Abstract

The present study explores the potential of extracellular fungal organophosphate (OP) hydrolase for the degradation of monocrotophos. Extracellular OP hydrolases were isolated and purified from five different fungal isolates viz. Aspergillus niger (M1), Aspergillus flavus (M2), Penicillium aculeatum (M3), Fusarium pallidoroseum (M4), and Macrophomina sp. (M5) by AmSO4 precipitation, dialysis, and G-100 chromatography. M3 showed highest percentage yield of 68.81 followed by 55.41 % for M1. Each of the purified enzyme fraction constituted of two different subunits of 33- and 67-kDa molecular weight. Optimum enzyme fraction (150 μg ml−1) rapidly degraded monocrotophos within 120 h in phosphorus-free liquid culture medium (CZM) with K deg of 0.0368, 0.0138, 0.048, 0.016, 0.0138, and 0.048 day−1 and half-life of 0.79, 2.11, 0.6, 1.8, and 2.11 days for M1, M2, M3, M4, and M5, respectively. The results were further confirmed by high performance thin layer chromatography and Fourier transform infrared which indicate the disappearance of monocrotophos by hydrolytic cleavage of vinyl phosphate bond. The overall order of enzymatic degradation was found to be P. aculeatum > A. niger > F. pallidoroseum > A. flavus = Macrophomina sp. Hence, the study concludes that extracellular OP hydrolases efficiently degraded monocrotophos and could be used as a potential candidate for the detoxification of this neurotoxin pesticide.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Monocrotophos (dimethyl (E)-1-methyl-2 methyl carbamoyl vinyl phosphate) is a broad-spectrum organophosphate insecticide with contact and systemic activity against various pests of various crops [1, 2].

Indiscriminate use of monocrotophos for pest control has brought about the serious problem of “3Rs,” namely resistance, resurgence, and residues. Less than 0.1 % of the applied pesticide reaches target organism [3]. Thus 99.9 % of used pesticides make its way to environment and remain persisting in soil, ground, surface waters, air, and agricultural products and hence adversely affect environment [4, 5]. Therefore, it is very necessary to remove these hazardous chemicals from the environment. Various strategies viz. physical, chemical, and biological methods are well known for the degradation of these hazardous chemicals.

Nowadays, enzymes have emerged as a new powerful tool for the degradation of pesticides. These are advantageous in many forms such as they function at a neutral pH, a moderate temperature, no production of hazardous waste [6–8], and specificity; the most pragmatic benefit of enzymatic treatment is that the enzymes themselves are biodegradable proteins, meaning that the enzymes that are not recovered will degrade in the environment after they are no longer needed. Unlike other remediation methods, there is no buildup of biomass or chemicals that must be removed [6].

Although enzymes tend to be expensive due to the extraction and purification costs, they can be very cost-effective because they minimize waste disposal and heating needs [7, 9]. The use of extracellular enzymes is standard for various industries; however, research has just begun on how enzymes can be used to enhance bioremediation. Gao et al. [10] had described the purification and characterization of a novel chlorpyrifos hydrolase from Cladosporium cladosporioides Hu-01, previously isolated from the organophosphorus pesticide-contaminated soils. Ekkhunnatham et al. [11] had purified and characterized methyl parathion hydrolase from a methyl parathion-degrading Burkholderia cepacia. Many researchers had reported on the involvement of enzymes in the degradation of monocrotophos (MCP) [12–20].

The most widely characterized enzymes are phosphotriesterase or organophosphate hydrolase (OPH) and organophosphate degrading (OPDA) enzymes. The OPDA or OPH enzyme is capable of hydrolyzing a wide range of OPs [21]. The OPDA enzyme is encoded by the opd gene. The bacterial opd genes have a similar sequence in different bacterial strains [12]. OPH (EC 3.1.8.1) is a homodimeric and metal-dependent enzyme with the molecular weight of 72 kDa which catalyses the hydrolysis of phosphoester bonds in organophosphorus neurotoxins at a remarkable rate [22, 23]. OPH hydrolyzes a large variety of OPs by producing less toxic products. It has applications in detoxification and decontamination of OPs containing agricultural field and chemical weapons stock. This makes OPH a suitable element for biodegradation of these compounds [24].

Therefore, the present study emphasizes the potential of extracellular fungal OP hydrolase for the degradation of monocrotophos in liquid growth medium.

Materials and Method

Chemicals

MCP of analytical grade (99.5 % purity) was purchased from Sigma, and stock solution (1 mg ml−1 in ethanol) was prepared. All the other chemicals used in this study were of analytical grade and were obtained from Himedia and Rankem, India.

Medium

Modified Czapek Dox medium was used as growth medium which contained 30 g sucrose, 2 g NaNO3, 0.5 g KCl, 0.5 g MgSO4·7H2O, 10 g glucose, 10 mg FeCl3, 0.2 g BaCl2, and 0.05 g/l CaCl2 and was supplemented with MCP (150 μg ml−1) as a sole source of phosphorus.

Soil Sampling

Soil samples were collected from various agricultural farms within a 10-km range of Banasthali Campus, Rajasthan, India. The collected samples were mixed, air-dried, and sieved through a 2-mm mesh prior to use. Samples were stored at 4 °C for further use.

Screening and Isolation of MCP Hydrolyzing Fungal Strains

Isolation of MCP hydrolyzing fungal strains was done by standard enrichment culture techniques [25, 26]. One gram of soil sample was suspended in 10 ml of 0.85 % saline and serially diluted up to 10−4. Each dilution (100 μl) was spread onto a potato dextrose agar (PDA) plate containing penicillin and streptomycin at the optimum concentrations (30 mg l−1). Screening of MCP hydrolyzing fungi was done using a gradient of MCP concentrations (50, 100, 150, 200, 250, and 300 μg ml−1). The plates were incubated at 28 ± 2 °C for 5 days and were observed for the presence of fungal colonies. Pure cultures of fungi were isolated by streaking the isolated fungal colonies on PDA medium. They were further identified based on colony morphology and staining properties.

These screened isolates were further analyzed for their MCP hydrolyzing ability Pure cultures of fungi were isolated by streaking the isolated fungal colonies on PDA medium, which were further identified, based on colony morphology and staining properties.

MCP Hydrolase Assay

MCP hydrolase activity of fungal strains was estimated using the method described by Jain et al. [27]. Enzyme activities were expressed as U units (in micromolar of MCP hydrolyzed per minute) per milliliter. After each successive purification step, enzyme activities and the total protein contents of the crude and purified fractions were determined in order to estimate the specific activity and fold purification. Protein content was determined as per the method of Lowry et al. [28].

Enzyme Purification

The experiments described below were carried out at 0 and 4 °C unless otherwise specified. MCP hydrolyzing fungal strains were grown for 10 days in 500-ml Erlenmeyer flasks containing 150 ml of modified Czapek Dox medium supplemented with MCP (150 μg ml−1) on a rotary shaker at 100 rpm and incubated at 30 °C. Further, the culture was centrifuged at 12,000 × 3g for 20 min, and the collected supernatant was filtered through Whatman filter paper no. 1 and stored for further processing. Filtrate was used as a source of crude enzyme. For the purification of extracellular hydrolases, the culture filtrate was precipitated overnight with 80 % ammonium sulfate. The precipitate was collected by centrifugation at 12,000 × 3g for 20 min and dissolved in the smallest possible volume of 50 mM Tris–HCl buffer (pH 8.0). Further, it was dialyzed against the same buffer and concentrated by polyethylene glycol. The concentrated enzyme solution was loaded onto a Sephadex G-100 column (1.8 by 100 cm) pre-equilibrated with 50 mM Tris–HCl buffer (pH 8.0). The column was washed at a flow rate of 24 ml/h with 400 ml of the same buffer, and 5-ml fractions were collected. Enzyme characterization was performed using sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) following the method of Laemmli [29]. The molecular weight of the native enzyme was determined by the method of Andrew [30] by using blue dextran and molecular weight markers from Sigma as standards.

Optimization of the Concentration of Hydrolases for the Degradation of MCP

Optimum concentration for the efficient degradation of monocrotophos was observed by calculating the enzyme activity of different purified fractions of protein. The reaction mixture contained 100 μl of different concentrations of protein viz. 50, 100, 150, 200, 250, and 300 μg ml−1. The enzyme activity was assayed by the method of Jain et al. [27] as described above. The fraction containing highest hydrolase activity was selected further for the degradation of MCP.

Degradation of MCP by Purified Extracellular Hydrolases

One milliliter (optimum concentration) each of the purified enzyme fraction was inoculated in 100 ml of CZM medium containing 150 mg l−1 of monocrotophos concentration. Effective antibiotics, streptomycin, and penicillin (30 mg l−1) were added in the medium to avoid bacterial contamination. Control sample containing CZM media + monocrotophos (150 mg l−1) was prepared simultaneously. All the experiments were conducted in triplicates. The flasks were incubated in orbital shaking incubator at 90 rpm for 5 days (120 h) under optimized culture conditions.

At regular time interval of 24 h, the flasks were withdrawn, and the samples were subjected to extraction and cleanup by equal amount of ethyl acetate on florosil column. The residual monocrotophos was quantified by spectrophotometer at 254 nm.

The percentage of monocrotophos degradation was calculated using the following formula:

The kinetics of MCP degradation was studied by plotting the logarithmic residual monocrotophos concentration as a function of time [26]. The results were further confirmed by high performance thin layer chromatography (HPTLC) and Fourier transform infrared (FTIR).

HPTLC

HPTLC (CAMAG Linomat 5, Switzerland) was used for the analysis of samples. The aqueous samples from MCP degradation flasks were extracted with ethyl acetate. The samples (20–25 ml) were inoculated on silica gel (60 F254) TLC plates (E. Merck, India) by using an applicator system. A twin trough glass chamber (20 × 20 cm) containing dichloromethane/methanol (9:1) as the mobile phase was used for the development of the chromatogram. Spots were detected using a CAMAG TLC scanner-3 at the wavelength of 254 nm using a deuterium lamp.

FTIR

Infrared spectra of the parent compound (MCP) and sample after fungal degradation were recorded at room temperature (25 °C) in the frequency range of 4,000–400 cm−1 with a FTIR spectrophotometer (8400 Shimadzu, Japan, with Hyper IR-1.7 software for Windows) with a helium neon laser lamp as a source of infrared radiation. Aqueous samples (96 h of incubation) from MCP degradation flasks were extracted with ethyl acetate, and solvent was evaporated using a rotary vacuum evaporator (Rotavapor R.214, Buchi, Switzerland). The contents were redissolved in acetone. A drop of this sample in acetone was placed in between two sodium chloride disks, after cleaning with ethyl acetate. The background spectrum for acetone was corrected from the sample spectrum.

Statistical Analysis

The statistical analysis was done by using Statistical Package for the Sciences System 17 (SPSS 17). The variables were subjected to Student t test and one-way ANOVA.

Results

Screening and Isolation of MCP Hydrolyzing Fungal Strains

Ten different fungal strains (MCP1-MCP10) possessing MCP tolerance were isolated from soil samples collected from different agricultural fields by the enrichment culture method. These strains were subjected to various concentrations of MCP to isolate the most efficient MCP hydrolyzing strain. Among them, five strains, having the high MCP hydrolyzing activity, were designated MCP1, MCP2, MCP3, MCP4, and MCP5. Their extracellular enzyme was designated as M1, M2, M3, M4, and M5 for MCP1, MCP2, MCP3, MCP4, and MCP5, respectively. These isolates were primarily identified on morphological basis. The fungal isolates were identified and authenticated by the Indian Agricultural Research Institute (New Delhi, India) as Penicillium aculeatum (MCP3): 7980.10; Aspergillus flavus (MCP2): 7981.10; Aspergillus niger (MCP1): 7982.10; Macrophomina sp. (MCP4): 7984.10; and Fusarium pallidoroseum (MCP5): 7985.10, respectively. They were tested for the production of hydrolase in the presence and the absence of MCP. It was observed that the MCP hydrolase was expressed even in the absence of MCP, suggesting it to be constitutive enzymes. The activity of the constitutively expressing extracellular hydrolase was found to be higher in M1 and M3 than that in the other isolates. These strains were further selected for MCP hydrolysis.

Enzyme Purification

All the five isolated strains viz. MCP1, MCP2, MCP3, MCP4, and MCP5 were grown in CZM medium containing 0.5 g ml−1 KH2PO4 for the production of extracellular enzyme secreted by the isolates. After 10 days of incubation period, the secreted enzyme was collected and was partially purified by ammonium sulfate precipitation and gel filtration on Sephadex G-100. The data for the purification of each of the extracellular OP hydrolase enzyme was summarized in Table 1.

It shows that the enzyme activity varied from 202.66 ± 4.4 to 516.71 ± 5.75 U with a maximum value for M3; protein content varied from 1.39 ± 0.08 to 5.26 ± 0.35 μg ml−1 M1 showed the highest protein content; specific activity showed a variation from 84.4 ± 4.72 to 321.66 ± 18.5 U mg−1 protein; and M4 was highest among the five. Purification fold varied from16.94 ± 0.45 to 56.95 ± 5.32 with highest purity of M2 and yield showed a variation from 40.72 ± 0.77 to 68.81 ± 1.21 % with its high value for M3. It was concluded from the above study that the M2 was purified to a maximum of 57-fold, while the yield of protein was highest in M3, i.e., 68.81 %.

Purified OP hydrolase composed of two different subunits. The molecular mass of each of the subunits as estimated by SDS-PAGE analysis was found to be approximately 33 and 67 kDa (Fig. 1).

SDS-PAGE of the partially purified extracellular enzyme from five isolated strains. Lane 1, marker proteins (from top to bottom) phosphorylase b (Mr, 97,400), bovine serum albumin (Mr, 67,000), ovalbumin (Mr, 43,000), carbonic anhydrase (Mr, 30,000), soyabean trypsin inhibitor (Mr, 20,100), and lysozyme (Mr,14,300), respectively; lane 2, purified enzyme M1; lane 3, purified enzyme M2; lane 4, purified enzyme M3; lane 5, purified enzyme M4; and lane 6, purified enzyme M5. The gel was stained for protein with Coomassie Brilliant Blue R-250 and destained in methanol–acetic acid–water (7:2:1)

Optimization of Purified Enzyme Fraction for the Degradation of Monocrotophos

After the purification of extracellular enzymes, its optimum concentration for the efficient degradation of monocrotophos was observed. The enzyme activity of different protein fractions followed an L-shaped pattern. It is evident from Fig. 2 that 150 μg ml−1 is the optimum concentration for all the tested enzymes. Therefore, this selected concentration was used for further degradation study. Moreover, it was also observed that the enzyme activity was higher for M1 and M3 in comparison to other strains.

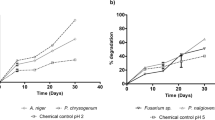

Residual Monocrotophos Concentration

Use of purified fraction of enzymes in liquid growth medium led to 90 % (approximately) monocrotophos degradation within 120 h of application by different enzyme fractions. Residual MCP concentration decreases exponentially within 48 h of incubation and reaches its minimum at 120 h. Data depicted in Fig. 3 showed that M1 and M3 restricted 2.45 and 0.49 μg ml−1 of residual MCP concentration of after 120 h of application. Whereas, the residual monocrotophos concentration by the rest of the strains were 30, 26.1, and 26.8 μg ml−1 for M2, M4, and M5, respectively, which was significantly low in comparison to control (145.9 μg ml−1 of MCP).

HPTLC

The results of the spectrophotometric determination of residual monocrotophos concentration were further confirmed by HPTLC analysis. Standard peak of monocrotophos was observed at 0.19–0.21 retention value (rf) value. The results depicted in Fig. 4 clearly indicated that increasing the incubation period significantly decreases the peak of monocrotophos. In case of M1 and M3, no peak was observed at this rf value after 96 h of incubation. This clearly indicated complete removal of monocrotophos from the sample with increasing incubation period, whereas for the other sample, the height of the peak reduces significantly.

FTIR

The FTIR spectrum of MCP degradation as shown in Fig. 5 clearly indicates hydrolytic cleavage of MCP with the formation of inorganic phosphates (–PO4). Peaks at 2,993.35 and 2,371.34 cm−1 characteristic for vinyl bonds were completely reduced in the spectrum after degradation, whereas a new peak at 1,443.95 cm−1 was observed characteristic of inorganic phosphates. Some other peaks at 1,171.33, 1,130.00, and 1,046.66 cm−1 were also observed which were characteristic for aliphatic amines. A new peak at 1,543.33 cm−1 characteristic for –NH or –NO was also pragmatic.

Degradation Kinetics

Degradation kinetics of monocrotophos followed a straight-line equation (Fig. 6). Hence, the rate constant and half-life were calculated by using first-order kinetics. The kinetic rate constants were observed to be 0.000014, 0.0138, 0.048, 0.016, and 0.0138 day−1, and hence the calculated half-life of monocrotophos was 2,107.75, 0.79, 2.11, 0.6, 1.8, and 2.11 days for control, M1, M2, M3, M4, and M5, respectively. As evident from the calculated values, the half-life of monocrotophos was significantly high in control samples.

Discussion

The present study is an endeavor to find the potential of extracellular fungal OP hydrolases for the degradation of monocrotophos. Extracellular OP hydrolases were isolated and purified from five different fungal strains viz A. niger (M1), A. flavus (M2), P. aculeatum (M3), F. pallidoroseum (M4), and Macrophomina sp. (M5) by a three-step purification. M3 showed highest percentage yield of 68.81 followed by M1. Similar to the previous study of Jain et al. [27], all the five enzymes were composed of two different subunits of 33 and 67 kDa. A composite mixture of both these subunits was used for the degradation of monocrotophos in phosphorus-free liquid medium for a period of 120 h.

It was observed from the study that enzymes exponentially and rapidly degraded monocrotophos within 96 h of incubation. The comparative overall order of degradation was found to be P. aculeatum (M3) > A. niger (M1) > F. pallidoroseum (M4) > A. flavus (M2) = Macrophomina sp. (M5).

Concurrent with our results, previous studies of Munnecke [31] had also showed a limited capacity of organophosphorus hydrolase or organophosphorus acid anhydrolase to cleave the thioether bond present in several organophosphorus pesticides (OPPs) by bacteria, such as Altermonas, Bacillus, Pseudomonas, and Flavobacterium for their detoxification.

Extracellular ligninolytic enzymes of Phanerochaete chrysosporium has been shown to mineralize chlorpyrifos, fonofos, and terbufos [32]. Hernandez et al. [33] had demonstrated that chloroperoxidase from the fungus Caldariomyces fumago was able to oxidize 7 of 10 OPPs assayed, while when other heme proteins such as lignin peroxidase, horseradish peroxidase, or cytochrome c were used, no oxidation was detected. Oxidative degradation of two nerve agents, VX and RVX, which are structurally similar to organophosphorus compounds containing thioether bonds, has been reported by a laccase of Pleurotus ostreatus [34]. However, this reaction was performed in an ABTS mediator-assisted form.

Han et al. [35] had studied on 46 and 65 % of 100 mg l−1 of degradation of phenanthrene after 36 h of incubation by shaken and static fungal cultures of Tinea versicolor, and its extracellular laccase was purified. Although the removal percentage was highest (76.7 %) at a lower concentration (10 mg l−1) of phenanthrene, the transformation rate was maximal (0.82 mg h−1) at a higher concentration (100 mg l−1). But in contrast, to our study, the purified laccase did not transform phenanthrene. However, Valli et al. [36] had demonstrated the mineralization of the dioxin 2,7-dichlorobenzenop-dioxin by purified lignin peroxidases and manganese peroxidases of P. chrysosporium in a multistep pathway.

However, the extracellular enzyme from these five strains has never been documented for the degradation of monocrotophos or any other OP pesticide.

As discussed above, our results largely agree with the interpretation of the use of enzymatic means for the removal of monocrotophos. These are much more efficient in the degradation of monocrotophos as compared to the use of whole microorganisms [8, 14, 19, 37]. There was a significant correlation between monocrotophos degradation, based on the percentage of monocrotophos degradation and extracellular protein content.

HPTLC and FTIR analyses revealed that the reduction in the standard peak of monocrotophos at rf 0.19–0.21 was due to hydrolytic cleavage of the vinyl bond. In addition, some other peaks characteristic of inorganic phosphates releasing carbon dioxide and ammonia were also seen. Similar results were reported by Bhalerao and Puranik [37] that during detoxification of monocrotophos, standard peak is reduced due to hydrolytic cleavage, and some by-products are also formed as evident from additional peaks in the FTIR spectrum.

Degradation of monocrotophos by extracellular fungal enzymes followed first-order kinetics with the half-life of 0.79, 2.11, 0.6, 1.8, and 2.11 days for M1, M2, M3, M4, and M5, respectively. This clearly demonstrates the efficiency of fungal hydrolases for the degradation of monocrotophos.

Glenn and Gold [38] had also suggested that extracellular protein plays a major role in the biodegradation of pesticides. Concurrent with our study, the routine use of culture filtrates of fungi as crude enzyme preparations for enzymatic degradation of organic compounds including organophosphate compounds had been previously reported by many researchers [39–42]. Tarafdar et al. [39] had also reported that there is no significant correlation between biomass production and organic P mineralization by fungi isolated from desert soils. A previous study of Netuzil et al. [43] also reported on enzymatic degradation of bromoxynil by Streptomyces felleus, Trichoderma viride.

Conclusion

The present study concludes that the extracellular enzyme of five distinct fungi was efficient for the degradation of monocrotophos from phosphorus-free liquid media. These enzymes were similar, and each was composed of two different subunits of 33 and 67 kDa. A small fraction of this purified protein was capable of degrading 99 % of applied monocrotophos concentration within 96 h of incubation. The overall order of monocrotophos degradation was found to be P. aculeatum > A. niger > F. pallidoroseum > A. flavus = Macrophomina sp.

References

Vig, K., Singh, D. K., Agarwal, H. C., Dhawan, A. K., & Dureja, P. (2001). J Environ Sci Health B, 36, 421–434.

Kanekar-Pradnya, P., Bhadbhade-Bharati, J., Neelima, M. D., & Sarnaik, S. S. (2004). Proc. Indian National Science Academy, B70(1), 57–70.

Pimental, D. (1995). J Agric Environ Ethics, 8(1), 17–29.

Tomlin, C. (ed.) (1994) The pesticide manual, 10th ed. Surrey: British Crop Protection Council and Royal Society of Chemistry

Gundi, A. K. B., & Vijay-Reddy, B. R. (2006). Chem, 62, 396–403.

Ahuja, S. K., Ferreira, G. M., & Moreira, A. R. (2004). Crit Rev Biotechnol, 24(2–3), 125–154.

Gianfreda, L., & Rao, M. A. (2004). Enzyme Microbial Tech, 35, 339–354.

Whiteley, C. G., Heron, P., Pletschke, B., Rose, P. D., Tshivhunge, S., van Jaarsveld, F. P., & Whittington-Jones, K. (2002). Enzyme Microb Technol, 31, 419–424.

Godfrey, T and Reichelt, J (eds) (1996) The application of enzymes in industry, 2nd ed. New York: Nature

Gao, Y., Chen, S., Hu, M., Hu, Q., Luo, J., et al. (2012). PLoS ONE, 7(6), e38137.

Ekkhunnatham, A., Jongsareejit, B., Yamkunthong, W., & Wichitwechkarn, J. (2012). World J Microbiol Biotechnol, 28(4), 1739–1746.

Holland, P., Mcnaughton, D., & Malcolm, C. (1994). Journal of AOAC, 77(1), 79–86.

Bhadbhade, B. J., Sarnaik, S. S., & Kanekar, P. P. (2002). J App Microbiol, 93, 224–234.

Horne, I., Sutherland, T. D., Harcourt, R. L., Russell, R. J., & Oakeshott, J. G. (2002). App Environ Microbiol, 68, 3371–3376.

Sogorb, M. A., & Vilanova, E. (2002). Toxicol Lett, 128, 215–228.

Singh, S., & Singh, D. K. (2003). Can J Microbiol, 49, 101–109.

Das, S. S., Kumar, D., & Singh, D. K. (2006). Can J Microbiol, 52(2), 157–168.

Jia, K.-z., Cui, Z.-l., He, J., Guo, P., & Li, S.-p. (2006). FEMS Microbiol Lett, 263, 155–162.

Jia, Kai-Zhi, KZ, Xiao-Hui, XH, Li, Jian, J He, Li-Feng, LF Gu, Ji-Ping, JP Ma & Shun-Peng, SP Li (2007) Environ. Sci. Technol. 28(4):908–12 PMID 17639959

Jiang, W. D., Xu, B., Lin, Q., Li, J. Z., Fu, H. Y., Zeng, X. C., & Chen, H. (2007). J Colloid Interface Sci, 311, 530.

Shimazu, M., Mulchandani, A., & Chen, W. (2001). Biotechnol Bioeng, 76, 318–324.

Efremenko, E. N., & Sergeeva, V. S. (2001). Russ Chem Bull, 50, 1826–1832.

Li, R., Liu, Y., Zhang, J., Chen, K., Li, S., & Jiang, J. (2012). App Microbiol Biotech, 94(6), 1553–1564.

Najavand, S., Lotfi, S. A., Mohsenifar, A., Arimand, S., & Mota, A. (2012). Spring, 15(1), 61–72.

Megharaj, M., Venkateswarlu, K., & Rao, A. S. (1987). Bull Environ Contam Toxicol, 39, 251–256.

Jain, R., Garg, V., Singh, K. P., & Gupta, S. (2012). Int J Environ Sci, 3(2), 1841–1851.

Jain, R., Garg, V., Dangwal, K., & Lily, M. K. (2013). Biosci Biotechnol Biochem, 77(5), 961–5.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., & Randall, R. J. (1951). J Biol Chem, 193, 265–275.

Laemmli, U. K. (1970). Nature (London), 227, 680–685.

Andrew, P. (1965). Biochem J, 91, 595–606.

Munnecke, D. M. (1976). App Environ Microbiol, 32, 7–13.

Bumpus, J. A., Kakar, S. N., & Coleman, R. D. (1993). App Biochem Biotechnol, 39(40), 715–726.

Hernandez, J., Robledo, N. R., Velasco, L., Quintero, R., Pickard, M. A., & Vazquez-Duhalt, R. (1998). Pestic Biochem Physiol, 61, 87–94.

Amitai, G., Adani, R., Sod-Moriah, G., Rabinovitz, I., Vincze, A., Leader, H., Chefetz, B., Leiovitz-Persky, L., Friesem, D., & Hadar, Y. (1998). FEBS Lett, 438, 195–200.

Han, C., Belenkaya, T. Y., Khodoun, M., Tauchi, M., & Lin, X. (2004). Development, 131, 1563–1575.

Valli, K., Wariish, H., & Gold, M. (1992). J Bacteriol, 174, 2131–2137.

Tejomyee Bhalerao, S., & Pravin Puranik, R. (2009). Int Biodeterior Biodeg, 63, 503–508.

Glenn, J. K., & Gold, M. H. (1985). Arch Biochem Biophys, 242, 329–341.

Tarafdar, J. C., Rao, A. V., & Bala, K. (1988). Folia Microbiol, 33, 453–456.

Abd-Alla, M. H. (1994). Biol Fertile Soils, 18, 216–218.

Abd-Alla, M. H. (1994). Lett App Microbiol, 19, 240–243.

Rana, B. K., Johri, B. N., & Thakur, I. S. (1996). World J Microbiol Biotechnol, 12, 12–15.

Neuzil, J., Kristufek, V., & Blumauerova, M. (1988). Folia Microbiol, 33, 349–354.

Acknowledgments

Authors gratefully acknowledge Prof. Aditya Shastri, Vice Chancellor, Banasthali University, for the financial support through the Department of Bioscience and Biotechnology, Banasthali University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jain, R., Garg, V. Enzymatic Degradation of Monocrotophos by Extracellular Fungal OP Hydrolases. Appl Biochem Biotechnol 171, 1473–1486 (2013). https://doi.org/10.1007/s12010-013-0438-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-013-0438-1