Abstract

The present study deals with the isolation of fungi from soil with the ability to degrade polyurethane (PU). A pure fungal isolate was analyzed for its ability to utilize PU as a sole carbon source in shaking culture for 30 days. Incubation of PU with Aspergillus flavus resulted in 60.6% reduction in weight of PU. The scanning electron microscopy and Fourier transform infrared spectroscopy (FTIR) results showed certain changes on the surface of PU film and formation of some new intermediate products after polymer breakdown. Thermogravimetric curves showed changes between the thermal behavior of the samples that were inoculated with A. flavus and control. FTIR spectra showed detectable changes in control and incubated samples, suggesting that degradation occurs, with the decreased intensity of band at 1,715 cm−1, corresponding to ester linkages. We have identified an extracellular esterase activity which might be responsible for the polyurethanolytic activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyurethanes (PU) are a versatile class of man-made synthetic polymers widely used throughout the world for diverse applications such as furniture, coatings, adhesives, constructional materials, fibers, paddings, paints, elastomers, and synthetic skins [1]. PU is replacing the old polymers for various reasons like increased tensile strength and melting point. Their resistance to degradation by water, oils, and solvents make them excellent for the replacement of thermoplastics [2].

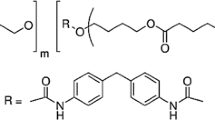

Polyurethanes were first investigated and produced by Dr. Otto Bayer in 1937. Polurethane is a general term used for a polymer derived from the condensation of polyisocyanates and polyols having intramolecular urethane bonds (–NHCOO–). The PU polymer that contains an ester type polyol is known as polyester PU, whereas the PU polymer that contains an ether type polyol is known as polyether PU. PU can adopt various forms (from soft to hard) depending on the chemical structures of the polyisocyanates and polyols (functional group number or molecular mass), the raw materials of PU [3].

Lack of degradability and the closing of landfill sites as well as growing water and land pollution problems have led to concern about synthetic polymeric plastics. Increasingly, raw materials such as crude oil are in short supply for the synthesis of plastics, and the recycling of waste plastics is becoming more important. Studies on elucidation of the biodegradability of polyurethanes are gaining importance since an understanding of how this degradation occurs may aid in the development of strategies to exploit these processes for waste management purposes [1, 4].

Unlike most synthetic polymers (e.g., polyethylene or polystyrene), PU are susceptible to biodegradation by a wide range of microorganisms [5]. The microbial degradation process of PU can roughly be divided into the degradation of urethane bonds and the degradation of polyol segments, which are the major constituents of PU, and PU degradability is largely influenced by the chemical structure of the polyol segment (polyester type or polyether type). Due to its susceptibility to microbial attack, biodegradation of PUs has been one of the thrust areas during the last few decades. Several reports have appeared in the literature on the susceptibility of PUs to fungal [4, 6–9] and bacterial attack [10–15]. It has been reported that polyester PU is more susceptible to biodegradation by bacteria, fungi, and enzymes whereas polyether PU has been found to be relatively more resistant to biodegradation [16]. Biodegradation of polyester polyurethane is mainly achieved by the hydrolysis of ester bond in the polyol segment of the polymer backbone by hydrolytic enzymes such as ureases, proteases, and esterases associated with both bacteria and fungi [12, 17]. Wales and Sagar [18] proposed a mechanism for the degradation of polyester PU by extracellular esterases. Polyurethane degradation is the result of synergistic activity between endopolyurethanases and exopolyurethanases. Endoenzymes hydrolyze the PU molecule at random locations throughout the polymer chain leading to loss of tensile strength. Exoenzymes remove successive monomer units from the chain ends however show little loss of tensile strength. So far, only two types of PUase enzymes have been isolated and characterized: a cell-associated, membrane-bound PU esterase [11] and soluble, extracellular PU esterases [19]. Purification and characterization of two PU esterase enzymes has been done from Pseudomonas fluorescens [20].

Recent work has included studies on the distribution of synthetic polymer-degrading microorganisms in the environment and the isolation and characterization of polyurethane degrading fungal strain from plastic waste disposal sites. Analysis of PU degradation was done through weight loss, Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). We also identified an extracellular esterase activity which might be responsible for the polyurethanolytic activity.

Material and Methods

Material

The polyurethane used for the present study was of the type polyester polyurethane and was kindly supplied as sheets by InstaparkR, USA.

Pretreatment of Polyurethane

Polyurethane sheet was cut into films of size 4 × 3 cm and 1 mm thickness. Films were sterilized with the help of absolute alcohol and kept in desiccator. The dried samples were used for subsequent analyses. Films were weighed before inoculation.

Isolation of Polyurethane-Degrading Microorganisms and Culture Conditions

Polyurethane-degrading microorganisms were isolated from soil samples collected from plastic waste disposal sites from Uttaranchal, India. A total of 12 fungal isolates were obtained. These isolates were further screened for ability to utilize PU as sole carbon source. Fungal cultures were maintained on potato dextrose agar (Himedia Laboratories, India). Unless otherwise specified, liquid cultures (100 ml) were incubated in flasks (250 ml) on a rotary shaker (120 rpm) at 30 °C.

All assays for studying degradation of PU were carried out in minimal medium containing (grams per liter of distilled water): NaNO3, 2.0; KH2PO4, 0.7; K2HPO4, 0.3; KCl, 0.5; MgSO4·7H2O, 0.5; FeSO4·7H2O, 0.1. The pH was adjusted to 6.0–6.5. Preweighed (100 mg) disinfected films (three films in number) were aseptically added to 50 ml sterilized culture medium in each flask before inoculation and incubated for 24 h with shaking to ensure the asepsis. Flasks containing culture medium (50 ml) were then inoculated with fungal culture having a spore concentration of 4.8 × 106 spores/ml and were incubated with shaking at 120 rpm for 30 days at 28 ± 2 °C. For control, sterile polyurethane films were incubated in culture medium containing 0.05% sodium azide to inhibit microbial contamination. Studies were carried out in triplicates and mean and standard deviation are reported here.

Film Harvest

After 30 days of incubation, polyurethane films were harvested, rinsed with sterile water, then washed in 70% ethanol to remove cells mass from the residual films as much as possible and then dried at 45 °C overnight.

Evaluation of Polyurethane Degradation

Weight Loss Measurement

PU degradation was monitored by measuring the weight of PU before and after incubation. The post-incubation weight was compared to the weight prior to incubation. The weight of the films in the control flask was also measured for comparison. The percent weight reduction was computed with the formula: % weight reduction = (W 1−W 2/W 1) × 100, where W 1 is the pre-incubation weight and W 2 is the post-incubation weight of the polyurethane films. Each value represents mean ± SD of triplicates.

Scanning Electron Microscopy

Pieces of fungal incubated polyurethane films were fixed overnight at 4 °C in 4% glutaraldehyde in 0.05 M phosphate buffer (pH 7.3) and washed three times (10 min each) in 0.05 M phosphate buffer. Samples were then dehydrated through 70%, 80%, 90%, and 100% ethanol (5 min in each stage) and three changes in 100% ethanol at room temperature. Samples were then dried under vacuum. They were then mounted, sputter-coated with gold, and examined (SEM LEO 435 VF; LEO electron microscopy, England).

Fourier Transform Infrared Spectroscopy

After incubation of PU film in liquid medium for 30 days, PU films were subjected to Fourier transform infrared spectroscopy to evaluate degradation on the basis of changes in functional groups by FTIR spectrometer (Thermo Nicolet Corporation, Madison). Films were affixed directly to standard infrared sample plates. A spectrum of untreated sample was recorded as control. The spectra were averaged over 32 scans in the range of 4,000–400 cm−1, with a resolution of 4 cm−1.

Thermogravimetric Analysis

The physical–chemical characterization was conducted using PerkinElmer (Pyris Diamond) thermal analyzer under nitrogen atmosphere. The instrument was calibrated using alumina. The thermogravimetric curves were obtained according to the following conditions: samples of approximately 5 mg, temperature range of 30–500 °C, heating rate of 10 °C/min and atmosphere of N2 (dynamic) of 100 cm3/min.

Esterase Activity Assay

The esterase activity was assayed by measuring the rate of hydrolysis of p-nitrophenyl ester as per method of Kordel et al. [21]. Briefly, p-nitrophenyl acetate (16.5 mM) was dissolved in 2-propanol and was mixed with 50 mM Tris–HCl buffer (pH 8.0), supplemented with triton X-100 (0.4%) and gum Arabic (0.1%). Then, 0.15 ml of cell-free supernatant was added to 1.35 ml of this substrate emulsion .The variation of the optical density at 410 nm was monitored for 2–5 min against a blank without enzyme using a Varian Carry 100 Conc UV/VIS spectrophotometer (USA). One unit of enzyme activity was defined as the amount of enzyme liberating 1 μmol of p-nitrophenol per minute under above conditions.

Results and Discussion

Increased attention has been focused at biodegradation as ecofriendly approach for plastic accumulation and environmental pollution. This problem and its curtailment are becoming more significant in India. The present study deals with the isolation and characterization of polyurethane-degrading microorganisms from soil. The assessment of PU degradation was accomplished by utilizing several test methods such as weight loss, SEM, FTIR, and thermogravimetric analysis.

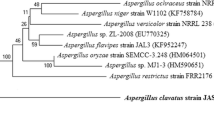

Soil samples collected from plastic waste dumpsites were used as source of isolation of potential microorganisms. In the current study, out of 12 fungal isolates, one fungal isolate could adhere and utilize PU film as sole carbon source. Araceli et al. [17] also isolated a number of fungal species including Aspergillus, Trichoderma, Fusarium, and Alternaria from soil buried PU. The recurrent presence of these fungal species in soil buried plastics may be due to the great amount of exoenzymes that fungi secrete and these enzymes allow the fungi to degrade plastics and probably use them as nutrient source [22]. The extensive network of fungal hyphae was observed on PU film after incubation with fungal isolate in minimal media, when examined under scanning electron microscope. The strain was identified as Aspergillus flavus (ITCC no. 6051) with the help of Indian Type Culture Collections (ITCC), IARI, New Delhi. Alejandro et al. [23] isolated Alicycliphilus sp. capable of degrading a commercial surface-coating PU. Similarly, four fungal species, Curvularia senegalensis, Fusarium solani, Aureobasidium pullulans, and Cladosporium sp. [7] and three bacterial species, Pseudomonas chlororaphis, Comamonas acidovorans, and P. fluorescens [3], isolated from soil, could degrade polyester polyurethane.

Polyurethane Weight Loss

PU degradation was monitored by measuring the weight of polyurethane films before and after incubation with A. flavus (ITCC no. 6051). Test polyurethane films exposed to A. flavus (ITCC 6051) showed 60.6 ± 0.3% reduction in weight after 30 days of incubation compared to no change in a control culture. In a similar study, Alternaria solani, a soil fungal isolate, was found to utilize polyester polyurethane as sole carbon source and resulted in 65.8% loss in weight of PU after 3 weeks of incubation [24].

Scanning Electron Microscopy

SEM studies were carried out to study the effect of the growth of A. flavus on PU film. Figure 1 represents SEM photomicrographs showing the surface topography of the polyurethane sample before and after incubation with A. flavus (ITCC no. 6051). In case of control sample (Fig. 1a, b), surface was smooth. Surface morphology of PU incubated with A. flavus (ITCC no. 6051) showed changes such as pits, erosions, and dark spots (Fig. 1c, d). Large number of fungal spores and hyphae can be seen dispersed over the polyurethane surface. The attachment of the spores and hyphae to the surface suggests that the development of a biofilm may be an important step in the biodegradation of polyurethane. The ability of Alicycliphilus sp. to degrade PU was demonstrated by numerous holes produced in solid PU observed by SEM [23].

Fourier Transform Infrared Spectroscopy

FTIR spectroscopy was used to monitor changes in the composition on the surface of polyurethane due to microbial degradation by hydrolysis of ester bonds. The chemical composition of solid PU after incubation with A. flavus (ITCC no. 6051) was analyzed for possible degradation. The untreated (control) PU films exhibits a peak due to C–H stretch at (2,950 cm−1) and was relatively greater than the N–H stretch at (3,350 cm−1; Fig. 2a). However, the C–H stretch was relatively smaller than the peak due to N–H stretch for A. flavus incubated PU films. Reduction in carbonyl content (1,715 cm−1) and increase in ether, methyl, methylene, and terminal alcohols (983 to 1,450 cm−1) appeared in fungal treated PU film. These changes indicate that ester bonds were hydrolyzed, producing increases in the signals of the indicated groups, in A. flavus exposed PU film (Fig. 2b).

Results of FTIR analysis supported chemical changes in PU film after exposure to A. flavus (ITCC no. 6051). The relative reduction in C–H stretch for the treated PU film indicated the loss of −CH2− groups from PU. The diacid or dialcohols contributes to the major portion of −CH2− in PU. Therefore, the relative reduction of the intensity of C–H stretch during the degradation indicated a loss of diacid and dialcohol groups form the polymer. This is in agreement with findings obtained by Pathirana and Seal [25] which indicate the release of diacid and dialcohols from PU hydrolysis. Sequentially, the ester bonds of the urethane groups (H2N–CO–OR) at 1,715 cm−1 could be hydrolyzed by the action of microbial esterase (Fig. 2b). PU breakdown products obtained by the action of Corynebacterium sp. were analyzed by FTIR and results revealed that hydrolysis of ester bonds resulted in PU degradation [14]. Filip [26] reported the disappearance of isocyanate group at 2,268 cm−1 in PU preparations incubated with Aspergillus niger and Cladosporium herbarum.

Thermogravimetric Analysis

An important application of the thermogravimetric method is to study the thermal behavior of the polymer. The TG curves provide information about the decomposition of different kind of polymers. In reference to the study of biodegradation of PU, a controlling TGA curve of the control sample that was exposed to culture media only, was made (Fig. 3). It was found that decomposition process takes place in three steps. The first step in the decomposition which takes place at 100–300 °C is related to the loss of the volatile compounds such as additives used during the synthesis. Second decomposition (300–400 °C) is related to the breakdown of urethane linkages and third step (400–500 °C) is related to the rupture of ester bonds. Comparing the thermogravimetric curves of the samples exposed to A. flavus (ITCC no. 6051) with control, third decomposition step corresponding to ester links disappeared after microbial attack (Fig. 3). Jose et al. [27] reported the study of biodegradation of castor oil-derived polyurethane by analyzing the TGA of polymer.

Esterase Enzyme Activity

Polyester polyurethane-degrading enzyme esterase has previously been reported to be associated with PU degradation [23, 24]. To detect the presence of esterase enzyme activity, cell-free supernatant was used to measure this activity by p-NPA method. Esterase activity (3.18 U/ml) was detected in the culture supernatant at the end of incubation period (1 month). Since it has been well established that esterase play important role in the PU degradation [12, 13], the PU degradation by A. flavus may be attributed to its high extracellular activity.

Conclusion

In the present study, a new fungal strain, A. flavus (ITCC no. 6051), was isolated from plastic waste dumpsites, capable of utilizing PU as sole carbon source. A. flavus (ITCC no. 6051), has not previously reported as polyester polyurethane-degrading fungi. Degradation of PU is attributed to rupture of ester bond as evident from thermogravimetric and IR spectra. It indicates that there is a great possibility of finding microorganisms from the environment that can degrade synthetic plastics.

References

Howard, G. T. (2002). International Biodeterioration and Biodegradation, 49, 245–252.

Saunders, H., & Frisch, K. C. (1964). Chemistry and technology, part II: technology. New York: Interscience Publishers.

Nakajima-Kambe, T., Shigeno-Akustu, Y., Nomura, N., Onuma, F., & Nakahara, T. (1999). Applied Microbiology and Biotechnology, 51, 134–140.

Russell, J. R., Huang, J., Anand, P., Kucera, K., Sandoval, A. G., Dantzler, K. W., Hickman, D., Jee, J., Kimovec, F. M., Koppstein, D., Marks, D. H., Mittermiller, P. A., Núñez, S. J., Santiago, M., Townes, M. A., Vishnevetsky, M., Williams, N. E., Vargas, M. P., Boulanger, L. A., Bascom-Slack, C., & Strobel, S. A. (2011). Applied and Environmental Microbiology, 77, 6076–6084.

Morton, L.H.G. and Surman, B. (1994). International Biodeterioration Biodegradation, 32, 203–221.

Barratt, S. R., Ennos, A. R., Greenhalgh, Robson, G. D., & Handley, P. S. (2003). Journal of Applied Microbiology, 95, 78–85.

Crabbe, J. R., Campbell, J. R., Thompson, L., Walz, S. L., & Schultz, W. W. (1994). International Biodeterioration and Biodegradation, 33, 103–113.

Darby, R. T., & Kaplan, A. M. (1968). Applied Microbiology, 16, 900–905.

Ossefort, Z. T., & Testroet, F. B. (1966). Rubber Chem. Technol, 39, 1308–1327.

Aamer, A. S., Fariha, H., Javed, I. Q., Abdul, H., & Safia, A. (2008). Annals of Microbiology, 58, 381–386.

Akutsu, Y., Nakajima-Kambe, T., Nomura, N., & Nakahara, T. (1998). Applied and Environmental Microbiology, 64, 62–67.

Allen, A. B., Hilliard, N. P., & Howard, G. T. (1999). International Biodeterioration and Biodegradation, 43, 37–41.

Blake, R. C., & Howard, G. T. (1998). International Biodeterioration and Biodegradation, 42, 63–73.

Kay, M. J., McCabe, R. W., & Morton, L. H. G. (1993). International Biodeterioration and Biodegradation, 31, 209–225.

Nakajima-Kambe, T., Onuma, F., Akutsu, Y., & Nakahara, T. (1997). Journal of Fermentation and Bioengineering, 83, 456–460.

Gautam, R., Bassi, A. S., Yanful, E. K., & Cullen, E. (2007). International Biodeterioration and Biodegradation, 60, 245–249.

Araceli, L.-T., Gilberto, G., Abraham, V.-T., Raúl, R.-H., & Cristóbal, N. A. (2011). Adv Bioscience Biotechnol, 2, 52–58.

Wales, D. S., & Sagar, B. R. (1988). In D. R. Houghton, R. N. Smith, & H. O. W. Eggins (Eds.), Biodeterioration (7th ed., pp. 351–358). London: Elsevier Applied Science.

Ruiz, C., Main, T., Hilliard, N., & Howard, G. T. (1999). International Biodeterioration and Biodegradation, 43, 43–47.

Howard, G. T., & Blake, R. C. (1999). International Biodeterioration and Biodegradation, 42, 213–220.

Kordel, M., Hofmann, B., Schomburg, D., & Schmid, R. D. (1991). Journal of Bacteriology, 173, 4836–4841.

Lagauskas, L. L., & Pečiulytė, D. (2009). International Biodeterioration and Biodegradation, 52, 233–242.

Alejandro, O.-C., Agustín, C.-G., Néstor, L., Sandra, B.-N., Javier, C.-G., Carmen, W., & Herminia, L.-T. (2007). Applied and Environmental Microbiology, 73, 6214–6223.

Ibrahim, N. I., Anwar, M., Khalid, M., Hameed, I. M., Saadoun, H. M. M., & Toshiaki, N.-K. (2009). Adv Environ Biol, 3, 162–170.

Pathirana, R. A., & Seal, K. J. (1985). International Biodeterioration, 21, 123–125.

Filip, Z. (1979). European Journal of Applied Microbiology and Biotechnology, 7, 277–280.

José, M. C., Salvador, C. N., & Gilberto, O. C. (2006). Polímeros: Ciência e Tecnologia, 16, 129–135.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mathur, G., Prasad, R. Degradation of Polyurethane by Aspergillus flavus (ITCC 6051) Isolated from Soil. Appl Biochem Biotechnol 167, 1595–1602 (2012). https://doi.org/10.1007/s12010-012-9572-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9572-4