Abstract

A novel immobilized enzyme system supported by poly(acrylic acid/N,N’-methylene-bisacryl-amide) hydrogel microspheres was prepared. This system exhibited characteristics of reversible pH-triggered release. The morphology, size, and chemical structure were examined through optical microscopy, particle size analyzer, and Fourier transform infrared spectrometer. Immobilization and release features were further investigated under different conditions, including pH, time, and microsphere quantity. Results showed the microspheres were regularly spherical with 3.8 ~ 6.6 μm diameter. Loading efficiencies of bovine serum albumin immobilized by gel entrapment and adsorption methods were 93.9% and 56.2%, respectively. The pH-triggered protein release of the system occurred when medium pH was above 6.0, while it was hardly detected when medium pH was below 6.0. Release efficiencies of entrapped and adsorbed protein were 6.38% and 95.0%, respectively. Hence, adsorption method was used to immobilize trypsin. Loading efficiency of 77.2% was achieved at pH 4.0 in 1 h. Release efficiency of 91.6% was obtained under optimum pH catalysis condition set at 8.0 and trypsin was free in solutions with retention activity of 63.3%. And 51.5% of released trypsin could be reloaded in 10 min. The results indicate this kind of immobilized enzyme system offers a promising alternative for enzyme recovery in biotechnology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Efficient immobilized enzyme systems are important in the field of biotechnology and other enzyme-related areas such as clinical investigations, automated analyses, and biosensor recognition [1–3]. Compared with free enzyme systems, the immobilized ones offer the advantages of having batch or continuous processes options, rapid termination of reactions, controlled product formation, ease of removal from the reaction mixture, and adaptability to various engineering designs [4]. Hence, the preparation, properties, and use of immobilized enzyme systems have attracted considerable attention in research and industrial applications.

At present, enzyme immobilization methods may be broadly divided into two main categories, physical and chemical methods. The former is based on molecular interactions between the enzyme and support, such as adsorption and entrapment. The latter is based on the formation of covalent bonds. Among these methods, adsorption appears to offer better commercial potential because it is simpler, less expensive, and retains higher catalytic activity [5, 6]. With this method, no coupling reagent and reactive group of any amino acid residue of the protein are required to form specific covalent bonds with the supports. However, several studies have found that physically adsorbed enzymes on most supports were generally not strong enough, causing slow enzyme leakage during washing and operation or reaction processes [7]. Moreover, enzymes immobilized on solid-supports refer to two-phase systems with inherent mass transfer limitations. Thus, these systems are subject to unavoidable diffusion hindrance [8, 9]. In addressing the abovementioned problems, developing a new strategy for enzyme immobilization is urgently needed.

Recently, intelligent hydrogels have attracted substantial attention, particularly in pharmaceutical and material fields. These hydrogels are able to alter their volume or other properties by recognizing external chemical or physical stimuli, such as pH, temperature, ions, and light strength [10–13]. The pH-dependent hydrogels are among the most widely studied intelligent hydrogels and some of them have already been used as potential enzyme supports in biotechnology. Brahim et al. immobilized glucose oxidase on p(HEMA-DMEMA) hydrogel microspheres and investigated its reaction kinetics in a packed-bed bioreactor. In another study, Bahar et al. synthesized poly(HPMA–co-MAA) hydrogel beads and loaded α-chymotrypsin onto their surface through covalent cross-link method. Adsorption method was likewise employed by Arslan et al. in immobilizing invertase on p(AAm/MA) and the effect of gel composition on immobilization was examined. In these studies, they made use of the special structure feature of pH-dependent hydrogels for convenient immobilization process or catalysis reaction mechanism investigation. Few reports involving pH-triggered release immobilized enzyme systems are available. In addition, it was revealed that the diffusion limitation of these systems was mitigated to some extent due to the gel swelling. It resulted in polymer conformation changes, such as in volume and in ionization degree. The said changes then affected enzyme activity and substrate access to the enzyme [14–17]. However, similar limitations are present in most of the supports mentioned above. For entrapped and covalent-linked enzymes, retention enzyme activity on the supports remained low due to harsh immobilization process. At the other end, gel swelling led to more frequent enzyme leakage for adsorbed enzymes.

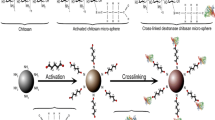

In this study, a new strategy for designing the immobilized enzyme system was proposed. Specifically, this system had the characteristics of reversible pH-triggered release, established on mild non-covalent cross-linking methods. The p(AAc/MBA) microspheres, among the most widely used and simplest polyacid hydrogels, were applied as the supports for alkaline enzymes. Trypsin was selected as the model owing to its appropriate activity pH range and to the considerable academic interest it has gained [18–20]. When the system used for catalysis at pH 8.0, conjugated trypsin can be released, while at pH 4.0, the catalysis reaction was almost impeded and trypsin was reloaded after a while. This was realized through repeated swelling and shrinking of the system. Thus, not only unfavorable enzyme leakage becomes controllable and desirable, but also the reaction speed can be controlled intelligently through pH adjustment. Most importantly, active enzyme performs in its free form ultimately without diffusion limitation and steric hindrance. Overall, the results obtained in this paper are consistent with what were expected. In other words, this kind of immobilized enzyme system could provide a new effective alternative for enzyme reuse in biotechnology in the future.

Materials and Methods

Materials

The AAc was obtained from Tianjin Chemical Plant (Peoples Republic of China) while the MBA was purchased from Red Star Chemical Factory (Peoples Republic of China). As for BSA (M W = 68,000), it was obtained from Roche (Germany), while Span-80 was purchased from Sigma (USA). TEMED and trypsin (1:250) were both obtained from aMResco (USA). BAEE was also purchased from the USA, specifically at Bio Basic Inc. (BBI). The medium pH was adjusted with HCl (0.01 mol l−1) and NaOH (0.01 mol l−1) solutions.

Preparation of p(AAc/MBA) Hydrogel Microspheres

The p(AAc/MBA) hydrogel microspheres were prepared by inverse suspension polymerization. Briefly, 2.0 ml of AAc, 0.05 g of MBA, and 0.1 g of KPS were added to 7.0 ml of 10% (w/v) NaOH solution to prepare the aqueous phase mixture (0 ~ 5 °C ice bath). In a separate process, oil phase mixture was obtained by adding 17 drops of span-80 into 100 ml dimethylbenzene, which was previously poured into a flask with three necks. After purging the flask with N2 for 10 mins at 30 °C, the prepared aqueous phase was added dropwise to the oil phase with a stirring rate of 300 rpm. This led to the formation of inverse uncontinuous phase (w/o). Afterwards, the polymerization was accelerated by injecting 0.80 ml of TEMED into the reaction mixture. This process was performed at 30 °C for 2 h. Finally, the bulk of dimethylbenzene was removed and the monodisperse hydrogel microspheres obtained were twice rinsed with pure ethanol (20.0 ml). The final p(AAc/MBA) hydrogel microspheres obtained were then stored at 4 °C prior to use.

Characterization of p(AAc/MBA) Hydrogel Microspheres

The morphology of p(AAc/MBA) hydrogel microspheres was observed with an optical microscope (OLYMPUS BX40, Japan). Their sizes and size distributions were determined using Particle Size Analyzer (Mastersizer 2000, UK). In terms of the swelling behavior of the hydrogel microspheres, it was investigated as a function of pH at 25 ± 1 °C. Briefly, appropriate amounts of the hydrogel microspheres were immersed in media with pH ranging from 2.0 ~ 10.0. Such media were prepared through the addition of HCl (0.01 mol l−1) or NaOH (0.01 mol l−1) solutions [21]. Immediately, their particle sizes were examined directly with the mixture. It is because that the whole reversible swelling process of p(AAc/MBA) can be detected clearly by optical microscope and it was found that the swelling equilibrium state was reached in no more than 2 min. The swelling ability could be estimated using this formula:

The results calculated here are expressed in a normalized form with the smallest particle size serving as comparison.

Using a Fourier transform infrared spectrometer (FTIR, IRPrestige-21, Japan), the chemical structures of p(AAc/MBA) microspheres were evaluated. As the controls, the FTIR spectra of monomer AAc and MBA were likewise presented.

Investigations of Protein Immobilization Characteristics

To explore suitable route for the preparation of immobilized enzyme system, BSA was selected as a pre-model, instead of enzymes. Entrapment and adsorption were used as potential methods for loading BSA molecules. For the former, certain quantity of BSA (30 ~ 50 mg) was dissolved directly in the monomer mixture prior to polymerization. These were then polymerized as previously described. The wash solutions were collected and treated through dialysis. The protein content was determined using the Coomassie Brilliant Blue method as described in a study by Bradford [22]. Alternatively, for the latter, BSA was loaded into preformed p(AAc/MBA) microspheres through adsorption. Varying amounts of p(AAc/MBA) microspheres (0.20 g ~ 0.40 g) were first mixed with standard concentrated solutions of BSA (8.0 ml, 1 mg ml−1). Afterwards, these mixtures were adjusted to different pH ranging from 2.0 to 8.0 and incubated for hours at 4 °C. Each mixture was centrifuged (9,000 rpm) for 10 min at hourly intervals to separate immobilized BSA from the residual solution. The supernatants obtained were assayed for BSA content. Finally, all experimental groups were adjusted to pH 2.0 followed by the removal of the supernatants through centrifugation. The concentrated microspheres were washed with pH 2.0 solutions and resuspended in buffer solutions at selected pH values for subsequent release studies. BSA content in the medium was measured using UV spectrophotometer (Ultrospec 2100 pro, Amersham Biosciences, Sweden) at 280 nm. The efficiency of BSA immobilized (ηL) by the samples was calculated as follows:

After immobilizing the BSA, the reversible pH-triggered release characteristics were tested. Firstly, to evaluate BSA release process, the hydrogel micropsheres containing BSA were immersed in media (8.0 ml) with pH ranging from 4.0 to 9.0. These mixtures were then centrifuged and the supernatants acquired were examined for BSA concentration. The BSA release efficiency was specifically evaluated using this equation:

Afterwards, BSA recovery from the release media was analyzed similarly with the mixtures adjusted to pH 2.0. In evaluating the efficiency of BSA recovered from this media, this formula was employed:

It must be noted that all loading studies were performed in duplicate. The average of these results was presented accordingly. To counteract absorbance value of microspheres at 280 nm, controls were set up by immersing the same quantity of microspheres in distilled water followed by pH adjustment.

Trypsin Immobilization System and its Reversible pH-Triggered Release Characteristics

The trypsin immobilized system was prepared through adsorption method and tested precisely as detailed above. However, there was one exception. Since trypsin was not stable at pH <2.5, the samples of the experimental groups were all adjusted to pH 4.0 for reservation and washed with solutions of pH 4.0. Trypsin activity was monitored directly in the cuvette of a UV spectrometer at room temperature using BAEE as the synthesized substrate. This process was based on the standard principle [23]. Briefly, 1.5 ml Tris–HCl (0.1 M, pH 8.0) and 1.5 ml BAEE (2 mmol l−1) were added into quartz colorimetric cuvette, followed by appropriate volumes of trypsin solutions added to the mixture. The absorbance of the mixture at 253 nm was measured every 30 s for six times. One unit of trypsin activity (U) is defined as the amount of trypsin that increased absorbance of 0.001 per minute at 253 nm (ΔA253 nm/min) under the condition described above, i.e.

To avoid error, the activity of native and immobilized trypsin was detected simultaneously. Retention activity represents the percentage of immobilized trypsin activity compared to that of free trypsin with the same amount (i.e. specific activity ratio). In investigating operational stability of the immobilized trypsin system estimated by inactivity rate, both immobilized and native trypsin were placed in Tris–HCl (pH 8.0) medium at room temperature. This simulates practical bioreactor environment. Given this set-up, their activity was examined at half hour intervals.

Results and Discussion

Characteristics of p(AAc/MBA) Hydrogel Microspheres

Morphology and Particle Size

The prepared p(AAc/MBA) hydrogel microspheres were monodisperse and approximately spherical (Fig. 1). Most of the hydrogel microspheres have a diameter of 3.8 ~ 6.6 μm swollen in aqueous solutions at pH 6.0 (Fig. 2). This pH value is in the suitable range for immobilized enzyme systems [24]. In addition, after being stored under common conditions, such as in a refrigerator or at room temperature for 6 months, the hydrogel microspheres did not exhibit any significant change in morphology and particle size. These are indicators of the stability and good fluidity of p(AAc/MBA) microspheres.

FTIR Analysis of p(AAc/MBA) Hydrogel Microspheres

Copolymers of the hydrogel microspheres were composed of AAc and MBA units as verified by FTIR-spectroscopy. In Fig. 3a, the peaks observed at 1,618 cm−1 and 1,637 cm−1 were associated with the C=C bond vibration of acrylic acid. Figure 3b illustrates that the peak at 1,651 cm−1 was assigned to the stretching vibrations of C=C bond of MBA. However, the C=C bond vibration of synthesized p(AAc/MBA) in Fig. 3c exhibited only a weak peak, if any. Apparently, polymerization occurred between C=C bond to a large extent. With regards to other typical groups in the molecules which have not taken part in the chemical polymerization, changes to their spectra occurred at an observable extent. This indicates that certain structural changes were formed after polymerization. For example, the peaks for AAc-OH group and MBA N–H bond were at 3,310 cm−1 and 2,936 cm−1, respectively, while the stretching vibrations of O–H and N–H bonds in Fig. 3c were found to overlap at the broad band with a shift to 3,445 cm−1.

pH-responsive Characteristics of p(AAc/MBA) Hydrogel Microspheres

Figure 2 presents the size distribution of p(AAc/MBA) hydrogel microspheres over a wide pH ranging from 2.0 to 10.0. On the other hand, Fig. 4 presents the calculated swelling degree. It was shown that the particle size of the hydrogel microspheres was pH-dependent and an abrupt phase transition occurred around pH 5 ~ 6. This finding suggests that the pKa of p(AAc/MBA) hydrogel microspheres was within this range, which is consistent with previous reports on polyacids bearing carboxylic groups [25]. At pH <6.0, pendant carboxylic groups of AAC moiety were in non-ionized states, which were less hydrophilic than their ionized counterparts. This made them get together more readily and thus water was excluded from the hydrogel network. As the medium pH increased to values above the pKa of p(AAc/MBA) microspheres, deprotonation occurred. As a result, negatively charged carboxylic groups were formed. The repulsion force between these groups drove the hydrogel microsphere chains to move apart spatially. Furthermore, countercations around the solutions were pulled into their structure to maintain electroneutrality (Donnan equilibrium) within the hydrogel microspheres. This eventually led to the swelling and the occurrence of discontinuous phase transition [26, 27]. Results also indicate that when pH was above 6.0, the polyacid hydrogels microspheres underwent an increase in the particle size as well as in the swelling degree upon further increasing pH. This finding is actually expected owing to the larger increase in ionization degree of p(AAc/MBA). The diameter of certain hydrogel microspheres at pH 10.0 was almost 40 times as large as those at pH 2.0 (Fig. 2, inset). The particle size was examined immediately after reaching appropriate pH, which revealed that the hydrogel microspheres had appropriate pH-sensitivity and rapid phase transition.

Investigations of Protein Immobilization Characteristics

Through adsorption and gel entrapment, BSA was loaded into p(AAc/MBA) hydrogel microspheres. Both are physical methods with relatively weak bond strength. Given this, possibilities for subsequent reversible release of the immobilized protein are opened up.

Adsorption Method

To improve combination stability of adsorbed protein, the adsorption process was modified here. Previously, adsorption mainly occurred directly on the surface of the supports through ion or hydrogen bond, among others [28]. However, in this research, the protein was wrapped within p(AAc/MBA) through a two-step process achieved by swelling and deswelling the p(AAc/MBA) microsphere supports. The media with different pH values for adsorption were then compared. Specially, after the hydrogel microspheres were soaked in standard BSA solutions, pH was adjusted to form four groups. Table 1 presents details on this. Results shows that much greater BSA quantity was loaded in low pH solutions of 4.0 (56.2%) and 2.0 (34.5%) than in high pH solutions of 6.0 (6.91%) and 8.0 (7.59%). As soon as the pH of those two media (pH 6.0, 8.0) was decreased to pH 2.0 or 4.0, more BSA was loaded within the hydrogel microspheres (data not shown). In other words, loading efficiency on p(AAc/MBA) was quite different between media with pH values below and above the pKa. This was attributed to the sudden volume transition of p(AAc/MBA) triggered by pH. The p(AAc/MBA) hydrogel microspheres soaked in standard BSA solutions were in their swollen states with increased particle and mesh sizes. When the pH was adjusted to 4.0 or 2.0, values below pKa, p(AAc/MBA) de-swelled rapidly to their collapsed states. In these states, they showed decreased particle and mesh sizes. Hence, both BSA molecules around and already adsorbed on p(AAc/MBA) could be tightly wrapped within the complex network of p(AAc/MBA). However, when the solution pH was adjusted to 6.0 or 8.0, which was also above pKa, p(AAc/MBA) still maintained the swollen state. Adsorption equilibrium could not be reached in a short span of time. More importantly, BSA adsorbed on swollen p(AAc/MBA) through equilibrium partition without the wrapping process was probably unable to resist high speed centrifugation (9,000 rpm). BSA concentration in swollen p(AAc/MBA) prior to centrifugation may be higher but this system was not stable. High speed centrifugation probably contributed to rule out certain BSA from the system. In other words, centrifugation during the immobilization process guaranteed combination stability of adsorbed protein. Therefore, it would reduce the possibility of further uncontrolled leakage of loaded protein.

The quantity of hydrogel microspheres was varied and its effect on loading efficiency was investigated. As can be gleaned from Table 2, loading efficiency (ηL) increased correspondingly as the mass of hydrogel microspheres increased, whereas the loading capacity of per mg gel was in a depressed trend. This suggests that the increase was not linear in proportion in relation with the hydrogel microsphere mass. Hence, the conclusion that higher hydrogel microsphere density leads to higher loading amount can be drawn. Taking this into account, the rest of the experiments would be conducted with higher density of hydrogel microspheres.

Due to the pH-dependent size change of p(AAc/MBA), loaded protein can be released out of the immobilized system into the bulk solution. Figure 4 shows the release efficiency of loaded protein under different test conditions with pH ranging from 4.0 to 9.0. It was determined that more than 90% of BSA was released out of the media with pH above pKa. However, the same is hardly detectable at pH below pKa. In addition, there was no significant change in release efficiency as pH varied above the pKa, which had a similar trend with that of the swelling degree (Fig. 4). Since trypsin has an optimum catalysis pH range of 7.6 ~ 8.0, the subsequent release studies would be carried out in media with pH 8.0. These studies include p(AAc/MBA) loaded with BSA and trypsin. Besides, the released BSA can be recovered from the release media by adsorption again. The recovery efficiency was about 40% as can be seen in Table 2.

Gel Entrapment Method

With respect to the entrapped protein, high loading efficiency of 93.9% was achieved, while the quantity of BSA released in bathing media at pH 8.0 was no more than 10% (Table 1). These findings were quite different from the adsorbed protein. In order to explain the discrepancy, methods used to immobilize BSA have to be examined. During entrapment, when p(AAc/MBA) polymerized in the presence of BSA, the byproducts and impurities from the hydrogel’s formation were removed. These were generally mixed with some BSA simultaneously, thus giving rise to a much higher loading efficiency than the actual one, which cannot be exactly evaluated. In addition, actual cross-links may form within the random entanglements between proteins and complex hydrogel networks [28]. Hence, only those loosely entrapped BSA contributed to the release efficiency on swollen p(AAc/MBA) at pH 8.0. In contrast, the BSA loaded by adsorption was much more loosely wrapped within the swollen p(AAc/MBA), due to the poor bond strength between them. As a result, they were more easily released. In this study, adsorption was the preferred method for immobilizing enzyme as compared with gel entrapment. This approach corresponds to the intention of the research which is designing novel immobilized enzyme systems for reversible controlled release.

Immobilization of Trypsin on p(AAc/MBA) Hydrogel Microspheres

As previously established, it is possible to prepare trypsin immobilization system on p(AAc/MBA) through adsorption. Different solvent conditions were also investigated to serve as the basis for comparison with BSA immobilization process. In addition, change of loading capacity with time was further investigated and the results were summarized in Table 3. The trend of pH effect on trypsin immobilization was found to be similar with that on BSA immobilization. However, it is worth noting that higher loading efficiency was obtained, especially in loading media with pH 4.0 (76.7%). Higher density of hydrogel microspheres used here and lower molecular weight of trypsin (M W = 23,000) may contribute to this. Apart from this, immobilization time was determined to have slight effect on loading efficiency of trypsin (Table 3). In terms of the loading capacity at pH 4.0, it reached 61.8 protein per hydrogel microsphere (mg g−1) in an hour and almost kept constant with time. This indicates that adsorption equilibrium was reached in a short span of time. Previously, Brahim et al. [28] got 34.8% of total offered protamine adsorbed after 24-h incubation by swollen p(HEMA-DMAEMA) hydrogel slabs. On the other hand, Hu et al. [24] obtained a loading capacity of 82 mg g−1 on PMMA microspheres. However, the calculated loading efficiency was lower than 40% of the total available pepsin. And enzyme leakage was not taken into consideration here. In comparison, better adsorption efficiency on p(AAc/MBA) hydrogel microspheres was achieved through the two-step adsorption method in a short period.

Reversible pH-Triggered Release Characteristics of Immobilized Trypsin System

The prepared immobilized trypsin system was repeatedly adjusted from pH 8.0 to 4.0, to detect the reversible release performance triggered by pH. As evident in Table 3, the amount of trypsin released at equilibrium swelling on the average was more than 94% of the total amount loaded. In the bulk solution, immobilized trypsin was free. After the pH of the catalysis system reached 4.0, about 50% of the released trypsin was recovered. The swollen state of the polymeric network at pH 8.0 translates to an increase in the network mesh size or pore size. As a result, pores within the network that are larger than trypsin molecules were created; thus allowing the loaded trypsin to diffuse out of the microspheres. Contrarily, p(AAc/MBA) hydrogel microspheres de-swelled and re-adsorbed trypsin at pH 4.0 due to the decreasing mesh or pore size. This is in line with the loading process discussed above. Meanwhile, the catalysis reaction was slowed down until it stopped. It is worth mentioning that the reaction speed can be controlled through the swelling rate of the hydrogels. This area of study can be further investigated in the future.

Activity retention on the support is one of the most significant aspects during enzyme immobilization. Any chemical modification or physical adsorption during immobilization will pose an effect on enzyme activity to some extent. Adsorption with the use of p(AAc/MBA) might relatively be a mild protein immobilization method. Figure 5 presents the retention activity of trypsin after being loaded within p(AAc/MBA) in three different immobilization solvents. Results indicate that the trypsin activity all decreased as compared with the calculated total adsorbed activity regardless of the immobilization solvent. However, the extent of the decline varied largely among the three immobilization solvents. Trypsin immobilized at pH 4.0 retained the highest activity percentage and its retention activity accounted for 63.3% of the total adsorbed activity. For those at pH 6.0 and 8.0, the retention activity reached only 36.2% and 10.3%, respectively. The activity loss here is mainly caused by structural changes in trypsin that may have been introduced during the loading process [29]. Possible factors may be the different microenvironments within p(AAc/MBA) and the long period of incubation. These can cause changes in the affinity of the enzyme to its substrate. Different inactivity extent among the three solvents may be attributed to the structures and properties of trypsin itself. Trypsin becomes less stable because of autolysis when media pH >5.0, and the optimum catalysis pH is within the 7.6 ~ 8.0 range. As a result, the long incubation period of trypsin in media with pH 8.0 caused more severe activity loss.

It is necessary to examine whether the enzyme reaction activity was disturbed by the presence of hydrogel microspheres. Hence, trypsin activity was measured congested both with and without hydrogel microspheres, i.e. before and after centrifugation of the released solutions. Prior to centrifugation, enzyme activity was measured directly with the mixture solutions. On the other hand, after centrifugation, most of the hydrogel microshperes precipitated at the bottom. The supernatants were then collected to measure the enzyme activity. No substantial difference was determined between their retention activity (63.3% prior to centrifugation and 58.9% after centrifugation). In conclusion, the catalysis reaction occurred in the bulk solution. Furthermore, the existence of hydrogel microspheres did not cause any disturbance on the enzyme reaction activity.

Several publications have appeared presenting investigations of new supports for trypsin immobilization. For example, trypsin covalently immobilized on porous glycidyl methacrylate was found to acquire retention activity of 29.2% and loading capacity of 23.8 trypsin per bead (mg g−1) [29]. In another study, Migneault et al. immobilized trypsin on controlled pore glass by glutaraldehyde (CPG-GA). The retention activity was 13.1% and V max/K m was decreased to 52.7% [19]. Wu et al. employed functional PMMA microspheres to load trypsin and this resulted in a decrease of V max/K m to 12.5% [30]. Dudra et al. immobilized trypsin on thermosensitive p(NIPAM-HEMA) copolymers forming an interpenetrated polymer network. The immobilization yield was 23.4% with retained activity lower than 35% [31]. Bryjak et al. also compared different activation methods for trypsin covalent immobilization on acrylic series carriers, and immobilization efficiencies of the protein and the activity could reach 65.0% and 26.5%, respectively [20]. In this particular study, however, trypsin was immobilized on pH-dependent p(AAc/MBA) hydrogel microspheres through modified adsorption method. Loading capacity of 61.8 mg g−1, loading efficiency of 76.7%, and retention activity of 63.3% were obtained. And according to Michaelis–Meten equation [32], the V max/K m value of immobilized trypsin retained more than 60% at maximum compared with that of native trypsin. Overall, trypsin immobilization on p(AAc/MBA) offers greater promise than those established by other strategies.

Stability of Immobilized Trypsin System

Figure 6 illustrates the operational stability of immobilized and native trypsin. When placed in unfavorable environment, the inactivity rate of trypsin showed similarity for both immobilized and native trypsin. Such result was expected because p(AAc/MBA) hydrogel microspheres swelled at pH 8.0 and most of the trypsin was released out of the system. Hence, it exhibited similar properties with native trypsin. Afterwards, both were placed in a 4 °C refrigerator to detect storage stability. After a long storage period (73 days), immobilized trypsin still retained 48.1% of the specific activity, while free trypsin retained only about 15.0%. This suggests that immobilized trypsin had relatively better storage stability than free trypsin.

Conclusion

The novel strategy of pH-triggered reversible release was introduced to enzyme immobilization. Enzymes conjugated to this kind of system can be released for reaction and then recovered intelligently. In this study, relatively high immobilization efficiency and trypsin retention activity were obtained on p(AAc/MBA) hydrogel microspheres supports. This new system may be an effective alternative for enzyme reuse in biotechnology.

Abbreviations

- AAc:

-

acrylic acid

- MBA:

-

N,N′-methylene-bisacrylamide

- BSA:

-

bovine serum albumin

- TEMED:

-

N,N,N′,N′-tetramethylethylenediamine

- BAEE:

-

N-Benzoyl-L-arginine ethylester hydrochloride

- p(AAc/MBA):

-

poly(acrylic acid/N,N′-methylene-bisacryl-amide)

- D pH :

-

main particle size of p(AAc/MBA) microspheres at certain pH

- ηL :

-

loading efficiency

- ηR :

-

release efficiency

- ηU :

-

recovery efficiency

- Ci :

-

initial BSA concentration introduced

- Cf :

-

final BSA concentration in supernatants after immobilization

- Cr :

-

BSA concentration in supernatants after release

- Cu :

-

BSA concentration in supernatants after recovery

- Vl :

-

loading solution volume

- Vr :

-

release solution volume

References

Jahnz, U., Schubert, M., Baars-Hibbe, H., & Vorlop, K. D. (2003). International Journal of Pharmaceutics, 256, 199–206. doi:10.1016/S0378-5173(03)00078-4.

Guilbault, G. G. (1982). Applied Biochemistry and Biotechnology, 7, 85–98. doi:10.1007/BF02798629.

Brahim, S., Narinesingh, D., & Guiseppi-Elie, A. (2002). Biosensors & Bioelectronics, 17, 973–981. doi:10.1016/S0956-5663(02)00089-1.

KatzirKatchalski, E. (1980). Enzyme engineering. New York, NY: Plenum Press.

Nenelson, D., & Maria, A. (2002). Enzyme and Microbial Technology, 31, 907–931. doi:10.1016/S0141-0229(02)00214-4.

Piacquadio, P., & Stefano, G. D. (1997). Biotechnology Techniques, 11, 515–517. doi:10.1023/A:1018418201268.

Krajewska, B. (2004). Enzyme and Microbial Technology, 35, 126–139. doi:10.1016/j.enzmictec.2003.12.013.

Huckel, M., Wirth, H. J., & Hearn, M. T. W. (1996). Journal of Biochemical and Biophysical Methods, 31, 165–179. doi:10.1016/0165-022X(95)00035-P.

Bailey, J. E., & Cho, Y. K. (1983). Biotechnology and Bioengineering, 25, 1923–1935. doi:10.1002/bit.260250803.

Akala, E. O., Kopeckova, P., & Kopecek, J. (1998). Biomaterials, 19, 1037–1047. doi:10.1016/S0142-9612(98)00023-4.

Hiroki, A., Maekawa, Y., Yashioda, M., & Katakai, R. (2001). Polymer, 42, 6403–6408. doi:10.1016/S0032-3861(01)00112-4.

Okahata, Y., & Lim, H. J. (1984). Journal of the American Chemical Society, 106, 4696–4700. doi:10.1021/ja00329a010.

Desponds, A., & Freitag, R. (2005). Biotechnology and Bioengineering, 91, 583–591. doi:10.1002/bit.20479.

Galaev, I. Y., & Mattiasson, B. (1999). Trends in Biotechnology, 17, 335–340. doi:10.1016/S0167-7799(99)01345-1.

Brahim, S., Narinesingh, D., & Guiseppi-Elie, A. (2002). Journal of Molecular Catalysis. B, Enzymatic, 18, 69–80. doi:10.1016/S1381-1177(02)00061-9.

Bahar, T., & Tuncel, A. (2000). Reactive & Functional Polymers, 44, 71–78. doi:10.1016/S1381-5148(99)00081-4.

Arslan, F., Tümtürk, H., Çaykara, T., Sen, M., & Güven, O. (2000). Food Chemistry, 70, 33–38. doi:10.1016/S0956-7135(99)00114-0.

Kang, E. T., Tan, K. L., Kato, K., Uyama, Y., & Ikada, Y. (1996). Macromolecules, 29, 6872–6879. doi:10.1021/ma960161g.

Migneault, I., Dartiguenave, C., Bertrand, M. J., Vinh, J., & Waldron, K. C. (2004). Electrophoresis, 25, 1367–1378. doi:10.1002/elps.200305861.

Bryjak, J., Liesiene, J., & Kolarz, B. N. (2008). Colloids and Surfaces B, Biointerfaces, 61, 66–74. doi:10.1016/j.colsurfb.2007.07.006.

Alvarez-Lorenzo, C., & Concheiro, A. (2002). Journal of Controlled Release, 80, 247–257. doi:10.1016/S0168-3659(02)00032-9.

Bradford, M. M. (1976). Analytical Biochemistry, 72, 248–254. doi:10.1016/0003-2697(76)90527-3.

Rick, W. (1976). In H. U. Bergmeyer (Ed.), Methods of enzymatic analysis, vol. 2: Trypsin pp. 1013–1024. New York, NY: Academic Press.

Hu, J., Li, S., & Liu, B. (2006). Biotechnology Journal, 1, 75–79. doi:10.1002/biot.200500022.

Gil, E. S., & Hudson, S. M. (2004). Progress in Polymer Science, 29, 1173–1222. doi:10.1016/j.progpolymsci.2004.08.003.

Schwarte, L. M., Podual, K., & Peppas, N. A. (1998). Tailored polymeric materials for controlled delivery systems. Washington, DC: American Chemical Society.

Brahim, S., Narinesingh, D., & Guiseppi-Elie, A. (2003). Biomacromolecules, 4, 497–503. doi:10.1021/bm020080u.

Brahim, S., Narinesingh, D., & Guiseppi-Elie, A. (2003). Biomacromolecules, 4, 1224–1231. doi:10.1021/bm034048r.

Malmsten, M., & Larsson, A. (2000). Colloids and Surfaces. B, Biointerfaces, 18, 277–284. doi:10.1016/S0927-7765(99)00153-8.

Wu, S., Liu, B., & Li, S. (2005). International Journal of Biological Macromolecules, 37, 263–267. doi:10.1016/j.ijbiomac.2005.12.007.

Hamerska-Dudra, A., Bryjak, J., & Trochimczuk, A. W. (2007). Enzyme and Microbial Technology, 41, 197–204. doi:10.1016/j.enzmictec.2007.01.008.

Gacesa, P., & Hubble, J. (1987). Enzyme technology. Oxford, UK: Open University Press.

Acknowledgment

This study was supported by grants from the National Natural Science Foundations of China (Nos. 30772658 and 30570494).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gai, L., Wu, D. A Novel Reversible pH-Triggered Release Immobilized Enzyme System. Appl Biochem Biotechnol 158, 747–760 (2009). https://doi.org/10.1007/s12010-008-8373-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8373-2