Abstract

Sponge-associated bacteria have been found to produce a variety of bioactive compounds including natural pigments. Here, we report the molecular identification of zeaxanthin-producing sponge-associated bacteria isolated from sponges in the Gulf of Thailand and the effect of environmental factors on zeaxanthin production from a bacterium. Three colorful sponge-associated bacteria (CHOB06-6, KODA19-6, and MAKB08-4) were identified based on the 16S rDNA profile. The 16S rDNA sequence-based analyses revealed that CHOB 06-6 and MAKB 08-4 were the closest relatives to Sphingomonas phyllosphaerae FA2T, and KODA19-6 was a relative of Shingomonas (Blastomonas) natatoria DSM 3183T. After all bacteria were cultivated in a modified Zobell medium, S. natatoria KODA19-6 was found to produce the highest zeaxanthin at 0.62 mg/l. pH and temperature considerably affected its zeaxanthin production. Its optimal condition for zeaxanthin production was found at a pH of 7 and 30 °C. The bacterium had a maximum specific growth rate (μ max) of 0.06 1/h with zeaxanthin productivity (Q p) of 6.27 μg/l·h. Therefore, this newly zeaxanthin-producing bacterium has a potential to produce natural zeaxanthin for the food, feed, pharmaceutical, and cosmetic industries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zeaxanthin (3,3′-dihydroxy-β-carotene) is the yellow pigment in the xanthophyll group of the carotenoid family which has a molecular formula of C40H56O2 and a molecular weight of 568.88. The molecule is polyene-like with nine alternating conjugated carbon single and double bonds which is terminated by a hydroxyl-attached ionone ring. Zeaxanthin is naturally found in yellow colored vegetables and fruits such as corn, orange peppers, mangoes, pink grapefruit, apricots, peaches, cantaloupe, and avocadoes [1, 2]. Moreover, it can be produced by various microorganisms such as the microalga, Dunaliella salina [3], and the bacteria, Flavobacterium multivorum [4], Zeaxanthinibacter enoshimensis [5], Mesoflavibacter zeaxanthinifaciens [6], Synechocystis sp. [7], Erwinia herbicola [8], Paracoccus zeaxanthinifaciens [9], Sphingobacterium multivorum [10], and Leeuwenhoekiella sp. [11]. The pigment shows various pharmaceutical properties. It prevents age-related macular degeneration [12–16], has cancer-preventive properties [17] and can be used as a food supplement. Currently, it is also employed as a feed additive for fish (color enhancement for the flesh) and poultry (yolk color enhancement). These beneficial properties make zeaxanthin an interesting product for industry. Due to its high demand from the market, finding a new source of natural zeaxanthin production is increasingly important.

Among all microorganisms found in nature, sponge-associated bacteria are relatively unfamiliar and increasingly attractive as a source of new chemicals and drugs. Various species of bacteria including archaea, heterotrophic bacteria, phototrophic bacteria, and cyanobacteria have been found associated with sponges and possess special physiological properties viz., aerobic chemoheterotrophic bacteria [18], nitrogen-fixing bacteria [19, 20], and Proteobacteria especially γ-Proteobacteria and α-Proteobacteria [21–23]. These bacteria inhabit the outer layers of sponges, the sponge mesohyl and inside sponge cells [24]. The bacteria may constitute up to 40 % of sponge biomass [25]. Sponges become suitable habitats for their associated bacteria because they have special structures (inner and outer endosomes) enabling them to seclude food and filter water. According to the symbiotic relationship, sponges offer nutrients and a safe habitat to bacteria while they receive some metabolites from translocated processes of microorganisms. Sponge-associated bacteria have been found to produce antimicrobial agents [18, 26, 27] which may play an important role for the defense mechanism of sponges. They also produce other bioactive compounds such as neuroactive compounds [28], cyclic peptides [29], terpenes [30], and pigments [27].

To our knowledge, zeaxanthin production from sponge-associated bacteria is rarely investigated. This work, therefore, is the first report on the identification of zeaxanthin-producing sponge-associated bacteria isolated from the Gulf of Thailand and the study of their zeaxanthin production.

Materials and Methods

Chemicals and Standards

Seawater was kindly provided by Burapha University, Cholburi, Thailand. Before used, seawater was filtered through a Whatman No.4 filter paper and kept at 4 °C. Zeaxanthin was used as a standard pigment purchased from Sigma-Aldrich (St. Louis, MO, USA). Other chemicals were analytical grade and HPLC grade.

Cultivation Medium

The cultural medium used was a modified Zobell medium containing 1 g/l proteose peptone (BBL, MD, USA), 1 g/l yeast extract, 0.5 g/l phytone peptone (BBL, MD, USA), 0.2 g/l Na2S2O3.5H2O, 0.05 g/l Na2SO3, and 0.002 g/l Fe(C6H5O7) dissolved in seawater and distilled water (90:10, v/v) at pH 7.6.

Isolation and Cultivation of Sponge-Associated Bacteria

Sponge-associated bacteria were isolated from sponges (Mycale (Zygomycale) parishii, Echinodictyum spp., Clathria (Microciona) sp., Echinodictyum spp., Clathria (Thalysias) reinwardti, Pseudoceratina sp., Gelliodes petrosioides, Pachastrissa nux, Coelocarteria singaporensis, and Tethya seychellensis) that were collected by scuba diving at a depth of 6–9 m. from Chaolao Beach of Chantha Buri Province, Mak Island of Trat Province, and Kood Island of Trat Province located in the Gulf of Thailand. The serial homogenate of 5 g sponge was spread on the modified Zobell agar medium and incubated at 30 °C for 3–7 days. Bacterial colonies were then picked up randomly and purified on the modified Zobell agar medium. The pure colonies were cultivated on slants of the medium at 30 °C for 48 h and kept at 4 °C before use.

Zeaxanthin Production of Sponge-Associated Bacteria

All sponge-associated bacterial isolates were grown on the modified Zobell broth for zeaxanthin production. A loop-full of each bacterium cultivated on the slant was transferred to 250-ml flasks containing 100 ml of the modified Zobell broth. The flasks were incubated at 30 °C on a rotary shaker operated at 120 rev/min for 4 days. After the incubation, bacterial growth and zeaxanthin production were determined.

Bacterial Growth Measurement

Bacterial growth was determined by cell dry weight measurement. A 100-ml broth was sampled and centrifuged at 5,700×g for 15 min to collect bacterial biomass. The biomass was then washed twice with distilled water. Supernatant was discarded and cell pellet was then dried to constant weight in an oven at 60 °C.

Zeaxanthin Analysis

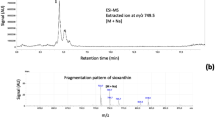

Bacterial cells were harvested by centrifugation at 5,700×g, 4 °C for 15 min, and washed twice with distilled water. The cell pellet was suspended in 95 % (v/v) ethanol and the cell suspension was shaken at 200 rev/min at 30 °C for 24 h. The ethanol extract was then collected by centrifugation at 5,700×g, 4 °C for 15 min. The extract was evaporated to dryness by nitrogen gas and re-dissolved in acetone. The extract was filtered through a 0.45-μm membrane and analyzed for zeaxanthin by using HPLC (Shimadzu, Kyoto, Japan). Twenty-microliter extract was subjected to a Polaris C18-A column (4.6 × 150 mm, 10 μm) with a guard column (MetaGuard, 4.6 × 10 mm; Varian, Kyoto, USA) operated at 25 °C with an isocratic solvent system of acetonitrile/methanol/tetrahydrofuran (58:35:7 %, v/v) and the flow rate of 1 ml/min [31]. The eluent was monitored with a photodiode array detector at 450 nm. Zeaxanthin was used as an external standard. It was eluted at a retention time of 3.23 min.

Bacterial Identification

The bacterial isolates were re-cultured on the agar medium at 25 °C for 48 h. Gram’s staining, morphological, physiological, and biochemical characteristics of the isolate were investigated according to Bergey’s Manual of Systematic Bacteriology Volume 2 [32]. A rapid bacterial identification test kit for Gram-negative non-Enterobacteriaceae, API 20 NE (BioMerieux, Marcy l’Etoile, France), was used to identify species of bacteria. The strains were confirmed by 16S rRNA gene sequence analysis. Genetic DNA extraction, PCR amplification of the 16S rRNA gene, and purification of PCR products were carried out. For DNA isolation, they were cultivated in the broth medium at 25 °C for 48 h. Bacterial genomic DNA was isolated using the Wizard® Genomic DNA purification kit (Promega, WI, USA). 16S rDNA genes were amplified using universal bacterial primers 8F (5′-AGAGTTTGATCCTTGGCTCAG-3′) and 1492R (5′-GCYTACCTTGTTACGACTT-3′) (Wardmedic, Bangkok, Thailand). PCR was done under the following condition: 5 min at 95 °C, 25 cycles of 50 s at 95 °C, 30 s at 55 °C, 2 min at 72 °C, and 7 min at 72 °C. PCR products were verified by agarose gel electrophoresis. PCR products were cloned into the pGEM-T vector (Promega, WI, USA) and then 16S rDNA-containing plasmids were transformed to the Escherichia coli competent cells. Bacterial cells containing plasmid were selected using a blue-white colony selection method. Plasmids were isolated by alkaline lysis Mini-Prep protocol. 16S rDNA on the plasmid was sequenced by the Sanger deoxy method using a DNA sequencer (ABI PRISM 3730 Genetic analyzer, CA, USA) with ABI BigDye Terminator version 3.1 chemistry kit (CA, USA). The DNA sequence was compared to the GenBank database in the National Center for Biotechnology Information (NCBI) using the BLAST program. A phylogenetic analysis was done using molecular evolutionary genetics analysis (MEGA) software version 4.0 [33].

Effect of pH and Temperature on Zeaxanthin Production

Zeaxanthin-producing strains were studied for the optimum pH and temperature on its growth and zeaxanthin production. An initial medium pH (6–8) and incubation temperature (25–35 °C) were examined. The strains were incubated at 150 rev/min for 4 days. All experiments were done in triplicate and the mean results were reported.

Growth and Zeaxanthin Production Under the Optimum Condition

Study on bacterial growth and zeaxanthin production was carried out under optimal pH and temperature. The bacterium was cultivated in 250-ml flasks containing 100 ml of modified Zobell broth. The flasks were incubated on a rotary shaker operated at 120 rev/min for 4 days. During incubation, samples were taken periodically to determine growth, pH, and zeaxanthin. All experiments were done in triplicate and their mean results were reported.

Statistical Analysis

The quantitative analyses of zeaxanthin were performed in triplicate and the mean values were calculated. The data was statistically analyzed by the SPSS 16.0 software (SPSS, IL, USA) using analysis of variance (ANOVA) and Duncan’s multiple range tests to determine significant differences between the means (p < 0.05).

Results

Isolation and Zeaxanthin Production of Sponge-Associated Bacteria

A total of 24 bacteria were isolated from the sponge samples collected in the Gulf of Thailand. Most of them were Gram negative rods (data not shown). Of all isolates tested, the three most distinctively colorful zeaxanthin-producing strains were CHOB06-6, KODA19-6, and MAKB08-4 (Fig. 1). They produced zeaxanthin in a range of 0.08–0.62 mg/l after 4 days of cultivation. The isolate KODA19-6 was found to be the best zeaxanthin producer. It produced the highest zeaxanthin yield of 4.1 mg/g and gave the lowest biomass of 0.15 g/l.

Identification of Zeaxanthin-Producing Bacteria Associated with Sponge

Three zeaxanthin-producing bacteria, CHOB06-6, KODA19-6, and MAKB08-4, were isolated from the sponges M. (Zygomycale) parishii from Chaolao Beach, Chanthaburi province, T. seychellensis from Kood Island, Trat province, and Pseudoceratina sp. from Mak Island, Trat province, respectively. All strains were Gram negative, weakly motile, non-spore-forming and short rods or cocci as shown in Table 1. The cells exhibited 0.9–1.7 μm in width and 1.3–2.4 μm in length. All strains formed circular, smooth yellow colonies on the modified Zobell agar and were able to grow at 30 °C under aerobic condition.

The three sponge-associated bacteria were then identified according to the 16S rRNA gene sequences. The lengths of the sequences for the strains CHOB06-6, KODA19-6, and MAKB08-4 were 1,450, 1,450, and 1,448 bp, respectively. The similarities of CHOB06-6, KODA19-6, and MAKB08-4 from the databases of EMBOSS pair-wise alignment algorithms option and EMBOSS needle method consecutively showed 88.8 % (1,334 bp/1,502 bp) similarity to Sphingomonas phyllosphaerae FA2T, 98.0 % (1,447 bp/1,477 bp) similarity to Sphingomonas (Blastomonas) natatoria DSM 3183T, and 89.0 % (1,322 bp/1,485 bp) similarity to S. phyllosphaerae FA2T, respectively, and their GenBank sequence accession numbers were FJ999661, FJ999662, and FJ843590, respectively. A phylogenetic tree was constructed using the neighbor-joining method (Fig. 2) to infer the genetic relationship among these strains with known species in the class of α-Proteobacteria.

Effect of pH and Temperature on Zeaxanthin Production

Since S. natatoria KODA19-6 appeared to produce the highest zeaxanthin, the pH and temperature affecting its growth and zeaxanthin production were further studied. The growth and zeaxanthin production were greatly influenced by pH as shown in Fig. 3. A pH of 7 was optimal for its zeaxanthin production (0.62 mg/l) with a yield of 4.1 mg/g, whereas a pH of 6 was most favorable for its growth (0.6 g/l).

Temperature considerably affected zeaxanthin production and growth of S. natatoria KODA19-6 (Fig. 4). A temperature of 30 °C was optimal for its zeaxanthin production (0.73 mg/l) and yield (4.9 mg/g).

Growth and Zeaxanthin Production Under the Optimum Condition

Fermentation kinetics of growth and zeaxanthin production from S. natatoria KODA19-6 under an optimal condition of 30 °C and pH 7 are shown in Fig. 5. Bacterial growth increased continuously until the end of fermentation (0.40 g/l) with a maximum specific growth rate (μ max) of 0.06 1/h. Zeaxanthin was produced slowly at the first 2 days and then increased rapidly until the end of day 3. After 4 days of incubation, zeaxanthin reached its maximum at 602 μg/l with a productivity (Q p) of 6.27 μg/l·h. In addition, pH had increased to 7.9 at the initial stage and then dropped to 6.7 at the end of fermentation.

Discussions

Most sponge-associated isolates found in the Gulf of Thailand were Gram negative rods which were similar to those isolated from other locations [22, 27]. It is reported that up to 58 % of all strains isolated from the marine sponge Petrosia ficiformis were Gram negative with long or short rods, non-spore forming and pigmented (yellow, orange, red, or brownish). However, a Gram positive coccus, Micrococcus luteus, isolated from the sponge, Xestospongia sp., in New Caledonia, and a Gram positive rod, Bacillus sp., isolated from the sponge, Sigmadocia fibulatus of the Tuticorin coast, South East India were found [18, 26]. Microorganisms inhabit sponges and help them in nutritional processes including intracellular digestion and translocation of metabolites by nitrogen fixation, nitrification, and photosynthesis [24, 34]. Moreover, microorganisms support sponge skeleton stabilization and participate in a chemical defense system against predators and biofouling of sponges. On the other hand, sponges can benefit their symbionts by providing them more nutrients and safer habitat than other surroundings such as seawater and sediments [24].

Several microbial sources have been reported to produce carotenoids especially algae (Neospongiococcum excentricum and Spirulina sp.), microalgae (D. salina and Microcystis aeruginosa), red yeast (Xanthophyllomyces dendrohous or Phaffia rhodozyma), and bacteria (Flavobacterium sp., E. herbicola, Synechocystis sp., Z. enoshimensis, and M. zeaxanthinifaciens) [16]. However, Flavobacterium sp. was reported to produce zeaxanthin mostly among carotenoids produced in their cells [16]. Alcantara and Sanchez [10] reported Flavobacterium sp. produced the maximum zeaxanthin of 0.75 mg/l within 32 h on a chemically defined medium with NH4Cl and yeast extract as a sole carbon source. Bhosale and Bernstein [35] also reviewed that F. multivorum produced zeaxanthin of 1.6 mg/g. Those reports also indicated that the amount of zeaxanthin produced by Flavobacterium sp. depended upon medium compositions. Microbial strain development by mutation and genetic recombination has been used to improve zeaxanthin production. Jin and co-workers [36] reported that a mutant of the microalga D. salina using ethylmethyl sulfonate mutagenesis produced zeaxanthin of 6 mg/g. Recombinant strains of Phaffia rhodozyma were reported to produce higher zeaxanthin concentrations (2.2–5.7 mg/l) [37]. In addition, a recombinant strain of Pseudomonas putida could produce zeaxanthin up to 239 mg/l under an optimum condition with lecitin addition during cell cultivation [38]. It seems that our strains produced less zeaxanthin than the reported strains due to the differences of microbial species, cultivation condition, medium composition, and nutrient requirements of microorganisms.

This work is the first to report that zeaxanthin is produced by S. phyllosphaerae and S. natatoria isolated from sponges. Two of our zeaxanthin-producing and sponge-associated strains (CHOB06-6 and MAKB08-4) were closely related to S. phyllosphaerae FA2T which was discovered and isolated from the phyllosphere of a legumous tree, Acacia caven, in Argentina in 2004 [39]. The bacterium formed yellow-pigmented colonies on a nutrient agar which was consistent to the isolates CHOB06-6 and MAKB08-4 showing yellow colonies on the modified Zobell agar. However, the habitat of the strains CHOB06-6 and MAKB08-4 was distinctively different from that of S. phyllosphaerae FA2T. Meanwhile, the strain KODA19-6 was closely related to S. (Blastomonas) natatoria DSM 3183T which formed yellow or orange colonies and was reported to produce carotenoids [40]. The habitat of the strain KODA19-6 was distinctively different from that of S. natatoria DSM 3183T which was originally isolated from a water sample from a swimming pool [41]. Recently, new bacterial species of Z. enoshimensis and M. zeaxanthinifaciens isolated from seawater samples at the Enoshima Island, Japan, and Nubsella zeaxanthinifaciens isolated from a freshwater sample collected at Misasa (Tottori, Japan) were found to produce zeaxanthin [5, 6, 42]. Thus, zeaxanthin-producing bacteria can be found in marine and freshwater environments.

Generally, Proteobacteria are bacteria which are reported to be associated with sponges. Li et al. [21] found bacteria isolated from the sponges, Dysidea avara and Craniella australiensis, living in the South China Sea were α-, β-, and γ-Proteobacteria and Sphingobacteria. Similarly, bacteria isolated from Mediterranean sponges were classified as α- and γ-Proteobacteria [23]. Lafi et al. [43] also reported α- and γ-Proteobacteria were associated with the sponges—Pseudoceratina clavata and Rhabdastrella globostellata, located at the Great Barrier Reef, Australia. Furthermore, Gram negative bacteria, Bacteroidetes sp., Planctomycetes sp., and Verrucomicrobia sp., and Gram positive bacteria, Firmicutes sp. and Actinobacteria sp., were found to associate with sponges [34]. Taylor et al. [34] also concluded that sponge-associated bacteria and archaea found at marine locations were Proteobacteria.

In general, pH affected carotenoid biosynthesis in microbial cells. pH is involved in enzyme activities which play an important role in carotenogenesis and microbial growth. S. natatoria KODA19-6 had an optimal pH of 7.0 for its zeaxanthin production. Similarly, a microalga, Haematococcus pluvialis, had the highest astaxanthin production and biomass at a neutral pH of 7.0 [44]. In contrast, carotenoid yields produced by the yeast Rhodotorula glutinis were maximized at the slightly acidic pH of 6 with a maximum biomass concentration occurring at a pH of 6.5 [45]. Astaxanthin formation and biomass of Xanthophyllomyces dendrorhous were also optimal at the pH values of 5.0 and 6.0, respectively [46].

S. natatoria KODA19-6 had an optimal temperature of 30 °C for its zeaxanthin production. It is expected that a temperature of 30 °C would be optimal for β-carotene hydroxylase which catalyzes β-carotene to zeaxanthin. This temperature was reported to be optimal for astaxanthin by H. pluvialis [47]. However, the astaxanthin producing yeast, Phaffia rhodozyma, had an optimal temperature for astaxanthin formation at 22 °C and astaxanthin content was drastically decreased at higher temperatures [48].

The formation of zeaxanthin by S. natatoria KODA19-6 was associated with its growth. Similarly, F. multivorum and Chlorella zofingiensis were found to produce zeaxanthin in association with their growth [4, 49]. In addition, Flavobacterium sp. was able to provide a zeaxanthin production of 23.44 μg/l·h [10]. Masetto et al. [50] also reported that the zeaxanthin productivity of Flavobacterium sp. was 109.38 μg/l·h after it was cultured in a 4-l fermentor operating at 600 rev/min and 2 vvm with a supplementary of 4.6 % corn steep liquor for 96 h. While, Bhosale et al. [51] reported zeaxanthin productivity of F. multivorum ATCC 55238 was maximum of 0.43 mg/l·h at the late exponential phase. The maximum specific growth rates of F. multivorum ATCC 55238 were found at 0.21–0.37 1/h when it was cultivated in different media [51, 52].

References

Ashton, O. B. O., Wong, M., McGhie, T. K., Vather, R., Wang, Y., Requejo-Jackman, C., Ramankutty, P., & Woolf, A. B. (2006). Journal of Agricultural and Food Chemistry, 54, 10151–10158.

Khachik, F., Beecher, G. R., & Lusby, W. R. (1989). Journal of Agricultural and Food Chemistry, 37, 1465–1473.

Jin, E. S., Polle, J. W., Lee, H. K., Hyun, S. M., & Chang, M. J. (2003). Journal of Microbiology and Biotechnology, 13, 165–174.

Bhosale, P., & Bernstein, P. S. (2004). Journal of Industrial Microbiology and Biotechnology, 31, 565–571.

Asker, D., Beppu, T., & Ueda, K. (2007). International Journal of Systematic and Evolutionary Microbiology, 57, 837–843.

Asker, D., Beppu, T., & Ueda, K. (2007). Systematic and Applied Microbiology, 30, 291–296.

Lagarde, D., Beuf, L., & Vermaas, W. (2000). Applied and Environmental Microbiology, 66, 64–72.

Hundle, B. S., O’Brien, D. A., Beyer, P., Kleinig, H., & Hearst, J. E. (1993). FEBS Letters, 315, 329–334.

Berry, A., Janssens, D., Humbelin, M., Jore, J. P., Hoste, B., Cleenwerck, I., Vancanneyt, M., Bretzel, W., Mayer, A. F., Lopes-Ulibarri, R., Shanmugam, B., Swings, J., & Pasamontes, L. (2003). International Journal of Systematic and Evolutionary Microbiology, 53, 231–238.

Alcantara, S., & Sanchez, S. (1999). Journal of Industrial Microbiology and Biotechnology, 23, 697–700.

Stafsnes, M. H., Josefsen, K. D., Kildahl-Andersen, G., Valla, S., Ellingsen, T. E., & Bruheim, P. (2010). Journal of Microbiology, 48, 16–23.

Beatty, S., Boulton, M., Henson, D., Koh, H. H., & Murray, I. J. (1999). British Journal of Ophthalmology, 83, 867–877.

Landrum, J. T., & Bone, R. A. (2001). Archives of Biochemistry and Biophysics, 385, 28–40.

Loane, E., Nolan, J. M., Donovan, O., Bhosale, P., Bernstein, P. S., & Beatty, S. (2008). Survey of Ophthalmology, 53, 68–81.

Mares-Perlman, J. A., Millen, A. E., Ficek, T. L., & Hankinson, S. E. (2002). Journal of Nutrition, 132, 518S–524S.

Sajilata, M. G., Singhal, R. S., & Kamat, M. Y. (2008). Comprehensive Review in Food Science, 7, 29–49.

Nishino, H., Murakoshi, M., Ii, T., Takemura, M., Kuchide, M., Kanazawa, M., Mou, X. Y., Wada, S., Masuda, M., Ohsaka, Y., Yogosawa, S., Satomi, Y., & Jinno, K. (2002). Cancer Metastasis Reviews, 21, 257–264.

Anand, T. P., Bhat, A. W., Shouche, Y. S., Roy, U., Siddharth, J., & Sarma, S. P. (2006). Microbiology Research, 161, 252–262.

Ridley, C. P., Bergquist, P. R., Harper, M. K., Faulkner, D. J., Hooper, J. N. A., & Haygood, M. G. (2005). Chemistry & Biology, 12, 397–406.

Webb, V. L., & Maas, E. W. (2002). FEMS Microbiology Letters, 207, 43–47.

Li, Z.Y., He, L.M., Wu, J. and Jiang, Q. (2006) Journal of Experimental Marine Biology and Ecology. 329, 75–85.

Olson, J. B., Harmody, D. K., & McCarthy, P. J. (2002). FEMS Microbiology Letters, 211, 169–173.

Thiel, V., & Imhoff, J. F. (2003). Biomolecular Engineering, 20, 421–423.

Lee, Y. K., Lee, J. H., & Lee, H. K. (2001). Journal of Microbiology, 39, 254–264.

Wilkinson, C. R. (1978). Marine Biology, 49, 169–176.

Bultel-Poncé, V., Cécile, D., Jean-Pascal, B., Claude, C., & Michèle, G. (1998). Journal of Marine Biotechnology, 6, 233–236.

Chelossi, E., Milanese, M., Milano, A., Pronzato, R., & Riccardi, G. (2004). Journal of Experimental Marine Biology and Ecology, 309, 21–33.

Perovic, S., Wichels, A., Schött, C., Gerdts, G., Pahler, S., Steffen, R., & Müller, W. E. G. (1998). Environmental Toxicology and Pharmacology, 6, 125–133.

De Rosa, S., Mitova, M., & Tommonaro, G. (2003). Biomolecular Engineering, 20, 311–316.

Kelecom, A. (2002). Annals of Brazilian Academy of Sciences, 74, 151–170.

Takaichi, S. (2000). Photosynthesis Research, 65, 93–99.

Brenner, D. J., Krieg, N. R., & Staley, J. T. (2005). Bergey’s manual of systematic bacteriology Volume II. In G. M. Garrity (Ed.), Alphaproteobacteria (pp. 1–1191). New York: Springer.

Tamura, K., Dudley, J., Nei, M., & Kumar, S. (2007). Molecular Biology and Evolution, 24, 1596–1599.

Taylor, M. W., Radax, R., Steger, D., & Wagner, M. (2007). Microbiology and Molecular Biology Reviews, 71, 295–347.

Bhosale, P., & Bernstein, P. S. (2005). Applied Microbiology and Biotechnology, 68, 445–455.

Jin, E. S., Feth, B., & Melis, A. (2003). Biotechnology and Bioengineering, 81, 115–124.

Hoshino, T., Ojima, K. and Setoguchi, Y. (2004) PCT Int. Appl., 21 pp. Application: WO 2003-EP10574 20030923.

Beuttler, H., Hoffmann, J., Jeske, M., Hauer, B., Schmid, R.F., Altenbuchner, J. and Urlacher, V.B. (2010) Applied Microbiology and Biotechnology, 89, 1137–1147.

Rivas, R., Abril, A., Trujillo, M. E., & Velázquez, E. (2004). International Journal of Systematic and Evolutionary Microbiology, 54, 2147–2150.

Hiraishi, A., Kuraishi, H., & Kawahara, K. (2000). International Journal of Systematic and Evolutionary Microbiology, 50, 1113–1118.

Sly, L. I., & Hargreaves, M. H. (1984). Journal of Applied Bacteriology, 56, 479–486.

Asker, D., Beppu, T., & Ueda, K. (2008). International Journal of Systematic and Evolutionary Microbiology, 58, 601–606.

Lafi, F. F., Garson, M. J., & Fuerst, J. F. (2005). Microbial Ecology, 50, 213–220.

Sarada, R., Tripathi, U., & Ravishankar, G. A. (2002). Process Biochemistry, 37, 623–627.

Aksu, Z., & Eren, A. T. (2007). Biochemical Engineering Journal, 35, 107–113.

Hu, Z. C., Zheng, Y. G., Wang, Z., & Shen, Y. C. (2006). Enzyme Microbial Technology, 39, 586–590.

Tjahjono, A. E., Hayama, Y., Kakizono, T., Terada, Y., Nishio, N., & Nagai, S. (1994). Biotechnology Letters, 16, 133–138.

Johnson, E. A., & Lewis, M. J. (1979). Journal of General Microbiology, 115, 173–183.

Wang, Y., & Peng, J. (2008). World Journal of Microbiology and Biotechnology, 24, 1915–1922.

Masetto, A., Flores-Cotera, L. B., Díaz, C., Langley, E., & Sanchez, S. (2001). Journal of Bioscience and Bioengineering, 92, 55–58.

Bhosale, P., Larson, A. J., & Bernstein, P. S. (2004). Journal of Applied Microbiology, 96, 623–629.

Bhosale, P., Ermakov, I. V., Ermakova, M. R., Gellermann, W., & Bernstein, P. S. (2003). Biotechnology Letters, 25, 1007–1011.

Acknowledgments

We would like to acknowledge the Thailand Research Fund (TRF) for awarding a scholarship of Patcharee Thawornwiriyanun under the Royal Golden Jubilee Ph.D. Program (Grant No. PHD/0056/2548) and the Royal Thai Government for financial support through the research budgets of KMUTT and Burapha University. We are also grateful to Miss Nimaradee Boonapatcharoen from KMUTT, Bangkhuntien campus, for her guidance and generous help with genetic techniques. Finally, we thank Michael Willing for editing our manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thawornwiriyanun, P., Tanasupawat, S., Dechsakulwatana, C. et al. Identification of Newly Zeaxanthin-Producing Bacteria Isolated from Sponges in the Gulf of Thailand and their Zeaxanthin Production. Appl Biochem Biotechnol 167, 2357–2368 (2012). https://doi.org/10.1007/s12010-012-9760-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9760-2