Abstract

The production of γ-decalactone and 4-hydroxydecanoic acid by the psychrophilic yeast R. aurantiaca was studied. The effect of both compounds on the growth of R. aurantiaca was also investigated and our results show that γ-decalactone must be one of the limiting factors for its production. The addition of gum tragacanth to the medium at concentrations of 3 and 4 g/l seems to be an adequate strategy to enhance γ-decalactone production and to reduce its toxicity towards the cell. The production of γ-decalactone and 4-hydroxydecanoic acid was significantly higher in 20-l bioreactor than in 100-l bioreactor. By using 20 g/l of castor oil, 6.5 and 4.5 g/l of γ-decalactone were extracted after acidification at pH 2.0 and distillation at 100 °C for 45 min in 20- and 100-l bioreactors, respectively. We propose a process at industrial scale using a psychrophilic yeast to produce naturally γ-decalactone from castor oil which acts also as a detoxifying agent; moreover the process was improved by adding a natural gum.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lactones are widely distributed in foods and beverages as aroma compounds. Among these compounds, γ-decalactone has characteristic peach and apricot flavors. This aroma compound is produced by biotechnological ways using microorganisms, mainly yeast strains [1–4]. The use of castor oil, ricinoleic acid or its methyl ester has been extensively employed for the microbial production of γ-decalactone [5]. Ricinoleic acid is degraded by four successive cycles of β-oxidation into 4-hydroxydecanoic acid which lactonizes to γ-decalactone [6]. γ-Decalactone concentrations in this process were reported from a few milligrams per litre up to 11 g/l [7]. The principal problem for the industrial production of lactones is that their accumulation in culture broth is strongly limited by their toxicity against the producing cells [8]. For that, it is necessary to maintain the concentration of volatile compounds in the fermentation medium below a certain level due to its inhibitory effect on microbial growth.

Some strategies have been developped to reduce lactone toxicity within the fermentation medium. The most common methods used to remove organic compounds from fermentation medium involve solvent extraction, trapping in vegetable oils, adsorption on activated carbon and porous hydrophobic polymers. β-Cyclodextrins were used to extract numerous compounds by inclusion, for instance they allowed an increase in some production yields such as the bioconversion of alcohols into the corresponding aldehydes [9]. Three techniques (in situ trapping in oily phases, on porous hydrophobic sorbents and on β-cyclodextrins) were studied to overcome the toxicity of γ-decalactone produced by Sporidiobolus salmonicolor using ricinoleic acid as precursor of the lactone [10]. Oily phases added to the media (olive, Miglyol and paraffin) had a protective effect on Sporidiobolus salmonicolor. The results of the trapping of γ-decalactone on β-cyclodextrins were shown insufficient for the preservation of cell viability. The adsorption of γ-decalactone on activated carbon and porous hydrophobic polymers (Porapak Q, Chromosorb 105 and SM4) is a suitable method to extract this molecule from aqueous medium [11]. These authors reported that the presence of adsorbents in the biotransformation medium allowed a very low concentration and it limited the toxicity of the lactone towards the yeast Sporidiobolus salmonicolor.

We have previously investigated the effects of temperature, initial pH and castor oil concentration on the production of γ-decalactone by the psychrophilic strain of the yeast Rhodotorula aurantiaca A19 [12]. The yeast was unable to grow at 20 °C. The inability of the yeast to grow at temperatures close to 20 °C is associated with profound alterations in morphology and integrity [13]. The use of a psychrophilic microorganism in a process may allow to decreace the working temperature and thus to save energy. In this paper, the production and the toxicity of γ-decalactone and 4-hydroxydecanoic acid from R. aurantiaca were studied. The production of γ-decalactone was then improved by using gum tragacanth as surfactant and the process was submitted to scaling up.

Materials and Methods

Yeast Cultures and Media

Rhodotorula aurantiaca is a psychrophilic strain previously isolated near the Antarctic Station Dumont d’Urville and deposited at the Mycotheque of the University of Louvain-la-neuve (MUCL) under registration N° 40267 [14]. This yeast was used in the present study for γ-decalactone production. It was maintained on 868 agar plates (868 media consisted of 6 g/l of peptone casein, 3 g/l of yeast extract, 20 g/l of glucose and 17 g/l of agar) at 12 °C. Before use, the strain was activated in 863 broth which consisted of the following ingredients: 6 g/l peptone casein, 3 g/l yeast extract and 20 g/l of glucose.

The seed culture used was 10% (v/v) of the working volume of reactor and was prepared by inoculating 863 broth (100 ml) with a loopful of yeast cells from isolated colonies of a fresh culture (5 days) on 868 agar at 12 °C. This preculture was incubated under agitation (150 rpm) for 4 days then transferred in 863 broth (1 litre) which was incubated for 3 days in the same conditions. The culture obtained was used as a seed culture for the biotransformation medium for reactor experiments.

Biotransformation of Castor Oil into γ-Decalactone

The biotransformation of castor oil (VWR, Belgium) or ricinoleic acid (Sigma, Belgium) into γ-decalactone was carried out in media containing 6 g/l of peptone casein, 3 g/l of yeast extract and 20 g/l of castor oil (or 20 g/l of ricinoleic acid). The effect of gum arabic (VWR, Belgium), gum xanthan (VWR, Belgium) and gum tragacanth (VWR, Belgium) on the production of γ-decalactone was performed in a series of Erlenmeyer flasks containing the biotransformation medium with variable concentration of each gum ranging from 0 to 4 g/l.

All fermentations were performed in a 20- and a 100-l reactor (Biolafitte, France) with an effective volume of 14 and 70 l, respectively. All fermentor trials were conducted with aeration (1.5 vvm) and at constant temperature (12 °C), pH (6.8) and agitation (250 rpm), by online control using the Freelance 2000 software. The pH was controlled by automatic addition of 6 M NaOH and 6 M H3PO4 solutions.

4-Hydroxydecanoic Acid Preparation

4-hydroxydecanoic acid was obtained by saponification of γ-decalactone as described by Feron et al. [15]; γ-decalactone (5 g) was saponified in 100 ml of KOH-methanol (15%, w/v) solution. After 2 hours of refluxing, the solution was cooled with 100 ml of distilled water and washed twice with distilled pentane to recover the unsaponified phase. The organic phase was discarded, and the aqueous phase was concentrated under vacuum by rotary evaporation to a final volume of 25 ml. The pH of this solution was adjusted to 8.0 with concentrated HCl. Then 5 g of CaCl2 was added to the acidified solution until a precipitate formed. The precipitate was recovered after 10 min of centrifugation at 2,000 × g. The resulting crystals were washed three times with double-distilled water. After the precipitate was redissolved in phosphate buffer (pH 8.0), the solution was used for the toxicity experiments.

Toxicity Studies

Cultures of R. aurantiaca were grown in 250 ml containing 100 ml of the medium 863 supplemented with γ-decalactone and 4-hydroxydecanoic acid at concentrations ranging from 0.1 to 0.5 g/l. The flasks were inoculated and incubated as described above. Biomass was evaluated in this experiment by measuring the apparent optical density at 650 nm using the turbidimetrical method.

Cell Dry Weight Determination

Cell dry weight was determined after the elimination of the fatty fraction of culture medium as described by Alchihab et al. [12].

γ-Decalactone and 4-Hydroxydecanoic Acid Extraction

γ-decalactone was extracted from a 25-ml sample of the culture medium of R. aurantiaca. 25 ml of distilled water were added to improve distillation process. Subsequently, the pH of the mixture was adjusted at 2.0 with 3 N HCl [15] and 25 mg of γ-valerolactone (internal standard) were added. Afterwards, the solution was submitted to hydrodistillation and about 40 ml of volatile distillate were collected. γ-decalactone extraction was performed by a liquid-liquid (1:1) method using diethyl ether. The ether layer was recovered and dehydrated by anhydrous Na2SO4. 4-hydroxydecanoic acid was extracted before acidifying the medium as described by Feron et al. [15] (10 ml of medium at pH 6.8 were extracted using 10 ml of diethyl ether containing 0.5 g/l of γ-valerolactone as an internal standard).

GC quantification was performed using a Hewlett-Packard 5890 series II (Palo Alto, CA, USA) gas chromatography equipped with a flame ionisation detector and an Alltech AT.AQUAWAX column (30 m × 0.25 mm ID, film thickness 0.25 µm). Oven temperature was held at 40 °C for 2 min, raised to 225 °C at a rate of 10 °C/min then fixed at 225 °C for 10 min. Injector and detector temperatures were 200 and 250 °C, respectively. The carrier gas, helium, was adjusted to a linear velocity 1 ml/min and 0.5 bars. 1-µl samples were injected into the GC apparatus.

Results and Discussion

Effect of Substrate on the Production of γ-Decalactone by R. aurantiaca

Preliminary experiments were done to compare the production of γ-decalactone by R. aurantiaca using pure ricinoleic acid (2%, w/v), castor oil (2%, w/v) or olive oil (2%, w/v) in shake-flask cultures. No significant difference was observed in γ-decalactone production with castor oil and ricinoleic acid. The production of γ-decalactone was around 5.2 g/l after 10 days of culture. In the same conditions by using olive oil as substrate, no traces of lactones were detected by GC-MS (data not shown). This can be related to the lack of hydroxylation activities of the fatty acids in a γ or δ-position, and therefore indicates that R. aurantiaca uses a hydroxylated precursor in its culture broth for the production of lactones. These results demonstrate that castor oil is convenient for the development of an industrial process for the production of γ-decalactone in a large-scale bioreactor owing to its cost by comparison with pure ricinoleic acid. Lipase activity was also assayed, but no detectable activity was measured in the culture broth although large amounts of oil were used.

Toxicity of 4-Hydroxydecanoic Acid and of γ-Decalactone

We previously reported that there is a decrease in growth of R. aurantiaca during the biotransformation of castor oil into γ-decalactone [12]. This could be due to a toxic effect of γ-decalactone and/or of 4-hydroxydecanoic acid. In order to assess the effect of these molecules on the growth of R. aurantiaca, different γ-decalactone and 4-hydroxydecanoic acid concentrations were added to a medium containing glucose as carbon source (Fig. 1). The growth of R. aurantiaca in the presence of 100 mg/l was not altered and it was significantly reduced with 300 mg/l of γ-decalactone. Above 400 mg/l of γ-decalactone the growth of R. aurantiaca is totally inhibited (Fig. 1a). By contrast, R. aurantiaca was able to grow in the presence of all the 4-hydroxydecanoic acid concentrations tested. The growth of R. aurantiaca in the presence of 100 mg/l of 4-hydroxydecanoic acid was not affected and it was similar to that in the absence of the acid (Fig. 1b). These results show that 4-hydroxydecanoic acid is much less toxic towards R. aurantiaca than γ-decalactone.

γ-Decalactone is one of the limiting factors for its production by R. aurantiaca, since it affects the yeast growth in the biotransformation medium. Comparable data were reported for Sporidibolus species by Feron et al. [15] who observed that no cell multiplication occurred with lactone concentrations of more than 100 mg/l for S. salmonicolor and with more than 300 mg/l for S. ruinenii.

The antimicrobial properties of some lactones were also reported: for example, 2-deceno-δ-lactone, at a concentration of 100 mg/l inhibits the growth of bacteria [16]. Also, 6-pentyl-α-pyrone is toxic towards a producing strain of Trichoderma viride [17]. γ-Decalactone was reported to inhibit the growth of the producing yeast Yarrowia lipolytica [18]. These authors demonstrated the strong interaction of γ-decalactone with model phospholipids and with cell membranes, leading to an increase of their fluidity and notably to a decrease of the yeast H+-ATPase activity. Therefore they suggest that these are the mechanisms underlying the toxic effects of γ-decalactone towards Yarrowia lipolytica. Whereas the acidic form (4-hydroxydecanoic acid) may be charged in the medium (pH 6.8) and thus it may not interact with the hydrophobic cell membranes as does the neutral γ-decalactone. Moreover, it was reported that the presence of a hydroxyl group on short-chain fatty acids decreases the toxicity towards microorganisms [19].

Effect of Gum Arabic, Gum Xanthan and Gum Tragacanth on the Production of γ-Decalactone by R. aurantiaca

In an attempt to enhance the production of γ-decalactone and reduce the toxicity of lactone, R. aurantiaca was cultured in presence of different natural gums (gum arabic, gum xanthan and gum tragacanth). These experiments were performed in a series of Erlenmeyer flasks containing the biotransformation medium with variable concentrations of each gum (0 to 4 g/l). The effect of the addition of the gum arabic and gum xanthan on the growth of R. aurantiaca and the production of γ-decalactone was similar to the control (data not shown). The influence of gum tragacanth on the growth and the production of γ-decalactone is summarised on Fig. 2. The gum tragacanth had a significant effect on the growth and the production of γ-decalactone by R. aurantiaca. The cell dry weight was maximal in presence of the gum tragacanth at concentrations of 3 and 4 g/l (Fig. 2a). The yield of γ-decalactone in medium containing 1 or 2 g/l of gum tragacanth was almost similar to the control. The highest concentration recorded (5.7 g/l) was obtained with the gum tragacanth at 3 and 4 g/l after 10 days of culture (Fig. 2b).

The gum tragacanth plays an important role as surfactant in the biotransformation of castor oil into γ-decalactone. The reasons for the improvement of the cell dry weight and γ-decalactone production by R. aurantiaca with the addition of gum tragacanth are not clear. However, this could be linked to an enhancement in oxygen transfer and solubility in the medium. Gomes et al. [20] reported that the addition of small amounts of Tween 80 to the medium strongly increase the oxygen transfer and thus improved γ-decalactone production by Yarrowia lipolytica. It could also be linked to the formation of small oil globules that would increase the contact surface of the oil phase, turning it more accessible to the cells [21].

The gum may also form complexes with γ-decalactone. Consequently, it contributes as a continuous extraction system for the lactone produced by the microbial cells. Similar results were reported by Vernocchi et al. [22] who observed that the addition of starch to the liquid media resulted in a significant enhancement of the production of primary and secondary metabolites including γ-decalactone and γ-octalactone. They found that the overproduction of γ-decalactone by yeasts and lactobacilli can be attributed to the ability of this hydrocolloid to reduce the lactone toxicity. Misharina et al. [23] observed also that γ-heptalactone and γ-decalactone were strongly sorbed by starch and chitosan.

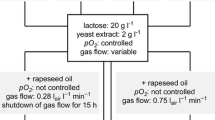

Production of γ-Decalactone and 4-Hydroxydecanoic Acid by R. aurantiaca in 20- and 100-l Bioreactors

To scale up γ-decalactone production, culture of R. aurantiaca was performed in a 20- and 100-l bioreactors with 14 and 70 litres of medium of biotransformation containing 2% (w/v) castor oil and 3 g/l gum tragacanth. In biotransformation medium, R. aurantiaca produced both γ-decalactone and its precursor 4-hydroxydecanoic acid. Maximum γ-decalactone (2.2 and 1.5 g/l) and 4-hydroxydecanoic acid (4.2 and 3.1 g/l) concentrations were obtained at a medium pH of 6.8 in a 20- and a 100-l bioreactor, respectively (Fig. 3). These values are higher than the γ-decalactone and 4-hydroxydecanoic acid concentrations shown in Fig. 1, but within the biotransformation medium part of γ-decalactone can be trapped in the castor oil fraction [11]. The data demonstrated that castor oil, which was used as a carbon energy source by the yeast, acts as an extractant of the lactone, thereby castor oil is here a detoxifying agent. Cell growth, 4-hydroxydecanoic acid and γ-decalactone production were monitored as a function of time.

To obtain a complete lactonization, the medium was acidified at pH 2.0 and distillated at 100 °C for 45 min. After 6 days of culture, the concentration of γ-decalactone obtained by R. aurantiaca was around 6.5 and 4.5 g/l in 20- and 100-l bioreactor, respectively (Fig. 3). The 100-l culture led to a γ-decalactone production lower than in the 20-l bioreactor. This difference is related to the decrease in cell growth (Fig. 3). The biomass of R. aurantiaca in a 20-L bioreactor was higher than that in 100-L, this can be attributed to a better oxygen transfer and solubility in the smaller reactor.

Consequently, the bioproduction of γ-decalactone with R. aurantiaca includes a 2-step procedure, i.e. the biotransformation of ricinoleic acid (the main fatty acid of castor oil) into 4-hydroxydecanoic acid and the lactonization of this acid (after acidification and heating). Moreover, owing to the controlled and optimized culture conditions in bioreactor, this yield of γ-decalactone production was obtained after 6 days as compared with 10 days in shake-flask cultures.

Conclusion

A decreace in growth of R. aurantiaca was observed and this was related to the toxicity of γ-decalactone. The addition of gum tragacanth to the biotransformation medium protected the yeast cells and enhanced the production of γ-decalactone. This gum appears suitable for large scale microbial γ-decalactone production.

References

Spinnler, H. E., Dufossé, L., Souchon, I., Latrasse, A., Piffaut-Juffard, C., Voilley, A., et al. (1994). French patent No. 2705971.

Endrizzi, A., Pagot, Y., Le Clainche, A., Nicaud, J. M., & Belin, J. M. (1996). Critical Reviews in Biotechnology, 16, 301–329.

Pagot, Y., Endrizzi, A., Nicaud, J. M., & Belin, J. M. (1997). Letters in Applied Microbiology, 25, 113–116.

Wang, X. D., Mauvais, G., Cachon, R., Diviès, C., & Féron, G. (2000). Journal of Bioscience and Bioengineering, 90, 338–340.

Janssens, L., De Pooter, H. L., Schamp, N. M., & Vandamme, E. J. (1992). Process Biochemistry, 27, 195–215.

Gatfield, I. L., Güntert, M., Sommer, H., & Werkhoff, P. (1993). Chemie Mikrobiologie Technologie der Lebensmittel, 15, 165–170.

Rabenhorst, J., & Gatfield, I. (2000). Patent WO 0024920.

Aguedo, M., Waché, Y., Mazoyer, V., Sequeira-Le Grand, A., & Belin, J. M. (2003). Journal of Agricultural and Food Chemistry, 7, 3007–3011.

Bar, R. (1989). Trends in Biotechnology, 7, 2–4.

Dufossé, L., Souchon, I., Feron, G., Latrasse, A., & Spinnler, H. E. (1999). Biotechnology progress, 15, 135–139.

Souchon, I., Spinnler, H. E., Dufossé, L., & Voilley, A. (1998). Biotechnology Technique, 12, 109–113.

Alchihab, M., Destain, J., Aguedo, M., Majad, L., Ghalfi, H., & Wathelet, J. P. (2009). Applied Biochemistry and Biotechnology, 158, 41–50. doi:10.1007/s12010-008-8297-x.

Sabri, A., Baré, G., Jaques, P., Jabrane, A., Ongena, M., & Van Heugen, J. C. (2001). The journal of Biological Chemistry, 276, 12691–12696.

Sabri, A., Jacques, P., Weekers, F., Baré, G., Hiligsmann, S., & Moussaïf, M. (2000). Applied Biochemistry and Biotechnology, 84–86, 391–399.

Féron, G., Dufossé, L., Pierard, E., Bonnarme, P., Le-Quere, J. L., & Spinnler, H. E. (1996). Applied and Environmental Microbiology, 62, 2826–2831.

Nago, H., Matsumoto, M., & Nakai, S. (1993). Bioscience Biotechnology and Biochemistry, 57, 2107–2110.

Bonnarme, P., Djian, A., Latrasse, A., Feron, G., Giniès, C., & Durand, A. (1997). Journal of Biotechnology, 56, 143–150.

Aguedo, M., Beney, L., Waché, Y., & Belin, J. M. (2003). Journal of Applied Microbiology, 94, 258–265.

Viegas, C. A., & Sa-Correia, I. (1995). Enzyme and Microbial Technology, 17, 826–831.

Gomes, N., Aguedo, M., Teixeira, J., & Belo, I. (2007). Biochemical Engineering Journal, 35, 380–386.

Waché, Y., Bergmark, K., Courthaudon, J. L., Aguedo, M., Nicaud, J. M., & Belin, J. M. (2000). Letters in Applied Microbiology, 30, 183–187.

Vernocchi, P., Ndagijimana, M., Serrazanetti, D., Gianotti, A., Vallicelli, M., & Guerzoni, M. E. (2008). Food Chemistry, 108, 1217–1225.

Misharina, T. A., Terenina, M. B., Krikunova, N. I., & Kalinchenko, M. A. (2006). Applied Biochemistry and Biotechnology, 42, 111–115.

Acknowledgement

We thank the government of Syria for their financial support to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alchihab, M., Destain, J., Aguedo, M. et al. The Utilization of Gum Tragacanth to Improve the Growth of Rhodotorula aurantiaca and the Production of γ-Decalactone in Large Scale. Appl Biochem Biotechnol 162, 233–241 (2010). https://doi.org/10.1007/s12010-009-8739-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-009-8739-0