Abstract

Production of inulinase by solid state fermentation always involves an extraction step, which dictates enzyme recovery yield and is related to cultivation conditions and control of process parameters. This work is focused on the study of extraction conditions aiming to maximize yield of an inulinase obtained by solid state fermentation of sugar cane bagasse and Kluyveromyces marxianus NRRL Y-7571. Kinetics of extraction was followed varying the kind of solvent used. After determining the best solvent, an experimental design was carried out to study the effect of the solid/liquid ratio (1:10–1:20), extraction temperature (20–53°C), and stirring rate (50–177 rpm). Results showed that maximum yield was obtained when sodium acetate buffer 0.1 M pH 4.8 was used, using a solid/liquid ratio of 1:10, at 53°C and 150 rpm for 40 min.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Inulinases are potentially useful enzymes for production of fructooligosaccharides and high-fructose syrups (HFS) from inulin. Fructooligosaccharides have functional and nutritional properties such as a low-calorie diet, Bifidus stimulation, and a source of dietary fiber in food preparations. Fructose production by inulin hydrolysis is more advantageous than conventional processes based on starch, which includes the action of α-amylase, amyloglucosidase, and glucose isomerase, yielding only 45% of fructose in the final product due to the thermodynamic equilibrium of the reaction. Inulinase-based hydrolysis of inulin can yield products with 95% fructose [1, 2]. Microbial inulinases are extensively produced through submerged fermentation [3, 4]. Few studies on the production of inulinase by solid state fermentation have been recently reported [5–7].

Solid state fermentation (SSF) represents an interesting alternative for the production of technical enzymes used in the food industry, where costs are a critical factor determining the economic feasibility of their applications [8]. Several practical and economic advantages have been attributed to SSF compared with the widely used submerged fermentations. In SSF, the product is more concentrated and shows higher concentration of other metabolites. However, this may cause difficulties in down-stream processes [9].

Recovery, concentration, and purification steps constitute an important part of a biotechnological process and are a key to obtaining products of high purity. In the commercial production of microbial enzymes, the costs of the recovery operations can reach 80% of the total production costs [10].

The factors that most influence enzyme extraction are the type of solvent, the solid–liquid ratio, the temperature, agitation, the contact time, and the interrelation between them. The thermal stability of the enzyme should also be considered because it is a function of exposure time [11].

Few studies on enzyme extraction in SSFs have been reported in literature. Some reports investigated extraction of pectinases obtained by SSF, verifying the influence of temperature, stirring rate, and time of extraction in batch extraction and in fixed-bed, multiple-stage extraction [10, 11]. Extraction of xylanases obtained by SSF was studied using an experimental design technique. The nature of the solvent, the extraction temperature, the solid–liquid ratio, the stirring rate, and the time of extraction were investigated [8]. So far, no study about the extraction of inulinase obtained by SSF has been reported.

This work aimed to study the extraction of inulinase obtained by SSF of sugarcane bagasse and Kluyveromyces marxianus NRRL 7571. The effects of solvent, stirring rate, temperature, and solid/liquid ratio were investigated using an experimental design technique.

Materials and Methods

Microorganism and Media

The strain of K. marxianus NRRL Y-7571 was maintained at 4°C on YM agar medium containing (in g L−1) yeast extract 3.0, malt extract 3.0, peptone 5.0, glucose 10.0, and agar 20.0 and subcultured every 3 weeks. Cell production for preinoculum was carried out in 50-mL test tubes with 10 mL of liquid YM medium. The medium was inoculated with a loopful of stock culture and incubated at 30°C for 24 h. This suspension was used for inoculation without any further treatment.

Medium for inoculum contained (in g L−1) sucrose 20.0, yeast extract 5.0, K2HPO4 5.0, NH4Cl 1.5, KCl 1.15, and MgSO4.7H2O 0.65. Each test tube with YM medium was transferred to a 500-mL Erlenmeyer flask with 100 mL of medium and incubated at 30°C and 150 rpm for 24 h.

Solid State Fermentation

Sugarcane bagasse from a local industry (Cooperativa Tritícola Erechim) was used as substrate for inulinase production. Fermentations were carried out in conical flasks (500 mL) with 5 g of dry bagasse, supplemented with 20 wt.% corn steep liquor (CSL, Corn Products Brazil). Moisture was adjusted to 65%; each flask was covered with hydrophobic cotton and autoclaved at 121°C for 20 min. Preliminary studies showed that no changes in moisture content of the substrate after autoclaving were detected. After cooling, each flask was inoculated with 3 mL of the suspension previously prepared and incubated for 72 h at 36°C in a chamber with temperature and humidity control.

Optimization of Enzyme Extraction

All extraction tests were run with an identical batch of fermented bagasse. The fermented samples were mixed, homogenized, and stored at −20°C. For each experimental plan, a sample was thawed and submitted to extraction conditions. Therefore, changes in initial activity might occur due to enzyme inactivation due to storage. However, because each experimental set was carried out at the same moment, the initial activity for each set is the same.

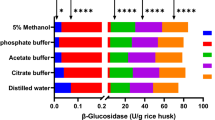

Different solvents were tested for extraction: water, sodium citrate buffer 0.1 M (pH 2.5, 3.0, 3.5), sodium acetate buffer 0.1 M (pH 4.0, 4.8, 5.5), sodium phosphate buffer (pH 6.0, 7.0, 8.0), NaCl solution (10 and 20%), aqueous acetone solution (10 and 20%), and aqueous ethanol solution (10 and 20%). The solvents and the studied range of pH and concentration were chosen based on some recent studies of extraction of xylanases [8] and pectinases [9–11] and in our previous experience with the inulinase [6–7, 12]. It is worth noting that no previous systematic study of inulinase extraction can be found in the literature. In this study, 50 mL of the selected solvent was added to 4 g of fermented bagasse. Samples were stirred in an orbital shaker at 30°C and 120 rpm. Extracts were filtered and inulinase activity was determined in the supernatant. Kinetics of extraction of each experimental run was followed, and the maximum yield was found at 40 min. The samples were analyzed in triplicate and comparisons between means were performed by Tukey’s test (p < 0.05).

The influence of extraction parameters was assessed by two sequential complete factorial designs to investigate the influence of solid–liquid ratio (S/L), temperature, and stirring rate. The effect of extraction time was studied following the extraction kinetics for each experimental run. Table 1 presents the actual and coded values for both complete factorial designs.

Enzyme Activity Assay

Enzyme activity was determined by the initial reaction rate of reducing sugar production under controlled conditions. The method consists in adding 0.5 mL of enzyme extract to 4.5 mL of sucrose solution (2% w/w) in 0.1 mol L−1 pH 4.8 sodium acetate buffer and incubating the reaction medium for 10 min at 50°C [3]. After the reaction, the reducing sugar concentration is determined by the DNS method [13]. One unit of inulinase activity is defined as the amount of enzyme necessary to hydrolyze 1 μmol of sucrose per minute at reaction conditions. The results are expressed in terms of units per gram of dry substrate (U gds−1).

Statistical Analysis

Statistical analysis was performed with the results obtained at 40 min of extraction using Statistica (StatSoft, version 5.1). The statistical significance of the regression coefficients was 95%. The optimum levels of the variables were obtained by graphical analysis.

Results and Discussion

The kind of solvent influenced the extraction of inulinase probably due to differences in ionic strength and polarity. Table 2 shows the results of inulinase activity obtained with the different solvents tested. Solvents that yielded highest inulinase extraction were sodium acetate pH 4.8 0.1 M (396.6 U gds−1), aqueous ethanol solution 10% w/w (384.1 U gds−1), and sodium citrate buffer 0.1 M pH 3.0 (375.8 U gds−1). When very high or very low pH was used, a decrease in extraction was observed because pH directly affects enzyme stability due to inactivation, as shown in previous studies [12]. Lowest extraction was verified when sodium phosphate buffer 0.1 M pH 8.0 was used (248.4 U gds−1). In the present work, concentrated acetone and ethanol solutions presented lower extraction because these solvents are usually good precipitating agents for protein solutions above some concentrations [1, 14]. These solvents in high concentrations can also inhibit enzyme activity by denaturation, and this may also be the cause of lower values of enzyme extraction. Good results have been reported using distilled water for extraction of pectinase from fermented wheat bran and xylanase from industrial fibrous soybean residues [8, 9]. In our work, intermediate extraction results were obtained when using pure water as solvent (340.8 U gds−1), which is 14.1% lower than the activity obtained when using sodium acetate buffer. In a scale up of the process, the use of water as extraction solvent could reduce recovery costs. An economic analysis would be necessary to verify if the activity gain would compensate the buffer cost.

Results in Table 2 show that the same extraction yield (p < 0.05) could be obtained with sodium acetate pH 4.8 0.1 M, aqueous ethanol solution 10% w/w, and sodium citrate buffer 0.1 M pH 3.0. However, sodium acetate buffer pH 4.8 was chosen for extraction because this solvent was already used in previous works [6, 7].

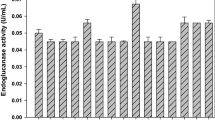

After solvent choice, a complete factorial design (23) with three central points was carried out. Solid/liquid ratio (1:10–1:20), temperature (20–50°C), and stirring rate (50–150 rpm) were evaluated. Kinetics of extraction of each experimental run was followed and maximum yield was found at 40 min. The kinetics of extraction at the best condition will be presented later in this text. Table 3 shows the results of the first experimental design after 40 min of extraction. The highest extraction was achieved in run 8 (300.1 U gds−1) at 50°C, 150 rpm, and solid/liquid ratio of 1:20. Lowest extraction was obtained in run 3 (164.1 U gds−1) 20°C, 150 rpm, and solid/liquid ratio of 1:10.

The significant factors were determined through the Pareto chart in Fig. 1. Temperature and stirring rate presented a positive significant influence (p < 0.05) on extraction, suggesting that an increment in such factors should improve extraction yield. The factors did not present synergistic or antagonistic effects.

One of the advantages of SSF in enzyme production is the lower dilution of products when compared to submerged fermentations [15]. This aspect is important because it is directly related to purification costs. In the present work, solid/liquid ratio did not significantly (p < 0.05) influence extraction, possibly because the volume of liquid used was enough for a good contact between the two phases. Moreover, some studies show that solid/liquid ratio below 1:10 can cause a decrease in extraction yield [9]. This effect may be attributed to a lower interaction between the solid and the liquid, caused by the low volume of liquid used in extraction. The quantities of liquid needed to allow good contact between solids and liquids can also be related to the properties of the solid matrix (water retention capacity). For ratios above 1:10, extraction also decreases due to dilution. Heck et al. [8] studied the influence of solid/liquid ratio in the range of 1:6–1:16 for extraction of xylanase and found the best results at 1:6 ratio. Therefore, the ratio was set to its lower level (1:10) for the sake of reducing costs with solvents, requirements of smaller extraction equipment, and production of more concentrated enzyme.

Based on the results obtained in the first experimental design, temperature and stirring rate levels were increased as shown in Table 1. A second complete factorial design 22, with three central points and two axial points for each factor, was carried out. Table 4 presents the results of this experimental design. Highest yield of extraction was achieved in experimental run 6 (150 rpm, 53°C, 354.0 U gds−1), and the lowest extraction was found in run 2 (139 rpm, 50°C, 292.9 U gds−1).

Statistical analysis of the results in Table 4 was performed yielding an empirical coded model of inulinase activity as a function of stirring rate and temperature. The coded model for inulinase activity was validated by analysis of variance (ANOVA) (data not shown). All parameters of the equation statistically (p < 0.05) affect the inulinase extraction. As it showed a high correlation coefficient (R = 0.98) and a good performance of the F test for regression, Eq. 1 can be considered predictive of inulinase extraction in the investigated range of factors and consists in a second-order function for temperature and stirring rate.

where:

- A :

-

inulinase activity (U gds−1)

- T :

-

coded temperature

- SR:

-

coded stirring rate

The response surface for inulinase extraction as a function of stirring rate and temperature is shown in Fig. 2. This figure shows that maximum extraction yield occurs at 53°C and 150 rpm. Figure 2 also suggests that the increase in temperature would increase extraction of inulinase. The extraction is strongly influenced by temperature, which can be observed by the difference of approximately 30% between the results obtained in the first and second experimental plans for similar conditions (run 7 in Table 3 and run 6 in Table 4). However, stability tests run at 55°C showed that a rapid denaturation (>30%) of inulinase occurs. If the enzyme extract is maintained at 60°C, the activity drops approximately 80% [12]. Therefore, we can conclude that 53°C is the limit temperature where maximum extraction could be obtained. Studies for different enzymes also showed this behavior [9]. The kinetics of inulinase extraction at the best condition (run 6, Table 4) is presented in Fig. 3, showing that the maximum extraction yield is achieved after 40 min.

Conclusions

This work studied the effect of the kind of solvent, temperature, stirring rate, pH, and solid/liquid ratio on inulinase extraction from fermented sugarcane bagasse. After studying the effect of the nature of the solvent and pH, the extraction was maximized investigating the combined effects of solid/liquid ratio, temperature, and stirring rate. Maximum extraction of the enzyme could be obtained using sodium acetate buffer 0.1 M pH 4.8, at 53°C and 150 rpm, in a solid/liquid ratio of 1:10.

References

Gill, P. K., Manhas, R. K., & Singh, P. (2005). Bioresource Technology, 97, 894–902.

Kim, C. H., & Rhee, S. K. (1989). Biotechnology Letters, 11, 201–206.

Kalil, S. J., Suzan, R., Maugeri, F., & Rodrigues, M. I. (2001). Applied Biochemistry and Biotechnology, 94, 257–264.

Silva-Santisteban, B. O. Y., & Maugeri, F. (2005). Enzyme and Microbial Technology, 36, 17–724.

Selvakumar, P., & Pandey, A. (1999). Process Biochemistry, 34, 851–858.

Mazutti, M. A., Bender, J. P., Treichel, H., & Di Luccio, M. (2006). Enzyme and Microbial Technology, 39, 56–59.

Bender, J. P., Mazutti, M. A., Oliveira, D., Di Luccio, M., & Treichel, H. (2006). Applied Biochemistry and Biotechnology, 129–132, 951–958.

Heck, J. X., Hertz, P. F., & Ayub, M. A. Z. (2005). Process Biochemistry, 40, 2891–2895.

Singh, S. A., Ramakrishna, M., & Rao, A. G. A. (1999). Process Biochemistry, 35, 411–417.

Castilho, L. R., Alves, T. L. M., & Medronho, R. A. (1999). Process Biochemistry, 34, 181–186.

Castilho, L. R., Medronho, R. A., & Alves, T. L. M. (2000). Bioresource Technology, 71, 45–50.

Mazutti, M., Ceni, G., Di Luccio, M., & Treichel, H. (2007). Bioprocess and Biosystems Engineering, 30(5), 297–304.

Miller, G. L. (1959). Analytical Chemistry, 31, 426–428.

Cruz-Guerrero, A., Garcia-Peña, I., Barzana, E., Racia-Garibay, M., & Gómez-Ruiz, L. Journal of Fermentation and Bioengineering, 80, 159–163.

Pandey, A. (2003). Biochemical Engineering Journal, 13, 81–84.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bender, J.P., Mazutti, M.A., Di Luccio, M. et al. Extraction of Inulinase Obtained by Solid State Fermentation of Sugarcane Bagasse by Kluyveromyces marxianus NRRL Y-7571. Appl Biochem Biotechnol 149, 195–203 (2008). https://doi.org/10.1007/s12010-007-8111-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-007-8111-1