Abstract

This study assessed the effects of thermal (40, 60, 80, 100 and 127 °C) and high hydrostatic pressure (HHP, 200, 400 and 600 MPa) treatments on the in vitro digestibility and structural properties of sweet potato protein (SPP). The results showed that the in vitro digestibility of SPP increased significantly with increasing heating temperature and heating time (0–60 min), while HHP treatment had little or no effect. Native SPP denaturation temperature (T d ) and enthalpy change (ΔH) were 89.0 °C and 9.6 J/g, respectively. Thermal and HHP treated SPP had T d of 84.6–88.9 °C and 86.4–87.6 °C, respectively. ΔH of thermal treated SPP was 3.6–6.4 J/g, while that of HHP treated SPP was 5.9–7.8 J/g. The differential scanning calorimetry (DSC) results demonstrated that HHP and thermal treatments both significantly reduced SPP thermodynamic stability. Circular dichroism analyses revealed that native SPP contains α-helixes, β-sheets and random coils (4.3, 48.0 and 47.7 %, respectively). After thermal treatment at 127 °C for 20 min, the content of α-helixes and turns increased significantly (13.2 and 27.6 %, respectively), whereas the content of β-sheets decreased significantly (12.3 %). In contrast, HHP treatment increased the content of β-sheets, but decreased the content of random coils. This study suggested that the SPP structure changes might be the main reason affecting the in vitro digestibility of SPP, and thermal treatment was more effective at changing SPP secondary structures and improving in vitro SPP digestibility than HHP treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sweet potato is an important crop in many Asian, African, and Latin American countries. Sweet potato contains 1.2–3.3 g protein/100 g (dry weight basis) [1], of which is still not made the best use in China. Sporamins are the most abundant storage protein in sweet potato roots [2], accounting for 60–80 % of the total soluble protein in sweet potato roots. Sporamins can be grouped into two sub-families: sporamin A and sporamin B, with the molecular weights of about 31 and 22 kDa, respectively [2].

Protein digestibility is an important nutritional characteristic of food proteins. In an in vivo digestibility study, we found that native sweet potato protein (SPP) has a digestibility of 50.4 % [3]. Sporamin A (31 kDa) inhibits trypsin activity, thereby limiting protein bioavailability [3, 4], but which is rapidly inactivated during thermal treatment (100 °C) or microwave-boiling treatment [5, 6]. In addition, protein structure, which determines the accessibility of enzymes to SPP, is another factor that affects protein digestibility [7].

Thermal treatment is a method used to improve enzymatic protein hydrolysis [8]. High hydrostatic pressure (HHP), which is an emerging technology that is being used as an alternative method to thermal treatment [9], improves the in vitro digestibility of whey and soy proteins [10, 11]. However, there is little information on the effect of thermal and HHP treatments on SPP structure and in vitro digestibility. Therefore, the objective of this study was to assess the effects of thermal and HHP treatments on SPP structure and in vitro digestibility, and provide theoretical basis for the processing and utilization of commercial SPP.

Material and Methods

Materials

The Mixuan No. 1 sweet potato variety (Ipomoea batatas L.) used in this study was supplied in three 50-kg batches by a sweet potato starch factory (Miyun County, Beijing, China) in early October. The sweet potatoes were stored at 10–14 °C. Pepsin (Cat. no. P7000), Porcine pancreatin (Cat. no. P7545), low molecular weight markers (14–66 kDa), SDS, Tris, Acrylamide, Ν,Ν′-methylene-bisacrylamide (BIS) and TEMED were purchased from Sigma-Aldrich, Inc. (St. Louis, MO, USA). β-mercaptoethanol, and Coomassie Brilliant Blue R-250 were obtained from Amresco Company (Amresco LLC, Ohio, USA). All other chemicals were of analytical grade.

SPP Preparation

SPP was prepared by isoelectric precipitation as reported by Sun et al. [3]. Freshly peeled sweet potatoes in 10 mg/mL NaHSO3 were ground and centrifuged at 10,000 g for 1 h at 5 °C. The protein in the supernatant was precipitated at pH 4.0 (sweet potato protein isoelectric point) with 1 mol/L HCl. The protein precipitate was re-suspended in water. The pH value of the solution was adjusted to 7.0 with 1 mol/L NaOH, and the solution was ultra-filtered and lyophilized. The resulting SPP powder had a crude protein content of 68.96 % and a moisture content of 8.05 %. SPP was further purified by DEAE-52 ion-exchange chromatography (Whatman, USA; Mfg. no. 4057050) and Sephadex G-75 gel filtration (Pharmacia, Piscataway, NJ; Cat. no.17-0050-01) [12]. The resulting SPP had a purity of 95.85 % and a moisture content of 3.50 %.

HHP and Thermal Treatment of SPP

Thermal treatment was performed with 3 mg/mL SPP at different temperatures, i.e., 40, 60, 80, 100, 110 (autoclaving), and 127 °C (autoclaving) for 20 min. The effect of heating time on SPP was assessed by heating 3 mg/mL SPP at 100 °C for 10, 20, 30, 40, 50, and 60 min. These thermal-treated SPP solutions were frozen and freeze-dried.

HHP was performed in high pressure equipment (Tianjin Huatai Senmiao Engineering and Technique Co. Ltd., Tianjin, China; model HHP.L3-600/0.6) with a hydraulic type cell. In this experiment, 50 mL of 3 mg/mL SPP was packaged in polyethylene bags under vacuum and subjected to high pressure treatment at 100, 200, 300, 400, 500, and 600 MPa for 20 min. The effect of HHP time on SPP was assessed by subjecting 3 mg/mL SPP to 600 MPa for 10, 20, 30, 40, and 50 min. These HHP-treated SPP solutions were transferred to small plastic petri dishes, frozen, and freeze-dried.

In Vitro Protein Digestibility of Thermal and HHP Treated SPP

The in vitro digestibility of thermal- and HHP-treated SPP was determined by the method reported by Vilela et al. [13] and Sun et al. [3]. Briefly, 10 ml of 3 mg/mL SPP was hydrolyzed with porcine pepsin (enzyme to substrate ratio = 1:100, w/w) at 37 °C and pH 1.5 for 5, 10, 20, and 30 min. The pH of each solution was adjusted to 6.0 with 4 mL of 1 mol/L NaOH to stop the enzymatic reaction. The solution was subjected to sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE). The peptic digest was subsequently adjusted to pH 7.8 with 1 mol/L NaOH and digested with pancreatin (enzyme to substrate ratio = 1:30, w/w) at 40 °C for 30, 60, and 120 min. Following pancreatin digestion, 100 μL of 0.15 mol/L Na2CO3 was added to stop the enzymatic reaction. The digests were clarified with Millipore centrifugal ultrafiltration filters (Amicon, Millipore, Billerica, MA, USA; Cat. no. UFC901024, 10 kDa) and centrifuged at 3,500 g for 50 min. These clarified digests were subjected to SDS-PAGE. The protein content in the supernatant was determined by the modified Lowry method. Digestibility was calculated by the following equation, Digestibility (%) = (protein content in the supernatant/total protein content) × 100.

SDS-PAGE was performed by the method reported by Laemmli [14] using an AE-6450 electrophoresis system (Atto Corporation, Tokyo, Japan). SPP solution (2 mg/mL) was dissolved in sample buffer (4:1, v/v), consisting of 0.5 mol/L Tris–HCl buffer (pH 6.8), 60 mmol/L Na2EDTA, 1 g/100 mL SDS, and 30 g/100 mL glycerol (pH 6.8), and centrifuged at 10,000 g for 20 min. Gel electrophoresis was run on 5 % loading gels and 15 % separating gels using a discontinuous buffer system at 30 mA until the tracking dye reached the bottom of the gel. Low molecular weight markers were used. The sample (1.6 mg/mL) was loaded in a volume of 15 μL.

Circular Dichroism (CD) Spectroscopy

Far-ultraviolet CD spectroscopy (190–260 nm) of purified SPP solutions (0.1 mg/mL) was recorded in a J-720 spectropolarimeter (Jasco Corporation, Tokyo, Japan) using a 0.1-cm length quartz cell. The CD spectra consisted of three accumulations collected at 50 nm/min, 0.5-s time constant, 0.5-nm resolutions, and 50-mdeg sensitivity at 25 °C. SPP secondary structures were determined by the Protein Secondary Structure Estimation Program software SSE-338 (Jasco, Tokyo, Japan). CD data were expressed in terms of mean residual ellipticity, i.e., θ, in deg × cm2/dmol.

Differential Scanning Calorimeter (DSC)

Approximately 2 mg of SPP was weighed in aluminum pans and 10 μL of 0.05 mol/L phosphate buffer (pH 7.0) was added. The pans were hermetically sealed and equilibrated at room temperature for 2 h. Thermograms were recorded from 20 to 110 °C at a heating rate of 10 °C/min [15].

Statistical Analyses

Measurements were performed in triplicate. Results were expressed as mean ± standard deviation (SD). Differences between treatments were assessed by Duncan’s Multiple Range Tests (p < 0.05) using SAS software (SAS Institute Inc., Cary, NC, USA; version 8.1).

Results and Discussion

Effect of HHP and Thermal Treatment on Digestibility of SPP

The effect of thermal treatment on the in vitro digestibility of SPP is shown in Fig. 1. The in vitro digestibility of native SPP increased from 52.83 to 99.65 % after thermal treatment at 110 °C (p < 0.05; Fig. 1a). With increasing heating time, SPP digestibility increased significantly (p < 0.05) (Fig. 1b); this result could be attributed to protein unfolding [16]. HHP had little or no effect on SPP digestibility (Fig. 1c). However, the digestibility of native SPP increased from 53.83 to 59.06 % with HHP treatment time ≥30 min (Fig. 1d).

The structural configuration of native SPP is shown in Fig. 2a (lane 2). Native SPP contained sporamin A (31 kDa) and sporamin B (22 kDa), which is in accordance with the findings of Maeshima et al. [2]. The digestion of sporamin is shown in Fig. 2a, b, and c. The results revealed that sporamin A and sporamin B were gradually hydrolyzed by pepsin (Fig. 2a). Following a 20-min pepsin digestion, a new band (29 kDa) emerged (Fig. 2a; lane 5). There were no differences in the intensity of the sporamin A, sporamin B, and 29-kDa bands between pepsin digestion (20 min) and pancreatin digestion (30–120 min; Fig. 2a, lanes 7–9). This result indicates that pancreatin could not further hydrolyze the SPP digests. Sporamin B seemed to have higher digestibility than sporamin A (Fig. 2a). These results suggest that native SPP could not be completely digested by pepsin and pancreatin. Therefore, it is imperative to increase the in vitro digestibility of SPP for commercial applications.

SDS-PAGE of pepsin-pancreatin digest of native SPP (a); thermal treated SPP at 127 °C (b); and HHP treated SPP at 600 MPa (c). Lane 1: molecular weight markers; lane 2: enzyme-untreated SPP; lanes 3–6: pepsin-digest at 5, 10, 20, and 30 min, respectively; lanes 7–9: pepsin-pancreatin digest at 30, 60, and 120 min, respectively. The sample (1.6 mg/mL) was loaded in a volume of 15 μL

The electropherogram of thermal-treated (127 °C) SPP is shown in Fig. 2b. Following thermal treatment, SPP had excellent digestibility. The thermal-treated SPP with bands at 45 and 22 kDa (Fig. 2b, lane 2) disappeared after a 5-min pepsin digestion (Fig. 2b, lane 3). These results indicated that thermal treatment improved SPP in vitro digestibility. Similar results have been reported in cowpea protein and chickpea vicilin-like protein; the native forms of these proteins are resistant to enzymatic hydrolysis, but are readily digested after thermal treatment [16, 17]. These results could be attributed to changes in protein structure as a result of disruptions in non-covalent and covalent bonds and increased accessibility of enzymes to specific peptide bonds [18].

The in vitro digestion pattern of HHP-treated SPP is shown in Fig. 2c. There were no differences in the intensity and number of bands after pepsin and pancreatic digestion of HHP-treated SPP, which might be related to covalent disulfide bond -mediated protein aggregation, causing digestive enzymes difficult to combine with enzyme digestion sites.

SPP Structural Properties

DSC results (Table 1) revealed that denaturation temperature (Td) and enthalpy change (ΔH) of native SPP were 89.0 °C and 9.6 J/g, respectively, which were similar to those reported by Arogundade and Mu [19]. Thermal temperature decreased Td and ΔH. According to Tang and Sun [20], Td reflects the thermal stability and disruption of hydrogen bonds involved in tertiary and quaternary structures. Therefore, the reduction of Td with increasing thermal temperatures suggests that the tertiary structure of SPP was disrupted. This might have increased the flexibility of SPP. ΔH, which represents the proportion of non-denatured protein, is correlated with the extent of protein unfolding [15, 20]. The ΔH values obtained in this study revealed more unfolding of thermal and HPP treated SPP compared to native SPP. A reduction in ΔH could be an indication of the partial loss in the ordered protein structure during thermal and HHP treatments.

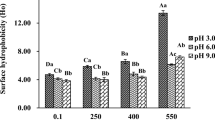

The far-UV spectrum of native SPP showed a positive peak in the vicinity of 191 nm, with a zero crossing at approximately 193 nm (Fig. 3a). Additionally, two peaks at approximately 197 and 204 nm and a broad shoulder between 205 and 219 nm were obtained. These far-UV results are good indicators of a highly ordered structure [18]. The data revealed that native SPP has a secondary structure characterized by β-sheets and random coils (Fig. 4). The higher content of β-sheets relative to α-helices is in agreement with the findings of Zirwer et al. [21], who reported that plant seed storage proteins belong to the β-sheet class. To gain further insight into the SPP structural changes induced by HHP and thermal treatment, the CD spectra were plotted as a function of these two processing methods (Fig. 3a and b). The content of α-helixes was significantly increased at 100 and 127 °C (Fig. 4a). After heating at 127 °C for 20 min, the content of α-helixes increased from 4.3 % (native SPP) to 13.2 %. The content of β-sheets increased at 40–60 °C and decreased with increasing heating temperature. After heating at 127 °C for 20 min, the content of β-sheets decreased from 48.0 % (native SPP) to 12.3 %. As shown in Fig. 4a, native SPP did not contain turns, but after heating treatment at 80–127 °C for 20 min, the content of turns increased significantly. After heating at 127 °C for 20 min, the content of turns increased from 0 (native SPP) to 27.6 %. The content of β-sheets increased with the increasing pressure (48.9, 60.4 and 61.3 % for 200, 400 and 600 MPa, respectively) (Fig. 4b). The content of random coils decreased with the increasing pressure (35.8, 35.4 and 34.8 % for 200, 400 and 600 MPa, respectively). The content of turns increased to 10.3 % after HHP treatment at 200 MPa for 20 min, but decreased to 0 at 400 and 600 MPa. The above SPP structure changes might suggest that HHP treatment can result in protein unfolding or denaturation (positive) as well as protein aggregation (negative). The unchanged digestibility of SPP after HHP treatment might reflect that the negative influence of protein aggregation on the digestibility was equal to the positive influence of protein denaturation. Our result was similar to the finding of Yin et al. [22], who reported that HHP treatment resulted in unfolding and aggregation of vicilin component.

Conclusions

The results of CD and DSC indicated that both thermal and HHP treatments reduced SPP thermal stability and changed its secondary structure. The results of in vitro digestibility of SPP showed that, thermal treatment improved in vitro digestibility of SPP significantly, while HHP treatment had little or no effect on in vitro digestibility of SPP. The possible reason was that, although thermal and HHP treatments both reduced thermal stability of SPP, the changes of SPP secondary structures between thermal and HHP treatments were different. Thermal treatment decreased the content of β-sheets, and increased the content of turns, protein structure unfolding, and digestive enzymes might be easier to combine with enzyme digestion sites, resulting in improvement of SPP digestibility. In contrast, after HHP treatment, protein aggregated, and digestive enzymes were difficult to combine with enzyme digestion sites, which resulted in little or no changes of SPP digestibility.

Abbreviations

- CD:

-

Circular dichroism

- DSC:

-

Differential scanning calorimeter

- HHP:

-

High hydrostatic pressure

- SPP:

-

Sweet potato protein

- Td :

-

Denaturation temperature

- ΔH :

-

Enthalpy change

References

Senanayake SA, Ranaweera KKDS, Gunaratne A, Bamunuarachchi A (2013) Comparative analysis of nutritional quality of five different cultivars of sweet potatoes (Ipomea batatas (L) Lam) in Sri Lanka. Food Sci Nutr 1(4):284–291

Maeshima M, Sasaki T, Asahi T (1985) Characterization of major proteins in sweet potato tuberous roots. Phytochemistry 24(9):1899–1902

Sun MJ, Mu TH, Zhang M, Arogundade LA (2012) Nutritional assessment and effects of heat processing on digestibility of Chinese sweet potato protein. J Food Compos Anal 26(1–2):104–110

Hou WC, Lin YH (2002) Sweet potato (Ipomoea batatas (L.) Lam) trypsin inhibitors, the major root storage proteins, inhibit one endogenous serine protease activity. Plant Sci 163(4):733–739

Kiran KS, Padmaja G (2003) Inactivation of trypsin inhibitors in sweet potato and taro tubers during processing. Plant Foods Hum Nutr 58:153–163

El Faki HA, Venkataraman LV, Desikachar HSR (1984) Effect of processing on the in vitro digestibility of proteins and carbohydrates in some Indian legumes. Plant Foods Hum Nutr 34:127–133

Deshpande SS, Damodaran S (1989) Structure-digestibility relationship of legume 7S proteins. J Food Sci 54(1):108–113

Adeyeye EI (1997) The effect of heat treatment on the in-vitro multienzyme digestibility of protein of six varieties of African yam bean (Sphenostylis stenocarpa) flour. Food Chem 60(4):509–512

Murchie LW, Cruz-Romero M, Kerry JP, Linton M, Patterson MF, Smiddy M, Kelly AL (2005) High pressure processing of shellfish: a review of microbiological and other quality aspects. Innov Food Sci Emerg Technol 6(3):257–270

Chicón R, Belloque J, Alonso E, López-Fandiño R (2008) Immunoreactivity and digestibility of high-pressure-treated whey proteins. Int Dairy J 18:367–376

Su D, Li SJ, Laurie HM, Zhao FM, Zhang LF, Zhao XP, Liu W, Cao YF (2010) Effects of high hydrostatic pressure on in vitro digestion of soy protein. Int Agric Eng J 19(1):49–58

Xiong ZD, Li PG, Mu TH (2009) The differentiation and proliferation–inhibitory effects of sporamin from sweet potato in 3T3-L1 preadipocytes. Agric Sci China 8(6):671–677

Vilela RM, Lands LC, Chan HM, Azadi B, Kubow S (2006) High hydrostatic pressure enhances whey protein digestibility to generate whey peptides that improve glutathione status in CFTR-deficient lung epithelial cells. Mol Nutr Food Res 50(11):1013–1029

Laemmli UK (1970) Cleavage of structural proteins during the assembly of head of bacteriophage T4. Nature 227:680–685

Yin SW, Chen JC, Sun SD, Tang CH, Yang XQ, Wen QB, Qi JR (2011) Physicochemical and structural characterisation of protein isolate, globulin and albumin from soapnut seeds (Sapindus mukorossi Gaertn.). Food Chem 128:420–426

Tang CH, Sun X, Yin SW (2009) Physicochemical, functional and structural properties of vicilin-rich protein isolate from three Phaseolus legumes: effect of heat treatment. Food Hydrocoll 23:1771–1778

Rajamohamed SH, Aryee ANA, Hucl P, Patterson CA, Boye JI (2013) In vitro gastrointestinal digestion of glabrous canaryseed proteins as affected by variety and thermal treatment. Plant Foods Hum Nutr 68(3):306–312

Stanciuc N, Hintoiu A, Stanciu S, Rapeanu G (2010) Thermal treatment can modify the susceptibility of whey protein concentrate to enzymatic hydrolysis. Innov Rom Food Biotechnol 7:30–36

Arogundade LA, Mu TH (2012) Influence of oxidative browning inhibitors and isolation technique on sweet potato protein recovery and composition. Food Chem 134(3):1374–1384

Tang CH, Sun X (2011) A comparative study of physicochemical and conformational properties in three vicilins from Phaseolus legumes: implications for the structure-function relationship. Food Hydrocoll 25(3):315–324

Zirwer D, Gast K, Welfle H, Schlesier B, Schwenke KD (1985) Secondary structure of globulins from plant seeds: a re-evaluation from circular dichroism measurements. Int J Biol Macromol 7:105–108

Yin SW, Tang CH, Wen QB, Yang XQ, Li L (2008) Functional properties and in vitro trypsin digestibility of red kidney bean (Phaseolus vulgaris L.) protein isolate: effect of high-pressure treatment. Food Chem 110:938–945

Acknowledgments

The authors gratefully acknowledge the earmarked fund for China Agriculture Research System (CARS-11-B-19), the International Science & Technology Cooperation Program of China (2010DFA32690), and the Fundamental Research Funds for the Central Public Scientific Research (2012ZL036).

Conflict of Interest

The authors declare that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 32 kb)

Rights and permissions

About this article

Cite this article

Sun, M., Mu, T., Sun, H. et al. Digestibility and Structural Properties of Thermal and High Hydrostatic Pressure Treated Sweet Potato (Ipomoea batatas L.) Protein. Plant Foods Hum Nutr 69, 270–275 (2014). https://doi.org/10.1007/s11130-014-0426-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-014-0426-9

40 °C;

40 °C;  60 °C;

60 °C;  80 °C;

80 °C;  100 °C;

100 °C;  127 °C;

127 °C;  200 MPa;

200 MPa;  400 MPa;

400 MPa;  600 MPa

600 MPa