Abstract

A synthetic polymer, polyvinyl alcohol (PVA), a cheap and nontoxic synthetic polymer to organism, has been ascribed for biocatalyst immobilization. In this work PVA–alginate beads were developed with thermal, mechanical, and chemical stability to high temperatures (<80 °C). The combination of alginate and bead treatment with sodium sulfate not only prevented agglomeration but produced beads of high gel strength and conferred enzyme protection from inactivation by boric acid. Naringinase from Penicillium decumbens was immobilized in PVA (10%)–alginate beads with three different sizes (1–3 mm), at three different alginate concentrations (0.2–1.0%), and these features were investigated in terms of swelling ratio within the beads, enzyme activity, and immobilization yield during hydrolysis of naringin. The pH and temperature optimum were 4.0 and 70 °C for the PVA–alginate-immobilized naringinase. The highest naringinase activity yield in PVA (10%)–alginate (1%) beads of 2 mm was 80%, at pH 4.0 and 70 °C. The Michaelis constant (K Mapp) and the maximum reaction velocity (V maxapp) were evaluated for both free (K Mapp = 0.233 mM; V maxapp = 0.13 mM min−1) and immobilized naringinase (K Mapp = 0.349 mM; V maxapp = 0.08 mM min−1). The residual activity of the immobilized enzyme was followed in eight consecutive batch runs with a retention activity of 70%. After 6 weeks, upon storage in acetate buffer pH 4 at 4 °C, the immobilized biocatalyst retained 90% of the initial activity. These promising results are illustrative of the potential of this immobilization strategy for the system evaluated and suggest that its application may be effectively performed for the entrapment of other biocatalysts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Flavonoids, naringin and naringenin, from citrus fruits are functional chemicals with important properties in the fields of health care, food, and agriculture. Naringin, composed of the aglycon naringenin and the disaccharide neohesperidose, is the principle bitter flavanone glycoside and the primary bitter component in grapefruit juice [1]. The aglycone and neohesperidose are not bitter compounds when present separately in free form. The sugar present at position 7 in the flavanone is crucial for its properties; neohesperidose imparts bitterness; glucose and rutinose impart no bitterness [2]. Enzymatic hydrolysis is a possibility to overcome the bitterness and obtain compounds with improved biological activities. Naringin can be hydrolyzed by α-l-rhamnosidase activity of naringinase to rhamnose and prunin (one third of the bitterness of naringin), which can be further hydrolyzed by the β-d-glucosidase component of naringinase into glucose and tasteless naringenin [3]. These molecules have a great potential, especially in the food and pharmaceutical industries due to their recognized antioxidant, anti-inflammatory [4], antiulcer, and hypocholesterolemic effects, whereas naringenin has also shown antimutagenic and neuroprotective activities. Both naringin and naringenin have these similar medical applications, indicating that the biological activity is related to the aglycon moiety, and it is not associated with the sugar residues. Prunin has antiviral activity.

A significant aspect of great concern is the entrapment of enzymes into the polymeric matrices, which also provides a technique of enzyme immobilization.

The main purpose of enzyme immobilization lies in the economic application of enzymes in various industrial and technological processes. Moreover, the recovery yield and reusability of free enzymes as industrial catalysts are quite limited and, hence, attention has been paid to enzyme immobilization [5]. Many researchers have studied the efficacy of entrapment of the naringinase in different matrices. It is concluded that each support has its own advantages and disadvantages in accordance with the enzyme employed. When the matters of reusability, thermal stability of the support at higher temperatures, and the cost-effectiveness of the immobilization method are addressed, polyvinyl alcohol (PVA)–alginate-based matrices can be considered highly ranked at the top of most suitable immobilization methods.

PVA is a particularly interesting material because it is innocuous, cheap, and also mechanically and chemically robust [6, 7]. Even though it has been mainly used for cell immobilization [8], it has been successfully applied to the immobilization of enzyme–polymer composites [9, 10] and enzyme aggregates [11]. The most common immobilization method is performed by mixing the biocatalyst with a solution of commercial PVA, and the promotion of gelification is accomplished by dripping the mixture over a surface, allowing for partial drying [8, 12] by freezing and thawing [13] or by UV light [14], or otherwise by dripping the mixture to an extrusion solution such as boric acid or sodium sulfate to promote the cross-link between PVA molecules [15–23].

Some authors [24] have produced PVA beads using only PVA cross-linked with boric acid, but the formed beads had a strong tendency to agglomerate into a mass of polymer, which is very difficult to break up. This agglomeration problem appears to be due to the relatively slow cross-link of the PVA by boric acid [16]. Agglomeration problem persisted even with vigorous stirring of the boric acid solution to keep the beads suspended. In order to form spherical beads, which is the preferred shape for application, a mixed solution of PVA and sodium alginate and a mixed solution of boric acid and calcium chloride were used. It was presumed that the PVA might contribute to improve the durability and strength of the beads, while calcium alginate might improve the surface properties of the beads, reducing the tendency to agglomeration [16]. It is believed that calcium alginate would be formed almost instantaneously when the sodium alginate comes in contact with calcium chloride solution, and the resulting polymeric structure is sufficient to keep the beads from agglomeration during the PVA cross-linking process [25]. In this technique, the boric acid solution containing tetrahydroxyborate ions, B(OH)4−, is added to an aqueous solution containing PVA (–CH2CHOH–) n . These borate ions are cross-linked with the alcohol groups on adjacent chains [15]. The mechanism of the cross-link reaction of borate ion with PVA is believed to be a “di-diol” complexation, which is formed between two diol units and one borate ion [26–30].

This cross-linking appears like chemical bonds, except that they are labile polar covalent interactions. They are constantly and rapidly breaking and reforming, resulting in the unusual intermediate solid and liquid properties [15, 30]. However, due to the mentioned unusual semisolid properties, the beads produced easily dissolved in distilled water. To overcome this problem, sodium sulfate was introduced in the bead formation. The sulfate ions would probably form thiosulfate linkages among the cross-linked PVA, increasing the elasticity and the strength of the beads and thus improving their physical/mechanical properties.

The main focus of this study was to investigate the feasibility of the acid boric/calcium chloride and sulfate method and evaluate the PVA–alginate beads in terms of the naringinase activity within the beads (Fig. 1). Different sodium alginate concentrations were used. The effects of the matrix composition, bead size, enzyme load, temperature, pH, and substrate concentration in the performance of the biocatalyst were studied, as well as its storage and operational stability.

Material and Methods

Materials

Naringinase (EC 3.2.1.40) from Penicillium decumbens (CAS number 9068-31-9) and naringin were obtained from Sigma Chemical Co. (USA). The enzyme was kept at 0 °C. PVA (99% hydrolyzed, average MW 4,441) and alginic acid sodium salt from brown algae were from Fluka (St. Louis, MO, USA). Sodium sulfate anhydrous, calcium chloride dehydrated, and boric acid were purchased from Merck Schuchardt OHG (Darmstadt, Germany).

All other chemicals were of analytical grade and obtained from various sources.

Analytical Methods

Reducing sugars were quantified by the 2,4-dinitrosalicylic acid (DNS) method [31]. Standardization was obtained with different concentrations of d-glucose (0.5–4 mM).

Any contribution of thermal hydrolysis was eliminated as no reducing sugars were observed after incubating the naringin solution at different temperatures.

Beads without naringinase were used as control for the DNS method. No significant differences in the reaction media with and without beads were observed in sample absorbance at 550 nm.

The quantification of reducing sugars by DNS method when used in this kind of immobilization experiences leads to a large number of samples in a short time and requires a large amount of material, which inflate the cost and resources. In order to develop a simpler, faster, and user-friendly method for detection of reducing sugars, with the same accuracy and reliability as the one described by Miller [31], every procedure was adapted to a micromethod (U96 MicroWell® plate, NUNC™, USA), using a microplate especially designed to process large number of samples at the same time in short periods of time, assuring uniform and thermostable conditions, avoiding loss of liquid due to evaporation, and with ability to resist high temperature thereby allowing a large number of reuses without degradation (Fig. 2).

Procedure

Seventy-five microliters of DNS reagent was added to 75 μL of sample in each well of the microplate, which was closed afterwards by assembling all the parts and placed at the surface of water bath at 95 °C for 5 min, assuring that there were no air bubbles in the submerged part of the microplate. After cooling to room temperature, the lid was disassembled by unscrewing the nuts, and the absorbance of samples was recorded with a spectrophotometer (Biophotomether, Eppendorf, UK) at 550 nm.

The method of quantification of protein (naringinase) was adapted from Bradford [32]. In order to develop a simpler, rapid, and user-friendly method, every procedure was adapted to micromethod, using a 96-well round-bottom microplate. Protein samples of 50 μL were diluted in 0.02 M sodium acetate buffer (pH 4.0) to a final volume of 100 μL. Coomassie-blue-containing solution (25 μL, Bio-Rad Protein Assay, Bio-Rad, Munich, Germany) was added, and absorbance was measured at 595 nm. Quantification was made with the help of a calibration curve obtained with standard solutions of naringinase (0–100 μg mL−1).

Swelling Ratio

To measure the swelling behavior, bead samples were dried at 40 °C in an oven for 20 min, and their weights (We) were immediately measured. They were then soaked in acetate buffer maintained at 4 °C and again weighed, following removal of excess buffer with filter paper, after 18 h (W s ). The swelling ratio was determined according to [33, 34]:

Swelling ratio trials were performed over beads obtained through different immobilization procedures or different features, namely: (1) bead size 1.0−3.0 mm; (2) different concentration and composition of extrusion solution I: boric acid 1−3% (w/v) and calcium chloride 1−2% (w/v); and (3) different alginate concentration beads (0.2−1.0%).

Enzyme Activity

Naringin bioconversion studies were carried out in standard solutions of naringin (500 mg L−1 in acetate buffer 0.02 M, pH 4.0), at 30 °C, 150 rpm (orbital shaker SI500, Stuart, UK) during 1 h (unless stated otherwise), in microplates (Costar® 24 Well Clear TC-Treated Microplate, Corning Inc., USA) at an established reaction volume of 2 mL. At given intervals (20, 30, and 60 min), aliquots of 100 μL were taken and analyzed after dilution in acetate buffer.

The degree of naringin hydrolysis was calculated according to the reducing sugar formation. Residual activity was defined as the ratio of the activity of immobilized enzyme to the activity of the free enzyme \( \left[ {{\text{Residual activity}}\left( \% \right) = \left. {{\text{Activity of immobilized enzyme}}\,\left( {{\text{mM h}}^{- 1} } \right)/{\text{Activity of free enzyme}}\left( {{\text{mM h}}^{- 1} } \right)} \right) \times 100} \right] \).

The experiments were performed in triplicate, and all results were the average of these determinations.

Immobilization Procedure

Immobilization was carried out by addition, at room temperature, of 3 g of PVA to 24 mL of acetate buffer at pH 4.0. The solution was mixed and heated to 80 °C to completely dissolve the PVA. Ten milliliters of sodium alginate 10% (w/v) solution in acetate buffer, pH 4.0, was prepared and then added to the PVA solution and gently stirred for 45 min. The PVA–alginate solution was then cooled to a temperature of around 35 °C, followed by addition of a certain volume of naringinase stock solution, in order to attain the desired concentration and then mixed thoroughly. Suitable PVA beads were produced with PVA concentrations ranging from 8% to 16% (however, 10% was the best one), alginate from 0.05% to 2.0%, and boric acid from 2.0% to 7.0%.

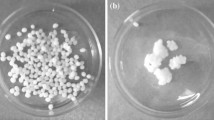

The mixture was dropped through a specific diameter (0.3, 0.5, and 0.8 mm) needle from TERUMO (Somerset, NJ, USA) into the extrusion solution I, containing boric acid 2% (w/v) and calcium chloride 1% (w/v), at 8 °C, producing a set of beads. Each set of beads was stirred gently at 150 rpm, during 15 min, and then transferred to extrusion solution II containing sodium sulfate 10% (w/v), unless stated otherwise. The gelling was allowed to proceed for 4 h, at 4 °C, to complete solidification. After, they were separated by filtration and then washed with acetate buffer at pH 4.0 to remove any excess of sodium sulfate. The beads were finally stored at 4 °C in fresh acetate buffer at pH 4.0, until constant weight (generally overnight) before usage (Fig. 3).

A ratio (v/v) of 4 (reaction media):1 (immobilized enzyme PVA–alginate beads) was used.

Bioconversion trials were performed with beads produced with different compositions of extrusion solution I: boric acid (1–3%) and calcium chloride (1%). In a second stage, all the beads were treated with the same extrusion solution II (sodium sulfate 10%).

The effect of alginate concentration on the activity of immobilized naringinase was evaluated with beads produced with different alginate concentrations (0.2–1.0%).

The effect of bead size on the activity of immobilized naringinase was evaluated with different bead size range of 1–3 mm.

Evaluation of Optimum pH and Temperature

The optimum pH of free and immobilized naringinase was determined by carrying out the enzyme assay using acetate buffer with pH ranging from 3.0 to 6.0, at 30 °C, 150 rpm, and incubation for 1 h.

The optimum temperature of free enzyme and immobilized naringinase beads was determined by incubating the microplated assay mixture in a shaking water bath (SW21, JULABO, PT) at various temperatures (from 30 to 90 °C), pH 4.0, at 150 rpm, for 1 h. In both cases, samples were collected at 20, 30, and 60 min, and the enzyme activity was assayed.

Kinetic Parameters

The effect of enzyme concentration on the activity of immobilized naringinase was evaluated on bioconversion trials performed with beads produced with different enzyme concentrations from 500 to 2,000 mg L−1.

The effect of naringin concentration on enzyme activity was studied for free and immobilized naringinase onto PVA–alginate beads. The activity of the biocatalyst (2,000 mg L−1 in reaction mixture) was determined by adding naringin standard solutions ranging 100–600 mg L−1 in sodium acetate buffer (0.02 M, pH 4.0). The rate of naringin hydrolysis was assayed at 30 °C, for up to 1 h, and the initial reaction rate method was used. The kinetic parameters were evaluated using the Lineweaver–Burk method.

Operational and Storage Stability

In order to test the reusability of naringinase in PVA–alginate beads, the beads were used several times for the hydrolytic reaction. Each run lasted 1 h after which the beads were separated and washed with 0.02 M acetate buffer (pH 4.0). The reaction medium was then replaced with fresh medium. The activity of freshly prepared beads in the first run was defined as 100%. The stability of immobilized naringinase beads at storage were monitored during 6 weeks at 4 °C. The residual activity was measured as stated above.

Results and Discussion

In the preparation of the naringinase immobilized PVA beads, contact time with the boric acid greatly affected gel strength. Boric acid is consumed during the PVA–gelling reaction. So, an excess amount of the boric acid is required for a rapid progression of PVA polymerization. Initially, the gelling reaction occurred immediately on the surface of the beads; subsequent gelling reaction inside is accomplished with further diffusion of the boric acid into the beads [21].

It is well known that immobilization can protect enzyme from inactivation and eventually from denaturation at extreme conditions, by creating a stable microenvironment [15]. Several studies were carried out, namely the effect of acid boric exposure time during naringinase immobilization procedure on the residual activity (Fig. 4). Different periods of exposure to boric acid were tested based in solidification times. Boric acid interferes with naringinase activity. Higher exposures times contribute to lower activities of naringinase in free and immobilized forms. These preliminary observations suggest that solvent systems need to be further tailored in order to improve cross-linking efficiency, by minimizing the naringinase leakage as well as preventing any deleterious effects on the enzyme conformation, assuring a stable and high strength support matrix.

Swelling Ratio and Enzyme Activity

Swelling measurements are relatively simple means to characterize cross-linked polymer networks being helpful in the interpretation of diffusion transport processes through the macromolecular material [35] and of drug release.

Penetration of solvent into the polymer leads to its swelling which is involved with diffusion of solvent molecules through the polymer matrix and local relaxation of polymer segments. For rapid relaxation rates, penetration speed is limited by diffusion process and Fickian transport is observed. In this type of swelling mechanism, diffusion of water molecules inside the polymer is a rate-limiting step [35].

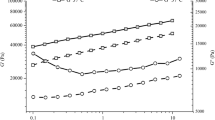

Gelation of alginate occurs in the presence of calcium ions. The mechanical strength of the gel generally increases with an increase in the Ca2+ concentration during the solidification process. Thus, it is possible to postulate that gelation of alginate in a suitable concentration of Ca2+ is effective for the promotion of mass transfer characteristics in PVA beads [18]. The effect of different ratios of cross-linkers/PVA–alginate on the swelling characteristics of the PVA hydrogel is shown in Fig. 5. The PVA beads obtained at calcium chloride concentrations of 1% and 2% exhibited a very weak gel structure, which was not sufficiently cross-linked (Fig. 5, a and b). In fact, only alginate was cross-linked with calcium chloride; PVA was in the soluble form and dissolved almost completely after transferring the beads into acetate buffer. This loss of mass (dissolution of PVA to buffer) corresponds to lower wet weights resulting in lower swelling ratios.

Effect of different ratios of cross-linkers/PVA–alginate on the swelling ratio of cross-linked PVA (10%)–alginate (1%) beads in sodium acetate buffer solution (pH 4.0) at 4 °C. Extrusion solution—a CaCl2 1%; b CaCl2 2%; c boric acid 1% + CaCl2 1%; d boric acid 2% + CaCl2 1%; e boric acid 3% + CaCl2 1%. All beads were treated with the second extrusion solution of sodium sulfate 10%

This observation was confirmed after naringin hydrolysis by naringinase immobilized in PVA (10%)–alginate (1%) beads treated with calcium chloride 1% and 2%, respectively, and with the second extrusion solution of sodium sulfate (10%). The sulfate ions would probably form thiosulfate linkages among the cross-linked PVA. Treatment of beads with sodium sulfate resulted in PVA beads, with a rubberlike elasticity and strength almost identical to beads that were produced by previous researchers [15, 29, 30] but with improved properties.

Different ratios of boric acid/PVA led to significant difference in water uptake by the beads. Higher ratios led to lower swelling ratio. Chain entanglement along with increase in cross-linking agent concentration would result in a decreased network expansion [35] (Fig. 5, c, d, and e). Lower boric acid/PVA ratios caused a significant increase in swelling properties. In general, it may be concluded that the increase of acid boric/PVA ratio increases the cross-linking density, which significantly reduces the swelling ratio of the gels [35] and that cross-linking of hydrogels contributes to the reduction of the molecular mesh size of the gel [36]. These results show the suitability of combined saturated boric acid solution and calcium chloride solution together to cross-link PVA–alginate.

Figure 6 shows the influence of the different concentrations of boric acid within the beads on naringinase activity. Higher concentrations of boric acid (e.g., 3%) resulted in lower residual activity. This is probably due to the excessive borate ions that may be present inside the beads, which may inactivate the enzyme. Also, the use of higher boric acid concentrations resulted in denser beads with smaller pores [15]. This property seems to limit the diffusivity of the substrate naringin and/or product naringenin. On this basis, both effects may contribute to the decrease in the activity of the enzyme, naringinase. Beads treated at lower boric acid concentration (1%) lead to higher residual activities but were shown to be more fragile. In fact, equilibrium between mechanical stability of the matrix and residual activity has to be considered.

Effect of different ratios of cross-linkers/PVA–alginate on residual activity of immobilized naringinase. All beads were treated with the second extrusion solution of sodium sulfate 10%. Reaction conditions: 500 mg enzyme per liter; initial naringin concentration, 500 mg/L; sodium acetate buffer 0.02 M; pH 4.0; reaction time, 1 h

PVA–alginate-immobilized beads have advantages on the simple operation of immobilization and on the high strength [37]. Calcium alginate facilitates the formation of hydrogen bond between PVA molecules, contributing to the formation of interpenetrating gel network [37].

The kinetic studies of swelling in water showed that pure PVA and PVA–alginate hydrogels reaches equilibrium after 4 h (Fig. 4).

A correlation was observed between the swelling behavior in acetate buffer at pH 4.0 and the equilibrium properties of alginic acid gels. High contents of cross-link gel (long guluronic acid blocks), known to give a high acid gel strength, reduced the rate of swelling and also the amount of solubilized alginate molecules leaching out of the gel beads [37].

The swelling ratio decreased with increasing alginate content (Fig. 7), indicating that it possibly contributes to low mass transfer in PVA beads, like observed by other authors [22, 33]. The higher resistance to mass transfer could be ascribed to premature formation of calcium alginate gel, which would in turn restrict the fluidity of PVA, shortening the distance between PVA molecules and increasing the number of hydrogen bonds between polymer chains, which leads to the increase in the density of physical cross-linking sites.

Swelling capacity, rate of swelling, and solubility of alginic acid seemed to depend on a balance between the tendency of homopolymeric blocks in alginate to form intermolecular junction zones and the tendency of alginate to reduce the chemical potential of water.

As expected, swelling rate increased with decreasing bead size, as it is evidenced from the results of bead size effect, presented in Fig. 8.

In order to study the effect of bead diameter and alginate concentration in enzyme activity, several sets of PVA (10%) beads were produced in three different sizes with three alginate concentrations (Fig. 9). All the beads were cross-linked with extrusion solution I [acid boric (2%) + calcium chloride (1%)] and extrusion solution II [sodium sulfate (10%)].

Effect of different bead sizes and alginate concentrations on the residual activity of immobilized naringinase in PVA 10% beads. Bead size obtained, at 40° hydrogel temperature: a ≈3 mm; b ≈2 mm, c ≈1 mm. All beads were treated with second extrusion solution of 10% sodium sulfate. Reaction conditions: 2,000 mg enzyme per liter; initial naringin concentration, 500 mg/L; sodium acetate buffer 0.02 M; pH 4.0; reaction time, 1 h

Surface area/volume ratio is inversely proportional to the bead diameter. The smallest beads correspond to the highest surface area/volume value [38]. The immobilized enzyme in 1-mm beads yields higher activity per gram of beads (34%, 50%, 67% at sodium alginate of 0.2%, 0.5%, 1.0%, respectively) than the enzyme immobilized in 3-mm beads (32%, 48%, 64% at sodium alginate of 0.2%, 0.5%, 1.0%, respectively).

These results showed an increase on enzyme activity with beads of lower diameter (Fig. 9). Beads with 1-mm diameter have higher surface area/volume ratio allowing a greater amount of enzyme accessible to substrate [38]. On other hand, at higher diameters, naringin could encounter more diffusion restrictions.

PVA–alginate beads with low concentration of alginate have lower resistance to mass transfer. Accordingly and in the absence of enzyme leakage, PVA beads with higher alginate concentration should have lower residual activity because substrate faces increased diffusion resistances to reach the enzyme inside the beads.

The effect of alginate concentration on enzyme activity (Fig. 9) revealed that PVA beads with higher alginate concentration (1%) have higher residual activity (64–67%). These unexpected results could be due to low enzyme loading with increased alginate concentration.

The enzyme loading reflects the amount of enzyme bound to the beads relative to the total enzyme used. The enzyme leakage could be explained by the gelling model of Mikkelsen and Elgsaeter [38]; when the alginate solution is dropped into the calcium bath, the difference of electrochemical potential between the two solutions is higher at higher calcium concentrations. The resulting gel is more homogenous than the one made with lower calcium content [38]. If the enzyme presents some affinity for alginate, especially ionic interactions between the carboxyl groups of the alginate and some lysine or arginine residues of the naringinase, the enzyme distribution will follow the alginate distribution. In agreement, with Mikkelsen and Elgsaeter [38], the lower calcium chloride and enzyme characteristics possibly contribute to a more heterogeneous gel, and the enzyme distribution follows the alginate distribution. If the alginate is heterogeneously dispersed, when the polymerization takes place, more enzymes are in contact with the interface and are easier to diffuse out of the PVA–alginate spheres. Also, more enzyme molecules at the surface of the bead could be desorbed into the extrusion solution.

Reusability is one of the most important of several aspects of biocatalyst immobilization to industrial scale. In order to choose the suitable bead size for the immobilization of naringinase, previous studies were carried out. The reusability was tested in the PVA–alginate beads which demonstrate higher activity [1 and 2 mm PVA (10%) alginate (1%)]. The 1-mm beads have higher residual activity than using 2-mm beads (Fig. 9). However, by analyzing the reusability of each set of beads, it is evident that the 2-mm beads are the best choice; in fact, the second reuse of the 2-mm beads leads to a residual activity of 83%, while the beads of 1 mm correspond to a residual activity of 74%.

Effect of Different Concentrations of Enzyme on Activity

The effect of different concentrations of naringinase used in free and immobilized form was tested in naringin hydrolysis. Preliminary trials with immobilized enzyme were performed with beads containing 500 mg L−1 of enzyme relative to the reaction medium, but, due to enzyme loss and low activity profiles, different enzyme concentrations were tested. Figure 10 shows the rate of reducing sugar formation (mM h−1). The degree of naringin hydrolysis was linearly proportional to the enzyme concentration up to 2,000 mg L−1. These results were similar to that reported by Sekeroglu et al. [39] for the same enzyme but using different immobilization method, although, in Pedro et al. [40] and Ribeiro et al. [41], linear proportionality was attained for enzyme concentrations below 500 mg L−1 with naringinase immobilized, respectively, on calcium alginate (2%) and K-carrageenan (2%) beads.

Effect of enzyme concentration on hydrolysis degree of naringin by free and immobilized naringinase. Free enzyme (empty circles); immobilized enzyme (filled circles). Reaction conditions: initial naringin concentration, 500 mg/L; temperature, 30 °C; sodium acetate buffer 0.02 M, pH 4.0; reaction time, 1 h

The naringinase concentration used in further experiments was 2,000 mg L−1 relative to the reaction media for both free and immobilized enzyme.

Effect of pH on the Activity of Free and Immobilized Naringinase

The effect of pH on the activity of free and immobilized naringinase for the naringin hydrolysis was examined from pH 3.0 to 6.0. The activities obtained are presented in Fig. 11. The maximum activity was observed at optimum pH around 4 for both free and immobilized naringinase. The pH profile of the immobilized enzyme reveals a broader profile of enzyme activity, which is suggestive of a protective role played by the beads, more noticeable at extreme pH values tested. The lower activity of the immobilized naringinase may be attributed to alteration of enzyme structure during entrapment into the acid boric solution or to diffusion limitations.

Effect of pH on degree of hydrolysis of naringin by free and immobilized naringinase. Free enzyme (empty circles); immobilized enzyme (filled circles). Reaction conditions: 2,000 mg enzyme per liter; initial naringin concentration, 500 mg/L; temperature, 30 °C; sodium acetate buffer; reaction time, 1 h

Similar observations has been frequently reported in the literature [5], namely in the work of Sekeroglu et al. [39], with naringinase from P. decumbens, and of Busto et al. [42], with naringinase from Aspergillus niger for free and immobilized forms, in PVA cryogel. Also, optimum pH values of 4.5 for naringinase from A. niger [43] and from P. decumbens [44] were referred. Lower pH values were reported for immobilized naringinase from P. decumbens, like 3.5 on Celite by the adsorption/cross-link with glutaraldehyde [45] and on activated seeds of Ocimum basilicum with covalent binding method [46]. Tsen et al. [47] referred an optimum pH value of 3.7 from Penicillium sp. with naringinase immobilized in cellulose triacetate fiber by the entrapment method.

Effect of Temperature on the Activity of Free and Immobilized Naringinase

The use of enzymes in bioprocesses often encounters the problem of its thermal inactivation. Under high temperature, enzymes may undergo partial unfolding by heat-induced destruction of noncovalent interactions [21].

The temperature dependence of the free and immobilized naringinase activity was studied in the temperature range 30–90 °C. The results obtained are depicted in Fig. 12. Optimum catalytic activity was observed at 70 °C, for both free and immobilized naringinase; however, the immobilized enzyme had a lower activity than the free one. This may be due to decreased affinity of the enzyme for the substrate caused by internal diffusion restriction of the immobilized naringinase. The immobilized naringinase exhibited a broader profile at the optimum temperature, showing a better thermal stability, whereas the free enzyme was less stable towards heat [48]. The polymer network is supposed to preserve the tertiary structure of the enzyme. It has been suggested that enzyme immobilized in the matrix with multiple-point attachment or with higher hydrophobicity exhibits greater thermal stability [48]. This statement is highlighted by data presented in Fig. 12, where residual activity tends to increase with the concomitant temperature increase, until 70 °C.

Effect of temperature on degree of hydrolysis of naringin by free and immobilized naringinase. Free enzyme (empty circles); immobilized enzyme (filled circles). Reaction conditions: 2,000 mg enzyme per liter; initial naringin concentration, 500 mg/L; sodium acetate buffer 0.02 M; pH 4.0; reaction time, 1 h

Similar observations were also reported by Tsen et al. [45], using Penicillium sp. naringinase.

The optimum temperature values reported from previous studies, for free naringinase, from P. decumbens showed values of 55 °C [45], 70 °C [43, 44], and 60 °C [45] from A. niger naringinase.

In previous studies on the immobilization of naringinase from P. decumbens, an optimum temperature of 60 °C was reported, with entrapment in gelatin open-pore matrix and in calcium alginate beads [45], with adsorption/covalent binding method with glutaraldehyde in Celite [44] and with covalent binding in hen egg white [45]. When naringinase from Penicillium sp. was entrapped in cellulose triacetate fiber [46], an optimum temperature of 55 °C was reported. An optimum temperature of 65 °C was reported for naringinase immobilized in activated seeds of O. basilicum [47], while 70 °C was referred for naringinase from A. niger immobilized in PVA cryogel with freeze and thawing method [42].

An almost identical behavior was observed by Dave and Madamwar [21] for both free and immobilized lipase at different temperatures. However, at higher temperatures, the activity of the free enzyme actually decays more noticeably when compared to immobilized enzyme.

Upon immobilization and operating at 70 °C and pH 4.0, the immobilized enzyme displayed activity retention of roughly 80% as compared to the free form. At standard reaction conditions of 30 °C and pH 4.0, the activity retention was 65%. When naringinase was used for immobilization in Ca–alginate beads under 0.1 and 160 MPa, a residual activity of 35% and 70%, respectively, was obtained [39]. A residual activity of 57% was referred at optimum conditions of 65 °C and pH 3.5, with naringinase immobilized on activated seeds of O. basilicum [47]. Using the absorption/covalent binding method with glutaraldehyde in Celite, the best result for activity retention upon immobilization was 83% at pH 3.5 and 60 °C [44]. Activity retention of 30–40% upon immobilization of naringinase from Penicillium sp. by entrapment in cellulose triacetate fiber was reported at optimum reaction conditions (55 °C, pH 3.7) [43].

Kinetic Parameters

The kinetic parameters, Michaelis constant (K m) and maximum reaction rate (V max) for free and immobilized naringinase in PVA–alginate beads, were determined by varying the concentration of naringin in the reaction medium (acetate buffer 0.02 M pH 4.0 at 30 °C).

The initial hydrolytic reaction rates of naringin were evaluated based on the results shown in Fig. 13.

Assuming that the hydrolytic reaction of naringin by the encapsulated naringinase obeyed Michaelis–Menten model, the kinetic parameters were evaluated. The apparent Michaelis constant (K Mapp) and the maximum velocity (V maxapp) were calculated by the linear regression of Lineweaver–Burk plot for free and immobilized naringinase, with a determination coefficient of 0.99, as shown in Fig. 14.

The apparent K M value (0.35 mM) for the immobilized naringinase was higher than for free enzyme (0.23 mM). This may be caused by mass transfer resistances, typical of immobilized systems, where the access of substrate to the enzyme entrapped in the matrix is hindered. On other hand, the V maxapp of the free enzyme (0.13 mM min−1) was found to be greater than that of the immobilized enzyme (0.08 mM min−1). As discussed in other works [5, 49], the V maxapp values follow the opposite trend of K Mapp, suggesting that the residual activity of the immobilized enzyme decreased in the course of entrapment.

The K Mapp value of 0.35 mM for the immobilized enzyme was similar to those reported in previous studies with other supports (K-carrageenan beads [41] 0.31 mM and Ca–alginate [39] 0.30 mM). However, the K Mapp value of 0.233 mM at 30 °C for free enzyme was lower than the 0.55 mM value reported by Vila-Real et al. [3], at 40 °C. As stated above, the reaction temperature also affects the kinetic parameters.

The V maxapp (0.08 mM min−1) of hydrolytic reaction with naringinase immobilized on PVA was higher when compared to the V maxapp of 0.046 mM min−1 obtained with naringinase immobilized in K-carrageenan and of 0.063 mM min−1 for free enzyme, reported by Ribeiro et al. [41] and Vila-Real et al. [3], respectively.

Operational and Storage Stability

The operational and storage stabilities of an immobilized enzyme without appreciable loss of enzyme activity are important for the economic viability of a biosynthetic process [50]. The operational stability of enzymes is one of the most important factors affecting the success of the applications of an immobilized system.

The production of an immobilized form of a biocatalyst is typically performed in a batchrun, where large amounts result. These are to be stored under suitable condition for use when required. It is therefore a key issue, particularly if large-scale application is envisaged, to ensure that the decay of catalytic activity of the immobilized biocatalyst is as reduced as possible. Since such decay is nevertheless inevitable, it is considered to be of relevance to have a sound estimate of the rate of such decay, irrespective of thepattern of storage decay of the free enzyme.

In this bioconversion, naringin PVA–alginate beads were allowed to proceed for nine runs performed over a 4-day period.

The residual activity of the immobilized naringinase retained over 70% of its initial activity after eight runs (Fig. 15). Since no significant protein levels were detected in the bioconversion medium once the reaction stopped, the decay may be due to loss of bound enzyme because of weak interaction during the first run, mainly during washing procedures.

Data on operational stability from previous reported studies involving PVA cryogel immobilization of naringinase from A. niger for naringin hydrolysis showed that only 36% of the initial activity was retained after six reuses, with runs of 24 h at 20 °C [42].

Entrapment methods retained an activity of 60% after four and of 40% after five consecutive reuses were reported for naringinase entrapped in Ca–alginate [39] and in K-carrageenan beads [41], respectively. Sekeroglu et al. [40], using a mixed method of adsorption/cross-linking with glutaraldehyde, reported an activity decay of roughly 40% after three repeated runs; no further activity decay was observed for two more runs.

In general, if an enzyme is in solution, it is not stable during storage, and the activity is gradually reduced [22]. Thus, storage stability of an enzyme is of significant importance for scheduling its application in a particular reaction.

The immobilized and free enzymes were stored in acetate buffer for 6 weeks at 4 °C. The residual activity of the enzyme was determined as a function of time (Fig. 16). One of the most important aims of the enzyme engineering is to enhance the conformational stability of enzymes [21].

Storage stability of immobilized PVA–alginate beads (filled circles) and free naringinase (empty circles), at 4 °C in acetate buffer 0.02 M, pH 4.0, during 6 weeks. Reaction conditions: 2,000 mg enzyme per liter; initial naringin concentration, 500 mg/L; 0.02 M sodium acetate buffer 0.02 M; pH 4.0; temperature, 30 °C; reaction time, 1 h

Figure 16 shows that, in the first week, an increase in residual activity was noticed and could be attributed to enhanced stabilization of the matrix during storage at 4 °C, creating a better microenvironment for enzyme activity. After 6 weeks, at 4 °C, a naringinase residual activity of 90% remains constant.

Conclusions

The application of micromethodology in the immobilization and analytical procedures proved to be a very efficient and low-cost technique when compared to the standard macromethod. Especially designed microplates, developed for DNS micromethod, were effectively used allowing for parallel assays of a large quantity of samples.

The degree of hydrolysis of naringin correlated linearly with the enzyme concentration up to 2,000 mg L−1 of enzyme. The pH and temperature activity profiles of the enzyme towards naringin were not significantly altered upon immobilization; the optimum pH (4.0) and temperature (70 °C) remain unaltered.

The higher naringin residual activity was of 80%, obtained at nearly optimum conditions of 70 °C and pH 4.0 for PVA–alginate-immobilized naringinase. At standard conditions of 30 °C and pH 4.0, immobilized naringinase displayed a maximum residual activity of 65%.

A residual activity of 70% remains after eight reutilizations of naringinase in PVA (10%)–alginate (1%) beads. The storage stability, after 6 weeks, of the PVA (10%)–alginate (1%) beads remains constant, corresponding to 90% of residual activity.

In contrast to biopolymers, PVA hydrogels are hardly biodegradable and show an excellent mechanical stability with a large elongation at break, and even in long-time reactions no significant abrasion could be observed [11]. In addition, the PVA–alginate support matrices developed evidenced physical stability at high temperatures (>50 and <80 °C). This increases the potential of the immobilized naringinase application as a practical catalyst on an industrial scale because higher temperatures reduce the viscosity of the reaction medium, minimize the mechanical energy in agitation, reduce the risk of contamination, and improve naringin solubility.

In conclusion, these very promising results achieved with immobilized naringinase on PVA–alginate beads are illustrative of the potential of this strategy for biocatalyst immobilization.

References

Ferreira, L., Afonso, C., Vila-Real, H., Alfaia, A., & Ribeiro, M. H. L. (2008). Food Technology and Biotechnology, 46(2), 146–150.

Ladaniya, M. (2008). Citrus fruit: Biology, technology and evaluation. Amsterdam: Elsevier.

Vila Real, H. J., Alfaia, A. J., Calado, A. R. T., & Ribeiro, M. H. L. (2007). Food Chemistry, 102(3), 565–570.

Ribeiro, I. A., Rocha, J., Sepodes, B., Mota-Filipe, H., & Ribeiro, M. H. L. (2008). Journal of Molecular Catalysis B Enzymatic, 52–53, 13–18.

Bajpai, A. K., & Bhanu, S. (2003). Colloid & Polymer Science, 282, 76–83.

Lozinsky, V. L., & Plieva, F. M. (1998). Enzyme and Microbial Technology, 23, 227–242.

Durieux, A., Nicolay, X., & Simon, J. P. (2000). Biotechnology Letters, 22, 1679–1684.

Czichocki, G., Dautzenberg, H., Capan, E., & Vorlop, K.-D. (2001). Biotechnology Letters, 23(16), 1303–1307.

Gröger, H., Capan, E., Barthuber, A., & Vorlop, K. D. (2001). Organic Letters, 3, 1969–1972.

Wilson, L., Illanes, A., Pessela, B. C. C., Abian, O., Fernández-Lafuente, R., & Guisán, J. M. (2004). Biotechnology and Bioengineering, 86(5), 558–562.

Parascandola, P., Branduardi, P., & Alteris, E. (2006). Enzyme and Microbial Technology, 38, 184–189.

Schlieker, M., & Vorlop, K. D. (2006). A novel immobilization method for entrapment LentiKats® methods in biotechnology. In J. M. Guisan (Ed.), Immobilization of enzymes and cells (2nd ed., pp. 333–343). Heidelberg: Springer.

Ariga, O., Takagi, H., Nishizawa, H., & Sano, Y. (1987). Journal of Fermentation Technology, 65, 651–658.

Imai, K., Shiomi, T., Uchida, K., & Miya, M. (1986). Biotechnology and Bioengineering, 28, 1721–1726.

Idris, A., Zain, N., & Suhaimi, M. (2008). Process Biochemistry, 43, 331–338.

Long, Z., Huang, Y., Cai, Z., Cong, W., & Ouyang, F. (2004). Process Biochemistry, 39, 2129–2133.

Chen, K., & Houng, J. (1994). Cell immobilization with phosphorylated polyvinyl alcohol (PVA) gel. In G. F. Bickerstaff (Ed.), Immobilization of enzymes and cells: Methods biotechnology (Vol. 1). Heidelberg: Springer.

Chen, K., Chen, S., & Houng, J. (1996). Enzyme and Microbial Technology, 18, 502–506.

Chang, C., & Tseng, S. (1998). Biotechnology Techniques, 12(12), 865–868.

Li-sheng, Z., Wei-zhong, W., & Jian-long, W. (2007). Journal of Environmental Science, 19, 1293–1297.

Dave, R., & Madamwar, D. (2006). Process Biochemistry, 41, 951–955.

Queiroz, A., Passos, E., Alves, S., Silva, G., Higa, O., & Vítolo, M. (2005). Journal of Applied Polymer Science, 102, 1553–1560.

Hsia, T., Feng, Y., Ho, C., Chou, W., & Tseng, S. (2008). Journal of Industrial Microbiology & Biotechnology, 35, 721–727.

Wu, A. K. Y., & Wiesecarver, K. D. (1992). Biotechnology and Bioengineering, 39, 447–449.

Grishin, S. I., & Tuovinen, O. H. (1989). Applied Microbiology and Biotechnology, 31, 505–511.

Lin, H., Liu, W., Liu, Y., & Cheng, C. (2002). Journal Polymer Research, 9, 233–238.

Kurokawa, H., Shibayama, M., Ishimaru, T., Nomura, S., & Wu, W. (1992). Polymer, 33(10), 2182–2188.

Leibler, L., Pezron, E., & Pincus, P. A. (1988). Polymer, 29, 1105–1109.

Keita, G., Ricard, A., Audebert, R., Pezron, E., & Leibler, L. (1995). Polymer, 36, 49.

Pattanapitpaisal, P., Brown, N. L., & Macaskie, L. E. (2001). Biotechnology Letters, 23, 61–65.

Miller, G. L. (1959). Analytical Chemistry, 31, 426–428.

Bradford, M. M. (1976). Analytical Biochemistry, 72, 248–254.

Kim, J., Choi, H., et al. (2008). International Journal of Pharmaceutics, 359, 79–86.

Li, M., Cheng, S., & Yan, H. (2007). Green Chemistry, 9, 894–898.

Braze, C. S., & Peppas, N. A. (2000). European Journal of Pharmaceutics and Biopharmaceutics, 49, 47–58.

Kim, C., & Lee, P. (1992). Pharmaceutical Research, 9, 10–16.

Nizam Horia, M., Abd Alla Safaa, G., & El-Naggar Abdel Wahab, M. (2007). Journal of Macromolecular Science A, 44(3), 291–297.

Mikkelsen, A., & Elgsaeter, A. (1995). Biopolymers, 36(1), 17–41.

Sekeroglu, G., Fadıloglu, S., & Gogus, F. (2006). European Food Research and Technology, 224, 55–60.

Pedro, H. A., Alfaia, A. J., Marques, J., Vila-Real, H. J., Calado, A. T., & Ribeiro, M. H. L. (2007). Enzyme and Microbial Technology, 40, 442–446.

Ribeiro, I. A., & Ribeiro, M. H. L. (2008). Journal of Molecular Catalysis B Enzymatic, 51, 10–18.

Busto, M. D., Meza, V., Ortega, N., & Perez-Mateos, M. (2007). Food Chemistry, 104, 1177–1182.

Soares, N., & Hotchkiss, J. (1998). Journal of Food Science, 63, 61–65.

Norouzian, F., Hosseinzadeh, A., Inanlou, D., & Moazami, N. (1999). World Journal of Microbiology and Biotechnology, 15(4), 501–502.

Puri, M., Kaur, H., & Kennedy, J. F. (2005). Journal of Chemical Technology & Biotechnology, 80(10), 1160–1165.

Norouzian, D. (2003). Iranian Journal of Biotechnology, 1(4), 197–206.

Tsen, H., Tsai, S., & Yu, G. (1989). Journal of Fermentation and Bioengineering, 67, 186–189.

Buchholz, K., & Klein, J. (1987). In K. Mosbach (Ed.), Methods in enzymology: Immobilized enzymes and cells (pp. 3–30). London: Academic.

Manjón, A., Bastida, J., Romero, C., Jimeno, A., & Iborra, J. L. (1985). Biotechnology Letters, 7(7), 477–482.

Luckarift, H. R., Spain, J. C., Naik, R. R., & Stone, M. O. (2004). Nature Biotechnology, 22, 211–213.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nunes, M.A.P., Vila-Real, H., Fernandes, P.C.B. et al. Immobilization of Naringinase in PVA–Alginate Matrix Using an Innovative Technique. Appl Biochem Biotechnol 160, 2129–2147 (2010). https://doi.org/10.1007/s12010-009-8733-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-009-8733-6