Abstract

A polyurethane (PU)-degrading fungus designated as strain S45 was isolated from a solid waste-dumping site in Islamabad, Pakistan. Strain S45 was identified as Aspergillus sp. through microscopic, morphologic as well as 18S rRNA sequencing (99% similarity with Aspergillus fumigatus). The degradation ability of strain S45, was analyzed through measurement of weight loss and evolution of CO2 as a result of breakdown of PU film. The degradation was confirmed through scanning electron microscopy, fourier transform infrared (FTIR) spectroscopy and differential scanning calorimetry (DSC). Surface changes like pits, cracks and holes were observed in scanning electron micrographs upon degradation of PU film by strain S45. FTIR spectra were carefully examined, changes were observed in various peaks at different wavelength ranges that also correspond to degradation of PU film. Differential scanning calorimetric technique was used to measure the melting temperature of PU film pieces before and after incubation with strain S45. DSC curve indicated an increase in melting temperature of PU from 191 to 196 °C that might be due to increase in crystallinity of the exposed PU after degradation of amorphous soft segment. A gradual increase in specific activity of esterase was observed up to the maximum of 15th day of incubation with PU film in mineral salt medium. Enzyme activity was further confirmed by tween 20 agar plates, demonstrated by formation of calcium complex. It is concluded from the results that Aspergillus sp. strain S45 might be applied for the treatment of plastics-contaminated environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plastics have changed the world of the material industry due to their good physical strength, resistance to chemicals, high volume to weight ratio and easy production as compared to other materials. An estimated 311 million tons of plastics are produced annually worldwide; 90% of these are derived from petrol. A considerable portion of these plastics is used for packaging, but only ~14% is collected for recycling. Most plastics degrade extremely slowly, thus constituting a major environmental hazard, especially in the oceans, where micro-plastics are a matter of major concern [1, 2]. Use of landfills for disposal of plastic wastes poses a serious threat to natural ecosystem as landfill sites for disposal of plastic waste became limited [3]. Polyurethane (PU) polymer is synthesized by polymerization of different components that include: a diisocyanate, a polyol and different low molecular weight pre-polymer blocks. These different components are joined together to form a PU polymer chain. The ratio and nature of polyols and polyisocynates may vary the infinite structure and formulation of PU that leads to PU with different properties of thermal insulation, conductance, elasticity and resistance. The morphology of PU polymers shown by X-ray diffraction identified specific crystalline and amorphous regions [4, 5]. The crystalline regions of polyisocyanate radicals serve as an extensor that provides strength and hardness to the polymer. The amorphous regions comprise of polyol radicals and have the characteristics of elasticity, absorption and elongation. PU polymer is divided into two sub-groups on the basis of types of polyol used in its synthesis i.e. polyester and polyether type of PU. PUs are insoluble in water and other conventional solvents that includes acetone, methanol, ethanol and isopropanol etc. Their chemical structure is not affected by wide range of pH and temperature etc. In this way chemical degradation has been proved inefficient to eliminate worldwide accumulation of polyurethane waste [6, 7].

Polyurethane resists microbial degradation but generally it was examined that polyester type of PU is more susceptible to microbial attack as compared to polyether type. Different reports in literature reveal susceptibility of PU to bacterial as well as fungal attack. Fungi that have been reported for their ability to utilize polyester PU as carbon source include Curvularia senegalensis, Aureobasidium pullulans, Fusarium solani, and Cladosporium sp., Nectria haematococca, Penicillium viridicatum, P. ochrochloron. Pestalotiopsis microspore, Aspergillus fumigatus and Penicillium chrysogenum [2, 8–11]. Different bacterial isolates including Bacillus subtilis, Pseudomonas fluorescens, Pseudomonas chlororaphis, Pseudomonas aeruginosa and Comamonas acidovorans have also been found to degrade PU [12–15]. Zafar et al., [16] analyzed changes in fungal communities associated with polyester PU coupons after composting at different temperatures. Fusarium solani and Candida ethanolica were found to be dominant organisms under mesophilic (35-37 °C) and thermophilic (45–50 °C) conditions. In our previous study, we reported the role of Pseudomonas sp. AF9, Bacillus sp. AF8, Arthrobacter sp. AF11, Micrococcus sp. AF10, and Corynebacterium sp. AF12 consortia in degradation of PU [17].

Santerre et al. [18] found that although urea and isocyanate are hydrolysable bonds, but are not easily accessible to hydrolytic enzymes. The size of hard segment or crystalline region within PU structure greatly affects the activity of degradative enzymes. When PU is subjected to the action of degrading microorganisms, the degradation of amorphous regions precedes that of crystalline region. Wales and Sagar suggested that degradation of PU is due to combined activity of exopolyurethanases and endopolyurethanases. Endoenzymes cleaves PU at different sites all over the polymer chain that leads to loss of polymer tensile strength while exoenzymes causes cleavage of monomer units [19].

The current study demonstrated the role of newly isolated fungus, Aspergillus sp. strain S45 in degradation of polyester PU. The degradation was analyzed through various techniques such as weight loss, CO2 evolution, scanning electron microscopy (SEM), fourier transform infrared (FTIR) spectroscopy, differential scanning calorimetry (DSC). The involvement of esterase in PU degradation has also been checked through both qualitative and quantitative assays.

Materials and Methods

Materials

Methylene diphenyl diisocyanate (MDI) polyester PU {poly[4,4′-methylene-bis(phenyl isocyanate)-alt-1,4-butanediol/poly (butylene adipate)]} (Fig. 1) pellets were obtained from Sigma-Aldrich, GmbH, Germany. Tetrahydrofuran (THF) was acquired from Panreac Quimica, SA. All other reagents used were commercial products of the highest possible grade available.

Polyurethane Film Preparation

Polyurethane films were prepared by dissolving 1 g of PU pellets in 100 ml of THF and poured equally in 4 clean glass petri dishes. The THF was allowed to evaporate gradually by placing the covered petri dishes in desiccators. It took about 03 days to form thin transparent PU films [13]. This film (~0.2 mm in thickness) was sterilized using 70% ethanol and exposure to UV radiation for 5 min (UV dosage 10,771 J/m2). These films were cut into rectangular pieces of 2 × 4 cm2 dimensions [20] for use in Sturm test, shake flask experiments and soil burial. For SEM, FTIR and DSC analysis the used films were further trimmed to a convenient size.

Isolation of PU-Degrading Fungal Strain

The soil samples were collected in sterilized PU sample bags from plastic waste dumping site in Islamabad. These soil samples were transferred to sterilized pots and placed in dark at room temperature. PU film was buried 4–6 inches deep vertically in pots containing soil. 200 ml of mineral salt medium (MSM) containing glucose was added to the pot at the time of burial, in order to meet the nutrient requirements of microorganisms. The film was recovered from soil after 04 weeks, washed with autoclaved distilled water and shifted to Sabouraud Dextrose agar (SDA) plate aseptically. The plate was incubated at 30 °C for 07 days. After incubation, the film was removed, washed with sterilized distilled water and shifted to fresh SDA plates. The process was repeated several time, finally it was shifted to MSM agar plate and incubated at 30 °C for 30 days. A fungus, designated as strain S45 was selected among 04 different fungal strains, on the basis of maximum growth on surface of PU film. The composition of MSM agar plates was [g/l: K2HPO4 0.5, KH2PO4 0.04, NaCl 0.1, CaCl2·2H2O 0.002, (NH4)2SO4 0.2, MgSO4·7H2O 0.02, FeSO4 0.001, agar–agar 20, pH adjusted to 7.0].

Identification of PU-Degrading Fungal Strain

Colony Morphology and Microscopic Examination

Colony morphology of strain S45 was observed on SDA and various features such as conidial and mycelial color, reverse color, colony diameter etc. were observed The fungus was stained with lacto phenol cotton blue and the diameter of hyphae, conidia, stipe color, vesicle serration, and appearance on slide was observed by compound microscope (Olympus Co. Ltd., Tokyo, Japan).

18S rRNA Sequencing

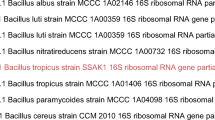

Fungal DNA was extracted according to the method of Zhang et al. [21] protocol with slight modifications. PCR amplification of 18 S rRNA gene was carried out with pair of primers, ITS1(TCCGTAGGTGAACCTGCGG) and ITS4(TCCTCCGCTTATTGATATGC). The standard PCR reaction of 50 µl contain 25 µl PCR master mix (Platinum super mix 2X, Invitrogen), 5 µl each primer (25 pmol/µl), 6 µl template DNA and 9 µl of PCR water to a final volume of 50 µl. The PCR conditions were set as primary denaturation at 96 °C for 5 min, 30 cycles of denaturation were repeated at 94 °C for 30 s, annealing was done at 55 °C for 45 s and extension at 72 °C for 45 s, followed by a final extension at 72 °C for 10 min. PCR product was purified with PCR clean up kit to remove any unincorporated primers and dNTPs and then confirmed by agarose gel electrophoresis. The amplified PCR product was sent to Macrogen, South Korea, for sequencing using ITS1 and ITS4 primers. Sequences were analyzed through DNA baser and further evaluated by comparing the nucleotide sequences available in NCBI database by BLAST search analysis. Phylogenetic tree was constructed from rDNA sequences by using the neighbor-joining method (CLUSTAL software in MEGA 6).

Preparation of Fungal Spore Suspension

Strain S45 was grown on SDA plates for 5 days at 28 °C. Spores were harvested by washing the plate with 0.01% Triton X-100 and scrubbing the spores from the surface with sterile bent glass. The resulting spore suspension was transferred to sterile container and stored at 4 °C. The spores were counted by Haemocytometer and final spore concentration for degradation experiments was calculated as 2 × 105 spores/ml.

Polyurethane Degradation Assays

Weight Loss of PU Film in MSM

A set of 10 Erlenmeyer conical flasks (100 ml), each with 50 ml MSM and 250 mg of PU film pieces (2 × 2 cm) were inoculated with spore suspension of strain S45. The flasks were incubated at 30 °C for 28 days in shaker incubator at 100 rpm. The test was conducted in triplicate with abiotic control (PU film + MSM & without strain S45) in separate for validation of results. PU films were recovered after every 3 days interval and thoroughly washed with distilled water in order to remove the adhering biomass and components of medium. The weight of these films was compared with those recovered from abiotic control after vacuum drying at room temperature. Weight loss can be calculated by using formulae:

\(weight~loss~\% = (initial~weight - final~weight)/initial~weight \times 100\)

Carbon dioxide (CO2) Evolution Test (Sturm test)

The utilization of oxygen and evolution of carbon dioxide as a result of oxidation of carbon by microorganisms under aerobic conditions is used as an indicator for PU degradation. CO2 evolved as a result of PU consumption by strain S45, was trapped and compared with the amount evolved in case of biotic control under similar conditions. Test bottle containing 300 ml MSM with 250 mg of PU film pieces was inoculated with fungal strain, an abiotic (PU + MSM) and biotic (Strain S45 + MSM) control was set up in separate under similar condition. Sterilized air was passed through pre-treatment chamber consisting of two bottles having 3 M KOH for removal of any CO2 already present before bubbling it through culture bottles. Magnetic stirrer was used to stir test and control bottles continuously. The test was performed at room temperature (30 °C) for 28 days. CO2 produced in test and control bottles was trapped in absorption chamber (containing 1 M KOH) and quantified gravimetrically by precipitating soluble carbonates produced in absorption chamber with the addition of 1 M barium chloride and measured its dry mass [22]. Fungal biomass in culture bottles was filtered through whatman filter paper and dried in oven at 60 °C over night before measuring its dry mass.

Analysis of Polyurethane Film Degradation by Fungal Strain S45

Polyurethane film pieces recovered from Sturm test experiment were analyzed for changes in surface morphology, chemical bonds and melting temperature by SEM, FTIR spectroscopy, and DSC, respectively, in comparison with PU films recovered from abiotic control (PU + MSM).

Scanning electron microscopy (SEM)

The surface topology of treated PU films was examined by scanning electron microscopy (MIRA3 TESCAN) in order to find any structural changes after incubation with strain S45. PU film pieces were thoroughly washed with sterilized distilled water and mounted on copper stubs with gold paint. Gold plating was done in vacuum in order to increase the conductivity of the samples. PU film pieces recovered from abiotic control (PU + MSM) were also examined for comparison.

Fourier transform infrared (FTIR) spectroscopy

Fourier transform infrared (FTIR) spectroscopy (Tensor 27, BRUKER, FTIR Series Germany) of PU film was carried out after culturing with strain S45 in MSM in order to examine changes in its functional groups or chemical structure that corresponds to its degradation. For this purpose, the PU film was placed on FTIR sample plate and spectra were taken at 500–4000 wavenumbers cm− 1 in single for each sample, including abiotic control (PU + MSM) for comparison.

Differential Scanning Calorimetry (DSC) Measurement

Differential scanning calorimetry (DSC) technique was used for thermal analysis of treated PU films. For this purpose a Mettler oscillating differential scanning calorimeter (DSC 822e, STARe V.9.00 software, USA) was used. In this process, treated film pieces were placed in a sealed aluminium pan and an empty pan was used as reference. The instrument was calibrated with indium, then samples were scanned at heating rate of 10ºC/min from −60 to 250 °C and finally samples were cooled down at a cooling rate of 10ºC/min to −60 °C. Thermograms of DSC were studied by using Mettler STARe V.9.00 software to find PU melting temperature (Tm) and non-isothermal crystallization temperature (Tc).

Esterase Activity Assays

Quantitative Assay

Strain S45 was inoculated in 100 ml of liquid MSM containing PU films (250 mg) and incubated at 30 °C for 28 days in shaker incubator at 100 rpm. Similar culture without PU films was used as a control. The experiment was run in triplicate. Samples were collected at 3 days interval, centrifuged at 10,000 rpm for 10 min at 4 °C and esterase activity was determined in cell free supernatant using p-nitrophenyl acetate (chromogenic compound) as a substrate and absorbance was recorded at 410 nm by the method of Lesuisse et al. [23]. The amount of p-nitrophenol released as a product is used as an indication of esterase activity (U/ml). Protein concentration was calculated by using method of Lowry et al. [24]. Dry mass of fungi was calculated using method described earlier.

Qualitative Assay for Esterase on Tween 20 Agar

The hydrolytic activity of esterase from strain S45 was determined on tween 20 agar according to the method of Samad et al., [25]. After incubation of strain S45 on tween 20 agar plates, esterase activity was demonstrated as formation of calcium complex that is visible around fungal growth throughout the plate. Calcium complex is formed due to fatty acids released as a result of esterase activity on tween 20 that binds with calcium in the medium. The medium remains clear in absence of esterase. The tween 20 medium is composed of (g/L): Peptone 10 g, NaCl 5 g, CaCl2.2H2O 0.1 g, Agar–agar 20 g, Tween 20 10 mL (v/v).

Results and Discussion

Isolation and Identification of Polyurethane Degrading Fungal Strain

Strain S45 appeared grey green with white margins on agar medium and nascent mycelia turned grey green upon maturity. The common features of strain S45 were matched with the descriptions of genus Aspergillus given in the FUNGUS HANDBOOK: Identification of Common Aspergillus Species [26]. Smooth globulous conidia and hyphae were observed upon microscopic examination after staining with lacto phenol cotton blue. 18 S rRNA sequencing results were analyzed by comparing the nucleotide sequences available in NCBI database by BLAST search analysis. The phylogenetic analysis of 18 S rRNA revealed that strain S45 belongs to genus Aspergillus having 99% similarity with A. fumigatus (KF961003). The nucleotide sequence reported here can be obtained from NCBI nucleotide sequence database under accession number KU948302.

Degradation of PU has been attributed to both bacteria and fungi, and various researchers have isolated PU-degrading microorganisms from different habitats [27]. PU-degrading bacteria, Bacillus subtillus MZA-75 [13] and P. aeruginosa MZA-85 [14] has already been reported by our group. Crabbe et al. [8] isolated four PU-degrading fungal strains from soil that includes F. solani, C. senegalensis, Cladosporium sp. and A. pullulans. These species has the capability to utilize PU as carbon and energy source. Boubendir [28] also reported PU-degrading fungal strains, Aspergillus terreus and Chaetomium globosum isolated from environmental samples.

Polyurethane Degradation by Aspergillus fumigatus Strain S45

Measurement of Weight Loss

Polyurethane film degradation ability of A. fumigatus S45 was determined in minimal salt medium by measuring its weight loss at different time intervals. Figure 2 shows the time course of PU film degradation at 30 °C within 28 days. The rate of degradation was slow and 15–20% decrease in weight was observed till the end of experiment. Recently, a consortium of strain MZA-75 and −85 has been developed that could degrade PU more efficiently as compared to individual strain [15]. During PU film degradation, an esterase activity was detected in the culture broth. Enzymes that degrade solid substrates possess certain properties that enable them to adsorb to the surface of substrates. It has been reported that a hydrophobic protein adheres to the plastic surface at first and then drags a plastic-degrading enzyme on to its surface [29, 30]. PU films in un-inoculated (abiotic) control were also incubated for 28 days for comparison.

CO2 Evolution

Strain S45 was used in case of Sturm test and its degradation efficiency against PU was studied in terms of difference in CO2 evolved both in test as well as control vessels (biotic and abiotic). High amount of CO2 was recovered after quantification in test vessel as compared to both biotic and abiotic control, as shown in Table 1. CO2 evolution test has been used to evaluate biodegradability of photosensitized polyethylene (PE), starch-PE, extensively plasticized polyvinyl chloride (PVC), and polypropylene (PP) [31]. Different methodologies and modifications have been proposed regarding measurement of carbon dioxide evolved during degradation of polymers as well as aliphatic and aromatic compounds [32].

Analysis of Degradation of PU Film by Strain S45

Fourier Transform Infrared Spectroscopy (FTIR) of PU Film

FTIR spectrum is indicative of degradative changes in soft segment of the polyester PU (Fig. 3). A peak at 2956.2 (representing vibration of C-H in aliphatic CH2) has substantially been decreased in intensity in FTIR spectrum of test sample as compared to abiotic control. Since a bulk of aliphatic CH2 is present in the soft segment of PU, reduction in intensity of peak may represents breakdown of polymer chain. Another peak at 1725 cm− 1 corresponds to stretching of ester functional group, almost disappeared in spectrum of treated PU films. Shen et al., [33] attributed the peak at 1725 cm− 1 to ester stretching in the PU soft segment, a substantial decrease in its intensity may be due to decrease in ester linkages during breakdown of the soft segment. In addition, a peak at 1146 cm− 1 represents symmetric stretching of C–O–C in polymer chain. Pramanik et al. [34] in his In vitro study of surface modified poly(ethylene glycol)-impregnated sintered bovine bone scaffolds on human fibroblast cells correlated this signal to symmetric ether stretching.

Fourier Transform Infra Red (FT-IR) spectra of PU film pieces before and after incubation with strain S45 in Sturm Test for 30 days. Both test (B) and control (A) spectra are compared. Arrows represent position of peaks disappeared or decreased in intensity after treatment of the PU film with Aspergillus fumigatus S45

Scanning Electron Microscopy of PU Film

The changes in surface morphology of the treated PU films were analyzed by scanning electron microscopy. SEM micrographs showed emergence of deformities in the surface of PU film by the test strain S45. Fungal growth can be observed in SEM micrographs on PU surface in the form of hyphae and spores (Fig. 4). The adhesion of spores and hyphae to the surface of PU demonstrated the establishment of a biofilm that leads towards PU degradation [35]. Here, the SEM micrographs showed changes in surface morphology of PU film such as appearance of pits and holes. Likewise, the Alicycliphilus sp [36]. and Comamonas acidovorans TB35 [37] have already been reported that deteriorate the surface morphology of PU film in the form of pits and holes, as examined by SEM.

Scanning electron micrographs (SEM) of PU films pieces after incubation with strain S45 in Sturm Test for 30 days. a Micrographs of abiotic control taken at different magnification b Micrographs of test samples before washing (x1.0 K, x2.5 K and x5.0 K); fungal hypae and spore could easily be seen attached to PU film c Micrographs of test samples after washing (x1.0 K, x2.5 K and x5.0 K); holes in PU film can be seen at different magnification. It revealed the involvement of strain S45 in PU film degradation

Differential Scanning Calorimetry (DSC) of PU Film

DSC analysis was carried out for PU films before and after culturing with strain S45 in MSM. The melting temperature (Tm) of treated PU film was increased from 191 ̊C to 196 ̊C that represents changes in morphology of PU film after degradation (Fig. 5; Table 2). PU is semicrystalline segmented polymer consisting of polyisocyanate with crystalline hard segment and polyester polyol soft segment which is amorphous in nature (Fig. 1). Jenkins and Harrison [38] while studying enzymatic degradation of a semicrystalline polymer polycaprolactone observed increase in crytallinity of polymer, attributed to prefrential degradation of the soft segment by the enzyme. In our study, the rise in melting temperature after treatment may be the result of similar increase in crystallinity of the exposed PU sample. Prestsch et al. [39] prepared polyester urethanes using methylene-bis(4-phenylisocyanate) (MDI), butandiol and polyadipate diol and studied its accelerated degradation in distilled water at 80 °C using DSC. He observed increase in melting peaks as well as crystallinity of the polymer after treatment. Coelho et al. [40] also used this technique to identify changes in polyethylene polymer after degradation. Like wise, Tatai et al. [41] carried out DSC analysis in order to find out the effect of chain extender on properties and in vitro degradation of PU.

Differential Scanning Calorimetry thermograms taken for PU films after incubation with strain S45 in Sturm Test for 30 days. a Abiotic control, b Test sample. The melting temperature (Tm) of treated PU film was increased from 191 to 196 °C that represents chemical changes in structure of PU film after degradation

Enzyme Activity Assays

Specific activity of esterase enzyme was increased steadily from 0.1440 µM/Min/mg at day one and reached its maximum upto 2.687 µM/Min/mg at day 15 and then dropped to 0.2953 µM/Min/mg till day 27 in the presence of PU as sole source of carbon in comparison to control (Fig. 6a). The role of esterase enzyme in degradation of PU has already been reported in our previous study [42]. Mathur and Prasad [43] detected the activity of esterase enzyme from Aspergillus flavus in cell free supernatant after 30 days of incubation, using p-nitrophenyl acetate as substrate. Both the FTIR and DSC analysis clearly indicates breakdown of polymer as a result of hydrolysis of ester linkages connecting soft segments. The cleavage of ester bonds accompanied by gradual increase in esterase activity during the time course experiment substantiated our belief that esterase might have catalyzed the degradation of polymer chain. Different authors have found polyester PU degrading enzyme from different microbial strains that catalyze ester hydrolysis [19, 44, 45].

Production of esterase enzyme was confirmed by both quantitative and qualitative assays. a Specific activity of esterase enzyme in cell free supernatent during inbuation of PU film pieces with Aspergillus fumigatus strain S45 in MSM as sole source of carbon. The samples were taken at 3 day interval upto the maximum of 27 days. A gradual increase in esterase activity (closed circle) and growth (closed triangle) was observed till 15th day of incubation followed by a decrease till the end of experiment. b Production of esterase was checked on Tween 20 agar plate. The hydrolytic activity of esterase was demonstrated by formation of calcium complex that was visible around fungal growth. Calcium complex was formed due to fatty acids released as a result of esterase activity on tweens 20 that bound with calcium in the medium

Tween 20 Agar Plate Assay for Esterase Activity

Aspergillus fumigatus strain S45 was inoculated on Tween 20 agar plate. After inoculation and incubation of test strain, hydrolytic activity of esterase was demonstrated by formation of calcium complex that was visible around fungal growth. Fatty acids were released as a result of esterase activity on tweens 20 that bound with calcium in the medium and formed calcium complex. The medium remained clear in the absence of esterase enzyme (Fig. 6b). Kumar et al. [45] also used tween 20 agar plates to analyze the hydrolytic activity of Bacillus sp. DVL2 lipase/esterase enzyme. Emanuilova et al. [46] used tween (fatty acid esters of poly-oxy-ethylene sorbitan) agar plates for the detection of Bacillus lipase/esterase activity.

Conclusion

The results presented here demonstrated that A. fumigatus strain S45 has capability to degrade PU. Aspergillus species have been found to cause serious respiratory infections in immuno-compromised people [47–51] such as chronic obstructive pulmonary disease, asthma, cystic fibrosis [52], however A. fumigatus and its purified enzymes can be used in a contained environment for degradation of the polyester PU. Furthermore it is concluded that microorganisms capable of efficiently degrading PU can be isolated from soil that could be applied for the treatment of plastics-contaminated environments.

References

MacArthur DE, Waughray D, Stuchtey MR (2016) New Plast Econ Rethink Future Plast. http://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf

Law KL, Thompson RC (2014) Science 345:144

Mukherjee K, Tribedi P, Chowdhury A, Ray T, Joardar A, Giri S, Sil AK (2011) Biodegradation 22:377

Loredo-Treviño A, Gutiérrez-Sánchez G, Rodríguez-Herrera R, Aguilar CN (2012) J Polym Environ 20:258

Rahman M, Brazel CS (2004) Prog Polym Sci 29:1223

Urgun-Demirtas M, Singh D, Pagilla K (2007) Polym Degrad Stab 92:1599–1610

Liggat J, Pethrick R, Rhoney I (2005) Google Pat

Crabbe JR, Campbell JR, Thompson L, Walz SL, Schultz WW (1994) Int Biodeterior Biodegrad 33:103–113

Morton L, Surman S (1994) Int Biodeterior Biodegrad 34:203

Cosgrove L, McGeechan PL, Handley PS, Robson GD (2010) Appl Environ Microbiol 76:810

Álvarez-Barragán J, Domínguez-Malfavón L, Vargas-Suárez M, González-Hernández R, Aguilar-Osorio G, Loza-Tavera H (2016) Appl Environ Microbiol 82(17):5225

Howard GT (2011) Rec Dev Polym Recycl. ISBN: 978-81-7895-524-7

Shah Z, Hasan F, Krumholz L, Aktas DF, Shah AA (2013) Int Biodeterior Biodegrad 77:114

Shah Z, Krumholz L, Aktas DF, Hasan F, Khattak M, Shah AA (2013) Biodegradation 24:865

Shah Z, Gulzar M, Hasan F, Shah AA (2016) Polym Degrad Stab 134:349

Zafar U, Houlden A, Robson GD (2013) Appl Environ Microbiol 79(23):7313

Shah AA, Hasan F, Akhter JI, Hameed A, Ahmed S (2008) Annal Microbiol 58:381

Santerre J, Labow R, Duguay D, Erfle D, Adams G (1994) J Biomed Mater Res 28:1187

Wales DS, Sagar BR (1988) Mechanistic aspects of polyurethane biodeterioration. In: Houghton DR, Smith RN, Eggins HOW (eds) Biodeterioration, 7th edn. Elsevier Applied Science, London

Ikram A, Alias O, Napi D (2000) J Rubb Res 3:104

Zhang Y, Zhang S, Liu X, Wen H, Wang M (2010) Lett Appl Microbiol 51:114

Müller R, Augusta J, Pantke M (1992) Mater Organ. (Germany) 27:17

Lesuisse E, Schanck K, Colson C (1993) Eur J Biochem 216:155

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) J Biol Chem 193:265

Samad MYA, Razak CNA, Salleh AB, Yunus WMZW, Ampon K, Basri M (1989) J Microbiol Methods 9:51

Klich MA (2002) Indentification of common Aspergillus species. Centraalbureau voor schimmelcultures, Utrecht

Howard GT (2012) Polyurethane biodegradation. In: Singh SN (ed) Microbial degradation of xenobiotics. Springer, Berlin

Boubendir A (1992) Purification and biochemical evaluation of polyurethane degrading enzymes of fungal origin. University of Salford, Manchester. EThOS ID: uk.bl.ethos.304605.

Shah AA, Nawaz A, Kanwal L, Hasan F, Khan S, Badshah M (2015) Int Biodeterior Biodegrad 98:35–42

Ohtaki S, Maeda H, Takahashi T, Yamagata Y, Hasegawa F, Gomi K, Nakajima T, Abe K (2006) Appl Environ Microbiol 72:2407

Yabannavar AV, Bartha R (1994) Appl Environ Microbiol 60:3608

Kim MN, Lee BY, Lee IM, Lee HS, Yoon JS (2001) J Environ Sci Health 36:447

Shen Z, Wang J, Lu D, Li Q, Zhou C, Zhu Y, Hu X (2015) BioMed Res Int 798721:11

Pramanik S, Ataollahi F, Pingguan-Murphy B, Oshkour AA, Osman NAA (2015) Scientifice Reports 5. doi. 10.1038/srep09806

Howard GT, Ruiz C, Hilliard NP (1999) Int Biodeterior Biodegrad 43:7

Oceguera-Cervantes A, Carrillo-García A, López N, Bolaños-Nuñez S, Cruz-Gómez MJ, Wacher C, Loza-Tavera H (2007) Appl Environ Microbiol 73:6214

Akutsu Y, Nakajima-Kambe T, Nomura N, Nakahara T (1998) Appl Environ Microbiol 64:62

Jenkins MJ, Harrison KL (2008). Polym Adv Technol 19:1901

Pretsch T, Jakob I, Müller W. (2009). Polym Degrad Stab 94:61

Coelho A, Costa L, Das Mercês Marques M, Fonseca I, Lemos MA, Lemos F (2010) React Kinet Mech Catal 99:5

Tatai L, Moore TG, Adhikari R, Malherbe F, Jayasekara R, Griffiths I, Gunatillake PA (2007) Biomaterials 28:5407

Ibrahim IN, Maraqa A, Hameed KM, Saadoun IM, Maswadeh HM, Nakajima-Kambe T (2009) Adv Environ Biol 3:162

Mathur G, Prasad R. (2012) Appl Biochem Biotechnol 167:1595

Crabbe JR, Campbell JR, Thompson L, Walz SL, Schultz WW (1994) Int Biodeter Biodegrad 33:103–113

Kumar D, Kumar L, Nagar S, Raina C, Parshad R, Gupta VK (2012) Arch Appl Sci Res 4:1763

Emanuilova E, Kambourova M, Dekovska M, Manolov R (1993) FEMS Microbiol Lett 108:247

Boyacioglu H, Haliki A, Ates M, Guvensen A, Abaci O (2007) Environ Monit Assess 135(1–3):327

Varani S, Stanzani M, Paolucci M, Melchionda F, Castellani G, Nardi L, Landini MP, Baccarani M, Pession A, Sambri V (2009) J Infect 58(5):346

Jain S, Nag V, Marak RSK, prasad N, Dhole T (2010) Int J Infect Dis 14(1):e206

Hedayati MT, Mayahi S, Denning DW (2010) Environ Monit Assess 168(1–4):481

Uztan AH, Ates M, Abaci O, Gulbahar O, Erdem N, Ciftci O, Boyacioglu H (2010) Environ Monit Assess 168(1–4):691

Baxter CG, Jones AM, Webb K, Denning DW (2011) J Microbiol Methods 85(1):75

Acknowledgements

We are thankful to Quaid-i-Azam University for providing necessary funds in order to accomplish experimental work in this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Osman, M., Satti, S.M., Luqman, A. et al. Degradation of Polyester Polyurethane by Aspergillus sp. Strain S45 Isolated from Soil. J Polym Environ 26, 301–310 (2018). https://doi.org/10.1007/s10924-017-0954-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0954-0