Abstract

Among 18 psychrophilic strains isolated near the Antarctic Station, the psychrophilic strain Rhodotorula aurantiaca A19 was selected for its ability of growth and γ-decalactone production at low temperatures. The effects of temperature, initial pH, and castor oil concentration on the growth and γ-decalactone production by a psychrophilic and a mesophilic strain of R. aurantiaca were investigated. The highest γ-decalactone production in flasks (5.8 g/l) was obtained with the strain A19 at 14 °C and initial pH 7.0 in medium containing 20 g/l castor oil. On the other hand, these factors did not affect the production of γ-decalactone by the mesophilic strain. In fermentor, a γ-decalactone concentration of 6.6 g/l was reached with the strain A19, whereas a maximum of 0.1 g/l was obtained with the mesophilic strain. Our results suggest that the ability to synthesize γ-decalactone is a particularity of the strain A19, since the mesophilic strain (no. 30645) produced small amounts, and the other (no. 31354) did not exhibit this property. It is, to our knowledge, the first report of γ-decalactone production by R. aurantiaca and furthermore by a psychrophilic yeast strain. Moreover, the amount of γ-decalactone obtained in fermentor with the strain 19 was on the order of concentrations usually described in patents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lactones are widely distributed in foods and beverages as aroma compounds. An increasing demand for natural products has resulted in the use of biotechnological processes for the production of these lactones. Most processes are based on the use of yeast strains to transform ricinoleic acid or its derivatives into lactones [1–4]. Among these compounds, γ-decalactone has characteristic peach and apricot flavors. Therefore, there has been a continuous need to define the most appropriate conditions for γ-decalactone production in bioconversion medium. Control of temperature, pH, agitation, aeration, and composition of bioconversion medium remains the critical factors governing γ-decalactone production. The effect of medium composition on γ-decalactone production has been previously studied, and there is general agreement that medium containing castor oil is one of the most appropriate for growth and γ-decalactone production by producer strains [5, 6].

In addition to the control of bioconversion parameters, the microorganism strain used was shown to significantly affect γ-decalactone production. In this regard, many studies on biotechnological production of γ-decalactone have been carried out with various mesophilic microorganisms, such as Yarrowia lipolytica [7–11], Fusarium poae [12], Tyromyces sambuceus [13], or Sporidiobolus salmonicolor [14–17]. Fermentor techniques were reported to enhance γ-decalactone production compared with flask bioconversion [14, 18]. The use of a psychrophilic microorganism in a process may allow to decrease the working temperature and thus to save energy. To our knowledge, no psychrophilic microorganisms has been investigated for its capacity to produce lactones. In the present study, we report the production of γ-decalactone in shake flask and in fermentor by the psychrophilic strain Rhodotorula aurantiaca A19 and two mesophilic strains of the same species. The strain A19 was shown to be highly efficient in the biotransformation of castor oil into γ-decalactone.

Materials and Methods

Microorganisms, Growth Media and Culture Conditions

The psychrophilic strain of R. aurantiaca A19 was previously isolated near the Antarctic station Dumont d’Urville and deposited at the Mucotheque of the University of Louvain-la-neuve (MUCL) under registration no. 40267. The mesophilic yeasts were purchased from the MUCL, Belgium (registration number 30645 and 31354).

Medium 863 is a complex medium containing: 6 g/l peptone casein, 3 g/l yeast extract, and 20 g/l glucose. Medium 868 was prepared by adding 17 g/l agar to the medium 863. Precultures were prepared by transferring a loopful of yeast cells grown on 868 agar to 100 ml of medium 863 in 250 ml Erlenmeyer flasks and incubation under agitation of 150 rpm at 12 °C for the strain A19 (4 days) and 25 °C for the mesophilic strains (3 days). The cells were then transferred to 1 l of medium 863 in 3-l flasks and incubated for 3 days in the same conditions.

Bioconversion Experiments

Experiments were carried out in medium, containing the following ingredients: 6 g/l peptone casein, 3 g/l yeast extract, and 20 g/l castor oil in flasks or in fermentors. When effects of cultivation temperature, initial pH, and castor oil concentration were studied, three series of 3-l flasks containing 1 l of sterile bioconversion medium were prepared. In the first series, cultures were carried out at 4, 8, 12, 14 and 20 °C for the strain A19 and at 15, 20, 25, and 30 °C for the mesophilic strain. In the second series, the initial pH of the medium was adjusted to different values (5, 6, 7, 8, and 9) with HCl (3 N) and NaOH (3 N). The third series aimed at evaluating the effect of castor oil concentration on γ-decalactone production and was performed in a series of Erlenmeyer flasks containing the bioconversion medium with variable concentration of castor oil ranging from 0 to 60 g/l.

A 20-l computer-controlled (Freelance 2000 software, ABB, Zaventem, Belgium) and in situ sterilizable fermentor (Biolafite, France) with 12 l of working volume was used throughout this study for cell biomass and γ-decalactone production in batch culture. All fermentor trials were conducted with aeration (1.5 vvm) and at constant temperature (14 and 25 °C for the strain A19 and the mesophilic strain, respectively), pH 6.8 and agitation of 250 rpm by online control. The pH was controlled by automatic addition of 6 M NaOH and 6 M H3PO4 solutions.

Cell Dry Weight Determination

Biomass yield was determined after the elimination of the fatty fraction of culture medium. Fifty milliliter of medium was centrifuged at 5,500×g for 15 min (Avanti J-25I, Beckman, USA). The supernatant was eliminated, and the cell pellets were washed with a mixture of ethanol/acetone (50:50, v/v) followed by a second washing with distilled water [15]. Biomass concentration was measured by cell dry weight (CDW) determination by filtration under vacuum of a 10-ml sample of the cellular suspension through 0.45 μm pore size filters (Pall Life Sciences, USA). The filtered biomass was put in small aluminum dishes and dried at 105 °C for 48 h.

Lactone Extraction and Identification

Lactones were extracted from a 50-ml sample of the culture medium of R. aurantiaca. Twenty-five milliliter of distilled water was added to improve distillation process. Subsequently, the pH of the mixture was adjusted to 2.0 by 3 N HCl solution [14], and 50 mg of γ-valerolactone (internal standard) was added. Afterwards, the solution was submitted to hydrodistillation, and about 70 ml of volatile distillate was collected. Lactone extraction was performed by a liquid–liquid (1:1) method using diethyl ether. The ether layer was recovered and dehydrated by anhydrous Na2SO4.

Gas chromatography (GC) quantification was performed using a Hewlett-Packard 5890 series II (Palo Alto, CA, USA) gas chromatography equipped with a flame ionization detector and an Alltech AT.AQUAWAX column (30 m × 0.25 mm ID, film thickness 0.25 μm). Oven temperature was held at 40 °C for 2 min, raised to 250 °C at a rate of 10 °C/min, then fixed at 250 °C for 20 min. Injector and detector temperatures were 200 and 250 °C, respectively. The carrier gas, helium, was adjusted to a linear velocity 1 ml/min and 0.5 bars. One-microliter samples were injected into the GC apparatus.

Identification was performed using a GC system [Agilent Technologies (AT) 6890 N, Palo Alto, CA, USA] interfaced to a single-quadrupole mass spectrometer (AT 5973 N, Palo Alto, CA, USA). The column and the gas chromatography conditions were the same as those described above. The transfer line temperature was adjusted to 260 °C. Mass spectroscopy conditions were as follows: electron ionization source set to 70 eV, emission current 34.6 μA, mass spectrometry (MS) Quad 150 °C, MS source 230 °C. The mass spectrometer was run in full-scan mode.

Chirality Analysis

Chirality analysis of γ-decalactone was carried out with a chromatograph Carlo Erba Mega 5160. General conditions were: column octakis (3-o-butyryl-2,6-o-pentyl)-γ-cyclodextrin (Lipadex from Macherey-Nagel) (25 m; 0.25 mm ID, film thickness 0.2 μm); the carrier gas, helium, was adjusted to a linear velocity 1.5 ml/min and 80 kPa; flame ionization detector at 220 °C; split injection; isothermal at 150 °C. The calibration was performed with a racemic mixture of a commercial γ-decalactone.

Results and Discussion

Selection of Psychrophilic Yeast Producing γ-decalactone

Psychrophilic strains collected in the Antarctic were compared on the basis of their ability to produce γ-decalactone. The psychrophilic strains used were identified by Sabri et al. [19], who reported that 18 strains were unable to grow near 20 °C, and only two strains showed weak growth at 25 °C. This comparison has led to the selection of the psychrophilic strain R. aurantiaca A19 which exhibited an interesting activity for the production of γ-decalactone. The strain A19 produced about 5.5 g/l of γ-decalactone after 8 days of culture. γ-Decalactone production by this strain was then compared with two mesophilic strains of the yeast R. aurantiaca.

Identification of the Lactones Produced by the Psychrophilic and Mesophilic Strains of R. aurantiaca

The biotransformation of castor oil (source of ricinoleic acid) into lactones by the strain A19 and two mesophilic strains of R. aurantiaca was studied. These strains were cultured in the same medium and conditions except the temperature (12 °C for the strain A19 and 25 °C for the mesophilic strains). The lactones produced with the three strains were identified by GC-MS. The strain A19 produced four lactones: γ-octalactone, γ-nonalactone, γ-decalactone, and γ-undecalactone (Fig. 1). The yeast S. salmonicolor was also described to produce some lactones such as γ-octalactone, γ-nonalactone, γ-decalactone, and γ-dodecalactone [17]. Among the lactones, γ-decalactone was the major one with a concentration around 5.8 g/l after 8 days of culture (Fig. 2b). The other lactone concentrations did not exceed 10 mg/l. In contrast, the mesophilic strain (no. 30645) produced only γ-decalactone with a very low concentration of 60 mg/l after 3 days of cultivation (Fig. 2b′), whereas no lactone was detected for R. aurantiaca 31354. These points show clearly the particular character of the strain A19 for the production of γ-decalactone. The effects of some factors including temperature, media initial pH, and castor oil concentration on the production of γ-decalactone by the strain A19 and the mesophilic strain (no. 30645) were investigated as described below.

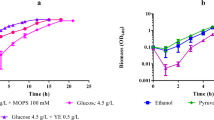

Time course of cell dry weight (a, a′) and γ-decalactone production (b, b′) during cultures of the psychrophilic and mesophilic strains of R. aurantiaca, respectively: psychrophilic strain A19 cultivated at: 4 (closed triangle), 8 (open triangle), 12 (closed square), and 14 °C (open square); mesophilic strain cultivated at: 15 (closed triangle), 20 (open triangle), 25 (closed square), and 30 °C (open square)

Influence of Cultivation Temperature

The influence of temperature on the growth and the production of γ-decalactone of the psychrophilic and mesophilic strains of R. aurantiaca was tested. Figure 2 illustrates the evolution of CDW and γ-decalactone production by the strains of R. aurantiaca. The temperature had a significant effect on the growth and γ-decalactone production mainly by the strain A19. The higher CDW of the strain A19 (3.5 g/l) was at 12 °C (Fig. 2a). The production of γ-decalactone by the strain A19 rose with increasing cultivation temperature until 14 °C (Fig. 2b). The yield of γ-decalactone was the highest (5.8 g/l) at 14 °C after 8 days of culture in flasks. These results suggest that the optimum temperature for the production of γ-decalactone by the strain A19 was 14 °C because it accelerates the growth of R. aurantiaca and minimizes the duration of fermentation compared to 4, 8, and 12 °C as shown in Fig. 2a,b. The strain A19 was unable to grow at 20 °C. This result was in agreement with the findings of Sabri et al. [20], who reported that the inability of this strain to grow at temperatures close to 20 °C associated with profound morphology and integrity alterations. However, for the mesophilic strain, the highest CDW and γ-decalactone production were obtained at 25 °C (Fig. 2a′,b′).

Influence of Initial pH

The effects of initial pH on the growth of the psychrophilic and mesophilic strains of R. aurantiaca are presented in Fig. 3a,a′, respectively. The variation of pH throughout the culture of both strains of R. aurantiaca is shown in Fig. 3c,c′. The best growth (2.4 g/l of CDW) and the highest γ-decalactone concentration (5.3 g/l) produced by the strain A19 were recorded at pH 6.8 after 10 days with initial pH 7.0 (Fig. 3a,b). The pH value of 6.8 was retained for fermentor experiments under controlled pH conditions. The highest production of γ-decalactone by the mesophilic strain was at pH 6.7 with initial pH 7.0. However, the production was maintained low and did not exceed 0.06 g/l (Fig. 3b′).

Time courses of cell dry weight (a, a′), γ-decalactone production (b, b′), and pH (c, c′) during cultures of the psychrophilic and mesophilic strains of R. aurantiaca in flasks, respectively, with initial pH of culture medium at: pH = 5 (closed rectangle), pH = 6 (open triangle), pH = 7 (open square), pH = 8 (closed square), and pH = 9(closed triangle)

Effect of Castor Oil Concentration

Figure 4 highlights the effects of castor oil concentration on γ-decalactone production by the psychrophilic and mesophilic strains in flasks. Our results show that γ-decalactone concentration obtained with the strain A19 was not proportional to the concentration of castor oil added. At 10 days in flasks, the highest γ-decalactone yield (5.5 g/l) was recorded with 20 g/l of castor oil. The production was reduced for higher castor oil contents (30, 40, 50, and 60 g/l). Similar results have been reported by Endrizzi et al. [21], who observed that a high concentration of ricinoleic acid methyl ester lowers the yield of γ-decalactone produced by Pichia guilliermondii. However, our results contrasted with those reported by Dufossé et al. [15], who showed that γ-decalactone concentration obtained in the culture broth of Sporidiobolus ruinenii increased almost proportionally with a ricinoleic acid methyl ester concentration between 0 and 160 g/l. To avoid possible initial inhibition of the yeast by high castor oil concentration, fed-batch technique seems to be an adequate strategy to ensure progressive but not excessive supply of substrate [16]. Immobilization of the producer strain by entrapment in a polymer in order to protect the cells from the toxicity of ricinoleic acid has also been developed [22]. In the case of the mesophilic strain, the production of γ-decalactone was below 0.06 g/l for the various concentrations of castor oil (Fig. 4).

Production of γ-decalactone by the psychrophilic and mesophilic strains of R. aurantiaca in medium supplemented with various concentrations of castor oil. γ-Decalactone concentration was determined after 10 days of culture for the psychrophilic strain (closed square) and 3 days for the mesophilic strain (open square)

Production of γ-Decalactone by R. aurantiaca in a 20-l Fermentor

The experiments in flasks permitted determination of the optimal parameters for the production of γ-decalactone by both strains of R. aurantiaca. The two strains were then cultured in a 20-l fermentor with a working volume of 12 l. The dynamics of R. aurantiaca growth and γ-decalactone production in batch fermentor are shown in Fig. 5. The biomass of the strain A19 increased progressively to reach 3.9 g/l after 4 days, whereas the biomass of the mesophilic strain reached 2.8 g/l after 3 days of culture. However, the maximum values of γ-decalactone (6.6 g/l) were reached after 6 days of growth for the strain A19. Maximum γ-decalactone production by the mesophilic strain was 0.1 g/l after 3 days of culture. The comparison of the strains of R. aurantiaca was mainly based on their ability to produce γ-decalactone. It is worth mentioning that the maximum CDW and γ-decalactone reached in the fermentor were higher than in the flask cultures. However, the difference of results from flasks to the fermentor can be attributed to differences in the stirring systems and rates (agitation and aeration) that have a high impact in emulsion characteristics and thus in liquid–liquid interfacial area [23].

Comparison of the Productivity of γ-Decalactone by the Strain A19 and Other Mesophilic Strains in the Literature

The comparison of γ-decalactone production by the psychrophilic strain A19 used in this work with other mesophilic strains reported in literature is presented in Table 1. The psychrophilic strain of R. aurantiaca produced a higher amount of γ-decalactone at low temperature than mesophilic strains of the same species and than other mesophilic microorganisms reported in literature [5, 24, 25]. Although the concentration of γ-decalactone obtained in the present study was lower than one reported production by Y. lipolytica strain HR 145 (DSM 12397) of 12.3 g/l [26], the ratio γ-decalactone/substrate is 1.4-fold higher in the present work (Table 1). Therefore, this strain appears suitable for commercial γ-decalactone production.

The results obtained in our study with the strain A19 show not only that this strain is able to produce high amounts of γ-decalactone but also that this strain did not degrade γ-decalactone in the biotransformation conditions because this concentration was then maintained after 8 days as shown in Fig. 5. Our results contrasted with other findings that Y. lipolytica degrades γ-decalactone as it is synthesized and other decalactones such as 3-OH-γ-decalactone, 2-decen-4-olide, and 3-decen-4-olide appear in the medium [7, 9, 27].

Chirality of γ-Decalactone Produced by the Psychrophilic Strain A19

A sample of γ-decalactone obtained from a culture of the strain A19 was concentrated by sample evaporation of ether at ambient temperature. This concentrated sample was then subjected to a chirality analysis on a substituted γ-cyclodextrin column. It resulted that the R-form of the γ-decalactone predominates with 99.6% against 0.4% for the S-form. Similar results have been reported by Dufossé et al. [15], who found that S. salmonicolor produced the form R-γ-decalactone (99%).

Conclusions

The comparison of the performance of the psychrophilic strain A19 and two mesophilic strains of R. aurantiaca for the production of γ-decalactone led to the selection of the first one (A19) which appeared highly productive.

In a next step, fed-batch and continuous processes will be investigated in our laboratory for γ-decalactone production by R. aurantiaca.

Moreover, in order to explain and understand the highly different lactone-producing character of both R. aurantiaca strains, we will focus on the β-oxidative systems of the yeasts. Indeed, peroxysomal β-oxidation enzymes were shown to be responsible for γ-decalactone production in other yeast strains [7, 21, 27–29].

References

Spinnler, H. E., Dufossé, L., Souchon, I., Latrasse, A., Piffaut, C., Voilley, A., et al.(1994), French Patent No. 2705971.

Endrizzi, A., Pagot, Y., Le Clainche, A., Nicaud, J. M., & Belin, J. M. (1996). Critical Reviews in Biotechnology, 16, 301–329. doi:10.3109/07388559609147424.

Pagot, Y., Endrizzi, A., Nicaud, J. M., & Belin, J. M. (1997). Letters in Applied Microbiology, 25, 113–116. doi:10.1046/j.1472-765X.1997.00182.x.

Wang, X. D., Mauvais, G., Cachon, R., Diviès, C., & Féron, G. (2000). Journal of Bioscience and Bioengineering, 90, 338–340.

Farbood, M.I., & Willis, B.J.(1985), US Patent 4.560.656.

Lee, S. L., & Chou, C. C. (1994). Journal of Fermentation and Bioengineering, 78, 114–116. doi:10.1016/0922-338X(94)90191-0.

Waché, Y., Aguedo, M., Le-Dall, M. T., Nicaud, J. M., & Belin, J. M. (2002). Journal of Molecular Catalysis. B, Enzymatic, 19–20, 347–351. doi:10.1016/S1381-1177(02)00185-6.

Groguenin, A., Waché, Y., Escamilla García, E., Aguedo, M., Husson, F., Le-Dall, M. T., et al. (2004). Journal of Molecular Catalysis. B, Enzymatic, 28, 75–79. doi:10.1016/j.molcatb.2004.01.006.

Aguedo, M., Gomes, N., Escamilla Garcia, E., Waché, Y., Mota, M., Teixeira, J. A., et al. (2005). Biotechnology Letters, 27, 1617–1621. doi:10.1007/s10529-005-2517-z.

Escamilla García, E., Belin, J. M., & Waché, Y. (2007). Journal of Applied Microbiology, 103, 1508–1515. doi:10.1111/j.1365-2672.2007.03379.x.

Gomes, N., Aguedo, M., Teixeira, J., & Belo, I. (2007). Biochemical Engineering Journal, 35, 380–386. doi:10.1016/j.bej.2007.02.002.

Sarris, J., & Latrasse, A. (1985). Agricultural and Biological Chemistry, 49, 3227–3230.

Kapfer, G. F., & Berger, R. G. (1989). Biotechnology Letters, 11, 561–566. doi:10.1007/BF01040036.

Féron, G., Dufossé, L., Pierard, E., Bonnarme, P., Le-Quere, J. L., & Spinnler, H. E. (1996). Applied and Environmental Microbiology, 62, 2826–2831.

Dufossé, L., Feron, G., Mauvais, G., Bonnarme, P., Durand, A., & Spinnler, H. E. (1998). Journal of Fermentation and Bioengineering, 86, 169–173. doi:10.1016/S0922-338X(98)80056-1.

Lee, S. L., Cheng, H. Y., Chen, W. C., & Chou, C. C. (1999). Process Biochemistry, 34, 845–850. doi:10.1016/S0032-9592(99)00010-2.

Dufossé, L., Feron, G., Latrasse, A., Guichard, E., & Spinnler, H. E. (1997). Chirality, 9, 667–671. doi:10.1002/(SICI)1520-636X(1997)9:7<667::AID-CHIR5>3.0.CO;2-4.

Lee, S. L., Lin, S. J., & Chou, C. C. (1995). Journal of Fermentation and Bioengineering, 80, 195–199. doi:10.1016/0922-338X(95)93219-A.

Sabri, A., Jacques, P., Weekers, F., Baré, G., Hiligsmann, S., Moussaïf, M., et al. (2000). Applied Biochemistry and Biotechnology, 84–86, 391–399. doi:10.1385/ABAB:84-86:1-9:391.

Sabri, A., Baré, G., Jaques, P., Jabrane, A., Ongena, M., Van Heugen, J. C., et al. (2001). The Journal of Biological Chemistry, 276, 12691–12696. doi:10.1074/jbc.M100155200.

Endrizzi, A., Awade, A. C., & Belin, J. M. (1993). FEMS Microbiology Letters, 114, 153–160.

Lee, S. L., Cheng, H. Y., Chen, W. C., & Chou, C. C. (1998). Process Biochemistry, 33, 453–459. doi:10.1016/S0032-9592(98)00013-2.

Aguedo, M., Waché, Y., Coste, F., Husson, F., & Belin, J. M. (2004). Journal of Molecular Catalysis. B, Enzymatic, 29, 31–36. doi:10.1016/j.molcatb.2003.11.018.

Cheetam, P. S. J., Maume, K. A., & De Rooij, J. F. M. (1993), US Patent 5. 219.742.

Boog, A. L. G. M., Van Grinsven, A. M., Peters, A. L. J., Roos, R., & Wieg, A. J.(1998), US patent. 5.789.212.

Rabenhorst, J., & Gatfield, I.(2002), US Patent. 6.451.565.

Waché, Y., Aguedo, M., Choquet, A., Gatfield, I. L., Nicaud, J. M., & Belin, J. M. (2001). Applied and Environmental Microbiology, 67, 5700–5704. doi:10.1128/AEM.67.12.5700-5704.2001.

Pagot, Y., & Belin, J. M. (1996). Applied Microbiology and Biotechnology, 45, 349–354. doi:10.1007/s002530050695.

Blin-Perrin, C., Molle, D., Dufosse, L., Le-Quere, J. L., Viel, C., Mauvais, G., et al. (2000). FEMS Microbiology Letters, 188, 69–74.

Acknowledgement

We thank the government of Syria for their financial support to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alchihab, M., Destain, J., Aguedo, M. et al. Production of γ-Decalactone by a Psychrophilic and a Mesophilic Strain of the Yeast Rhodotorula aurantiaca . Appl Biochem Biotechnol 158, 41–50 (2009). https://doi.org/10.1007/s12010-008-8297-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8297-x