Abstract

A macroporous copolymer of glycidyl methacrylate and ethylene glycol dimethacrylate, poly(GMA-co-EGDMA), with various surface characteristics and mean pore size diameters ranging from 44 to 200 nm was synthesized, modified with 1,2-diaminoethane, and tested as a carrier for immobilization of horseradish peroxidase (HRP) by two covalent methods, glutaraldehyde and periodate. The highest specific activity of around 35 U g−1 dry weight of carrier was achieved on poly(GMA-co-EGDMA) copolymers with mean pore diameters of 200 and 120 nm by the periodate method. A study of deactivation kinetics at 65 °C and in 80 % dioxane revealed that periodate immobilization also produced an appreciable stabilization of the biocatalyst, while stabilization factor depended strongly on the surface characteristics of the copolymers. HRP immobilized on copolymer with a mean pore diameter of 120 nm by periodate method showing not only the highest specific activity but also good stability was further characterized. It appeared that the immobilization resulted in the stabilization of enzyme over a broader pH range while the Michaelis constant value (K m) of the immobilized HRP was 10.8 mM, approximately 5.6 times higher than that of the free enzyme. After 6 cycles of repeated use in a batch reactor for pyrogallol oxidation, the immobilized HRP retained 45 % of its original activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Macroporous copolymers are often used as carriers for enzyme immobilization and as adsorbents in chromatography. One of the most widely used is a copolymer of styrene and divinylbenzene [1]. Copolymers based on glycidyl methacrylate are more suitable for enzyme immobilization since they have epoxy groups that can be easily transformed into hydroxyl, keto, carboxyl, or amino groups to facilitate binding of the enzyme for the carrier. Compared to polystyrene, they also have higher hydrophilicity which has been proven to have a positive influence on protein stability and enzyme activity. That is why there is a growing interest in the use of such polymers commercially available under the name Eupergit® or Sepabeads® [2, 3]. The porosity of the carrier used in enzyme immobilization is also a very important parameter influencing the activity and stability of immobilized enzyme [4]. Therefore, precise control of these properties could significantly improve the performance of immobilized enzymes. Using different types and amounts of inert component during suspension, copolymerization of monomers seems to make possible to control the porosity of macroporous copolymer and obtain batches with very different surface characteristics [5].

Horseradish peroxidase (HRP, E.C.1.11.1.7) is the most known peroxidase from plants that can be used for organic synthesis of specialty chemicals like DOPA [6] and biphenols [7] in polymerization reactions during elimination of pollutants such as phenol and aniline from wastewater [8] and in the manufacture of biosensors [9–12]. The enzyme belongs to the ferroprotoporphyrin group of peroxidases and has limited operational stability due to inactivation by its own substrate. Thus, it is recommended to use HRP in immobilized form to enable the repeated use of the enzyme and enhance its properties such as activity and stability under these extreme operational conditions [13, 14].

Different methods have been used to immobilize HRP on a solid carrier, including covalent bonding [13, 15], entrapment in a solid matrix [16, 17], or electrodeposition at the electrode surfaces [18]. Enzymes covalently immobilized to solid supports offer some particularly attractive advantages: improved stability and reusability, flexibility in reactor design, possibility of continuous operation, and better control—hence more favorable economical factors can be expected. Although there are numerous reports on the immobilization of HRP on different matrices, not much work has been done on the use of glycidyl methacrylate-based copolymers. Therefore, development of new covalent immobilization techniques on these inexpensive and industrially applicable carriers in order to obtain biocatalysts with high activity retention is of economical significance.

There are a variety of methods for coupling enzymes to glycidyl methacrylate-based copolymers. Glutaraldehyde coupling chemistry is one of the most commonly used method for enzyme immobilization via amino groups of its exposed amino acids [13, 19]. The immobilization procedure consists of activation of the copolymer with an alkylamine derivate and subsequent coupling of enzyme via glutaraldehyde. It seems that glutaraldehyde forms a stable covalent bond between the enzyme molecule and the carrier used in immobilization, but it can also inactivate the enzyme due to reaction with the protein part of the molecule. Specifically, coupling can lead to intra- and inter- enzyme cross-linking in addition to desired enzyme carrier cross-linking. On the other hand, immobilization of glycoproteins like invertase [20], lipase [2], and others through their carbohydrate moiety seems to be effective and site specific, bringing about little change in the overall conformation of the enzymes or of their active sites. In our previous works, it was shown that lipase from Candida rugosa bound to the epoxy carrier such as Eupergit or Sepabeads EC-EP via carbohydrate moiety previously modified by periodate oxidation is more active and stable than that bound via glutaraldehyde [2, 3]. Other glycoproteins in combination with other epoxy carriers can, in principle, be used in this approach. Accordingly, here we report the feasibility of this enzyme immobilization approach for HRP immobilization on macroporous copolymer of glycidyl methacrylate (GMA) and ethylene glycol dimethacrylate (EGDMA) as an industrially applicable epoxy carrier.

In the present work, several macroporous poly(GMA-co-EGDMA) samples with the same chemical composition but different surface characteristics and mean pore size diameters were synthesized and screened for the first time for immobilization of horseradish peroxidase by applying two different covalent methods. We compared a widely used glutaraldehyde method for enzyme immobilization and the periodate method that we previously developed and optimized for invertase [20] and lipase [2] in order to obtain high activity and stability of immobilized enzyme (glycoprotein). The immobilization methods were compared with regards to specific activity and thermal stability. The stability of immobilized HRP in the presence of polar organic solvent has also been investigated and the deactivation process has been modeled. Finely, the best carrier and immobilization method were selected for further use and characterization. The pH profile, kinetic properties, and operational stability of immobilized and free HRP were compared.

Experimental

Materials

Horseradish peroxidase (lyophilized powder, 150–259 units mg−1, using pyrogallol), EGDMA, GMA, H2O2, pyrogallol, sodium dihydrogen phosphate anhydrous, and sodium periodate were purchased from Sigma-Aldrich; dioxane was obtained from Merck, while polyvinylpyrrolidone (Kolidon 90, molar mass 360,000), cyclohexanol, dodecanol, and other alcohols were obtained from Fluka.

Copolymer Preparation

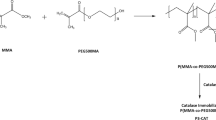

Several macroporous poly(GMA-co-EGDMA) samples with the same chemical composition but different porosity parameters were synthesized by radical suspension copolymerization, as previously described [5], and used for enzyme immobilization (see Scheme 1).

Typically, the monomer phase (80.9 g), which contained the monomer mixture (24.2 g GMA and 10.3 g EGDMA), azobisisobytironitrile as the initiator (0.8 g), and 45.6 g inert component (cyclohexanol and corresponding alcohol), was suspended in aqueous phase, consisting of 237.6 g water and 2.4 g poly(N-vinyl pyrrolidone). Copolymerization was carried out at 70 °C for 2 h and at 80 °C for 6 h with a stirring rate of 200 rpm. When the reaction was over, the copolymer particles were washed with water and ethanol, stored in ethanol for 12 h, and then dried in a vacuum at 45 °C. A series of copolymer samples, with varying alcohol type (butanol, dodecanol, and hexadecanol) or alcohol weight concentration (10, 15, and 20 wt.% of alcohol in the inert component), was synthesized and labeled as SGE-10/4 (10 wt.% of butanol in the inert component), SGE-10/12 and SGE-20/12 (10 wt.% and 20 % of dodecanol in the inert component, respectively), and SGE-15/16 (15 wt.% of hexadecanol in the inert component). Particle size distribution was determined by sieve analysis. A commercial mercury porosimeter, Model 2000 Carlo Erba, was used for the determination of specific pore volume, pore size distribution, and specific surface area. Prior to use, the copolymer was modified with 1 M 1,2-diaminoethane at 60 °C for 4 h at pH 10. The concentration of amino groups was determined by titration with 0.100 M HCl in 0.5 M KCl.

HRP Immobilization by Glutaraldehyde Method

Aminated copolymer was incubated in 2 % (w/v) glutaraldehyde in 50 mM sodium phosphate buffer at pH 8 for 2 h. The copolymer was then washed several times with the same buffer and incubated with native HRP in sodium phosphate buffer at pH 7 and 4 °C for 48 h. After incubation with enzyme, the copolymer was washed three times with 1 M NaCl in 50 mM sodium phosphate buffer pH 6.0 and two times with buffer alone. The washings were collected and the immobilized enzyme was stored in the same buffer at 4 °C prior to use.

HRP Immobilization by Periodate Method

HRP was oxidized by periodate method in a similar way as previously described for invertase [20]. A total of 2.5 mg mL−1 of HRP was oxidized with 5 mM sodium periodate for 6 h in the dark at 4 °C in 50 mM sodium acetate buffer of pH 5.0. Oxidation was stopped by adding glycerol to a final concentration of 0.2 % (v/v) and HRP was dialyzed overnight against the same acetate buffer. The aminated copolymer was incubated with oxidized HRP in 50 mM sodium acetate buffer of pH 5.0 at 4 °C for 48 h. Subsequently, the copolymer was washed three times with 1 M NaCl in 50 mM acetate buffer pH 5.0 and three times with the buffer. The immobilized enzyme was stored prior to use as cited earlier.

Measurement of Enzyme Activity

Peroxidase activity was measured using pyrogallol and H2O2 as substrates. Typical tests were carried out by adding 10 μL of enzyme dilution into 1 mL of 13 mM solution of pyrogallol and 9.7 mM H2O2 in 0.1 M sodium phosphate buffer at pH 6.0 and 20 °C. Absorbance was followed for the first 3 min at 420 nm and the amount of enzyme activity was calculated by using the absorbance coefficient of purpurogallin (12 mg−1 cm2). For the immobilized enzyme, several milligrams of wet immobilizate was resuspended in 3 mL of 13 mM solution of pyrogallol in 0.1 M sodium phosphate buffer at pH 6.0 and 20 °C. Reaction was started by adding 30 μL of 0.97 M H2O2 and performed under constant stirring for 3 min. Every 60-s aliquots was taken and filtrated and the absorbance at 420 nm was measured. One unit of enzyme activity was defined as the amount of enzyme that produces 1 mg of purpurogallin in 20 s at 20 °C. The specific activity of the immobilized enzyme was calculated per gram of dry mass of copolymer.

Stability Studies

For measurement of thermostability, the immobilized enzyme was incubated at 65 °C in 0.1 M sodium phosphate buffer at pH 7.0. After specified time intervals, the immobilized enzyme was cooled down to 20 °C in the same buffer and its residual specific activity was measured as described previously.

For measurement of stability in dioxane, the immobilized enzyme was incubated at 20 °C in 80 % (v/v) dioxane in 0.1 M sodium phosphate buffer pH 7.0. After specified time intervals, the immobilized enzyme was transferred into 0.1 M sodium phosphate buffer at pH 7.0 and its residual specific activity was measured as described previously.

The enzyme deactivation process was modeled according to a single-step kinetic model which considers the final enzymatic state, E 1 with a steady-state residual activity, and is illustrated in the following scheme:

where k D is the first-order deactivation rate constant and α is the ratio of specific activities E 1/E.

This mechanism leads to a model where the residual enzyme activity at time t can be determined from the following equation:

In the proposed kinetic model, the adjustable parameters are k D and α which were determined by the nonlinear Levenberg–Marquardt regression method by using the MATLAB software. The stabilization factor, F, was calculated as the ratio between the half-life of the immobilized and free enzymes.

Activity Measurement at Different pHs

The activity of free and immobilized enzyme was determined in 0.1 M sodium phosphate–citrate buffer at pH from 2.0 to 8.0 and in 0.1 M sodium glycinate buffer at pH 9.0 as described previously. The relative activity at different pH values was measured and normalized by the maximal activity at optimal pH, i.e., relative activity in percentage was presented.

Determination of Kinetic Parameters

The effect of pyrogallol concentration on the initial activity of both free and immobilized HRP was studied to determine the kinetic parameters (the Michaelis constant value, K m, and maximum rate, V max) as described previously. The apparent K m and V max values were determined directly from the Michaelis–Menten model by nonlinear regression analysis using the MATLAB software.

Enzyme Reusability

Several consecutive operating cycles were performed using pyrogallol and H2O2 as substrates in a 3-mL batch reactor in order to determine the operational stability of the immobilized peroxidase. At the end of each cycle, the immobilized enzyme was collected and left for 24 h at 4 °C, and the procedure was repeated with a fresh aliquot of substrate.

Results and Discussion

Synthesis and Characterization of the Copolymers

Four different copolymer samples were obtained using different types and amounts of inert component during suspension copolymerization of GMA and EGDMA as shown in Table 1. Specific pore volume, specific area, and the mean pore diameter of copolymers were determined prior to modification and the concentration of amino groups was determined after copolymer modification with diaminoethane by titration with 0.100 M HCl.

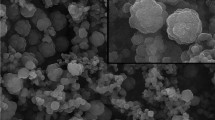

Particles of the obtained copolymers exhibited a spherical shape with diameters in the range of 150–500 μm and the surface of these particles was highly porous. For example, scanning electron microscope images of the copolymer SGE-20/12 are shown in Fig. 1.

The results of the copolymers’ surface properties indicated that the addition of an alcohol with higher alcohol chain length and in higher amount in inert phase increased both the mean pore diameter and the specific surface area of the carrier. The concentration of amino groups also increased with the increase of active surface at first and afterwards declined sharply in the case of copolymers SGE-15/16. The finding that the concentration of amino groups after modification of the copolymer with the highest specific surface area had the lowest value was interesting, and this could be associated mainly with the rather irregular pore size distribution in this case that ranged from micropores to large pores with a size of a few hundred nanometers. As a result, only a fraction of the overall amount of the epoxy groups appeared to be modified with diaminoethane.

Immobilization of HRP onto Macroporous Poly(GMA-co-EGDMA)

Recent studies have revealed that the kinetics and stability of enzymes immobilized on porous carriers are usually modified by diffusion effects, depending strongly on the surface characteristics of carriers used for their immobilization [4]. Thus, in the present study, we wanted to determine which of the copolymer batches were most suitable for HRP immobilization by both glutaraldehyde and periodate method previously optimized for hydrolases [2, 4, 21].

The glutaraldehyde method was based on HRP binding to glutaraldehyde-activated carrier by Schiff base reaction, while the periodate method assumed lipase binding to copolymers through the enzyme carbohydrate moiety previously modified by periodate oxidation. Different amounts of enzyme were added per gram of copolymers and the specific activity of immobilized enzyme was determined for all copolymer samples. The results obtained for both methods are shown in Fig. 2.

As expected, the specific activity of immobilized HRP increased as the amount of added enzyme per gram of copolymer increased in all experiments. For all cases studied, the periodate method for HRP immobilization gave in average 1.5 times higher specific activity of the immobilized enzyme compared to the glutaraldehyde method when using the same copolymer and the same amount of added enzyme. Similar results have been obtained previously for lipase from C. rugosa using Eupergit C or Sepabeads EC-EP as carriers [2, 3]. The superior performance of the periodate method could be due to the fact that the protein part of the enzyme molecule remained intact, hence preserving activity. Oxidation of the carbohydrate part of protein created a high number of reactive aldehyde groups, increasing the probability of the enzyme multipoint attachment to the carrier. Also, the presence of the long spacer between the carrier and the immobilized enzyme molecule such as oligosaccharide chain placed the enzyme active site far away from the copolymer surface, decreasing diffusional limitations that can reduce the activity of the immobilized enzyme.

Surface characteristics of the copolymer were found also to have influence on the specific activity of the immobilized enzyme. For the periodate method, the highest specific activity of around 35 U g−1 dry weight of carrier was obtained with the copolymer samples with larger pore sizes (mean pore diameter 120 and 200 nm), namely, SGE 20/12 and SGE 15/16. A similar trend has also been observed for glutaraldehyde method when the specific activity of HRP immobilized on copolymer with 200-nm mean pore diameter was approximately three times higher than that of HRP immobilized on copolymer with 44-nm mean pore diameter. Copolymers with a small pore size provided a large total surface area, but the pores appeared to be too small, resulting in restricted mass transfer and pore penetration of the enzyme. The observed enhancement in the specific activity of carriers with larger pores was consistent with the study on subtilisin immobilization on different silica carriers, which reported that silicas with large mean pore diameters presented higher total and specific activities relative to those with smaller pore sizes [22]. Similar results were also obtained by using Eupergit C and Eupergit C 250 L for immobilization of formate dehydrogenase, showing that the retention of activity with the latter was almost twofold higher than that observed with the former because of the ten-times-higher pore mean diameter [23]. In contrast, our previous work has shown that lipase from C. rugosa immobilized on Eupergit C was more active and stable than that immobilized on Eupergit C 250 L [2]. The optimal pore size of the carrier appeared to be highly dependent on the particular enzyme and coupling method used. In this work, for HRP (molecular weight 40,000; size of the molecules 5–6 nm), it was found that a 120–200-nm pore size in the carrier microbeads gave the best results that were much higher than the recommended value for efficient enzyme immobilization. Basically, a generally accepted principle is that the diameter of the entry pores must be at least four to five times higher than the size of the enzyme molecule [24].

Comparison of Thermal Stabilities of Immobilized HRP Obtained by Two Methods

The thermal stability of HRP immobilized by two covalent methods has been evaluated and the results were compared to the kinetics of deactivation of the free enzyme. For all the cases studied, the immobilized preparations seemed to exhibit increased thermal stability compared with the free enzyme (see Fig. 3).

The stabilization factor varied depending on the copolymers’ surface properties and the coupling method used. In order to compare the deactivation processes quantitatively, the simple first-order kinetic model assuming the possible partial retention of activity by the final enzymatic state was adopted to fit the kinetic data. The deactivation parameters for both immobilization methods were all determined at 65 °C and are summarized in Table 2.

It is apparent that the stability of immobilized HRP obtained by periodate method was higher than that obtained by the glutaraldehyde one. For both covalent methods, we determined that the proposed deactivation model correlated well with the experimental data, suggesting the existence of a final enzymatic state with a residual activity. This is often admitted for hemoenzymes as peroxidases [25]. It was immediately obvious that HRP immobilized on the copolymer with a mean pore diameter of 53 nm (SGE 10/12) by the periodate method exhibited both the longest half-life (t 1/2) and the highest residual activity of the final enzymatic state of around 8.35 h and 29.2 %, respectively. By comparison of the t 1/2 values, it can be concluded that HRP immobilized by periodate method was more than twofold more stable than the one immobilized by glutaraldehyde method on the same copolymer and almost fourfold than that of the free enzyme. For both periodate and glutaraldehyde methods, copolymer SGE 20/12 with 120-nm mean pore diameter that has already shown to give immobilized enzyme with high activity also showed a rather good stability and after 30 h at 65 °C kept 25 % of original activity. The low thermal stability of HRP immobilized on copolymer with the highest mean pore diameter (t 1/2 values were 1.46 and 3.89 h for glutaraldehyde and periodate methods, respectively) could be due to the fact that the copolymer has a finite number of binding sites, excluding the possibility of enzyme multipoint attachment to the carrier which is crucial for the stabilization of the biocatalyst (see Table 1).

Stability in the Presence of Organic Solvent

In this step, we also compared the stability of immobilized HRP in the presence of organic solvent for periodate and glutaraldehyde methods. Immobilized enzymes which exhibit excellent thermal stability and even more favorable activity do not necessarily exhibit excellent stability in the presence of organic solvent. Since the organic solvent stability of an enzyme is important for polymer synthesis reactions and other syntheses of specialty chemicals, it is also worthwhile to study this characteristic of immobilized enzyme preparations [26].

The free enzyme was practically inactivated after 48 h of incubation in 80 % dioxane, while the immobilized HRP preserved 5.3–42.8 % of its original activity, depending on the copolymer and the coupling method used (see Fig. 4). The activity of immobilized HRP dropped fast within the initial hours of treatment and then remained constant. Accordingly, for all copolymers, the proposed deactivation model suggesting the existence of a final enzymatic state with a residual activity predicted the experimental behavior with a smaller error, which was less than 2.5 %. That was not the case for the free enzyme where the whole activity was destroyed in a single phase (α = 0) with a rate constant of 0.35 h−1. The estimated kinetic parameters were presented in Table 3.

Residual activity of immobilized and free HRP in the presence of 80 % dioxane as a function of time. Open symbols periodate immobilization, closed symbols glutaraldehyde immobilization, filled diamond free enzyme. Copolymer sample used: squares SGE-10/4, circles SGE-10/12, triangles SGE-20/12, and inverted triangles SGE-15/16

Effect of HRP Immobilization on pH Profile and Kinetic Parameters

HRP that was immobilized onto SGE 20/12 copolymer by periodate method with a mean pore diameter of 120 nm showing the highest activity and a rather high stability was further characterized.

The effect of pH on the activity of immobilized and free HRP was evaluated and the results are presented in Fig. 5. Both forms of the enzyme exhibited an optimum at pH 7, but immobilized HRP displayed a broadened pH profile relative to the free one. A higher activity of immobilized enzyme was more pronounced at basic pH values, which could be interesting for practical application.

The enzyme appeared to follow Michaelis–Menten kinetics and kinetic parameters were determined directly by fitting the experimental data to the kinetic model (data not shown). K m was determined for pyrogallol when H2O2 is maintained at saturating conditions. The value of Michaelis constant for the immobilized enzyme appeared to be 10.8 mM, approximately 5.6 times higher than that of the free enzyme (K m value for free HRP was 1.93 mM), suggesting decreased accessibility of enzyme to the substrate. The V max of the immobilized enzyme was determined to be 54.9 U g−1 dry weight of carrier corresponding to 1.23 U/mg of immobilized enzymes or k cat of 110.7 s−1. This was in accordance with previous immobilization studies of peroxidases where increase of K m constant for immobilized enzyme was also observed [13, 15]. For instance, 15.6 times higher K m value for guaiacol has been reported with chitosan-immobilized HRP compared to that of free enzyme [27] or K m value for H2O2 was 1.65 times higher in the case of HRP immobilized on magnetic poly(glycidylmethacrylate-co-methylmethacrylate) compared to the free one [13].

In order to test the operational stability of immobilized peroxidase during usage, the same batch of immobilized enzyme was used in several cycles of pyrogallol oxidation in a batch reactor and the residual activity of the immobilized enzyme was determined after each cycle (see Fig. 6).

During the first 4 cycles, the activity was dropping and after that it remained constant at 45 % of initial activity. Immobilized peroxidase showed good stability under operational conditions and optimization of hydrogen peroxide concentration and delivery to the reaction system could further improve the performance of immobilized peroxidase.

The novelty of the present work lies in the combination of using both, novel copolymer particles fabricated from glycidyl methacrylate based copolymers and the periodate method previously developed in our lab for invertase [20] and lipase [2], for the first time for HRP immobilization. The copolymer particles with pore sizes between 120 and 200 nm showed a high capacity of protein immobilization and highest activity. In addition the thermal stability, organic solvent stability, and operational stability for HRP immobilized by periodate method in this work showed an overall higher stability compared to the glutaraldehyde-immobilized HRP and previously reported HRP-immobilized systems [16].

Conclusions

In this work, HRP was covalently immobilized onto the characterized copolymer of glycidyl methacrylate and ethylene glycol dimethacrylate by two covalent methods. The effect of mean pore diameter and surface characteristics of copolymer on enzyme activity and stability has been examined. Overall, the peroxidase immobilized by the periodate method performed substantially better than that immobilized by glutaraldehyde. In particular, when HRP was immobilized by periodate method onto copolymer SGE-20/12 with 120 nm mean pore diameter, the biocatalyst showed enhanced specific activity and a rather high thermal and organic solvent stability. By comparison of the t 1/2 values, it can be concluded that it was 5.3-fold more stable in 80 % dioxane than that immobilized by glutaraldehyde method on the same copolymer and almost 3.5-fold than that of the free enzyme. The K m value was determined to be 10.8 mM for the immobilized HRP, approximately 5.6 times higher than that of the free enzyme. Both forms of the enzymes exhibited an optimum at pH 7, but immobilized HRP displayed a broadened pH profile relative to the free one. The operational stability also proved to be satisfactory after five consecutive uses with a residual activity of 45 %.

References

Hernandez, K., Garcia-Galan, C., & Fernandez-Lafuente, R. (2011). Simple and efficient immobilization of lipase B from Candida antarctica on porous styrene-divinylbenzene beads. Enzyme and Microbial Technology, 49, 72–78.

Knezevic, Z., Milosavic, N., Bezbradica, D., Jakovljevic, Z., & Prodanovic, R. (2006). Immobilization of lipase from Candida rugosa on Eupergit (R) supports by covalent attachment. Biochemical Engineering Journal, 30, 269–278.

Prlainović, N., Knežević-Jugović, Z., Mijin, D., & Bezbradica, D. (2011). Immobilization of lipase from Candida rugosa on Sepabeads®: The effect of lipase oxidation by periodates. Bioprocess and Biosystems Engineering, 34, 803–810.

Prodanović, R. M., Milosavić, N. B., Jovanović, S. M., Ćirković Veličković, T., Vujčić, Z. M., & Jankov, R. M. (2006). Stabilization of alpha-glucosidase in organic solvents by immobilization on macroporous poly(GMA-co-EGDMA) with different surface characteristics. Journal of the Serbian Chemical Society, 71, 339–347.

Jovanovic, S. M., Nastasovic, A., Jovanovic, N. N., & Jeremic, K. (1996). Targeted porous structure of macroporous copolymers based on glycidyl methacrylate. Materials Science Forum, 214, 155–162.

Klibanov, A. M., Berman, Z., & Alberti, B. N. (1981). Preparative hydroxylation of aromatic compounds catalyzed by peroxidase. Journal of the American Chemical Society, 103, 6263–6264.

Schwartz, R. D., & Hutchinson, D. B. (1981). Microbial and enzymatic production of 4,4′-dihydroxybiphenyl via phenol coupling. Enzyme and Microbial Technology, 3, 361–363.

Klibanov, A. M., Tu, T. M., & Scott, K. P. (1983). Peroxidase-catalyzed removal of phenols from coal-conversion waste waters. Science, 221, 259–261.

Alonso-Lomillo, M. A., Dominguez-Renedo, O., del Torno-de Roman, L., & Arcos-Martinez, M. J. A. (2011). Horseradish peroxidase-screen printed biosensors for determination of Ochratoxin A. Analytica Chimica Acta, 688, 49–53.

Presnova, G. V., Rybcova, M. Y., & Egorov, A. M. (2008). Electrochemical biosensors based on horseradish peroxidase. Russian Journal of General Chemistry, 78, 2482–2488.

Yu, D. H., Blankert, B., & Kauffmann, J. M. (2007). Development of amperometric horseradish peroxidase based biosensors for clozapine and for the screening of thiol compounds. Biosensors & Bioelectronics, 22, 2707–2711.

Guschin, D. A., Sultanov, Y. M., Sharif-Zade, N. F., Aliyev, E. H., Efendiev, A. A., & Schuhmann, W. (2006). Redox polymer-based reagentless horseradish peroxidase biosensors influence of the molecular structure of the polymer. Electrochimica Acta, 51, 5137–5142.

Bayramoglu, M., & Arica, M. Y. (2008). Enzymatic removal of phenol and p-chlorophenol in enzyme reactor: Horseradish peroxidase immobilized on magnetic beads. Journal of Hazardous Materials, 156, 148–155.

Pramparo, L., Stuber, F., Font, J., Fortuny, A., Fabregat, A., & Bengoa, C. (2010). Immobilisation of horseradish peroxidase on Eupergit (R) C for the enzymatic elimination of phenol. Journal of Hazardous Materials, 177, 990–1000.

Monier, M., Ayad, D. M., Wei, Y., & Sarhan, A. A. (2010). Immobilization of horseradish peroxidase on modified chitosan beads. International Journal of Biological Macromolecules, 46, 324–330.

Shukla, S. P., Modi, K., Ghosh, P. K., & Devi, S. (2004). Immobilization of horseradish peroxidase by entrapment in natural polysaccharide. Journal of Applied Polymer Science, 91, 2063–2071.

Alemzadeh, I., & Nejati, S. (2009). Phenols removal by immobilized horseradish peroxidase. Journal of Hazardous Materials, 166, 1082–1086.

Ozoner, S. K. (2012). Poly(glycidyl methacrylate-co-3-thienyl-methylmethacrylate) based working electrodes for hydrogen peroxide biosensing. Journal of Chemical Technology & Biotechnology, 87, 146–152.

Arıca, M. Y., Altıntas, B., & Bayramoglu, G. (2009). Immobilization of laccase onto spacer-arm attached non-porous poly(GMA/EGDMA) beads: Application for textile dye degradation. Bioresource Technology, 100, 665–669.

Prodanovic, R., Jovanovic, S., & Vujcic, Z. (2001). Immobilization of invertase on a new type of macroporous glycidyl methacrylate. Biotechnology Letters, 23, 1171–1174.

Milosavic, N., Prodanovic, R., Jovanovic, S., & Vujcic, Z. (2007). Immobilization of glucoamylase via its carbohydrate moiety on macroporous poly(GMA-co-EGDMA). Enzyme and Microbial Technology, 40, 1422–1426.

Ferreira, L., Ramos, M. A., Dordick, J. S., & Gil, M. H. (2003). Influence of different silica derivatives in the immobilization and stabilization of a Bacillus licheniformis protease (Subtilisin Carlsberg). Journal of Molecular Catalysis B: Enzymatic, 21, 189–199.

Boller, T., Meier, C., & Menzler, S. (2002). Eupergit oxirane acrylic beads: How to make enzymes fit for biocatalysis. Organic Process Research and Development, 6, 509–519.

Torres-Salas, P., Monte-Martinez, A., Cutino-Avila, B., Rodriguez-Colinas, B., Alcalde, A., Ballesteros, A. O., & Plou, F. J. (2011). Immobilized biocatalysts: Novel approaches and tools for binding enzymes to supports. Advanced Materials, 23, 5275–5282.

Garcia, D., Ortega, F., & Marty, J.-L. (1998). Kinetics of thermal inactivation of horseradish peroxidase: Stabilizing effect of methoxypoly(ethylene glycol). Biotechnology and Applied Biochemistry, 27, 49–54.

Prodanovic, R., Milosavic, N., Jovanovic, S., Prodanovic, O., Cirkovic Velickovic, T., Vujcic, Z., & Jankov, M. R. (2006). Activity and stability of soluble and immobilized alpha-glucosidase from baker's yeast in cosolvent systems. Biocatalysis and Biotransformation, 24, 195–200.

Bindhu, L. V., & Abraham, E. T. J. (2003). Immobilization of horseradish peroxidase on chitosan for use in nonaqueous media. Journal of Applied Polymer Science, 88, 1456–1464.

Acknowledgments

This work was supported by Grant No. ON173017 and Grant No. ON172049, sponsored by the Ministry of Education and Science, Republic of Serbia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prodanović, O., Prokopijević, M., Spasojević, D. et al. Improved Covalent Immobilization of Horseradish Peroxidase on Macroporous Glycidyl Methacrylate-Based Copolymers. Appl Biochem Biotechnol 168, 1288–1301 (2012). https://doi.org/10.1007/s12010-012-9857-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9857-7