Abstract

Pulsed vacuum osmotic dehydration (PVOD) is a widely used technique for reducing moisture content and water activity in biological products. This study aimed to analyze the effect of vacuum application (VA) on PVOD of beetroot, carrot, and eggplant slices, with respect to chemical (moisture, water activity, specific pigments, polyphenols, and sodium content), optical (color), mechanical (shrinkage, maximum stress, and elasticity), and structural (microstructure) properties. PVOD was conducted at three different vacuum pressures (0, 40, and 80 kPa, for 10 min), during a total process time of 300 min. Osmotic processing was performed at 35 °C by using a ternary osmotic solution [40% sucrose + 10% sodium chloride (w/w)]. Eggplant and carrot samples were more sensitive to VA, compared to beetroot. This was related to their porous and less compact structure. In general, VA reduced the moisture content and water activity and preserved the carotenoid content. VA caused loss of betalain and phenolic acid, favored sodium uptake, and induced significant changes in the optical, mechanical, and structural properties, compared to the osmotic processing conducted at atmospheric pressure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Osmotic dehydration (OD) is often applied as a pretreatment, which induces the exchange of water and solutes, mainly in fruits and vegetables, allowing partial removal of water, solute uptake, and decrease in water activity (aw). It offers some benefits such as reducing heat-induced damage to the nutritional and sensorial characteristics (preserving flavor, color, and inhibiting enzymatic browning) and energy saving (Herman-Lara et al. 2013; Ramya and Jain 2017).

This process is influenced by associated process variables and the characteristics of the material (moisture content, structure, porosity, and the geometric shape of the samples) (Dimakopoulou-Papazoglou and Katsanidis 2016; Lech et al. 2018; Sette et al. 2016). However, the influence of vacuum application (VA) on the structure of the material is related to the effects on mass transfer parameters. Few studies have focused on the changes to the chemical, optical, mechanical, and structural properties (Corrêa et al. 2016; Junqueira et al. 2017a). A reduction in the OD pressure during the initial period promotes an increase in the rate of mass transfer, by a process called pulsed vacuum osmotic dehydration (PVOD). VA causes the internal gases in the pores of the material to expand, expelling them by hydrodynamic mechanisms (HDM) and increasing the surface area available for mass transfer because of the pressure difference (Fito 1994; Viana et al. 2014).

Vegetables show relevant differences in the composition and physicochemical properties. Beetroots (Beta vulgaris L.) are roots rich in polyphenols and a water-soluble nitrogenous pigment group, the betalains. This vegetable presents a compact structure, associated with lower porosity (Boukouvalas et al. 2006; Ravichandran et al. 2013). Carrot (Daucus carota L.) is an important vegetable rich in phytonutrients, in particular, carotenoids, minerals, and vitamins. Morphologically, this root consists of two fractions, namely, an inner xylem surrounded by an outer phloem (Kaur and Sogi 2016; Nahimana et al. 2011a). Eggplants (Solanum melongena L.) are fruits and a source of minerals, vitamins, and anthocyanins. Approximately 50% of its volume comprises voids, and therefore, it has been classified as a highly porous fruit (Russo et al. 2013).

These vegetables are basically composed of water, which limits their shelf life. Therefore, it is necessary to employ techniques that enhance their stability, such as dehydration. The aim of this study was to evaluate the influence of different vacuum pressure (VP; 0, 40, and 80 kPa) on the chemical (moisture, aw, specific pigments, and polyphenol and sodium content), physical (color), mechanical (shrinkage, maximum stress, and elasticity), and structural (microstructure) properties of osmodehydrated beetroot, carrot, and eggplant slices.

Materials and Methods

Sample Preparation

Fresh beetroots, carrots, and eggplants were purchased from a local market (Lavras, MG, Brazil) and stored in a refrigerator at 8 °C ± 1 °C until experimental use. All vegetables were washed with tap water, peeled, and sliced (2.00 cm length × 2.00 cm width × 0.40 ± 0.03 cm thickness) by using a stainless steel mold.

Osmotic Processing

The osmotic solution was prepared with distilled water, sucrose [40 kg/100 kg (w/w)], and sodium chloride [10 kg/100 kg (w/w)]. The aw of the ternary solution was 0.836 ± 0.001. Osmotic processing was performed in an osmotic dehydrator with temperature and inner pressure controls. The dehydrator was composed of a stainless steel chamber covered by a jacket, with water acting as the thermal fluid (Viana et al. 2014).

The total process time was 300 min. This period was chosen based on the results obtained in previous tests, considering the higher water loss and lower solid uptake (data not shown) during the dehydration of these vegetables. No pre-osmosis blanching was performed because blanching was reported to be detrimental to OD because of the loss of the semi-permeability of the cell membrane and reduction of nutrients and pigments (Kargozari et al. 2010). For all vegetables, the experiments were conducted at atmospheric pressure (OD) and under vacuum conditions (PVOD). For PVOD, a VP of 40 or 80 kPa was applied to the system during the first 10 min of processing, and then, the local atmospheric pressure (101.32 kPa) was restored, and OD was conducted for the remaining process period (290 min).

The temperature was set at 35 °C ± 1 °C, and the solution-to-vegetable ratio was maintained at 1:10 (w/w) to prevent the dilution of the osmotic solution during experiments (Junqueira et al. 2017a). After osmotic processing, the samples were removed from the solution and immersed in a cold distilled water bath for 10 s to halt osmosis and to remove the excess solution. The surface of the samples was gently wiped with absorbent paper, and they were weighed and submitted for moisture content determination (AOAC 2010). All experiments were performed in four replicates.

Quality Analyses

Quality analyses were performed using fresh and osmodehydrated vegetables.

Moisture Content and a w

The moisture content of the vegetables was determined using a vacuum drying oven (SL104/40; Solab, Piracicaba, Brazil) at 70 °C until constant weight was achieved (AOAC 2010). aw determination was performed using a hygrometer (Aqualab, 3-TE model; Decagon Devices, Inc., Pullman, WA, USA). The analyses were performed in triplicate.

Betalain Content

Betalain content (BC) was separately determined as betacyanin content (BCC) and betaxanthin content (BXC). This analysis was performed for beetroot samples. Approximately 1.0 g of the sample was dissolved in 10.0 mL of 50% ethanol. The mixture was stirred in a shaker at 800 rpm for 10 min, and the homogenate was centrifuged at 6000 rpm for 10 min. The supernatant was collected at two repeat stages of centrifugation to ensure maximum extraction, which was further used for the determination of BC (Nistor et al. 2017; Ravichandran et al. 2013). The BCC and BXC in the extracts were determined spectrophotometrically (Cary 50; Varian, Australia) at 538 and 480 nm, respectively. The absorbance value was used to calculate the concentration of betalain in each sample (Eq. 1), by using the following formula:

where Abs is the absorbance, DF is the dilution factor, MW is the molecular weight (g/mol), and E1% is the molar extinction coefficient in water. The MW of BCCs (red-violet color) was 550 g/mol, while that of BXCs (yellow-orange color) was 308 g/mol. The E1% of each betalain in water (E1%1cm) was 60,000 (BCCs) and 48,000 (BXCs). The results of four replicates were expressed as mg/100 g of betalains (d. b.).

Carotenoid Content

Carotenoid content (CC) was determined for carrot according to the method described by Rodriguez-Amaya (2001), with modifications wherein 1.0 g of carrot was used. The carotenoids were exhaustively extracted with cold acetone, partitioned into petroleum ether, and washed with distilled water. Absorbance was measured by UV/Vis spectrophotometry (Cary 50, Varian, Australia) at 444; 450; and 470 nm, which correspond to α-carotene, β-carotene, and lycopene determination, respectively. These are the most abundant carotenoids found in carrots (Nahimana et al. 2011a). Carotenoid content was determined according to Eq.2:

where Abs is the absorbance, V is the total extract volume (mL), and P is the sample weight (g). The E1% of each carotenoid in petroleum ether (E1%1 cm) was 2800 (α-carotene), 2592 (β-carotene), and 3450 (lycopene). The results of four replicates were expressed as mg/100 g of carotenoids (d. b.).

Polyphenol Content

The polyphenols for high-performance liquid chromatography (HPLC) were extracted from 2.5 g of pulp and a 20 mL solution containing 70% methanol in water (v/v), according to Ramaya et al. (2013) with modifications. Briefly, the samples were homogenized and placed in an ultrasonic bath at 20 °C for 60 min. The extracts were centrifuged at 1400×g for 15 min at 4 °C and filtered through Whatman no. 2 filter paper. The extracts were refiltered through regenerated cellulose filters (0.45 μm thick; Millipore, Bedford, MA, USA) and stored at − 18 °C until analyses.

Chromatographic analyses were performed using an Ascentis C18 5-μm (250 mm × 4 mm) column. The mobile phase consisted of 2% (v/v) acetic acid in water (mobile phase A) and 70:28:2 methanol/water/acetic acid (mobile phase B), set to a flow rate of 1.0 mL/min and conducted using a gradient elution program and a 65-min-long run time. The injection volume was 20 μL. Analyses were performed at 15 °C. The phenolic compounds generated a UV–Vis spectrum in the HPLC chromatogram at 280 nm. Quantitative determination of compounds was performed by comparison of the dose–response curves based on the m/z data by using authentic polyphenol standards. The results of three replicates were expressed as mg/100 g (d. b.).

Sodium Content

Sodium content was determined according to Malavolta et al. (1997). The dried samples were mashed, and the powdered material was subjected to nitric-perchloric acid digestion, the material being analyzed by flame photometer (Micronal, B-262 model; São Paulo, Brazil). The results of three replicates were expressed as mg/100 g of sodium (d. b.).

Color Parameters

Color parameters were measured using a colorimeter (Minolta, Model CR-400; Osaka, Japan). The parameters were recorded using CIE L*a*b* uniform color space (CIE-Lab) with D65 as the illuminant. L*, a*, and b* were quantified for each sample. These color parameters were used to calculate the total color difference (∆E) (Eq. 3) (Junqueira et al. 2017b). Seven samples were evaluated for each treatment.

where the subscripts 0 and t indicate the color parameters of samples treated for 300 min and fresh samples, respectively.

Volumetric Shrinkage

This parameter was determined by measuring the area and thickness of the samples. The area was measured by image analysis using the free software Image J® 1.45 s, which provides the sample area by converting the pixels in the image into real dimensions, from a known scale (Nahimana et al. 2011a). For each sample, the thickness at five different points was determined using a digital caliper (DC-6 model; Western, China). The dimensionless volume (β) was determined according to Eq. 4. A higher β value indicates lesser shrinkage (Junqueira et al. 2017c).

where Vf indicates the apparent volume after 300 min of processing (m3), and V0 indicates the initial volume (m3).

Texture

Textural characteristics were measured by uniaxial compression tests by using a texturometer (TA-X2T; Stable Micro Systems, Surrey, England). The diameter and height of the cylindrical samples were 13.80 ± 0.03 and 3.00 ± 0.50 mm, respectively. Vegetable texture was studied based on the load and strain curves recorded during the compression of samples by using two horizontal parallel plates (70 mm length), with the sample being placed at the center of the lower plate. The crosshead speed was 60 mm min−1.For beetroot and carrot slices, the compression was about 40% of the initial height, and for the eggplant samples, it was about 70% of the initial height. Eight replicates were performed for each treatment. Maximum stress (σ) and elasticity modulus (E) were determined according to the methods described by Ferrari et al. (2011) and Moreira et al. (2008).

Scanning Electron Microscopy

Scanning electron microscopy (SEM) was used to analyze the internal structure of the vegetables, before and after osmotic processing. Initially, all samples were fixed with modified Karnovsky solution for 24 h. These samples were immersed in a cryoprotectant solution (30% glycerol in water) for 30 min and transversely sectioned with a scalpel after immersion in liquid nitrogen. These sections were rinsed in distilled water and post-fixed in 1% osmium tetroxide aqueous solution for 1 h, and then dehydrated in an increasing series of acetone solution (25%, 50%, 70%, and 90% for 10 min, and thrice for 10 min at 100%). After dehydration, the samples were subjected to drying on a Critical Point Drier (CPD 030®; Balzers, Germany). Then, the samples were placed on aluminum supports and covered with a film of aluminum foil by using double-sided carbon tape. Finally, all samples were covered with a layer of gold using a Sputter coater (SCD 050®; Balzers, Germany) and observed using a microscope (LEO Evo 40; Zeiss, Cambridge, UK) operating at 20 kV, with a working distance of 8.5 mm (Freitas et al. 2017).

Statistical Analyses

The results were analyzed by one-way analysis of variance (ANOVA) using the software Statistica 8.0 (Statsoft Inc., Tulsa, USA). Differences among means were determined using Tukey’s test at 95% of confidence interval (p ≤ 0.05). All experiments were carried out in triplicate.

Results and Discussion

Moisture Content and a w

The moisture content (MC) and aw of the vegetables are presented in Table 1. A reduction in the moisture content and aw (p ≤ 0.05) was observed for all osmodehydrated products. The products subjected to OD presented a reduction because of dewatering and solute impregnation (sugar and sodium chloride, in this study), as extensively discussed in available literature (Ketata et al. 2013; Mendonça et al. 2016; Porciuncula et al. 2013). According to Fellows (2006), the moisture content and aw of intermediate-moisture foods (IMF) ranges from 15 to 50 kg/100 kg and from 0.65 to 0.90, respectively. Thus, all osmotically treated vegetables can be classified as IMF, showing that osmotic processing is an efficient method for pretreatment of the evaluated vegetables (Table 1).

Beetroot showed slight differences after OD. The MC of osmodehydrated samples was similar to that of samples subjected to PVOD; no difference was observed in the final aw (Table 1). Carrot presented a significant difference in the MC (p ≤ 0.05) after OD. A lower MC was observed in case of samples subjected to PVOD at 80 kPa. The aw also reduced, as the VP increased. In case of eggplant, VP directly influenced the reduction in moisture and aw (p ≤ 0.05). During PVOD, the capillary pores of the vegetables are filled, resulting in an increase in the solid–liquid surface contact area, enhancing the mass transfer rate (Ahmed et al. 2016; Fito 1994). Carrot and eggplant present a less compact structure than beetroot, and they are more sensitive to VA. Viana et al. (2014) observed little effect of VA during the OD of fodder palm, which has a sturdy structure. On the other hand, porous tissues such as those in eggplants (Junqueira et al. 2017a), pears (Moreno et al. 2011), and mangoes (Lin et al. 2016) are related to significant reduction in moisture and aw after vacuum osmotic processing.

Betalain Content

The BCC and BXC in fresh and osmodehydrated beetroots are presented in Table 2. Osmotic treatment significantly affected the BCC and BXC in beetroot samples (p ≤ 0.05). The high BCC and BXC in the fresh product were reduced after osmotic processing. There was a reduction in the BC, with the retention ranging from 53.67 to 60.29% and 53.12 to 55.20% for BCC and BXC, respectively. In general, VA reduced the BCC (p ≤ 0.05), and VP had no effect on the BXC, as observed in osmodehydrated beetroot samples (Table 2). The loss of these pigments is related to leaching, because both compounds are water-soluble. Moreover, the long processing time and exposure to light, oxygen, and temperature promotes the isomerization, deglycosylation, dehydrogenation, decarboxylation, and hydrolysis of the betalains, resulting in a gradual reduction of the red color and appearance of a brown shade (Celli and Brooks 2016; Nistor et al. 2017; Paciulli et al. 2016).

CC

The CC in fresh and osmodehydrated carrots are presented in Table 2. A significant difference (p ≤ 0.05) was noted for all known carotenoids (α-carotene, β-carotene, and lycopene). The predominant carotenoid found in the carrot was β-carotene, in accordance with the findings of Kaur and Sogi (2016) and Sulaeman et al. (2001). α-Carotene, β-carotene, and lycopene contents reduced after OD (Table 2). Dehydration causes gradual breakdown in the cellular structure, with subsequent loss of turgor pressure and consequent disruption of carrot cells (Nieto et al. 2013). Mendonça et al. 2017 also reported CC reduction in pequi slices after osmotic processing. They suggested that this reduction could not be attributed to the leaching flux, as these molecules are hydrophobic. Carotenoids are highly unsaturated molecules susceptible to degradation or isomerization followed by cleavage, in particular under the influence of heat and light during processing (Saini et al. 2015).

Lower CC losses were observed after treatments conducted with VA (PVOD, 40 kPa, and PVOD, 80 kPa), according to Table 2, and a significant difference was noted (p ≤ 0.05) for all the analyzed carotenoids (α-carotene, β-carotene, and lycopene). High carotenoid retention obtained in PVOD could be attributed to the fact that the creation of vacuum enhances cell breakdown, by internal gas removal, releasing the carotenoids attached to the more available cells, compared to OD, facilitating their extraction. Furthermore, carotenoid degradation depends on the presence of oxidative enzymes, which can be diminished by the lack of oxygen (Arkoub-Djermoune et al. 2016; Carvalho et al. 2014; Corrêa et al. 2016; Guiamba et al. 2016). At mild temperatures, lycopene may isomerize to the cis-isoform during dehydration. At 35 °C, lycopene loss primarily occurs through oxidation, which proceeds faster than isomerization and degradation (Xianquan et al. 2005). Lycopene isomerization improves its bioavailability from food matrices (Arkoub-Djermoune et al. 2016).

Polyphenol Content

With respect to the polyphenol profile, significant differences have been noted in the post-processing levels of analyzed phenolic acids (p ≤ 0.05; Table 3). Catechin was identified in all vegetables, with a higher concentration in beetroot samples, but chlorogenic acid was identified only in eggplant samples. In this study, other analyzed acids (trans-cinnamic, caffeic, vanillic, p-coumaric, ferulic, and o-coumaric) were not identified, neither in fresh nor osmodehydrated samples. A reduction in the catechin content was observed in all osmodehydrated samples (Table 3). This could be attributed to the lixiviation. During osmotic processing, as the water is removed, some hydrophilic bioactive compounds migrate from the plant cells to the osmotic solution (Luchese et al. 2015).

Moreover, some loss can be attributed to degradation, because the treatment was conducted for longer time at a temperature close to the optimum temperature for enzymatic action, favoring oxidation (Gonçalves et al. 2017). Moreno et al. (2016) observed significant differences in catechin content in fresh and osmodehydrated blueberries. They concluded that VA reduced catechin content, compared to OD. Chlorogenic acid is the main antioxidant phenol in eggplants (Lo Scalzo et al. 2016), whose content is reduced by PVOD, by almost 50~75% (Table 3). This result can be attributed to mass transfer intensification by VA. Nevertheless, the loss of this polyphenol acid was also observed during OD and was associated with oxidative and hydrolytic modifications. In a general way, vacuum creation reduced the polyphenol content, compared to OD.

As a general remark, the retention of betalains, carotenoids, and polyphenols is desirable, because they present a wide range of biological activity, including antioxidant, anti-inflammatory, and anti-cancer properties (Celli and Brooks 2016; Del Rio et al. 2013).

Sodium Content

The sodium content of beetroot, carrot, and eggplant (fresh and osmodehydrated) is shown in Table 4. There was a significant increase (p ≤ 0.05) in the sodium content of all vegetables after osmotic processing. During osmosis, solute flux occurs from the osmotic solution to the material, increasing its concentration in the food material (Brochier et al. 2015; Corrêa et al. 2010; Ramya and Jain 2017).

In general, VP increased sodium incorporation. Eggplant is a highly porous entity and seemingly more sensitive to the HDM occurring during VA, which improves the surface area for mass transfer, by replacing the internal gases by an osmotic solution (Betoret et al. 2015; Boukouvalas et al. 2006; Vallespir et al. 2018). Junqueira et al. (2017a) reported significant differences in the sodium content of osmodehydrated eggplant slices with and without VA.

Beetroot and carrot are considered low porosity products (Boukouvalas et al. 2006), and might be less sensitive to VA, presenting lower sodium incorporation (compared to eggplant) (Table 4). Although carrot is a low porosity product, it is composed of a peripheral cortex layer and a central stele (vascular tissue) that presents a fibrous and porous structure to facilitate HDM action (Aguiló-Aguayo et al. 2017; Nahimana et al. 2011a; Parthasarathi and Anandharamakrishnan, 2014). On the other hand, Corrêa et al. (2016) observed a reduction in sodium content during the osmotic dehydration of tomatoes in ternary solutions in the presence of vacuum, which suggests that the structure and composition of the product significantly affect the solute gain response.

Color

The color of the osmodehydrated vegetables can be indicative of the retention of pigment-based nutrients as betalains, carotenoids, and chlorophyll (Aral and Beşe 2016). Table 5 presents the mean values and standard deviations of the luminosity (L*), redness (a*), yellowness (b*), and total color difference (∆E) observed for beetroot, carrot, and eggplant (fresh and osmodehydrated) slices.

The beetroot slices subjected to OD and PVOD presented a significant decrease (p ≤ 0.05) in the L* and a* values (Table 5). When BC decreases (Table 2), the decrease in lightness and redness are recorded. Fresh beetroot contains very high amounts of red-violet pigments, and after osmotic processing, the sample surface became darker; hence, the redness reduces (Gokhale and Lele 2014). Statistical difference was observed for the b* parameter (p ≤ 0.05); VP treatment with 0 and 40 kPa presented higher yellowness values, while the treatment conducted at 80 kPa tended to move toward blueness, compared to fresh beetroot subjected to other treatments. According to Table 5, VP promoted higher ∆E (p ≤ 0.05) in beetroot samples. In OD, color variation is a very complex aspect related to the moisture content, solute incorporation, and pigment content (loss or concentration). Moreover, in PVOD, the presence (or absence) of occluded gas affects this quality parameter (Corrêa et al. 2014). Since significant differences were observed in the L*, a*, and b* color parameters, ∆E differences were expected. Higher ∆E values, for the beetroot samples, were probably caused by the intensification of mass transfer occurring because of application of reduced pressure during the initial period of the process, which lead to leaching of pigments (Table 2).

For carrot samples, the L* value decreased significantly (p ≤ 0.05) in all osmodehydrated samples. An increase was observed in the a* and b* values (Table 5), compared to the fresh samples. An increase in redness and yellowness was also reported by Amami et al. (2014) during the OD of carrots, which was related to the intensification of orange coloration. However, the reason underlying these changes in the color parameters (Table 5) and CC (Table 2) is not clear. However, the presence of heat and light causes cis/trans isomerization of the carotenoids, altering their biological activities and discoloring the food (Saini et al. 2015).

For carrot, the higher ∆E was due to the intensification of the a* and b* values (Table 5). The higher the pigment retention, the higher was the ∆E (VP = 80 kPa). As observed for beetroot samples, the pigments are unstable during osmotic processing, contributing to the browning. Moreover, oxidative enzymatic activity makes the sample darker (Betoret et al. 2015; Paciulli et al. 2016). Statistical analysis showed a significant difference (p ≤ 0.05) in the color parameters of the osmodehydrated eggplant samples (Table 5). When the eggplant slices were subjected to OD and PVOD, a significant decrease (p ≤ 0.05) was noted in the L* values. Darker samples were obtained after PVOD. Similar results were reported by Junqueira et al. (2017a) after the OD of eggplant slices.

Since the eggplant is a highly porous fruit (Russo et al. 2013), the reduction in L* value could be related to the removal of internal gases and the impregnation of the tissues with the osmotic solution after restoration of atmospheric pressure (Moreno et al. 2013). A significant increase in the a* and b* values (p ≤ 0.05) was observed in osmodehydrated eggplant samples. Contrary to that observed for beetroot and carrot, the eggplant presents lower pigment concentration, and the intense browning is mainly related to the action of oxidative enzymes, since the eggplant is rich in polyphenol oxidase, peroxidase and its substrate (phenolic compounds) (Arkoub-Djermoune et al. 2016; Mishra et al. 2013).

During eggplant processing, enzymatic browning starts immediately after cutting and rapidly increases as the fruits are exposed to air. This color change is limited by tissue integrity, rather than by substrate or enzyme availability, which could explain the lower L* values, with a consequent increase in ∆E (p ≤ 0.05) after vacuum treatment (Table 5), because VP promotes intense cellular decompartmentalization (Moreno et al. 2012; Zaro et al. 2015). Moreno et al. (2011) noted a higher ∆E in the VA-treated apple samples, when compared to the ∆E of samples subjected to osmotic processing at atmospheric pressure.

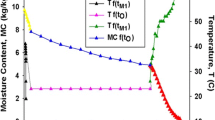

Volumetric Shrinkage

The dimensionless volume (β) (mean values and standard deviations) of the samples after osmotic processing is presented in Fig. 1. All treatments exhibited volume reduction. OD promotes a reduction in the moisture content, decreasing the tension exerted by the liquid against the cell wall, which can cause pressure imbalance between the interior and exterior. This can generate contracting stress, resulting in material shrinkage or collapse (Junqueira et al. 2017c; Nahimana et al. 2011b; Toğrul and İspir 2007).

Regarding volumetric shrinkage, different vegetables showed different patterns. Eggplant presented a lower β (as low as 13.81%), indicating higher shrinkage, whereas beetroot exhibited a higher β (lower shrinkage). This differential behavior could be associated to the different physicochemical characteristics of the vegetables, such as chemical composition, mechanical properties, initial porosity, and apparent volume, which can generate different types of stress during the process (Mayor et al. 2011; Parthasarathi and Anandharamakrishnan 2014). Mújica-Paz et al. (2003) reported that high porosity products present greater susceptibility to mechanical deformation. Higher volume reduction in eggplant can be explained by its high porosity, while the lower reduction in beetroot can be related to its low porosity (Boukouvalas et al. 2006).

VP influenced the extent of shrinkage (p ≤ 0.05) observed in all vegetables. According to Fig. 1, VA caused a reduction in the β of beetroot and eggplant samples, which suggests that on adopting reduced pressure-based treatment, the expansion and escape of gases that occurs after the restoration of atmospheric pressure also contributes to volumetric shrinkage, although these vegetables exhibit different properties. The opposite behavior was shown by carrot samples (Fig. 1), with an increase in β values and reduced shrinkage being observed when vacuum was employed. This behavior is probably related to the heterogeneous tissue composition of carrot, composed of a peripheral cortex (parenchymatous cells) and a core (xylem tracheary elements), which may cause differential response to OD (Nahimana et al. 2011a). Lin et al. (2016) also concluded that PVOD can reduce the shrinkage observed in mango cubes.

Texture

The maximum stress (σ) and elasticity modulus (E) of the fresh and osmodehydrated vegetables are shown in Table 6. There was a significant reduction in these parameters after OD (p ≤ 0.05).

According to Moreno et al. (2013) and (2011), when the vegetable tissue is subjected to osmotic processing, in addition to moisture removal, textural changes are dependent on the physical and chemical changes due to the degradation of the middle lamella and solute incorporation, which causes loss of turgor and movement of ions from the cell wall to the media. These changes create internal stress, leading to cellular disruption and plasmolysis (such as volumetric shrinkage presented in Table 5), causing tissue softening, which might be the reason for the reduction in stress at rupture after osmotic processing (Castelló et al. 2009).

Such a reduction in σ after osmotic treatment, with consequent loss of firmness, was also observed in eggplant (Junqueira et al. 2017a), pear (Oliveira et al. 2016), mango (Lin et al. 2016), pumpkin (Silva et al. 2011), and melon (Ferrari et al. 2011). When fresh and osmodehydrated vegetables are compared, higher firmness maintenance was observed for the eggplant (Table 6). This occurred because of the high porosity of this fruit, which causes the solid matrix to undergo minor deformation, thus preserving the food structure (Gras et al. 2002). For beetroot samples, VP did not have a significant effect on the σ values (Table 6). Comparing OD and PVOD for pear slices, Moreno et al. (2011) concluded that no differences were reported in the firmness values.

However, vacuum creation significantly reduced the σ values for carrot and eggplant slices (p ≤ 0.05; Table 6). During PVOD, the exchange of internal gases and liquids occurred in the open pores, with the help of the osmotic solution, because of the pressure change-induced action of HDM. More intense deformation and rupture were noted, with a decreasing effect on σ. For these vegetables, VA susceptibility is related to the porous structure of eggplant and the lack of internal structural uniformity and heterogeneity of the carrot, which, in general, presents low porosity. Even the core tissue (mainly represented by xylem-type cells) show some voids (Nahimana et al. 2011a).

Gras et al. (2002) pointed that the carrot tissue presented almost no intercellular space, and that no significant HDM was expected. On the other hand, those authors observed that the vascular system of this vegetable (xylem and phloem elements) might be related to HDM, under conditions of reduced pressure. The system is composed of tracheary elements in the central zone of fresh carrots, wherein empty or full spaces can be found. They also observed that the vessels were separated by water-permeable membranes, and when water pressure in the system decreased, the vessel elements closed to avoid progressive plant dehydration.

With respect to the elastic modulus (E) (Table 6), the osmodehydrated eggplant presented a remarkable decrease (compared to the fresh sample), reaching up to 90% elasticity loss, because of gas replacement during osmotic processing.

Microstructure

To evaluate the impact of osmotic processing on vegetable structure, the samples were analyzed using a scanning electron microscope (SEM). The differences between fresh and osmodehydrated tissue are shown in Figs. 2, 3, and 4.

For fresh beetroot (Fig. 2a), carrot (Fig. 3a), and eggplant (Fig. 4a) tissues, the cells were round and long in shape, and tightly connected to each other. Similar findings were pointed out by Oliveira et al. (2016), Salazar-López et al. (2015), and Corrêa et al.(2015) for fresh tissues of pear, pineapple, and tomato, respectively. For samples subjected to OD (Fig. 2b, 3b, and 4b), the cells were irregularly shaped and moderately collapsed with tissue disruption. During osmotic treatment, the cell walls break down, intercellular contact is decreased, plasmolysis occurs, and the cell structure of the samples collapses (Deng and Zhao 2008; Mayor et al. 2008; Vallespir et al. 2018). Brochier et al. (2015) studied yacon slices treated by OD and observed plasmolysis caused by the loss of water from the cytoplasm, in addition to deformed, collapsed, and nonturgid cells.

Osmotic dehydration is known to cause changes in the structure of plant tissue. During OD treatment, the mass transfer of water from the tissue into the osmotic solution and the solute from the osmotic solution into the intercellular and extracellular spaces of the tissue leads to structural damage to the cells at the microscopic level (Nowacka et al. 2014; Nowacka and Wedzik 2016).

For PVOD treatment (Figs. 2c, d, 3c, d, 4c, d), changes to the cellular structure were observed for all vegetables. Such changes are related to the different mass transfer parameters and textural changes (Table 6). In general, the higher the water loss and solid gain, the higher is the cellular tissue damage during osmotic processing. The removal of occluded gases also influences the cellular structure, and unlike OD, the cells shrank, acquiring an irregular shape (Deng and Zhao 2008; Nieto et al. 2013). Lin et al. (2016) observed changes in the mango tissues subjected to PVOD, who attributed the microstructural changes, occurring after restoration of atmospheric pressure, to cell porosity. They also concluded that the expansion of gases leads to an increase in the intercellular space, in addition to alteration of cell membrane permeability.

Conclusions

The effect of VA on different materials during osmotic processing was investigated and a thorough study of the quality parameters of osmodehydrated vegetables was undertaken. In general, the beetroot samples were less sensitive to the effects of VA. This was related to their compact structure. The carrot and eggplant samples presented more pronounced changes in the quality parameters evaluated. In case of beetroot, VA reduced the BCC and increased the total color difference and volumetric shrinkage. In case of carrot, VA reduced the aw and volumetric shrinkage, preserved the CC, and increased the sodium uptake, total color difference, and textural properties. In case of the more porous structure (eggplant), VA reduced the moisture content, aw, and chlorogenic acid content and increased the sodium uptake, total color difference, and volumetric shrinkage. In general, an evaluation of all quality parameters showed that the treatment undertaken at atmospheric pressure (OD) was the most suitable for all vegetables. The retention of food components and changes in the mechanical properties of the osmotically dehydrated products were associated to both VA and the structure of the biological material.

References

Aguiló-Aguayo, I., Gangopadhyay, N., Lyng, J. G., Brunton, N., & Rai, D. K. (2017). Impact of pulsed light on colour, carotenoid, polyacetylene and sugar content of carrot slices. Innovative Food Science and Emerging Technologies, 42, 49–55.

Ahmed, I., Qazi, I. M., & Jamal, S. (2016). Developments in osmotic dehydration technique for the preservation of fruits and vegetables. Innovative Food Science and Emerging Technologies, 34, 29–43.

Amami, E., Khezami, L., Jemai, A. B., & Vorobiev, E. (2014). Osmotic dehydration of some agro-food tissue pre-treated by pulsed electric field: Impact of impeller’s Reynolds number on mass transfer and color. Journal of King Saud University - Engineering Sciences, 26(1), 93–102.

AOAC - Association of Official Agricultural Chemists. (2010). Official methods of analysis of AOAC international. USA: Gaithersburg.

Aral, S., & Beşe, A. V. (2016). Convective drying of hawthorn fruit (Crataegus spp.): effect of experimental parameters on drying kinetics, color, shrinkage, and rehydration capacity. Food Chemistry, 210, 577–584.

Arkoub-Djermoune, L., Boulekbache-Makhlouf, L., Zeghichi-Hamri, S., Bellili, S., Boukhalfa, F., & Madani, K. (2016). Influence of the thermal processing on the physico-chemical propreties and the antioxidant activity of a solanaceae vegetable: eggplant. Journal of Food Quality, 39(3), 181–191.

Betoret, E., Betoret, N., Rocculi, P., & Dalla Rosa, M. (2015). Strategies to improve food functionality: structure-property relationships on high pressures homogenization, vacuum impregnation and drying technologies. Trends in Food Science and Technology, 46(1), 1–12.

Boukouvalas, C. J., Krokida, M. K., Maroulis, Z. B., & Marinos-Kouris, D. (2006). Density and porosity: literature data compilation for foodstuffs. International Journal of Food Properties, 9(4), 715–746.

Brochier, B., Marczak, L. D. F., & Noreña, C. P. Z. (2015). Osmotic dehydration of yacon using glycerol and sorbitol as solutes: water effective diffusivity evaluation. Food and Bioprocess Technology, 8(3), 623–636.

de Carvalho, L. M. J., de Smiderle, L., A. S. M., de Carvalho, J. L. V., de Cardoso, F., S. N., & Koblitz, M. G. B. (2014). Assessment of carotenoids in pumpkins after different home cooking conditions. Food Science Technology, 34(2), 365–370.

Castelló, M. L., Igual, M., Fito, P. J., & Chiralt, A. (2009). Influence of osmotic dehydration on texture, respiration and microbial stability of apple slices (Var. granny smith). Journal of Food Engineering, 91(1), 1–9.

Celli, G. B., & Brooks, M. S. L. (2016). Impact of extraction and processing conditions on betalains and comparison of properties with anthocyanins — a current review. Food Research International, 100, 501–509.

Corrêa, J. L. G., Ernesto, D. B., Alves, J. G. L. F., & Andrade, R. S. (2014). Optimisation of vacuum pulse osmotic dehydration of blanched pumpkin. International Journal of Food Science and Technology, 49(9), 2008–2014.

Corrêa, J. L. G., Ernesto, D. B., & Mendonça, K. S. (2016). Pulsed vacuum osmotic dehydration of tomatoes: sodium incorporation reduction and kinetics modeling. LWT - Food Science and Technology, 71, 17–24.

Corrêa, J. L. G., Justus, A., de Oliveira, L. F., & Alves, G. E. (2015). Osmotic dehydration of tomato assisted by ultrasound: evaluation of the liquid media on mass transfer and product quality. International Journal of Food Engineering, 11, 505–516.

Corrêa, J. L. G., Pereira, L. M., Vieira, G., & Hubinger, M. D. (2010). Mass transfer kinetics of pulsed vacuum osmotic dehydration of guavas. Journal of Food Engineering, 96(4), 498–504.

Del Rio, D., Rodriguez-Mateos, A., Spencer, J. P. E., Tognolini, M., Borges, G., & Crozier, A. (2013). Dietary (poly) phenolics in human health: structures, bioavailability, and evidence of protective effects against chronic diseases. Antioxidants and Redox Signaling, 18(14), 1818–1892.

Deng, Y., & Zhao, Y. (2008). Effects of pulsed-vacuum and ultrasound on the osmodehydration kinetics and microstructure of apples (Fuji). Journal of Food Engineering, 85(1), 84–93.

Dimakopoulou-Papazoglou, D., & Katsanidis, E. (2016). Mass transfer kinetics during osmotic processing of beef meat using ternary solutions. Food and Bioproducts Processing, 100, 560–569.

Fellows, P. (2006). Food processing technology - principles and practice (second ed.). USA: Florida.

Ferrari, C. C., Arballo, J. R., Mascheroni, R. H., & Hubinger, M. D. (2011). Modelling of mass transfer and texture evaluation during osmotic dehydration of melon under vacuum. International Journal of Food Science and Technology, 46(2), 436–443.

Fito, P. (1994). Modelling of vacuum osmotic dehydration of food. Journal of Food Engineering, 22(1-4), 313–328.

Freitas, A. S., Pozza, E. A., Moreira, S. I., de Oliveira Soares, M. G., Silva, H. R., & Alves, E. (2017). Infection process of Pseudocercospora musae on banana leaf. Phytoparasitica, 45(3), 317–324.

Gokhale, S. V., & Lele, S. S. (2014). Betalain content and antioxidant activity of beta vulgaris: effect of hot air convective drying and storage. Journal of Food Processing and Preservation, 38(1), 585–590.

Gonçalves, G. A. S., Resende, N. S., Carvalho, E. E. N., de Resende, J. V., Boas, V., & E.V. de B. (2017). Effect of pasteurisation and freezing method on bioactive compounds and antioxidant activity of strawberry pulp. International Journal of Food Science and Nutrition, 68(6), 682–694.

Gras, M., Vidal-Brotóns, N., Betoret, A., Chiralt, F., & P. (2002). The response of some vegetables to vacuum impregnation. Innovative Food Science and Emerging Technologies, 3(3), 263–269.

Guiamba, I., Ahrné, L., Khan, M. A. M., & Svanberg, U. (2016). Retention of β-carotene and vitamin C in dried mango osmotically pretreated with osmotic solutions containing calcium or ascorbic acid. Food and Bioproducts Processing, 98, 320–326.

Herman-Lara, E., Martínez-Sánchez, C. E., Pacheco-Angulo, H., Carmona-García, R., Ruiz-Espinosa, H., & Ruiz-López, I. I. (2013). Mass transfer modeling of equilibrium and dynamic periods during osmotic dehydration of radish in NaCl solutions. Food and Bioproducts Processing, 91(3), 216–224.

de Junqueira, J. R., J., Corrêa, J. L. G., de Mendonça, K. S., Resende, N. S., & de Barros Vilas Boas, E. V. (2017a). Influence of sodium replacement and vacuum pulse on the osmotic dehydration of eggplant slices. Innovative Food Science and Emerging Technologies, 41, 10–18.

de Junqueira, J. R., J., Corrêa, J. L. G., de Oliveira, H. M., Ivo Soares Avelar, R., & Salles Pio, L. A. (2017b). Convective drying of cape gooseberry fruits: effect of pretreatments on kinetics and quality parameters. LWT - Food Science and Technology, 82, 404–410.

de Junqueira, J. R., J., Corrêa, J. L. G., & Mendonça, K. S. (2017c). Evaluation of the shrinkage effect on the modeling kinetics of osmotic dehydration of sweet potato (Ipomoea batatas (L.)). Journal of Food Processing and Preservation, 41, e12881.

Kargozari, M., Moini, S., & Emam-Djomeh, Z. (2010). Prediction of some physical properties of osmodehydrated carrot cubes using response surface methodology. Journal of Food Processing and Preservation, 34(6), 1041–1063.

Kaur, A., & Sogi, D. S. (2016). Effect of osmotic dehydration on physico-chemical properties and pigment content of carrot (Daucus carota L) during preserve manufacture. Journal of Food Processing and Preservation, 1–6.

Ketata, M., Desjardins, Y., & Ratti, C. (2013). Effect of liquid nitrogen pretreatments on osmotic dehydration of blueberries. Journal of Food Engineering, 116(1), 202–212.

Lech, K., Michalska, A., Wojdyło, A., Nowicka, P., & Figiel, A. (2018). The influence of physical properties of selected plant materials on the process of osmotic dehydration. LWT - Food Science and Technology, 91, 588–594.

Lin, X., Luo, C., & Chen, Y. (2016). Effects of vacuum impregnation with sucrose solution on mango tissue. Journal of Food Science, 81, 1412–1418.

Lo Scalzo, R., Fibiani, M., Francese, G., D’Alessandro, A., Rotino, G. L., Conte, P., & Mennella, G. (2016). Cooking influence on physico-chemical fruit characteristics of eggplant (Solanum melongena L.). Food Chemistry, 194, 835–842.

Luchese, C. L., Gurak, P. D., & Marczak, L. D. F. (2015). Osmotic dehydration of physalis (Physalis peruviana L.): evaluation of water loss and sucrose incorporation and the quantification of carotenoids. LWT - Food Science and Technology, 63(2), 1128–1136.

Malavolta, E., Vitti, G. C., & Oliveira, S. A. (1997). Avaliação do estado nutricional das plantas (second ed.). Brazil: São Paulo.

Mayor, L., Moreira, R., & Sereno, A. M. (2011). Shrinkage, density, porosity and shape changes during dehydration of pumpkin (Cucurbita pepo L.) fruits. Journal of Food Engineering, 103(1), 29–37.

Mayor, L., Pissarra, J., & Sereno, A. M. (2008). Microstructural changes during osmotic dehydration of parenchymatic pumpkin tissue. Journal of Food Engineering, 85(3), 326–339.

de Mendonça, K. S., Corrêa, J. L. G., de Jesus Junqueira, J. R., Pereira, M. C. D. A., & Vilela, M. B. (2016). Optimization of osmotic dehydration of yacon slices. Drying Technology, 34(4), 386–394.

de Mendonça, K. S., Corrêa, J. L. G., de Junqueira, J. R., J., Cirillo, M. A., Figueira, F. V., & Carvalho, E. E. N. (2017). Influences of convective and vacuum drying on the quality attributes of osmo-dried pequi (Caryocar brasiliense Camb.) slices. Food Chemistry, 224, 212–218.

Mishra, B. B., Gautam, S., & Sharma, A. (2013). Free phenolics and polyphenol oxidase (PPO): The factors affecting post-cut browning in eggplant (Solanum melongena). Food Chemistry, 139(1-4), 105–114.

Moreira, R., Chenlo, F., Chaguri, L., & Fernandes, C. (2008). Water absorption, texture, and color kinetics of air-dried chestnuts during rehydration. Journal of Food Engineering, 86(4), 584–594.

Moreno, J., Gonzales, M., Zúñiga, P., Petzold, G., Mella, K., & Muñoz, O. (2016). Ohmic heating and pulsed vacuum effect on dehydration processes and polyphenol component retention of osmodehydrated blueberries (cv. Tifblue). Innovative Food Science and Emerging Technologies, 36, 112–119.

Moreno, J., Simpson, R., Pizarro, N., Parada, K., Pinilla, N., Reyes, J. E., & Almonacid, S. (2012). Effect of ohmic heating and vacuum impregnation on the quality and microbial stability of osmotically dehydrated strawberries (cv. Camarosa). Journal of Food Engineering, 110(2), 310–316.

Moreno, J., Simpson, R., Pizarro, N., Pavez, C., Dorvil, F., Petzold, G., & Bugueño, G. (2013). Influence of ohmic heating/osmotic dehydration treatments on polyphenoloxidase inactivation, physical properties and microbial stability of apples (cv. Granny Smith). Innovative Food Science and Emerging Technologies, 20, 198–207.

Moreno, J., Simpson, R., Sayas, M., Segura, I., Aldana, O., & Almonacid, S. (2011). Influence of ohmic heating and vacuum impregnation on the osmotic dehydration kinetics and microstructure of pears (cv. Packham’s Triumph). Journal of Food Engineering, 104(4), 621–627.

Mújica-Paz, H., Valdez-Fragoso, A., López-Malo, A., Palou, E., & Welti-Chanes, J. (2003). Impregnation properties of some fruits at vacuum pressure. Journal of Food Engineering, 56(4), 307–314.

Nahimana, H., Munjumdar, A. S., & Zhang, M. (2011a). Drying and radial shrinkage characteristics and changes in color and shape of carrot tissues (Daucus carota L) during air drying. African Journal of Biotechnology, 10, 15327–15345.

Nahimana, H., Zhang, M., Mujumdar, A. S., & Ding, Z. (2011b). Mass transfer modeling and shrinkage consideration during osmotic dehydration of fruits and vegetables. Food Reviews International, 27(4), 331–356.

Nieto, A. B., Vicente, S., Hodara, K., Castro, M. A., & Alzamora, S. M. (2013). Osmotic dehydration of apple: influence of sugar and water activity on tissue structure, rheological properties and water mobility. Journal of Food Engineering, 119(1), 104–114.

Nistor, O. V., Seremet (Ceclu), L., Andronoiu, D. G., Rudi, L., & Botez, E. (2017). Influence of different drying methods on the physicochemical properties of red beetroot ( Beta vulgaris L. var. Cylindra ). Food Chemistry, 236, 59–67.

Nowacka, M., Tylewicz, U., Laghi, L., Dalla Rosa, M., & Witrowa-Rajchert, D. (2014). Effect of ultrasound treatment on the water state in kiwifruit during osmotic dehydration. Food Chemistry, 144, 18–25.

Nowacka, M., & Wedzik, M. (2016). Effect of ultrasound treatment on microstructure, colour and carotenoid content in fresh and dried carrot tissue. Applied Acoustics, 103, 163–171.

Oliveira, L. F., Mendonça, K. S., Corrêa, J. L. G., Junqueira, J. R. J., & Justus, A. (2016). Efeito de ondas ultrassônicas e de pulso de vácuo nos parâmetros de qualidade peras osmoticamente desidratadas. Caderno de Ciências Agrárias, 8, 38–48.

Paciulli, M., Medina-Meza, I. G., Chiavaro, E., & Barbosa-Cánovas, G. V. (2016). Impact of thermal and high pressure processing on quality parameters of beetroot (Beta vulgaris L.). LWT - Food Science and Technology, 68, 98–104.

Parthasarathi, S., & Anandharamakrishnan, C. (2014). Modeling of shrinkage, rehydration and textural changes for food structural analysis: a review. Journal of Food Process Engineering, 37(2), 199–210.

Porciuncula, B. D. A., Zotarelli, M. F., Carciofi, B. A. M., & Laurindo, J. B. (2013). Determining the effective diffusion coefficient of water in banana (Prata variety) during osmotic dehydration and its use in predictive models. Journal of Food Engineering, 119(3), 490–496.

Ramaya, S. D., Bujang, J. S., Zakaria, M. H., King, W. S., & Sahrir, M. A. S. (2013). Sugar, ascorbic acid, total phenolic content and total antioxidant activity in passion fruit (Passiflora) cultivars. Journal of the Science of Food Agriculture, 93(5), 1198–1205.

Ramya, V., & Jain, N. K. (2017). A review on osmotic dehydration of fruits and vegetables: an integrated approach. Journal of Food Process Engineering, 40, 1–22.

Ravichandran, K., Saw, N. M. M. T., Mohdaly, A. A. A., Gabr, A. M. M., Kastell, A., Riedel, H., Cai, Z., Knorr, D., & Smetanska, I. (2013). Impact of processing of red beet on betalain content and antioxidant activity. Food Research International, 50(2), 670–675.

Rodriguez-Amaya, D. B. (2001). A guide to carotenoid analysis in food (71 p). Washington: International Life Sciences Institute.

Russo, P., Adiletta, G., & Di Matteo, M. (2013). The influence of drying air temperature on the physical properties of dried and rehydrated eggplant. Food Bioproducts Processing, 91(3), 249–256.

Saini, R. K., Nile, S. H., & Park, S. W. (2015). Carotenoids from fruits and vegetables: Chemistry, analysis, occurrence, bioavailability and biological activities. Food Research International, 76(Pt 3), 735–750.

Salazar-López, E. I., Jiménez, M., Salazar, R., & Azuara, E. (2015). Incorporation of microcapsules in pineapple intercellular tissue using osmotic dehydration and microencapsulation method. Food and Bioprocess Technology, 8(8), 1699–1706.

Sette, P., Salvatori, D., & Schebor, C. (2016). Physical and mechanical properties of raspberries subjected to osmotic dehydration and further dehydration by air- and freeze-drying. Food and Bioproducts Processing, 100, 156–171.

Silva, K. S., Caetano, L. C., Garcia, C. C., Romero, J. T., Santos, A. B., & Mauro, M. A. (2011). Osmotic dehydration process for low temperature blanched pumpkin. Journal of Food Engineering, 105(1), 56–64.

Sulaeman, A., Keeler, L., Giraud, D. W., Taylor, S. L., Wehling, R. L., & Driskell, J. A. (2001). Carotenoid content and physicochemical and sensory characteristics of carrot chips deep-fried in different oils at several temperatures. Journal of Food Science, 66(9), 1257–1264.

Toğrul, İ. T., & İspir, A. (2007). Effect on effective diffusion coefficients and investigation of shrinkage during osmotic dehydration of apricot. Energy Conversion Managment, 48(10), 2611–2621.

Vallespir, F., Cárcel, J. A., Marra, F., Eim, V. S., & Simal, S. (2018). Improvement of mass transfer by freezing pre-treatment and ultrasound application on the convective drying of beetroot (Beta vulgaris L.). Food Bioprocess Technology, 11(1), 72–83.

Viana, A. D., Corrêa, J. L. G., & Justus, A. (2014). Optimisation of the pulsed vacuum osmotic dehydration of cladodes of fodder palm. International Journal of Food Science and Technology, 49(3), 726–732.

Xianquan, S., Shi, J., Kakuda, Y., & Yueming, J. (2005). Stability of lycopene during food processing and storage. Journal of Medicinal Food, 8(4), 413–422.

Zaro, M. J., Ortiz, L. C., Keunchkarian, S., & Chaves, A. R. (2015). Chlorogenic acid retention in white and purple eggplant after processing and cooking. LWT - Food Science and Technology, 64(2), 802–808.

Acknowledgements

The authors gratefully acknowledge CAPES (Coordination for the Improvement of Higher Education Personnel), CNPq (National Council for Scientific and Technological Development), and FAPEMIG (State of Minas Gerais Research Foundation).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Jesus Junqueira, J.R., Corrêa, J.L.G., de Mendonça, K.S. et al. Pulsed Vacuum Osmotic Dehydration of Beetroot, Carrot and Eggplant Slices: Effect of Vacuum Pressure on the Quality Parameters. Food Bioprocess Technol 11, 1863–1875 (2018). https://doi.org/10.1007/s11947-018-2147-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2147-9