Abstract

Sweet potato is one of cheap sources for starch industries worldwide, and exploiting starch wastewater as an alternative protein source is mainly environmental and economic concerns. In this study, the effects of high hydrostatic pressure (HHP; 250, 400, and 550 MPa) on chemical forces, structure, and gelation properties of sweet potato protein (SPP) at pH 3.0, 6.0, and 9.0 were investigated. The values of surface hydrophobicity (Ho) and absolute value of zeta potential of SPP significantly increased from 250 to 550 MPa (p < 0.05) at all three pH conditions. The total amount of sulfhydryl (-SH-) groups in SPP decreased after HHP at pH 9.0, whereas the amount of free -SH- increased. High molecular mass aggregates (> 180 kDa) were observed in SPP after HHP at pH 6.0 and 9.0 by SDS-PAGE. Regarding elastic rheological behaviors, storage modulus (G′) values of SPP were significantly strengthened after HHP treatment. In addition, textural properties and water-holding capacity of gels made from SPP after 250 and 400 MPa at pH 9.0 were significantly improved, and the gels showed a compact and uniform gel network with the contribution of immobilized water fractions. The gel properties exhibited by SPP after HHP treatment at different pH levels, in particular after 400 MPa at pH 9.0, suggested that it could be potential protein resources as new gelling reagent in the food system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, market demand has steadily grown for protein ingredients, especially those that have multiple functions, such as ingredients that act as a supplement and also have functional properties. The ability of protein to form a gel makes it suited to improve the textural and functional properties of food products (Han et al. 2014). Many plant proteins have been reported to have gelation properties, including soy protein (Wu et al. 2017), pea protein (Sun and Arntfield 2012), gluten (Wang et al. 2017a), and canola protein (Chang et al. 2015). Meanwhile, many modification methods have been developed to improve the functional properties of proteins, including physical (Wihodo and Moraru 2013), chemical (Boutureira and Bernardes 2015), and enzymatic treatments (Gaspar and De Góes-Favoni 2015).

High hydrostatic pressure (HHP) has made significant development over the last 20 years, which is utilized realistically in food system and offers the applications in the innovation of novel textures and tastes of foods (Norton and Sun 2008). As a nonthermal, safe, and promising technology, HHP treatment can be used to produce healthy and fresh-like foods due its minimal effects on nutritional and aroma compounds (De Maria et al. 2016). HHP also presents encouraging potential to manipulate the functionality, extractability, allergenicity, and bioavailability of micronutrients and components in foods (Barba et al. 2015). HHP has interesting functional effects based on how it changes protein structure, as well as how it affects the chemical forces between protein molecules, including surface hydrophobic activity, electrostatic interactions, disulfide linkages, and hydrogen bonding (Sun and Arntfield 2012; Wang et al. 2017b). HHP treatment could induce protein molecule aggregation, promote surface hydrophobicity (Ho) of protein isolates, change the secondary structure of the protein, and result in good gel textural properties (He et al. 2014). Zhang et al. (2017) reported that as pressure increased, the total sulfhydryl (-SH-) group content of myofibrillar protein decreased and the absolute zeta potential increased. Puppo et al. (2004) indicated that HHP modified secondary structure of soybean protein isolates by leading to a more disordered structure and resulting in insoluble aggregates. Peyrano et al. (2016) found that HHP was more efficient than thermal treatment to enhance gelation properties and water-holding capacities of cowpea protein isolates. Moreover, Yang et al. (2014) also showed better mechanical strength of canola protein gels formed at high pH level compared to that of low pH conditions over a broad range of pH levels (5–11).

Sweet potato (Ipomoea batatas (L.) Lam) is one of the main food crops and a source of starch in China, and accounts for 67.3 and 90.1% of sweet potato production worldwide and in Asia, respectively (FAOSTAT 2016). It is considered to be one of the most promising economic crops with remarkable spectrum of antioxidant activities, based on the high level of valuable compounds in extracts, such as protein and polyphenols (e.g., anthocyanins) (Zhu et al. 2017). Sweet potato contains about 1.7–9.1% crude protein on a dry weight basis (Zhang et al. 2014). Sweet potato protein (SPP) has a high content of essential amino acids, and therefore, has higher nutritive value than most other plant proteins (Mu et al. 2009b), but is normally discarded as industrial waste in the process of sweet potato starch manufacturing. In our recent study, we investigated the structure, physicochemical properties, emulsifying properties, and in vitro digestibility of SPP after HHP treatment, and found that HHP (200–600 MPa) could improve emulsifying properties, alter in vitro digestibility, and reduce thermodynamic stability of SPP (Khan et al. 2013, 2014; 2015; Sun et al. 2014). Additionally, we studied the gelation properties and gel microstructure of isoelectric and ultrafiltered SPP at atmospheric pressure and pH 7.0 (Arogundade et al. 2012). The gelation behavior and chemical forces of protein were varied by the protein types and significantly modulated by pH (Wang et al. 2014; Kim et al. 2016). However, no study on the effects of pH on the chemical forces, structure, and gelation properties of SPP after HHP treatment is currently available, and even the basic information both including dispersion, thermal gelation process, and SPP gel products are still limited.

Normally, the most popular pressure levels used in commercial applications ranged from 200 to 600 MPa (San Martin et al. 2002). Moreover, the applied pH of almost gel-like food or soft gel-like food (e.g., beverages and yogurt) is slightly below pH 7.0, being closer to pH 6.0. And the pH of some fruit juice and baked products is usually close to 3.0 and 9.0, respectively. The -SH- groups could easily form disulfide bonds by intermolecular interactions at alkaline condition of pH 9.0, which might further contribute to the gel texture (Chang et al. 2015). Hence, the real aims of this study are to investigate the effects of HHP treatment on chemical forces (surface hydrophobicity, zeta potential, sulfhydryl group), structure, rheological properties, and gelation properties of SPP as affected by HHP (250, 400, and 550 MPa) at below (pH 3.0), near (pH 6.0), or far away from (9.0) the isoelectric point of SPP (4.0), respectively, and to provide basic information about the gelation properties of SPP and its potential applications as a functional agent in food industry.

Materials and Methods

Materials

Sweet potatoes of the cultivar Shang Shu No. 19 were provided by Shangqiu Academy of Agriculture and Forestry Sciences, Henan Province, China. All chemicals used were of analytical grade and purchased from Sigma-Aldrich (St. Louis, MO., USA).

Preparation of SPP

SPP was prepared as described previously by Arogundade and Mu (2012), with slight modifications. Briefly, fresh peeled tubers were grounded with 0.1% sodium bisulfite solution at a solid-to-solvent ratio of 1:2, sieved with cheese cloth (0.15–mm pore diameter), and centrifuged at 10,000g for 45 min to collect supernatant. The pH value of the supernatant was adjusted to 4.0 (using 2 M HCl), and then centrifuged at 6000g for 30 min to collect the precipitate, which was resolubilized in distilled water at pH 7.0 using 2 M NaOH, centrifuged at 10,000g for 45 min, ultrafiltered, and then lyophilized to obtain SPP with purity of 92.95% by the Kjeldahl method (N × 6.25).

High Hydrostatic Pressure

HHP treatment was performed using a laboratory-scale HHP unit (model HHP–L3–600/0.6; HuaTaiSenMiao Engineering & Technique Ltd. Co., Tianjin, China) with a 0.6-L cylindrical pressure vessel (60 × 210 mm) and a water jacket for temperature control at 25 °C. For HHP processing, each dispersion of SPP (4%, w/v) at pH 3.0 (50 mM glycine–HCl buffer), 6.0 (50 mM phosphate buffer), and 9.0 (50 mM glycine–NaOH buffer) was vacuum-packed in food-grade polyethylene bags, pressurized at a speed of 3.5 MPa/s, and then held at 250, 400, and 550 MPa for 30 min before the pressure was released within 5 s, respectively. SPP dispersion without pressurization (0.1 MPa) at pH 3.0, 6.0, and 9.0 were used as reference. Each SPP dispersion was then freeze dried and stored at −18 °C for subsequent analysis.

Chemical Forces of SPP

Surface Hydrophobicity (Ho)

Ho of SPP was determined using 1-anilinonaphthalene-8-sulfonic acid (ANS) as a hydrophobic fluorescence probe according to Chang et al. (2015) with some modification. The stock solution (0.1%, w/v) was prepared by dissolving SPP in 10 mM phosphate buffer (pH 7.0), then serially diluted to a final concentration of 0.004–0.02% (w/v) with the same buffer. An aliquot of 20 μL ANS (8.0 mM in 10 mM phosphate buffer, pH 7.0) was added to 4.0 mL of each diluted solution. The fluorescence intensity (FI) was measured using a fluorescence spectrometer (F2500; Hitachi, Tokyo, Japan) at wavelengths of 390 nm (excitation) and 470 nm (emission). The initial slope of FI versus the protein concentration plot (calculated by linear regression analysis) was used as an index of Ho.

Zeta Potential Test for Electrostatic Interactions

The zeta potential was measured using a zetasizer (Nano-ZS90; Malvern Instruments Ltd. Malvern, UK) equipped with an avalanche photodiode detector based on the previous literature (Yang et al. 2014). SPP solution (1.0 mg/mL) was prepared by dissolving SPP powder into Milli-Q water. A 1.0-mL aliquot of SPP solution (1.0 mg/mL) was injected into a disposable clear test cell (DTS1060C; Malvern Instruments Ltd.) and equilibrated at 25 °C for 3.0 min before starting the test. The absolute value of the zeta potential is positively related to the electrostatic interactions of the charged amino acids (Zhang et al. 2015; Chang et al. 2015).

Sulfhydryl Group Measurement

Total and free -SH- group contents were measured according to the method of He et al. (2014). The total -SH- group was determined by dissolving SPP in Tris–glycine buffer (containing 0.086 mol/L Tris, 0.09 mol/L glycine, and 0.004 mol/L EDTA; pH 8.0) with 8.0 mol/L urea to break the disulfide bonds and make the molecular internal -SH- group exposed. An aliquot (1.0 mL) of SPP solution (1.0 mg/mL) was mixed with 50 μL DTNB (5, 5′-dinitrobis [2-nitrobenzoic acid], 4.0 mg/mL) and incubated for 20 min at 25 °C, then centrifuged at 10,000g for 20 min. The absorbance of the supernatant was read at 412 nm by a UV–Vis spectrophotometer (TU-1810; Puxi Instrument Ltd. Co. Beijing, China) using a molar extinction coefficient value of 13,600 mol/cm. The content of free -SH- groups was measured by using the same procedure with Tris–glycine buffer in the absence of 8.0 mol/L urea.

Secondary Structure

The secondary structure of SPP was performed using the circular dichroism (CD) spectrophotometry with the modified method described by Han et al. (2015). Far-ultraviolet spectra (190 to 250 nm) of SPP solutions (1.0 mg/mL) were recorded on a MOS–450/AF–CD chromatograph (Bio-Logic Co., Seyssinet-Pariset, France) under constant nitrogen flush with a 0.1-cm optical path–length quartz cell. The spectra obtained represent a mean of three consecutive scans at a speed of 1000 nm/min, bandwidth of 1.0 nm, response time of 0.5 s, and a step resolution of 0.5 nm. The secondary structures were predicted using the online tool “DichroWeb” website according to the method by Whitmore and Wallace (2004). Data were expressed according to mean residue ellipticity (θ) in deg·cm2/dmol.

Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis

Molecular weight distribution of SPP treated by HHP was investigated using sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) according to the method described by Laemmli (1970). Mixtures of 40 μL of SPP solution (5.0 mg/mL) and 10 μL of sample solubilizing solution (containing 1% SDS, 50 mM Tris–HCl buffer [pH 6.8], 60 mM EDTA–2Na, and 12% sucrose) were prepared with or without 1% β-mercaptoethanol. A 10-μL aliquot of each mixture was loaded on each gel lane, and 12.5% acrylamide separating gel and 5% acrylamide stacking gel were used. Gel electrophoresis was conducted at 30 mA for 1.5 h. And the molecular weight of the protein bands was compared with a low standard molecular weight marker (10–180 kDa, Sigma-Aldrich).

Gelation Properties

Dynamic Shear Rheology–Temperature Relationship

The dynamic shear rheological properties were measured with an Anton Paar rheometer (Physica MCR 301; Graz, Austria) equipped with a temperature-controlled Peltier system. The test was conducted using our previous method (Arogundade et al. 2012) by making a 10% (w/v) SPP dispersion (10 mM phosphate buffer, pH 7.0) at a constant angular frequency of 10 s−1 and strain of 0.5% (within the linear viscoelasticity range). Invariable 2.3 mL of protein dispersion was loaded onto the lower platen, and the upper parallel platen (PP–50 probe; 50-mm diameter) was lowered to contact the sample with 1.0 mm gap. The temperature was increased from 25 to 95 °C at a heating rate of 2 °C/min, held at 95 °C for 30 min, and then cooled to 25 °C at a cooling rate of 2 °C/min. Silicon oil was applied to the exposed part to prevent the sample from drying out during heating. The storage modulus (G′), loss modulus (G″), and complex viscosity (η*) were followed during a heating–cooling cycle for each sample, and the phase angle tangent (tan δ) was computed from the raw oscillatory data using the accompanying software (32V3.21).

Preparation of SPP Gels

For gelation experiments, SPP gels were prepared with 10% (w/v) SPP dispersion in 10 mM phosphate buffer (pH 7.0). The SPP dispersion were injected into glass mold with 2.3-cm internal diameters, covered with aluminum foil, placed in water bath, heated from 25 to 95 °C, and maintained at 95 °C for 30 min. Then, SPP gels in glass molds were immediately cooled under running water and stored at 4 °C for 12 h. The cylindrical gels were used for the measurements of scanning electron microscopy (SEM), mechanical properties, water-holding capacity (WHC), and low-field NMR relaxation test.

Scanning Electron Microscopy

The microstructure of SPP gels was observed using a scanning electron microscope (Hitachi S-3400n, Japan). SPP gels were cut into small piece, fixed, dehydrated, pasted on a copper stub with double-sided tabs, and rendered conductive by coating with platinum, of which the microstructure was viewed with a scanning electron microscope (S-3400n; Hitachi) at an accelerating voltage of 15.0 kV and ×2000 magnification.

Mechanical Properties

The mechanical properties of the prepared gels were assessed by uniaxial compression test using a TA-XT2i texture analyzer (Stable Micro System Ltd., Godalming, UK) equipped with a 35-mm-diameter cylindrical plate and a 12.0-mm-diameter probe (P 0.5R). The cylindrical protein gels (1.0 cm in height and 2.3 cm in diameter) were compressed to 30% of their original height at a crosshead speed of 0.3 mm/s for 5 s. The resulting data were interpreted using Texture Expert analysis software (Stable Micro Systems Ltd.), and following parameters could be obtained: hardness (maximum peak force of the first compression cycle), springiness (height during the second compression divided by the original compression distance), and cohesiveness (ratio of the positive force area during the second compression to that of the first compression). Chewiness was then calculated as hardness × cohesiveness × springiness.

Low-Field NMR Spin-Spin Relaxation (T2) Measurements

NMR relaxation measurement was performed using low-field NMR according to the method of Han et al. (2014) and Zhang et al. (2015) with some modification. Freshly prepared gel was placed in a cylindrical glass tube (2.3 cm internal diameters) of a Niumag pulsed NMR analyzer (MesoMR23-060H-I, Niumag Electric Corporation, Shanghai, China). The analyzer was operated at 32 °C and using the Carr–Purcell–Meiboom–Gill (CPMG) sequence with spectral width (SW) of 250 kHz, resonance frequency (RF) of 23 MHz, and receiver gain (RG) of 10 db. A total of 10,000 echoes were recorded and conducted by the MultiExp Inv Analysis software (Niumag Electric Corporation, Shanghai, China). The parameters of T2b and T21 were presented as the relaxation components, and A2b and A21 were the corresponding area fractions, respectively.

Water-Holding Capacity

The water-holding capacity (WHC) was determined according to the method of Wang et al. (2017b). After gelation by thermal treatment, fresh SPP gels were stored at 4 °C for 12 h to enhance and stabilize the net structure during cooling. Each SPP gel (2.0 g) was centrifuged at 10,000g at 4 °C for 15 min. Subsequently, the supernatant, which is related to the free water component or un-bound water released by loose structural units, was carefully removed. The centrifuge tube containing SPP gel was weighed both before and immediately after centrifugation. Thus, allowing the WHC to be expressed as the ratio of the gel weight after centrifugation to the initial weight:

where W2 and W1 are the weight (g) of the centrifuge tube containing the SPP gel after and before centrifugation, respectively; W0 is the weight (g) of the empty centrifuge tube.

Statistical Analysis

All experiments were carried out in triplicate, and the data were expressed as means ± SD. The statistical analysis was performed by means of one-way ANOVA followed by a Duncan’s multiple range test using SAS 8.1 software (SAS Institute Inc., Cary, NC, USA). And the differences were considered significantly at p < 0.05.

Results and Discussion

Chemical Forces of SPP

Surface Hydrophobicity (Ho)

Fluorescence scanning was performed to determine the optimal excitation wavelength of SPP, and a wavelength of 390 nm was employed (data not shown). As shown in Fig. 1, Ho of SPP at pH 3.0 was higher than that at pH 6.0 and 9.0, both for non-HHP- (0.1 MPa) and HHP-treated ones (250, 400, and 550 MPa). The dissociation of protein subunits at pH 3.0 might explain the higher hydrophobicity relative to the other pH levels (Chang et al. 2015). Furthermore, with increasing of pressure level, Ho of SPP steadily increased at different pH values, which indicated that HHP remarkably improved the Ho, reflecting conformation changes of SPP structure during HHP (Chen et al. 2014). Khan et al. (2015) indicated that HHP treatment for 15 min showed a significant increase in Ho with pressure increased from 200 to 600 MPa at pH 3.0, but a decrease at pH 6.0 and 9.0. While in the present work, Ho of HHP-treated SPP showed an increase tendency at pH 3.0, 6.0, and 9.0 for a longer holding time of 30 min. This suggested that HHP induced changes in SPP structure were sensitive to the applied pH and pressure, as well as the pressurization time, which caused more hydrophobic groups exposed to the external environment. The application of pressure resulted in extension of SPP peptide chains, which exposed a large number of hydrophobic residues or non-polar active binding sites from SPP interior (He et al. 2014), and might have contributed to the molecular interactions, including intra-protein molecules, protein–protein interactions, and protein–solution interactions (Wang et al. 2017b). Moreover, unfolding was also a necessary prior step of the molecular interactions in the SPP dispersion system.

Surface hydrophobicity (Ho) of sweet potato protein (SPP) treated by high hydrostatic pressure (HHP) at pH 3.0 ( ), 6.0 (

), 6.0 ( ), and 9.0 (

), and 9.0 ( ). Bars with different uppercase letters (A–D) indicate significant differences of SPP treated by same pH values but under different pressure, and bars with different lowercase letters (a–c) mean significant differences of SPP treated by same pressure but combined with different pH values (p < 0.05)

). Bars with different uppercase letters (A–D) indicate significant differences of SPP treated by same pH values but under different pressure, and bars with different lowercase letters (a–c) mean significant differences of SPP treated by same pressure but combined with different pH values (p < 0.05)

Electrostatic Interactions

The changes of zeta potential of SPP after HHP at different pH values are shown in Fig. 2. The absolute value of zeta potential of SPP at pH 9.0 was higher than that at pH 3.0 and 6.0. This might be due to the intensive electrostatic interactions between SPP molecules when the pH value was much higher than its isoelectric point (about pH 4.0). The lowest zeta potential was found for SPP at pH 3.0 (0.1 MPa), which attributed to the fewer charged amino acids exposed at the protein surface at low pH (Kim et al. 2016), as well as the isoelectric counteraction between positive and negative charges. In addition, the absolute value of zeta potential slightly increased with pressure increasing from 0.1 to 400 MPa, and significantly enhanced by 550 MPa at pH 3.0, 6.0, and 9.0 (p < 0.05). The above results suggested that HHP could induce partial unfolding of SPP structure and expose more interior functional residues and charged amino acids to the protein surface (Tang and Ma 2009), which contributed to the increase in absolute value of zeta potential, thus enhanced the electrostatic interactions between SPP molecules. In addition, as varied by pH conditions, the charged amino acids increased with pH increasing, resulting in strong electrostatic repulsion between SPP molecules, which would also promote the unfolding of protein structure (De Maria et al. 2016).

Zeta potential of sweet potato protein (SPP) treated by high hydrostatic pressure (HHP) at pH 3.0 ( ), 6.0 (

), 6.0 ( ), and 9.0 (

), and 9.0 ( ). Bars with different uppercase letters (A–D) indicate significant differences of SPP treated by same pH values but under different pressure treatment, and bars with different lowercase letters (a–c) mean significant differences of SPP treated by same pressure but combined with different pH values (p < 0.05)

). Bars with different uppercase letters (A–D) indicate significant differences of SPP treated by same pH values but under different pressure treatment, and bars with different lowercase letters (a–c) mean significant differences of SPP treated by same pressure but combined with different pH values (p < 0.05)

Sulfhydryl Groups

Disulfide bonds (-S-S-) are formed by the oxidation of -SH- groups and can be found in cysteine residues, which play an important role in the formation of the three-dimensional gel network structure (Wang et al. 2017a). Changes in total -SH- and free -SH- contents are shown in Table 1. The total -SH- content of SPP treated at pH 6.0 was greater than that at pH 3.0 and 9.0 for both non-HHP (0.1 MPa) and HHP-treated SPP. In the case of pH 3.0, the total -SH- content decreased from 13.1% (0.1 MPa) to 11.9% (400 MPa), then increased to 12.6% (550 MPa). It continuously increased from 13.5% (0.1 MPa) to 14.2% (550 MPa) at pH 6.0. And, it first increased then reduced from 10.6% (250 MPa) to 10.0% (550 MPa) at pH 9.0. The total -SH- content of actomyosin of tilapia decreased sharply with the increase of pressure were also reported by Zhou et al. (2014). The decrease in total -SH- content could possibly be explained by the formation of disulfide bonds as intensified by the protein–protein interactions (De Maria et al. 2016), which greatly contributed to the final gel network and enhanced textural properties and WHC of SPP gels (Zhang et al. 2015).

On the other hand, the free -SH- content decreased with increasing pH at 0.1 and 250 MPa, whereas it first increased then decreased at pH 6.0 and 9.0 at 400 and 550 MPa. In addition, free -SH- content decreased with HHP treatment from 250 to 550 MPa at pH 3.0. However, it steadily increased from 9.7% (0.1 MPa) to 12.7% (550 MPa) and from 6.7% (0.1 MPa) to 9.9% (550 MPa) at pH 6.0 and 9.0, respectively. The increase in free -SH- content could be resulted from the exposure of the internal -SH- groups during unfolding and extension induced by pressurization (De Maria et al. 2016). The above results mainly suggested that with pH increase up to pH 6.0, especially at alkaline condition of pH 9.0, HHP induced partial or complete unfolding of SPP, expose of internal -SH- groups and the formation of disulfide bonds, which further contributed to the subsequent covalent aggregation by formation of disulfide bonds and final gel quality.

Circular Dichroism

The changes in secondary structure of SPP after HHP at different pH values over the far–UV range of 190–250 nm are shown in Table 1. For non-HHP-treated SPP (0.1 MPa), α-helix and random coil contents increased with pH value increasing from 3.0 to 9.0, while β-sheet decreased and β-turn slightly changed. Moreover, it exhibited a negative band over the range of 200–208 nm in the spectrogram (data not shown), and the peak wavelength shifted from 205 nm (pH 3.0) to 207 nm (pH 9.0), which indicated the reduction of hydrophobicity of SPP. Meanwhile, the ellipticity of SPP at pH 9.0 was greater than that at pH 3.0 and 6.0 (data not shown), reflecting the increase of α-helix content and unfolding of structure (He et al. 2014). These findings were consistent with hydrophobicity (Fig. 1) and zeta potential (Fig. 2) results, suggesting that high pH value (pH 9.0) might cause low hydrophobicity and strong electrostatic interactions between SPP and water molecules, thus promoting the unfolding of protein structure and extension of protein chains.

As shown in Table 1, α-helix content of SPP increased from 18.3% (0.1 MPa) to 20.5% (250 MPa), β-sheet content decreased from 32.0% (0.1 MPa) to 30.0% (550 MPa), and β-turn content slightly decreased at pH 3.0. The exchange of secondary structure component indicated the destruction of natural structure of SPP. On the contrary, α-helix content gradually decreased from 20.3% (0.1 MPa) to 17.8% (550 MPa), and β-sheet increased from 30.2% (0.1 MPa) to 32.0% (550 MPa) at pH 6.0. Khan et al. (2015) reported that the α-helix content of SPP decreased at 200–400 MPa but increased significantly at 600 MPa at pH 6.0 and 9.0, while the β-sheet content conversely increased at 200–400 MPa then decreased at a high level of 600 MPa. Differently, the present work showed a gradually decrease tendency of α-helix and an increase trend in β-sheet content at pH 6.0 with pressure increased from 250 to 550 MPa, while no significant changes in α-helix was observed and β-sheet content decreased first then increased slightly at pH 9.0. The above differences might be due to the longer holding time and the different applied pressure levels in the present work compare to the previous study. In addition, functional properties of proteins attributed to both structural modification and functional group interactions. Typically, unfolding degree of a protein chain gradually increases with increasing pressure and holding time, accompanied by an increase in the disordered structure and exposed functional groups, which may result in protein rearrangements and/or aggregation, and would induce the improvement in functional properties (Queirós et al. 2018). The pressure commonly used in food processing mainly focused on changing the secondary (300–600 MPa), tertiary (above 200 MPa), and quaternary (150–200 MPa) structures of proteins (San Martin et al. 2002). Thus, the differences in structural changes of protein chains as affected by different applied pressure levels and holding time might lead to multiple functional characteristics, which provided more possibilities for the utilization of SPP in food systems. Sun et al. (2014) found that HHP (200–600 MPa) increased the content of β-sheets, but decreased the content of random coils. This suggested that β-sheets and β-turns had better stability than α-helices during HHP treatment, being more vulnerable to pH at the same pressure levels. Moreover, random coil units of SPP steadily increased with increasing pressure at pH 3.0, slightly changed at pH 6.0, and firstly increased from 250 to 400 MPa then decreased up to 550 MPa at pH 9.0. Previous report believed that α-helix was stabilized by intra-hydrogen bonding, and β-sheets relied on inter-hydrogen bonds (Zhang et al. 2017). With increasing pressure at higher pH levels (pH 6.0 and 9.0), proteins unfolded, α-helix content decreased, and β-sheet and β-turn contents increased, suggesting weaker intra-hydrogen bonding and stronger inter-hydrogen bonding induced by HHP treatment (Grossi et al. 2016). The unfolding resulted in the disruption of ordered secondary structure (α-helix, β-sheet) and the increase of disordered units (β-turn, random coil) respectively, which might lead to the formation of inter-hydrogen bonding, thus promote the interactions between proteins (Zhang et al. 2017).

SDS-PAGE

The molecular weight distribution of non-HHP- and HHP-treated SPP at different pH values are shown in Fig. 3. Both of non-HHP- and HHP-treated SPP at pH 3.0, 6.0, and 9.0 showed similar characteristics under reducing conditions (Fig. 3a–c), with the main band located at 25 kDa and a minor band at about 55 kDa indicating the endogenous β-amylase subunit (Jia et al. 2010).

Under non-reducing conditions, there were no high molecular weight aggregates larger than 180 kDa produced at pH 3.0 under each pressure level when compared with those at pH 6.0 and 9.0 (Fig. 3a–c), which indicated that SPP still maintained a spherical structure and has a low degree of stretch. These results might be caused by higher Ho and lower zeta potential in acidic environments than in alkaline and neutral environments (Mu et al. 2009a). Notably, compared with non-HHP-treated SPP, the bands between new aggregates became more intense with increasing pressure from 250 to 550 MPa at pH 6.0 (Fig. 3b), and even more at pH 9.0 (Fig. 3c). This suggested a higher degree of aggregation induced by HHP. Moreover, this aggregation could be ascribed to the formation of disulfide bonds between the molecules at high pressure levels (Cheung et al. 2014). A previous report also suggested that pressure above 200 MPa could induce the formation of urea-insoluble complexes, disulfide bonds, and/or other strong protein aggregates (Angioloni and Collar 2013).

In addition, with HHP increased from 0.1 to 550 MPa, surface hydrophobicity, zeta potential, free sulfhydryl group content, and band intensity of new aggregates of SPP significant increased at different pH, especially at pH 9.0 (Figs. 1, 2, 3 and Table 1). This might be explained by the exposing of hydrophobic site, free sulfhydryl group, and charged amino acids of SPP with pressure increasing, and could be contributed to viscoelasticity of SPP gels (Fig. 4). The unfolding and aggregation was happened separately during the pressurization. The unfolding of SPP might be responsible for subsequent aggregation and as a precondition of polymerization between protein molecules, leading to the formation of higher molecular weight polymers (Tang and Ma 2009; Qin et al. 2013; De Maria et al. 2016).

Gelation Properties

Dynamic Rheology–Temperature Relationship

Rheological behavior is useful for describing gelation properties of SPP during thermal treatment. G′ value represents the elastic component and strength of the gel structure, and contributes to the three-dimensional gel network, whereas G″ reflects the protein–protein interactions, but does not contribute to the gel network (Arogundade et al. 2012; Angioloni and Collar 2013; Wu et al. 2017; Renkema et al. 2002). As shown in Fig. 4a–c, the thermomechanical characteristics showed three different models corresponding to the three different pH values (3.0, 6.0, and 9.0). G′ consistently showed higher values at pH 3.0 than that of observed at pH 6.0 and 9.0 for both non-HHP- (0.1 MPa) and HHP-treated SPP during thermal treatment, which indicated that SPP gels behave in a more elastic manner at the pH close to the isoelectric point.

For HHP treatment at pH 3.0, the initial G′ rapidly increased at 70.8 °C, which represented the gelation point (Tgel). Arogundade et al. (2012) and Renkema et al. (2002) also reported that heat denaturation was a prerequisite for gel formation. After Tgel, G′ rapidly peaked, and both Tgel (70.8 °C) and peak denatured temperature Tpeak (82.2 °C) of SPP at 550 MPa were lower than those treated at 0.1, 250, and 400 MPa. Furthermore, HHP-treated SPP had a higher G′ value than non-HHP-treated one (0.1 MPa), especially at 400 and 550 MPa, which suggested that HHP could significantly improve elastic properties of SPP gel as a result of peptide chains unfolding. In addition, Cando et al. (2015) reported that the improvement in rheological property induced by HHP treatment could be attributed to the denaturation of SPP followed by further protein aggregation. With pressure increasing at pH 6.0, both non-HHP- and HHP-treated SPP gels presented the same Tgel (86.5 °C) and Tpeak (90.8 °C), and the highest G′ value was observed at 400 MPa. A continuously increasing trend was seen after Tgel. Moreover, further cooling enhanced gel network structure with a steady increase in G′, which could be attributed to the consolidation of attractive forces, such as van der Waals forces and hydrogen bonding (Arogundade et al. 2012; Wu et al. 2017). It was also indicated that with increasing of pressure, the irreversible unfolding and the consequent aggregation were promoted by the enhanced chemical forces, thus inducing the formation of stretch-conformation and an increase in viscoelasticity.

Microstructure Analysis

Protein gel can be considered as a high moisture three-dimensional polymeric network that traps or immobilizes water molecules within it (Wang et al. 2014). Gelation involves the association and crosslinking of the protein chains to form a rigid network, which can contribute to the microstructure and physical property of protein gels (Zhang et al. 2017; Wang et al. 2017a). The microstructure of heat-induced SPP gels after HHP at different pH values was observed by SEM as shown in Fig. 5. For non-HHP-treated SPP, a coarse and disordered gel network was observed at pH 3.0 (Fig. 5a); a better improved gel network was observed at pH 6.0 (Fig. 5e); and a compact gel network was obtained at pH 9.0 (Fig. 5i). The lack of charge at pH 3.0 might cause the SPP molecules to be randomly aggregated during the thermal processing (Ni et al. 2014). Moreover, it could be noticed that a much more denser and uniform network after 400 and 550 MPa treatment at pH 9.0 was observed (Fig. 5k, l), owing to more functional site being exposed by HHP and intense electrostatic repulsion between proteins. The properties of gel networks were strongly related to the speed of unfolding and aggregation of protein (Zhang et al. 2017). Compared with SPP treated at low pH values (3.0 and 6.0), SPP was more negatively charged at pH 9.0 (Fig. 2). The strong electrostatic repulsion between SPP molecules might lead to a slower rate of aggregation than that of unfolding (Kim et al. 2016; Wang et al. 2017a), which could finally form a homogeneous gel network with smaller cavities and contribute to increased hardness and improved WHC (Wang et al. 2014).

Textural Analysis

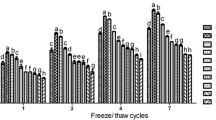

The textural properties of SPP treated by HHP at different pH values are shown in Fig. 6a–c. Generally, hardness and springiness are used to describe the quality of protein gels, whereas chewiness is the mouth feel sensation of labored chewing due to sustained, elastic resistance from the food. At pH 3.0, hardness of SPP gels increased from 0.1 to 250 MPa then slightly decreased at 400 and 550 MPa, whereas springiness (Fig. 6b) and chewiness (Fig. 6c) clearly improved with increasing pressure. At pH 6.0, hardness reduced at 400–550 MPa, while springiness and chewiness increased initially at 250 MPa, then decreased at 400–550 MPa. At pH 9.0, the highest value of hardness of SPP gels was found by HHP at 250 MPa, and both chewiness and springiness were enhanced by HHP at 250, 400, and 550 MPa compared with non-HHP-treated SPP. In addition, SPP gels made from non-HHP- (0.1 MPa) and HHP-treated SPP at pH 9.0 exhibited higher hardness, springiness, and chewiness than those at pH 3.0 and 6.0 (Fig. 6a–c), being consistent with the observation by SEM (Fig. 5). The poor performance of texture behaviors observed at low pH value could be due to the intense surface hydrophobicity, the loss of net charge and weak hydration of proteins (Wang et al. 2014). Besides, high pH value presented stronger effect on textural behaviors, which might be significantly depended on the relative speed of unfolding and aggregation and thus led to a rigid mish (Ni et al. 2014; Cando et al. 2015).

Textural properties (a–c) and water-holding capacity (d) of gels from sweet potato protein (SPP) treated by high hydrostatic pressure (HHP) at pH 3.0 ( ), 6.0 (

), 6.0 ( ), and 9.0 (

), and 9.0 ( ). Bars with different uppercase letters (A–D) indicate significant differences of SPP treated by same pH values but under different pressure; and bars with different lowercase letters (a–c) means significant differences of SPP treated by same pressure but combined with different pH values (p < 0.05)

). Bars with different uppercase letters (A–D) indicate significant differences of SPP treated by same pH values but under different pressure; and bars with different lowercase letters (a–c) means significant differences of SPP treated by same pressure but combined with different pH values (p < 0.05)

Low-Field NMR Proton Relaxation Times

Low-field NMR technique was useful in measuring the mobility and proportion of different water molecules in protein gels without destroying its structures. It had been suggested that T2b component reflected water closely associated with macromolecules, and T21 component indicated water trapped within gel networks, viz. corresponded to bound and immobilized water fractions, respectively (Han et al. 2014; Zhang et al. 2015).

The changes of T2 relaxation times of SPP gels treated by HHP at different pH values are presented in Table 2. T2b decreased with pH increasing from 3.0 to 9.0, while T21 increased from pH 3.0 to 6.0, then decreased at pH 9.0, both for non-HHP- (0.1 MPa) and HHP-treated SPP. With pressure increasing, T2b and T21 increased from 0.1 to 400 MPa then decreased up to 550 MPa at pH 3.0, slightly increased at pH 6.0, and no significant changes were observed at pH 9.0. A short relaxation time (T2) at pH 9.0 indicated water bound more closely to SPP than that with longer T2. The reduction of T2b mainly suggested the bound water (T2b) had lower water mobility than that of T21, and was more closely associated with SPP, which might related to the increase in negative electric (Fig. 2). Moreover, the increase in T21 upon HHP treatment was probably due to the more unfolding extent of SPP structure, which caused a greater variation of water proton population in final gels (Zhang et al. 2015).

For non-HHP-treated SPP, the proportion of A2b of SPP gels decreased at pH 6.0 and 9.0 compared with that at pH 3.0, while A21 inversely increased. The opposite trend in A2b and A21 was possibly due to the transformation between different water fractions. And the increase in A21 suggested that more immobilized water presented in SPP at pH 6.0 and 9.0. For HHP-treated SPP, A2b of SPP gels first increased (0.1–400 MPa) then decreased at pH 3.0, steadily increased from 0.1 to 550 MPa at pH 6.0, and decreased from 0.1 to 550 MPa at pH 9 0. In the case of A21, no significant changes were observed from 0.1 to 400 MPa at different pH values, while it was slightly decreased up to 550 MPa both at pH 3.0 and 6.0. The decrease of A21 at low pH values probably related to the loss of immobilized water fractions, which transferred to free water or more loosely immobilized water fractions. The results above were consistent with the microstructure by SEM (Fig. 5) and mechanical properties (Fig. 6). It was suggested that water mobility in gel system was restricted by high pH values (Han et al. 2014), and the gels formed by HHP-treated SPP (250 and 400 MPa) at pH 9.0 hold more immobilized water fractions with a less mobilized state.

Water-Holding Capacity

Water-holding capacity (WHC) of SPP treated by HHP at different pH values is shown in Fig. 6d. WHC is considered to be an important tool for evaluating the ability of adsorbing or binding with active components. As shown in Fig. 6d, WHC of SPP firstly increased with pressure increasing from 0.1 to 400 MPa, then slightly decreased up to 550 MPa at pH 3.0 and 9.0. At pH 6.0, no significant changes were observed in WHC of SPP from 0.1 to 400 MPa, but presented a slight decrease at 550 MPa. Remarkably, SPP gels treated at pH 9.0 presented higher WHC than those treated at pH 3.0 and 6.0 (Fig. 6d), which were consistent with the results from SEM (Fig. 5), texture (Fig. 6), and NMR (Table 2). This might be explained by that high absolute value of zeta potential could lead to fast extension of protein chains, and followed by a reduction in the diameter of gel cavities (Wang et al. 2014). The high pH condition could result in a larger specific surface of SPP, which produced a relatively larger contact area between proteins and water molecules (Zhang et al. 2015; Liang et al. 2016). Wang et al. (2014) also found that WHC of duck blood plasma protein gels significantly increased with pH increasing from 5.5 to 7.5. Furthermore, Wang et al. (2017b) reported that WHC of rabbit myosin gel was enhanced at 100 MPa, suggesting the potential ability of HHP in improvement on the water-holding behavior and gel properties of proteins ingredients.

According to above results, it could be supposed that the gel characteristic of SPP was possibly associated with its chemical forces and protein molecules arrangement. In addition, although the isoelectric point and inherent structure characters varied by SPP and proteins from other sources (e.g., other plant proteins, animal proteins), high quality of gel behavior was constantly obtained at the pH far away from the isoelectric point (Wang et al. 2014; Kim et al. 2016). At pH 3.0, the weak charge density and high hydrophobicity enhanced by HHP might cause fast aggregation of SPP, which tended to form a coarse and disordered gel network and was associated with the lower hardness and WHC of the gels (Ni et al. 2014). With pH values increased to 6.0, particularly up to 9.0, the interactions between SPP molecules were enhanced by HHP, which was attributed to the more exposed functional group and charged amino acid residues due to protein unfolding (Puppo et al. 2004). And a compact gel matrix with small mesh diameter was therefore formed, contributing to better texture, holding capacity, and reduced mobility of water molecules (Peyrano et al. 2016).

Conclusions

HHP treatment exposed interior hydrophobic residues and -SH- groups, modified secondary structure, and promoted the unfolding of protein chains of SPP. The unfolding was responsible for the subsequent aggregation of SPP and leading to the formation of higher molecular weight polymers by the disulfide linkage with the increase of pressure level at pH 6.0 and 9.0. Rheological behavior of SPP was strongly dependent on the pH values, and the G′ was significantly increased after HHP treatment (p < 0.05). The hardness, springiness, chewiness, and WHC of gels made from SPP treated at moderate pressure (250 and 400 MPa) in an alkaline dispersion system (pH 9.0) were significantly improved, leading to a compact and uniform three-dimensional gel network, which indicated that more immobilized water fractions with a less mobilized state in SPP gels formed at pH 9.0. It was suggested that 400 MPa treated SPP at different pH values, especially at pH 9.0, followed by those at pH 6.0 and 3.0, were reasonable choices in the present study for preparing novelty food products with structural modification. These results would be of great help for understanding the gelling behavior of SPP at different pH levels, and the development of HHP technique in improving gelation properties of SPP in handling of this new protein resource as natural gelatin, adjusting textures of gel-like food in alkali (e.g., baked products), weak acidic (e.g., yogurt, beverages), and acidic (e.g., fruit juice) conditions.

References

Angioloni, A., & Collar, C. (2013). Impact of high hydrostatic pressure on protein aggregation and rheological properties of legume batters. Food and Bioprocess Technology, 6(12), 3576–3584.

Arogundade, L. A., & Mu, T. H. (2012). Influence of oxidative browning inhibitors and isolation techniques on sweet potato protein recovery and composition. Food Chemistry, 134(3), 1374–1384.

Arogundade, L. A., Mu, T. H., & Añón, M. C. (2012). Heat-induced gelation properties of isoelectric and ultrafiltered sweet potato protein isolate and their gel microstructure. Food Research International, 49(1), 216–225.

Barba, F. J., Terefe, N. S., Buckow, R., Knorr, D., & Orlien, V. (2015). New opportunities and perspectives of high pressure treatment to improve health and safety attributes of foods. A review. Food Research International, 77, 725–742.

Boutureira, O., & Bernardes, G. J. L. (2015). Advances in chemical protein modification. Chemical Reviews, 115(5), 2174–2195.

Cando, D., Herranz, B., Borderías, A. J., & Moreno, H. M. (2015). Effect of high pressure on reduced sodium chloride surimi gels. Food Hydrocolloids, 51, 176–187.

Chang, C., Tu, S., Ghosh, S., & Nickerson, M. T. (2015). Effect of pH on the inter-relationships between the physicochemical, interfacial and emulsifying properties for pea, soy, lentil and canola protein isolates. Food Research International, 77, 360–367.

Chen, X., Li, P., Nishiumi, T., Takumi, H., Suzuki, A., & Chen, C. G. (2014). Effects of high pressure processing on the cooking loss and gel strength of chicken breast actomyosin containing sodium alginate. Food and Bioprocess Technology, 7(12), 3608–3617.

Cheung, L., Wanasundara, J., & Nickerson, M. T. (2014). Effects of pH and NaCl levels on the physicochemical and emulsifying properties of a cruciferin protein isolate. Food Biophysics, 9(2), 105–113.

De Maria, S., Ferrari, G., & Maresca, P. (2016). Effects of high hydrostatic pressure on the conformational structure and the functional properties of bovine serum albumin. Innovative Food Science & Emerging Technologies, 33, 67–75.

FAOSTAT. (2016). Production quantity [Internet]. Food and Agricultural Organization. http://www.fao.org/faostat/en/#data/QC. Accessed 01/06/18.

Gaspar, A. L. C., & De Góes-Favoni, S. P. (2015). Action of microbial transglutaminase (MTGase) in the modification of food proteins: A review. Food Chemistry, 171, 315–322.

Grossi, A., Olsen, K., Bolumar, T., Rinnan, Å., Øgendal, L. H., & Orlien, V. (2016). The effect of high pressure on the functional properties of pork myofibrillar proteins. Food Chemistry, 196, 1005–1015.

Han, M., Wang, P., Xu, X., & Zhou, G. (2014). Low-field NMR study of heat-induced gelation of pork myofibrillar proteins and its relationship with microstructural characteristics. Food Research International, 62, 1175–1182.

Han, Y., Wang, J., Li, Y., Hang, Y., Yin, X., & Li, Q. (2015). Circular dichroism and infrared spectroscopic characterization of secondary structure components of protein Z during mashing and boiling processes. Food Chemistry, 188, 201–209.

He, R., He, H. Y., Chao, D., Ju, X., & Aluko, R. (2014). Effects of high pressure and heat treatments on physicochemical and gelation properties of rapeseed protein isolate. Food and Bioprocess Technology, 7(5), 1344–1353.

Jia, Y. J., Liang, X. H., & Zhu, W. X. (2010). Separation of β-amylase from sweet potato by different precipitation methods. Food Science, 31, 22–25.

Khan, N. M., Mu, T. H., Zhang, M., & Chen, J. W. (2013). Effects of high hydrostatic pressure on the physicochemical and emulsifying properties of sweet potato protein. International Journal of Food Science & Technology, 48(6), 1260–1268.

Khan, N. M., Mu, T. H., Zhang, M., & Arogundade, L. A. (2014). The effects of pH and high hydrostatic pressure on the physicochemical properties of a sweet potato protein emulsion. Food Hydrocolloids, 35, 209–216.

Khan, N. M., Mu, T. H., Sun, H. N., Zhang, M., & Chen, J. W. (2015). Effects of high hydrostatic pressure on secondary structure and emulsifying behavior of sweet potato protein. High Pressure Research, 35(2), 189–202.

Kim, J. H. J., Varankovich, N. V., & Nickerson, M. T. (2016). The effect of pH on the gelling behaviour of canola and soy protein isolates. Food Research International, 81, 31–38.

Laemmli, U. K. (1970). Cleavage of structural proteins during assembly of head of bacteriophage T4. Nature, 227(5259), 680–685.

Liang, Y., Guo, B., Zhou, A., et al. (2016). Effect of high pressure treatment on gel characteristics and gel formation mechanism of bighead carp (Aristichthys nobilis) surimi gels. Journal of Food Processing and Preservation, 6, 1–8.

Mu, T. H., Tan, S. S., Chen, J. W., & Xue, Y. L. (2009a). Effect of pH and NaCl/CaCl2 on the solubility and emulsifying properties of sweet potato protein. Journal of the Science of Food and Agriculture, 89(2), 337–342.

Mu, T. H., Tan, S. S., & Xue, Y. L. (2009b). The amino acid composition, solubility and emulsifying properties of sweet potato protein. Food Chemistry, 112(4), 1002–1005.

Ni, N., Wang, Z. Y., He, F., et al. (2014). Gel properties and molecular forces of lamb myofibrillar protein during heat induction at different pH values. Process Biochemistry, 49(4), 631–636.

Norton, T., & Sun, D. W. (2008). Recent advances in the use of high pressure as an effective processing technique in the food industry. Food and Bioprocess Technology, 1(1), 2–34.

Peyrano, F., Speroni, F., & Avanza, M. V. (2016). Physicochemical and functional properties of cowpea protein isolates treated with temperature or high hydrostatic pressure. Innovative Food Science & Emerging Technologies, 33, 38–46.

Puppo, C., Chapleau, N., Speroni, F., de Lamballerie-Anton, M., Michel, F., Añón, C., & Anton, M. (2004). Physicochemical modifications of high-pressure-treated soybean protein isolates. Journal of Agricultural and Food Chemistry, 52(6), 1564–1571.

Qin, Z., Guo, X., Lin, Y., Chen, J., Liao, X., Hu, X., & Wu, J. (2013). Effects of high hydrostatic pressure on physicochemical and functional properties of walnut (Juglans regia L.) protein isolate. Journal of the Science of Food and Agriculture, 93(5), 1105–1111.

Queirós, R. P., Saraiva, J. A., & Da Silva, J. A. L. (2018). Tailoring structure and technological properties of plant proteins using high hydrostatic pressure. Critical Reviews in Food Science and Nutrition, 58(9), 1538–1556.

Renkema, J. M. S., Gruppen, H., & Van, V. T. (2002). Influence of pH and ionic strength on heat-induced formation and rheological properties of soy protein gels in relation to denaturation and their protein compositions. Journal of Agricultural and Food Chemistry, 50(21), 6064–6071.

San Martin, M. F., Barbosa-Cánovas, G. V., & Swanson, B. G. (2002). Food processing by high hydrostatic pressure. Critical Reviews in Food Science and Nutrition, 42(6), 627–645.

Sun, X. D., & Arntfield, S. D. (2012). Molecular forces involved in heat-induced pea protein gelation: Effects of various reagents on the rheological properties of salt-extracted pea protein gels. Food Hydrocolloids, 28(2), 325–332.

Sun, M. J., Mu, T. H., Sun, H. N., et al. (2014). Digestibility and structural properties of thermal and high hydrostatic pressure treated sweet potato (Ipomoea batatas L.) protein. Plant Foods for Human Nutrition, 69(3), 270–275.

Tang, C. H., & Ma, C. Y. (2009). Effect of high pressure treatment on aggregation and structural properties of soy protein isolate. LWT-Food Science and Technology, 42(2), 606–611.

Wang, P., Xu, X., Huang, M., Huang, M., & Zhou, G. (2014). Effect of pH on heat-induced gelation of duck blood plasma protein. Food Hydrocolloids, 35, 324–331.

Wang, K. Q., Luo, S. Z., Zhong, X. Y., Cai, J., Jiang, S. T., & Zheng, Z. (2017a). Changes in chemical interactions and protein conformation during heat-induced wheat gluten gel formation. Food Chemistry, 214, 393–399.

Wang, M., Chen, X., Zou, Y., Chen, H., Xue, S., Qian, C., Wang, P., Xu, X., & Zhou, G. (2017b). High-pressure processing-induced conformational changes during heating affect water holding capacity of myosin gel. International Journal of Food Science & Technology, 52(3), 724–732.

Whitmore, L., & Wallace, B. A. (2004). DICHROWEB, an online server for protein secondary structure analyses from circular dichroism spectroscopic data. Nucleic Acids Research, 32(suppl 2), 668–673 http://dichroweb.cryst.bbk.ac.uk. Accessed 13. 02. 17.

Wihodo, M., & Moraru, C. I. (2013). Physical and chemical methods used to enhance the structure and mechanical properties of protein films: A review. Journal of Food Engineering, 114(3), 292–302.

Wu, C., Hua, Y., Chen, Y., Kong, X., & Zhang, C. (2017). Effect of temperature, ionic strength and 11S ratio on the rheological properties of heat-induced soy protein gels in relation to network proteins content and aggregates size. Food Hydrocolloids, 66, 389–395.

Yang, C., Wang, Y., Vasanthan, T., & Chen, L. (2014). Impacts of pH and heating temperature on formation mechanisms and properties of thermally induced canola protein gels. Food Hydrocolloids, 40, 225–236.

Zhang, M., Mu, T. H., & Sun, M. J. (2014). Purification and identification of antioxidant peptides from sweet potato protein hydrolysates by Alcalase. Journal of Functional Foods, 7, 191–200.

Zhang, Z., Yang, Y., Tang, X., Chen, Y., & You, Y. (2015). Chemical forces and water holding capacity study of heat-induced myofibrillar protein gel as affected by high pressure. Food Chemistry, 188, 111–118.

Zhang, Z., Yang, Y., Zhou, P., Zhang, X., & Wang, J. (2017). Effect of high pressure modification on conformation and gelation properties of myofibrillar protein. Food Chemistry, 217, 678–686.

Zhou, A. M., Lin, L. Y., Liang, Y., et al. (2014). Physicochemical properties of natural actomyosin from threadfin bream (Nemipterus spp.) induced by high hydrostatic pressure. Food Chemistry, 156, 402–407.

Zhu, Z., Guan, Q., Koubaa, M., Barba, F. J., Roohinejad, S., Cravotto, G., Yang, X., Li, S., & He, J. (2017). HPLC-DAD-ESI-MS2 analytical profile of extracts obtained from purple sweet potato after green ultrasound-assisted extraction. Food Chemistry, 215, 391–400.

Acknowledgments

The authors gratefully acknowledge the earmarked fund for China Agriculture Research System (CARS-10-B21). We also thank the National Key R&D Program of China (2016YFE0133600).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Zhao, ZK., Mu, TH., Zhang, M. et al. Chemical Forces, Structure, and Gelation Properties of Sweet Potato Protein as Affected by pH and High Hydrostatic Pressure. Food Bioprocess Technol 11, 1719–1732 (2018). https://doi.org/10.1007/s11947-018-2137-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2137-y