Abstract

When grown on wheat bran as the only carbon source, the filamentous fungus Talaromyces thermophilus produces large amounts of β-xylosidase activity. The presence of glucose drastically decreases the β-xylosidase production level. The β-xylosidase of T. thermophilus was purified by ammonium sulfate precipitation, DEAE–cellulose chromatography, and gel filtration (high-performance liquid chromatography). The molecular mass of the enzyme was estimated to be 97 kDa by sodium dodecyl sulfate polyacrylamide gel electrophoresis and gel filtration. The enzyme activity was optimum at 50 °C and pH 7. The apparent Michaelis constant K m of the β-xylosidase was 2.37 mM for p-nitrophenyl-β-d-xylopyranoside, with a V max of 0.049 μmol min−1 per milligram protein. Enzyme activity was inhibited by Cu2+, Hg2+, and Zn2+ and activated by Ca2+, Mn2+, and Co+ at a concentration of 5 mM. At high xylose concentration, this enzyme catalyses the condensation reaction leading to xylobiose production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hemicelluloses are the second most abundant polysaccharides in nature. The major constituents of hemicellulose, the hetero-1,4-β-d-xylan, represent a potentially renewable resource of energy that could be employed to improve the bioconversion of plant biomass into useful products.

Xylan has a relatively complex structure based on a β-(1,4)-linked d-xylose backbone substituted to varying extents with acetyl, l-arabinofuranosyl, galactosyl, glucuronyl, and 4-O-methylglucuronyl groups [1]. Xylan can form cross-linkages with lignin via α-l-ara-binofuranosyl residues, which can be esterified with hydroxycinnamic acids, such as ferulic or p-coumaric acids [2].

In nature, the complete degradation of xylan requires the synergistic action of several enzymes, mainly endo-β-1,4-xylanases (EC 3.2.1.8), which cleave the β-1,4 glycosidic bond between xylose residues to produce xylooligosaccharides of weak polymerisation degree, and β-xylosidase (EC 3.2.1.37), which hydrolyze short xylooligomers and xylobiose from the nonreducing end, liberating xylose [3]. In combination with other enzymes, especially cellulases, xylanolytic enzymes have opened new possibilities for food industry and for the bioconversion of agricultural wastes into easy fermentable products [4]. This being so, the fermentation of xylose or xylose-containing hydrolyzates for ethanol production or bioconversion into xylitol has recently been reviewed [5].

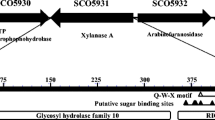

The β-xylosidase is an essential enzyme of the microbial xylanolytic system, as it contributes to the decrease in the inhibition of xylanases by the end-product of xylan hydrolysis [6]. This enzyme is cell-associated in most bacteria and yeast but is found free in the culture media of some fungi [7]. Although many bacterial and fungal β-xylosidases have been purified and characterized, only few β-xylosidases from thermophilic fungi have been reported in the literature [8–10]. Based on their amino acid sequence and structural similarities, β-xylosidases are currently classified into families 39, 43, and 52 of glycosyl hydrolases [11].

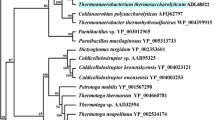

The potential biotechnological applications of thermostable enzymes have motivated the search of strains expressing the activities that possess desired features. In the course of such a quest, a thermotolerant Talaromyces thermophilus growing at 50 °C was isolated in our laboratory. This strain secretes one thermotolerant endo-1,4-β-xylanase activity in the presence of xylan as the sole carbon source. This protein has been purified and characterized [12]. In the present report, the production, purification, and characterization of an extracellular β-xylosidase from the newly isolated T. thermophilus were studied.

Materials and Methods

Materials

Xylobiose, xylan (oat spelt), p-nitropenyl β-D-xylopyranoside, p-nitrophenol methylumbelliferyl-4,7-β-d-xyloside, and 3,5-dinitrosalycilic acid were purchased from Sigma-Aldrich. d-Xylose was from Amersham. Polyethylene glycol (PEG) was from Fluka. DEAE-cellulose was from Pharmacia. Column for high-pressure liquid chromatography (HPLC) was from Shodex.

Microorganism and Culture Conditions

In this study, a newly isolated thermotolerant fungus strain from El Hamma thermal station in the south of Tunisia is used. The fungus was identified by CBS (Centraalbureau voor Schimmelcultures, Baarn, The Netherlands) as being T. thermophilus Stolk. The latter was cultivated in a liquid medium (Mandels medium) [13], with some modifications as follows: KH2PO4, 1 g; K2HPO4, 2.5 g; (NH4)2SO4 1.4 g; MgSO4 7H2O, 0.3 g; CaCl2, 0.3 g; yeast extract, 1 g; urea, 0.7 g; Tween 80, 1 ml; water, 1 l; and 2% xylan oat spelt or 2% wheat bran. The pH of the medium was 7.0. The medium was supplemented with 1 ml of an oligoelements solution: MnSO4, 1.6 g/l; ZnSO4, 1.4 g/l; FeSO4, 5 g/l; and CoCl2, 2 g/l. The enzyme’s production was carried out in 500-ml flasks, each containing 100 ml of culture medium and was incubated for 5 days at 50 °C at an agitation rate of 160 rpm.

To investigate the effect of various substrates on β-xylosidase production, T. thermophilus was cultivated for 5 days in the medium mentioned earlier that contained either wheat bran, xylan, rabbit food, xylose, arabinose, or glucose at 2% (w/v) as sole carbon sources.

Methods

Enzyme Assays

β-Xylosidase activity was measured by a spectrophotometric method, with p-nitrophenyl β-d-xylopyranoside as a substrate [14]. The assay mixture contained 200 μl of pNPX in 50 mM phosphate buffer (pH 7.0) and 200 μl of enzyme solution. After incubation for 10 min at 50 °C, the reaction was stopped by the addition of 1.6 ml of Na2CO3 (1 M). The absorbance in nanometer due to the release of p-nitro phenol was measured at 405 nm. One unit (IU) of β-xylosidase activity was defined as the amount of enzyme that released 1 μmol of p-nitro phenol per minute in the reaction mixture under these assay conditions.

Xylanase activity was assayed by measuring the reducing groups released from Birchwood xylan [15]. The reaction mixture consisted of 500 μl of 1% xylan solution, 400 μl of 50 mM phosphate buffer, pH 7.0, and 100 μl of enzymatic extract. After incubation for 10 min at 50 °C, reducing sugars formed were determined by adding 3 ml of dinitrosalicylic acid reagent, boiling the mixture for 10 min, adding 20 ml of water, and then measuring the absorbance at 550 nm [16]. One unit (IU) was defined as the amount of enzyme that released 1 μmol xylose per minute under the assay conditions.

Purification of β-Xylosidase

Ammonium Sulfate Treatment

The Talaromyces fungus was cultured on wheat bran as a carbon source in a 1.2-l medium in Erlenmeyer flasks for 5 days. The culture was centrifuged at 8,000 rpm and filtered on Whatman GF/A glass microfiber filters. A 1-l supernatant was recovered, treated with ammonium sulfate (80% saturation), and left overnight at 4 °C. The precipitate was collected through centrifugation at 9,000 rpm for 15 min, dissolved in a 20-mM phosphate buffer (pH 6), and then dialyzed overnight against the same buffer at 4 °C.

DEAE-Cellulose Column Chromatography

The dialyzed enzyme solution was loaded on a DEAE-cellulose (1.25 × 28 cm) that was pre-equilibrated with a 20-mM phosphate buffer (pH 6). The column was extensively washed with the same buffer. Xylanase and β-xylosidase activities were also eluted with a gradient of 0–0.5 M NaCl in the same buffer. The active fractions were pooled, concentrated using PEG 6000, and then dialyzed overnight against 20 mM phosphate buffer (pH 6.0).

Gel Filtration by HPLC

The active β-xylosidase fractions obtained from the ion exchanger column were gathered, concentrated, and then applied to a column of gel filtration by HPLC (Shode,. Protein kw P 802.5, 300 LS mms). The column was then equilibrated with the 50-mM phosphate buffer (pH 7.4) and elution was at a flow rate of a 0.8 ml/min by the same buffer containing NaCl 0.15 M. The proteins were quantified by measuring the absorbance at 280 nm.

Electrophoresis in Polyacrylamide Gels

Polyacrylamide gels were prepared according to Laemmli [17]. Native PAGE gels were performed in the absence of sodium dodecyl sulfate (SDS). Samples were mixed with an equal volume of a native sample buffer that did not contain SDS or β-mercaptoethanol. To prepare the gels to be used as zymogram, the samples were not boiled. The zymogram needed for β-xylosidase activity was prepared by overlaying a 1% (w/v) agarose in 50 mM phosphate buffer (pH 7.0) containing the artificial substrate 4-methylumbelliferyl-β-d-xylopyranoside (0.083 mg/ml) on the native polyacrylamide gel. After agarose solidification, the adhering gels were incubated for 10 min at 50 °C. The fluorescent bands generated due to the methylumbelliferyl released by β-xylosidase activity were observed after exposure to UV light.

Effect of pH and Temperature

The optimum temperature for β-xylosidase activity was determined by incubating the enzyme preparation with pNPX (2 mM) at different temperatures ranging from 30 to 70 °C. The thermal stability was assessed by incubating the enzyme preparation at 40, 45, 50, 55, and 60 °C, and activity was determined at various time points using the standard assay.

The optimum pH for β-xylosidase activity was determined by incubating the purified enzyme with pNPX for 10 min at 50 °C in different buffers: 50 mM citrate, pH 3, 4, and 5; 50 mM phosphate, pH 6 and 7; 50 mM 3-N-(α,α-Dimethylhydroxyethyl)-amino-2-hydroxypropanesulfonic acid (AMPSO) buffer, pH 8 and 9; and 50 mM glycine, pH 10, 11, and 12. The stability at 4 °C in various pH conditions was assessed by incubating the enzyme at different pH and by measuring the residual activity at different times using the standard protocol.

Determination of Kinetic Constants

The kinetic parameters of the purified enzyme were determined for pNPX as substrate. K m and V max were estimated using a specific program of enzymology (Hyper 32 exe program, version 1.0.0, 2003). The enzyme was incubated with pNPX at various concentrations (ranging from 0.5 to 20 mM) in the optimum assay conditions. The initial velocities were determined and used to estimate K m and V max from Lineweaver–Burk plot.

Effect of Various Reagents

The effect of metal ions and various reagents on the activity of β-xylosidase was determined by incubating the purified enzyme (0.38 U/ml) for 10 min at 50 °C in 0.05 M phosphate buffer (pH 7) containing various compounds (5 or 10 mM). The relative activities were expressed in terms of their relative percentages vis-à-vis the control. The effects of methanol, ethanol, acetonitrile, acetone, butanol-1, and butanol-2 (0–40% v/v) on β-xylosidase activity were studied using pNPX at (2 mM).

Condensation Reaction

The incubation mixture (1 ml) contained xylose at 40% in 50 mM phosphate buffer (pH 7.0) and 0.1 mg of β-xylosidase, and different sorbitol concentrations (1, 2, 3, and 4 M) were incubated at 40 °C for 6 days. The samples were withdrawn at different time intervals, and the xylobiose that was formed was analysed by a high-performance liquid chromatography system (Aminex HPX-42A column, 300 × 7.8 nm). The products were separated by elution with water at a flow rate of 0.6 ml/min and detected with a refractive index detector (Agilent). A xylobiose solution (10 g/l) was used as standard.

Results and Discussion

Effect of Carbon Sources on β-Xylosidase Production

Among the lignocellulosic materials tested as carbon sources, wheat bran was the most effective for β-xylosidase production (0.5 U/ml) than rabbit food. Xylose, arabinose, and xylan resulted in lower activities, while glucose was a strong repressor (Table 1). Similar results were obtained with other species of fungi, such as Aspergillus versicolor and A. fumigatus [18, 19]. As the β-xylosidase activity observed during growth on wheat bran was much higher than those observed on the other substrates, wheat bran was used as the only carbon source in subsequent experiments (Fig. 1). The highest xylanase activity was obtained when the fungus was grown on xylan (oat spelt). Yet, as xylan is an expensive material for large-scale production of xylanases, lignocellulosic materials, such as rabbit food, can be used as alternative substrates.

Purification of β-Xylosidase

An extracellular β-xylosidase was purified to homogeneity from the culture filtrates of T. thermophilus grown on wheat bran. The β-xylosidase from this fungus was precipitated using ammonium sulfate (80% saturation) to yield an active pellet. The active pellet was dialyzed and used as a starting material for further purification. β-Xylosidase purification was achieved in two steps: anion exchange DEAE-cellulose chromatography and gel filtration by HPLC. The β-xylosidase activity was found in the peak that was observed in the 0.15-M NaCl elution buffer (Fig. 2). This peak, with β-xylosidase activity, was pooled and concentrated for gel filtration. After this step, only a single protein peak that coincided with the peak of enzyme activity was obtained (Fig. 3).

Elution profile of the β-xylosidase activity from DEAE-cellulose chromatography column. (open circle) absorbance at 280 nm, filled triangle β-xylosidase, dotted line linear gradient of sodium chloride (0–0.5). Details in “Material and Methods”

A summary of the purification procedures is presented in Table 2. The purified enzyme behaves as a single band on SDS polyacrylamide gel electrophoresis (SDS–PAGE; Fig. 4a). This band, coinciding with the activity band, was revealed on zymogram with MUX (Fig. 4b). The final purification step resulted in a yield of 9.42% of the activity, a 12.8% retention of the total protein, and a 73.75-fold increase in the specific activity (Table 2).

a SDS–PAGE of purified β-xylosidase from Talaromyces thermophilus. The enzyme (~10 μg protein) was electrophoresed at pH 8.6 on a 10% acrylamide gel and stained with Coomassie Brillant Blue R-250. 1 Molecular weight standards, 2 purified β-xylosidase, 3 total enzymes concentrated by ammonium sulfate precipitation. b Overlay gel. The β-xylosidase activity was detected with 0.083 mg/ml MUX at 50 °C. MUX 4-methylumbelliferyl-β-d-xyloside, P protein

Characterization of β-Xylosidase

The apparent molecular weight of the purified enzyme was estimated to be approximately 97 kDa by SDS/PAGE and gel filtration. It was consistent with those found in T. viride (100 kDa) and A. carbonarius (100 kDa) [20, 21]. On the other hand, the molecular weight of β-xylosidase from T. emersonii is a dimmer with a molecular weight of 181 kDa [22].

Effect of pH and Temperature on Enzyme Activity and Stability

Figure 5a and b indicates the influence that pH and temperature had on β-xylosidase activities, respectively. The enzyme showed an optimum of activity at pH 6–7 and at 50 °C. Both pH and temperature optima were similar to those reported for the enzymes of Malbranchea pulchella [23] and Sporotrichum thermophile [24].

Effect of temperature and pH on β-xylosidase activity. a pH optimum (filled circle); the enzyme activity was assayed by the standard method after changing the buffer to obtain the desired pH. The buffers used were citrate (pH 3.0 to 5.0), phosphate (pH 6.0 to 7.0), AMPSO (pH 8 to 9), and glycine-hydroxide (pH 10 to11). b Optimum temperature (filled triangle). The enzyme activity was assayed at various temperatures by the standard assay method

The effect of pH on the stability of the enzyme was also examined. The purified enzyme was stable at pH values between 6 and 9 (Fig. 6a). A range that was also observed with S. thermophile [24] but violated with the β-xylosidase of A. phoenicic [8] and A. nidulans [25] that were more stable when pH was inferior to 6. The enzyme was quite stable during 24 h at 40 °C and lost about 50% of its activity after 12 h at 45 °C and about 60% at 50 °C. The half life-time of the β-xylosidase was 2 h at a temperature of 55 °C (Fig. 6b). Studies of thermal stability indicated that the purified T. thermophilus β-xylosidase was more thermostable than the fungal β-xylosidases from A. versicolor [18] but less thermostable than the fungal β-xylosidases from A. phoenicis [8], Scytalidium thermophilum [10] and A. fumigatus [19]. Stability and activity at high temperatures are desirable properties in this type of enzymes, considering the fact that the most industrial processes where xylanolytic enzymes can be useful are carried out at high temperatures [26].

Stability of β-xylosidase activity at different pH (a) and temperature values (b). pH stability was determined by pre-incubating this enzyme at 4 °C at different pH: citrate buffer, pH 5.0 (open circle); phosphate buffer, pH 6 (filled square) and pH 7 (open circle); and AMPSO buffer, pH 8 (filled diamond) and pH 9 (filled triangle). Stability of β-xylosidase was determined by incubating samples at pH 7 and at various temperatures: 40 °C (filled diamond), 45 °C (filled triangle), 50 °C (filled square), 55 °C (open square), and 60 °C (open circle)

Kinetic Constants

The Michaelis constants were determined using a bioinformatics software. The calculated K m and V max values of β-xylosidase were found to be 2.37 mM and 0.049 μmol min−1 mg−1 of protein. These values are in the range of those reported for other β-xylosidases of A. phoenicic and A. carbonarius [8, 21].

Effects of Various Reagents on β-Xylosidase Activity

The effects of various metallic ions and reagents on the activity of purified β-xylosidase were investigated. As shown in Table 3, the activity was dramatically inhibited by Hg2+, Cu2+, and Zn2+. Inhibition was also observed in the presence of SDS and ethylenediaminetetraacetic acid (EDTA). The enzymatic activity was slightly stimulated in the presence of Ca2+, Mn2+, and Co2+.

Dithiothreitol (DTT) and β-mercaptoethanol are two detergents that can modify the structure of the enzyme and make it more active. The enzyme activity was significantly inhibited by sulfhydryl oxidant metal (Hg2+), suggesting the importance of a sulfhydryl group, such as cysteine, for enzyme activity.

Effect of Alcohol

All tested alcohols inhibited the enzyme activity at high concentration (40% v/v; Fig. 7); butanol-1 and butanol-2, for instance, dramatically inhibited the β-xylosidase activity even at low concentrations. At a concentration of 5%, methanol stimulated β-xylosidase activity. Ethanol at 10% was found to be an inhibitor of enzyme activity, yielding a decrease of 30% with respect to the original activity. These results are similar to those observed with other β-xylosidases [24]. It is worth noting here, however, that an increase in activity caused by ethanol has been reported for β-xylosidases from Pichia anomala [27] and Candida utilis [14].

Effect of methanol (filled diamond), ethanol (filled circle), acetone (filled square), acetonitrile (filled triangle), butanol-1 (open square), and butanol-2 (open circle) on the activity of β-xylosidase from Talaromyces thermophilus. The data presented are averages with standard errors from two independent experiments

Condensation Reaction

We deemed essential to investigate the role of condensation reactions in the production of useful oligosaccharides, obtention of helpful information on the yield of oligosaccharides, and the elucidation of the kinetics and substrate specificities of carbohydrolases. To test whether our enzyme is able to catalyze reverse hydrolysis reaction, we incubated the enzyme with a high concentration of xylose (40%) in the presence of different sorbitol concentrations. Interestingly, the β-xylosidase from T. thermophilus catalyzed reverse hydrolysis reaction, forming xylobiose, in the presence of high concentrations of d-xylose (Fig. 8). At a concentration of 40% d-xylose, β-xylosidase synthesized 5.6 mg/ml of xylobiose after 6 days, corresponding to a 1.4% of xylobiose production yield that was improved by sorbitol addition at 3 M. In fact, we obtained 22.6 mg/ml of xylobiose after 3 days, corresponding to 5.65%. However, a 4-M sorbitol reduced the yield of xylobiose to 0.5%. Sorbitol, a well-known water activity depressor, must have favored the synthesis reaction and have been able to stabilize the enzyme by modifying the proteic microenvironment (by water stripping) [28]. The high concentration in sorbitol significantly decreases the water activity and slowed down the synthesis reaction presumably by enzyme denaturation.

To our knowledge, so far, there have been only two reports that have described the synthesis of xylobiose by the condensation reaction using xylose [24, 29]. According to our findings, the β-xylosidase from T. thermophilus has a high yield production of xylobiose and can thus be considered as a potential strong candidate for future industrial applications.

Conclusion

The results of this study have shown that T. thermophilus produces a single β-xylosidase as T. emersonii [22] in the submerged culture. The best carbon source for β-xylosidase production was wheat bran. The purified enzyme has a high specific activity of 147.5 U/mg proteins. The purification procedure resulted in a single form of enzyme as evidenced by the absence of other forms in gel filtration and SDS–PAGE. This enzyme seems to be a monomeric protein (molecular weight, 97 kDa). The optimum temperature and pH of the enzyme activity were 50 °C and 6–7, respectively. The purified enzyme, with interesting thermostability and tolerance to organic solvent, might be used in industrial applications as an enzyme for xylobiose synthesis.

References

Coughlan, M. P., & Hazlewood, G. P. (1993). Biotechnology and Applied Biochemistry, 17, 259–289.

Carpita, N. C. (1996). Annual Review of Plant Physiology and Plant Molecular Biology, 47, 445–476.

Biely, P. (1985). Trends in Biotechnology, 3, 286–290.

Bajpai, P. (1997). Advances in Applied Microbiology, 43, 141–194.

Wheals, A. E., Basso, L. C., Alves, D. M. G., & Amorim, H. V. (1999). Trends in Biotechnology, 17, 482–487.

Poutanen, K., & Plus, J. (1988). Applied Microbiology and Biotechnology, 28, 425–432.

Saha, B. C., & Bothast, R. J. (1999). In S. H. Imam, R. V. Greene, & B. R. Zaidi (Eds.), Biopolymers: Utilizing nature’s advanced materials (pp. 167–194). ACS Symposium Series 723, Washington, DC.

Rizzatti, A. C. S., Jorge, J. A., Terenzi, H. F., Rechia, C. G. V., & Polizeli, M. L. T. M. (2001). Journal of Industrial Microbiology and Biotechnology, 26, 156–160.

Almeida, E. M. D., Lourdes, M. D., Polizeli, T. M., Terenzi, H. F., & Jorge, J. A. (1995). FEMS Microbiology Letters, 130, 171–176.

Zanoela, F. F., Teixeira, M. L. T. M., Terenzi, H. F., & Jorgen, J. A. (2004). Journal of Industrial Microbiology and Biotechnology, 31, 170–176.

Henrisaat, B., & Bairoch, A. (1996). Biochemical Journal, 316, 695–696.

Maalej, I. (2004). Master of Biotechnology, Faculté de pharmacie de Monastir, Tun.

Mandels, M., & Weber, J. (1969). Advances in Chemistry Series, 95, 391–413.

Yanai, T., & Sato, M. (2001). Bioscience, Biotechnology, and Biochemistry, 65, 527–533.

Bailey, M. J., Biely, P., & Poutanen, K. (1992). Journal of Biotechnology, 23, 257–270.

Miller, G. L. (1959). Analytical Chemistry, 3, 1426–428.

Laemmli, U. K., & Favre, M. (1973). Journal of Molecular Biology, 80, 575–599.

Vargas, A. S., Polizeli, M. T. L. M., Terenzi, H. F., & Joao, A. J. (2004). Process Biochemistry, 39, 1931–1938.

Lenartovicz, V., Souza, C. G. M., Moreira, F. G., & Peralta, R. M. (2003). Process Biochemistry, 38, 1775–1780.

Matsuo, M., & Yasui, T. (1984). Agricultural and Biological Chemistry, 48, 1845–1852.

Kiss, T., & Kiss, L. (2000). World Journal of Microbiology and Biotechnology, 16, 465–470.

Tuohy, M. G., Puls, J., Claeysens, M., Vrsanska, M., & Coughlan, M. P. (1993). Biochemical Journal, 290, 515–523.

Matsuo, M., Yasui, T., & Kobayashi, T. (1977). Agricultural and Biological Chemistry, 41, 1593–1599.

Katapodis, P., Nerinckx, W., Claeyssens, M., & Christakopoulos, P. (2006). Process Biochemistry, 41, 2402–2409.

Kumar, S., & Ramón, D. (1996). FEMS Microbiology Letters, 135, 287–293.

Wong, K. K. Y., & Saddler, J. N. (1993). In M. P. Coughlan & G. P. Hazlewood (Eds.), Hemicellulose and hemicellulases (pp. 127–143). London: Portland Press.

Manzanares, P., Ramon, D., & Querol, A. (1999). International Journal of Food Microbiology, 46, 105–112.

Ravet, C., Thomas, D., & Legoy, M. D. (1993). Biotechnology and Bioengineering, 42, 303–330.

Iizuka, Y., Shinoyama, H., Kamiyama, Y., & Yasui, T. (1992). Bioscience, Biotechnology, and Biochemistry, 56, 331–332.

Acknowledgment

This work have been supported by grants from the Tunisian government Contrat-Programme, Ministère de l’Enseignement Supérieur de la Recherche Scientifique et de la Technologie of Tunisia. The authors wish to express their thanks to Mr. Anouar Smaoui from FSS for his valuable proofreading of the English of the present paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guerfali, M., Gargouri, A. & Belghith, H. Talaromyces thermophilus β-d-Xylosidase: Purification, Characterization and Xylobiose Synthesis. Appl Biochem Biotechnol 150, 267–279 (2008). https://doi.org/10.1007/s12010-008-8260-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8260-x