of 94.2 % from contaminated soils under aerobic conditions. RT-qPCR results indicate the presence of organophosphate hydrolase (opdA) enzyme in KPA-1 and its constitutive expression in cytoplasm upon the exposure of monocrotophos. A study of the degradation characteristics in KPA-1 will help us to understand how a soil bacterium is involved in the degradation of monocrotophos and other organophosphorus insecticides. Agriculture soil becomes richer in bacterial population after repeated applications of a degradable pesticide. Such bacterial population is capable of degrading it dramatically which reduces the effectiveness of subsequent monocrotophos applications [46]. Thus, soil bacteria are a major component of agricultural ecosystem and play a considerable role in the degradation of organophosphorus insecticides in contaminated environments.

References

Singh, B. K., & Walker, A. (2006). FEMS Microbiology Reviews, 30, 428–471.

Anonymous., (2013a). http://www.cseindia.org/userfiles/paper_pesticide.pdf.

Shetty, P. K., Ayyappan, S., & Swaminathan, M. S. (2013). Indian Council of Agricultural Research. India: New Delhi.

Anonymous., (2013b). http://164.100.47.134/intranet/Currenteconomicscenario.pdf

Chapalamadugu, S., & Chaudhry, G. R. (1992). Critical Reviews in Biotechnology, 12, 357–389.

Ortiz-Hernández, M. L., Sánchez-Salinas, E., Vázquez, R., & Quintero, R. (1997). Biotechnology, 2, 129–151.

Karpouzas, D. G., & Singh, B. K. (2006). Advances in Microbial Physiology, 51, 119–185.

Ortiz-Hernández, M. L., & Sánchez-Salinas, E. (2010). Revista Internacional de Contaminación Ambiental, 26, 27–38.

Bhadbhade, B. J., Dhakephlkar, P. K., Sarnaik, S. S., & Kanekar, P. P. (2002). Biotechnology Letters, 24, 647–650.

Singh, S., & Singh, D. K. (2003). Canadian Journal of Microbiology, 49, 101–109.

Bhalerao, T. S., & Puranik, P. R. (2009). International Biodeterioration & Biodegradation, 63, 503–508.

Gundi, V. A. K. B., & Reddy, B. R. (2006). Chemosphere, 62, 396–403.

Jia, K. Z., Cui, Z. L., He, J., Guo, P., & Li, S. P. (2006). FEMS Microbiology Letters, 263, 155–162.

Jia, K. Z., Li, X. H., He, J., Gu, L. F., Ma, J. P., & Li, S. P. (2007). Huan Jing Ke Xue, 28, 908–912.

Kavikarunya, S., & Reetha, D. (2012). International Journal of Pharmaceutical and Biological Archive, 3, 685–691.

Vijayalakshmi, P., & Usha, M. S. (2012). Journal of Chemical and Pharmaceutical Research, 4, 2532–2539.

Mulbry, W. W., Karns, J. S., Kearney, P. C., Nelson, J. O., McDaniel, C. S., & Wild, J. R. (1986). Applied and Environmental Microbiology, 51, 926–930.

Ang, E. L., Zhao, H. M., & Obbard, J. P. (2005). Enzyme and Microbial Technology, 37, 487–496.

Gorla, P., Pandey, J. P., Parthasarathy, S., Merrick, M., & Siddavattam, D. (2009). Journal of Bacteriology, 191, 6292–6299.

Horne, I., Sutherland, T. D., Harcourt, R. L., Russell, R. J., & Oakeshott, J. G. (2002). Applied and Environmental Microbiology, 68, 3371–3376.

Pinjari, A. B., Pandey, J. P., Kamireddy, S., & Siddavattam, D. (2013). Letters in Applied Microbiology, 57, 63–68.

Blatchford, P. A., Scott, C., French, N., & Rehm, B. H. (2012). Immobilization of organophosphohydrolase opdA from Agrobacterium radiobacter by overproduction at the surface of polyester inclusions inside engineered Escherichia coli. Biotechnology and Bioengineering, 109, 1101–1108.

Skripsky, T., & Loosli, R. (1994). Review in Environmental Contamination and Toxicology, 139, 13–39.

Krieg, N. R., & Holt, J. G. (1984). Bergey’s manual of systematic bacteriology. USA: Williams & Wilkins.

Altschul, S. F., Madden, T. L., Schaffer, A. A., Zhang, J., Zhang, Z., Miller, W., & Lipman, D. J. (1997). Nucleic Acids Research, 25, 3389–3402.

Thompson, J. D., Gibson, T. J., Plewniak, F., Jeanmougin, F., & Higgins, D. G. (1997). Nucleic Acids Research, 25, 4876–4882.

Tamura, K., Peterson, D., Peterson, N., Stecher, G., Nei, M., & Kumar, S. (2011). Molecular Biology and Evolution, 28, 2731–2739.

Kimura, M. (1980). Journal of Molecular Evolution, 16, 111–120.

Greenberg, A. E., Clesceri, L. S., & Eaton, A. D. (1992). Standard methods for examination of water and waste water (18th ed.). Washington, DC, USA: APHA.

Surekha, R. M., Lakshmi, P. K. L., Suvarnalatha, D., Jaya, M., Aruna, S., Jyothi, K., Narasimha, G., & Venkateswarlu, K. (2008). African Journal of Microbiology Research, 2, 026–031.

Bhadbhade, B. J., Sarnaik, S. S., & Kanekar, P. P. (2002). Journal of Applied Microbiology, 93, 224–234.

Horiba, Y., Khan, S. T., & Hiraishi, A. (2005). Environmental Microbiology, 20, 25–33.

Yu-bin, T., Xu, Y., Fang-yan, C., Rui-ling, J., & Xin-gang, W. (2011). African Journal of Biotechnology, 10, 6549–6557.

Pandey, J. P., Gorla, P., Manavathi, B., & Siddavattam, D. (2009). Molecular Biology Reports, 36, 449–454.

Qui, X. H., Bai, W. Q., Zhong, Q. Z., Li, M., He, F. Q., & Li, B. T. (2006). Journal of Applied Microbiology, 101, 986–994.

Yang, C., Liu, N., Guo, X., & Qiao, C. (2006). FEMS Microbiology Letters, 265, 118–125.

Ahire, K. C., Kapadnis, R. L., Kulkarni, G. J., Shouche, Y. S., & Deopurkar, R. L. (2012). Biodegradation, 23, 165–176.

Deshpande, N. M., Dhakephalkar, P. K., & Kanekar, P. P. (2001). Letters in Applied Microbiology, 33, 275–279.

Awad, N. S., Sabit, H. H., Abo-Aba, S. E. M., & Bayoumi, R. A. (2011). African Journal of Microbiology Research, 5, 2855–2862.

Beynon, K. I., Hutson, D. H., & Wright, A. N. (1973). Research Reviews, 47, 55–142.

Eto, M. (1974). Organic and Biological Chemistry. Cleveland, OH, USA: CRC Press.

Hassal, A. K. (1990). Structure, metabolism and mode of action (2nd ed.). UK: ELBS Publication.

Lee, P. W., Fukudo, J. M., Hernandez, H., & Stearns, S. M. (1990). Journal of Agricultural and Food Chemistry, 38, 567–573.

Bhadbhade, B. J., Sarnaik, S. S., & Kanekar, P. P. (2002). Current Microbiology, 45, 345–349.

Wolfenden, R., & Spence, G. (1967). Biochemica Biophysica Acta, 146, 296–298.

Madigan, M.T., Martinko, J.M., & Parker, J. (2004). Biología de los micoorganismos, Pearson Prentice Hall. Madrid. Pp-1011.

Acknowledgment

The authors are grateful to Xcelris Labs Ltd., Ahmadabad, India, for bacterial identification services and Gujarat Laboratories, Ahmadabad, India, for HPLC analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 242 kb)

Rights and permissions

About this article

Cite this article

Acharya, K.P., Shilpkar, P., Shah, M.C. et al. Biodegradation of Insecticide Monocrotophos by Bacillus subtilis KPA-1, Isolated from Agriculture Soils. Appl Biochem Biotechnol 175, 1789–1804 (2015). https://doi.org/10.1007/s12010-014-1401-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1401-5