Abstract

The apparent reduction of β-glucan (BG) molecular weight in rice-based gluten-free (GF) breads fortified with cereal BG concentrates reveals the presence of β-glucanase activity in rice flour. Inactivation of endogenous β-glucanase in rice flour thus seems to be a necessary step when developing GF breads enriched with BG of high molecular weight. The aim of this work was to study the thermal inactivation of endogenous β-glucanase in rice flour by means of microwave (MW) processing; rice flours preconditioned at four different moisture levels (13, 16, 19, 25 %) were treated by MW radiation at 900 W and five MW treatment times (ranging from 40 s to 8 min, applied stepwise at 20-s intervals). The effects of microwaves on starch crystallinity, pasting, and thermal properties of MW-treated rice flours were also explored. The β-glucanase activity in rice flours was assessed by the rate of decrease in specific viscosity of a dilute solution of a purified β-glucan preparation, upon addition of flour extracts. MW proved to be a useful alternative for thermal inactivation of endogenous β-glucanase in rice flours when applied to moistened samples. The inactivation process followed a first-order kinetic response and the apparent rate constant of thermal inactivation increased exponentially with the moisture content of the flour, M, according to the equation 0.0146·exp (0.212·M) (R 2 = 0.97). The MW time required for complete β-glucanase inactivation was only 4 min when the initial flour moisture increased to 25 %. Following MW treatment, the starch crystallinity was unaffected (p > 0.05) and the side effects of the treatment on flour pasting and thermal properties were rather negligible.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The (1-3) (1-4) β-D-glucans (BG) are major components of cell walls in the starchy endosperm and the aleurone layer of commercially important cereals, mostly oat and barley and to a lesser extent, rye and wheat (Lazaridou and Biliaderis 2007). These polysaccharides are classified as soluble dietary fiber with well recognized nutritional implications as specified in several health claims authorized by many regulatory authorities around the globe. The US Food and Drug Administration (USFDA) (2005) has approved a health claim for the reduction of coronary heart disease risk with a daily consumption of 3 g of β-glucan-soluble fiber from whole-grain barley or oat and dry-milled barley/oat grain products as part of a low-saturated fat and low cholesterol diet. Recently, the European Food Safety Authority (EFSA) has also authorized a health claim, according to which barley β-glucan ingestion leads to the reduction of blood plasma cholesterol levels, which is a major risk factor for the development of coronary heart disease (EFSA 2011a); the recommended daily intake is 3 g of oat β-glucan as part of a balanced diet. Other health claims for oat and barley β-glucans were also approved by EFSA concerning the reduction in post-prandial glycemic responses, at doses of about 4 g of β-glucans per 30 g of available carbohydrates in bread and pasta products (EFSA 2011b), and the increase of fecal bulk (EFSA 2011c); the latter claim can be used for foods containing barley or oat grain fiber at least 6/100 g product or 3 g/100 kcal.

On the other hand, the demand for gluten-free (GF) products steadily increases. Although several GF products are nowadays available on the market, baked products with gluten-free ingredients are generally of poor nutritional and sensorial quality and exhibit undesirable physico-chemical properties; i.e., they contain low amounts of fiber, vitamins, and other essential nutrients, which exert a worsening effect on the already nutritionally unbalanced diet of celiac disease (CD) sufferers (Thomson 2009). Despite the current trend for development of food products with improved nutritional quality, the GF products often receive only marginal attention from a formulation point of view. The enrichment of GF breads and other bakery items (cookies, pasta products, etc.) with BG, holds a special interest among the vulnerable population of celiac patients which encounters a significant incidence rate of other associated chronic diseases, such as obesity and diabetes due to higher fat and caloric intensity diets (Cronin and Shanahan 1997).

Rice flour is the most suitable ingredient for GF bakery formulations due to its bland taste, white color, digestibility, and hypoallergenic properties. Other attributes such as the low content of protein and sodium as well as the presence of easily digested carbohydrates are additional benefits (Rosell et al. 2014). Furthermore, in rice flour, the ratio of albumin–globulin–prolamin–glutelin is rather unique among the cereals, revealing a high concentration in glutelins and low in prolamins. As with other cereals, rice proteins are deficient in the essential amino acid lysine, but as a consequence of the respective ratio of protein fractions, rice has higher content of lysine than other cereals, and this is shared by oats (Rosell et al. 2014).

Previous works have demonstrated the potential of baking rice-based GF breads enriched with commercial BG concentrates to fulfill the EFSA health claim requirements as well as to provide products with acceptable quality (Perez-Quirce et al. 2014; Ronda et al. 2015). In these studies, although the final content of BG in the bread was not affected, the molecular weight of BG was notably reduced compared with the initial concentrate used as ingredient in the formulation mixture (Hager et al. 2011; Ronda et al. 2015).

The ability of β-glucans to decrease serum cholesterol levels and moderate the glycemic responses is often linked to the potential of these polysaccharides to enhance the viscosity of the intestinal contents (Tosh et al. 2008; Wolever et al. 2010). Since the viscosity of a β-glucan solution is a function of its molecular weight and polysaccharide concentration, the intensity of MW treatment and the amount of water-extractable β-glucans in a given food product can influence the extent of their physiological effect (Brummer et al. 2012; Lazaridou and Biliaderis 2007; Tosh 2013; Tosh et al. 2008; Wolever et al. 2010). In order to retain the full physiological impact of β-glucan in formulated products, it is therefore crucial to minimize its depolymerization (hydrolysis) during food processing and storage. This is a challenging problem during production of β-glucan-enriched bread, since the activity of endogenous flour β-glucanases, in combination with the long contact time during mixing of ingredients, fermentation, and proofing, can cause a substantial reduction in β-glucan molecular weight (Åman et al. 2004; Andersson et al. 2004; Trogh et al. 2004).

The role of enzymes from wheat flour in β-glucan degradation during dough handling has been demonstrated by Moriartey et al. (2010), who showed that ethanol-refluxed wheat flour (resulting in enzyme inactivation) gave lower β-glucan degradation and higher extract viscosities from doughs prepared with added barley β-glucan concentrate. The addition of yeast, on the other hand, did not seem to affect β-glucan degradation (Andersson et al. 2004; Moriartey et al. 2010) nor did differences in fermentation temperature or the water addition (Andersson et al. 2004). Andersson et al. (2004) also suggested that the baking process itself does not result in further degradation of the polysaccharide, whereas the endogenous β-glucanase activity in flour (wheat or barley) and reaction time in the dough system (during mixing, fermentation, and proofing) are the most important determinants of β-glucan degradation during production of β-glucan-enriched breads (Andersson et al. 2004; Moriartey et al. 2010). Inactivation of flour enzymes and the use of relatively short processing times have been proposed as effective means to minimize β-glucan degradation (Andersson et al. 2004; Moriartey et al. 2010; Vatandoust et al. 2012). However, adopting long mixing and fermentation-proofing regimes is often crucial for quality parameters of the final products, i.e., improved loaf volume, crumb porosity, and texture. Thus, the reduction of fermentation time to avoid β-glucan degradation does not appear as a feasible-practical approach. Consequently, the destruction of β-glucanase activity in raw flour materials seems to be a necessary and convenient step to develop breads enriched with BG of high molecular weight. Endogenous β-glucanase activity has not been demonstrated in rice flour so far. In spite of the low BG content of rice flour that would make someone to anticipate a rather low β-glucanase activity, an apparent reduction of the BG molecular weight in rice-based GF breads, fortified with barley and oat BG concentrates, has pointed towards the presence of β-glucanase activity in rice flour (Ronda et al. 2015; Hager et al. 2011).

The aim of this work was to study the inactivation of β-glucanase enzymes in rice flour by means of microwave treatments (MW). Some of the methods previously used to inactivate β-glucanase activity are autoclaving, scalding, oven heating, and ethanol refluxing (Lazaridou et al. 2014; Rieder et al. 2015; Moriartey et al. 2010). However, there is no literature information on the use of microwave heating for inactivation of β-glucanase enzymes. The high efficiency and the relatively short treatments adopted in MW processing, in comparison to other conventional heating procedures, led us to explore this alternative method for thermal inactivation of the endogenous rice flour β-glucanase. Only few works, with promising results, have been reported till now on flours or whole cereal grain stabilization by MW (Jiaxun-Tao et al. 1993). In rice processing, MW has been applied to control the growth of pests and mildew (Zhao et al. 2007) as well as to inactivate lipases and lipoxygenase enzymes in order to increase its stability during storage (Chang and El-Dash 1998; Zhong et al. 2013).

In other heat treatments of flours (e.g., autoclaving), hydration has been identified as a critical parameter for successful β-glucanase inactivation in barley flours (Lazaridou et al. 2014); only in flours with the highest moisture content was there a full destruction of this enzyme. Taken this into account and the fact that the principle of microwave heating is mainly based on water molecule polarization, a study of the effect of rice flour moisture content on β-glucanase inactivation kinetics by MW seemed to be necessary. Moreover, to limit starch gelatinization during the thermal processing stage, the moisture content of the flour was kept below 30 % (Biliaderis 2009; Biliaderis et al. 1980; Maache-Rezzoug et al. 2008). The effect of MW heating under these conditions on starch crystallinity, pasting, and thermal properties of microwave-treated rice flours was also tested.

Materials and Methods

Materials

Sixteen different rice flour samples, varying in moisture content and hydrothermal treatment using MW, were examined in this work as specified in Table 1. Rice flour from an Indica variety was supplied by Herba Ricemills SLU (Tarragona, Spain), having 13.12 % moisture, 79.1 % starch, 0.46 % ash, 7.5 % protein, and 0.49 % fat. The particle size distribution of the flour was 6 % > 150 μm, 150 μm > 63.2 % > 100 μm, and 30.8 % < 100 μm) (data provided by the manufacturer).

Methods

Several preliminary tests were conducted in order to establish the working conditions for microwave treatment. A particular attention was paid to achieve a uniform temperature and constant water content during the process. The initial moisture content of the rice flour was measured following the AACC 44–19 method, and the water needed to adjust it to the selected value was calculated. Flours were sprayed with the appropriate amount of water while they were mixed in a Kitchen Aid (Model 5KPM50, Kitchen Aid, St. Joseph, MI, USA) mixer for 10 min. The samples were then allowed to stand 24 h at 4 ± 2 °C in order to equilibrate the moisture. Four different water contents (13, 16, 19, 25 %) and five microwave treatment times (1, 2, 4, and 8 min for moistures of 13 to 19 %, and 40 s and 1, 2 and 4 min for 25 % moisture) were tested. The β-glucanase activity of untreated flour was taken as the value corresponding to zero time conditions.

Microwave Treatment of Flour Samples

Rice flours were heated in a Panasonic Inverter NN-GD566M (Osaka, Japan) microwave oven. The frequency of microwave radiation was 2450 MHz. Samples of hydrated flours (50.0 g) were introduced into (polyamide + polypropylene) bags of 20 × 30 cm (NOP101, Cryovac, Sealed air, NY, USA) and hermetically closed by heat sealing (Magneta 300 MG model, brand Audio Elektro, Holland) in order to maintain the moisture content constant during the MW treatment. All samples were spread out to form a thin layer inside the bag (layer thickness ~1 mm) to ensure a uniform moisture and temperature distribution in the flour during treatment. The microwaves dish, where the sample was placed, rotated during the treatment to assure a good distribution of MW energy in the sample. The microwaves power, 900 W, was applied in cycles of 20-s intervals combined with downtimes of 1 min. Under these conditions, the sample bags withstood the water vapor pressure without breaking during the treatment. Between stops, the packed flours were manually mixed by moving and turning the bags to facilitate a common temperature within the sample. Samples were subsequently left to cool for 30 min and then were stored at 4 °C until further analyses. The moisture contents of the flour before and after the microwave treatment were determined following the AACC 44–19 method. Water losses did not exceed 1 %, which implies a good hermetic sealing of the bags. Previous tests have showed a marked loss of water in samples processed in non-hermetically closed containers; i.e., samples in open containers treated for 6 min in the microwave oven exhibited moisture losses from 13 to 5 %. Some experiments described in literature also used open or non-hermetically closed containers (glass beakers sealed with a perforated polyethylene film), but the moisture retention in the samples was not reported. As moisture shows a marked effect on heat-induced inactivation of enzymes in plant materials, its control seems of extreme importance in order to obtain conclusive results; therefore, sealing of the bags was adopted in all experimental trials of the present study. The temperature evolution over time of the microwave treatment was monitored with an infrared thermometer Testo 826-T2 (Lenzkirch, Germany) in the shutdown periods of the treatment cycles. All microwave treatments were carried out at least in duplicate.

β-Glucanase Activity Determination

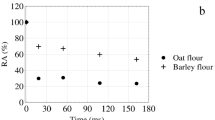

The β-glucanase activity in control and hydrothermally treated rice flours was assessed by measuring the rate of decrease in specific viscosity of a dilute solution of a pure β-glucan preparation, following addition of flour extracts, according to the method reported in a previous work (Lazaridou et al. 2014). The flour extracts were obtained by aqueous extraction (flour/water 1:10) under stirring at 25 °C for 30 min and subsequent centrifugation at 2500g for 20 min. An aliquot (6 ml) of the resultant supernatant was added to 36 ml of the aqueous solution (0.1 % w/v) of a high molecular weight (2 × 106) β-glucan preparation (purity 95 %). The mixture of flour extract with the β-glucan solution was then transferred into an Ubbelohde glass capillary viscometer (UBBEL04NC, K 0.01, range 2–10 cSt, brand Paragon Scientific Ltd, Wirral, UK) and the specific viscosity (η sp = (η − η o)/η o, where ηo is the viscosity of water) was measured over a 1-h period at 20 ± 0.1 °C every 5-min intervals. The η sp data versus time were fitted to a linear regression model and the β-glucanase activity in rice flours was calculated from the slope of the fitted line and expressed as the decrease in specific viscosity per hour of the pure β-glucan solution upon addition of the flour extracts. The principle of this procedure is based on the linear relationship between the intrinsic viscosity and the molecular weight of some polymers in solution which, in turn, follows an inverse linear response (depolymerization) with the reaction time when the polymer, i.e., β-glucan, is subjected to a random depolymerization by the action of β-glucanase (Rieder et al. 2015). At low polymer concentrations, specific viscosity can be used instead of intrinsic viscosity (Hjerde et al. 1994). Residual β-glucanase activity of each treated flour sample was analyzed at least in triplicate.

β-Glucanase Inactivation Kinetics

The β-glucanase activity values obtained in duplicate from heat-treated flours under the 16 treatment conditions, plus the untreated flour activity value, were fitted against the flour moisture and the time of microwave treatment using a non-linear multivariate regression model. The individual effect of the time of microwaves application on β-glucanase inactivation kinetics at each level of moisture content of the flour was described by a first-order kinetic model, according to the equation, A = A 0 exp (−k·t), where A is the β-glucanase activity, t is the time of the microwave treatment, A 0 is a constant that represents the initial activity of the untreated flour (t = 0); and k (per min) is the apparent rate of enzyme inactivation, representing the reduction of enzyme activity per unit time. The flour moisture content also had a marked effect on the rate constant k which varied exponentially with it.

Pasting Properties of Flours

Pasting properties were studied by using the Rapid Visco Analyzer (RVA-4, Newport Scientific Pvt. Ltd., Australia) using ICC Standard method 162. The pasting temperature (PT), peak time (when peak viscosity occurred) (VT), peak viscosity (PV), holding strength or trough viscosity (TV), breakdown (BD), final viscosity (FV), and setback (final viscosity minus peak viscosity) (SB) were calculated from the pasting curve using Thermocline v.2.2 software. Viscoamylography of aqueous flour dispersions (3 g of flour 14 % moisture basis to 28 g total weight with distilled water) was carried out in triplicate.

X-Ray Diffraction

Samples were analyzed using a Bruker D8 Discover A25 diffractometer (Bruker AXS, Rheinfelden, Germany) equipped with a copper tube operating at 40 kV and 40 mA, using the CuKa radiation of 0.154-nm wavelength. Diffractograms were obtained by scanning from 5° to 40° (2θ) at a rate of 1.2°/min, a step size of 0.02°, a divergence slit width variable (DS) of 5 mm and a scatter slit width (SS) of 2.92° and a nickel filter 0.02 to exclude the Kβ radiation.

Differential Scanning Calorimetry

Thermal characteristics of flours were determined using a differential scanning calorimeter (DSC-822e, Mettler Toledo, SAE). Flour samples were weighed into aluminum pans (40 μl) and distilled water was added using a micropipette to make 70 % moisture content of the aqueous flour dispersions to avoid the effects of water scarcity on the thermal profile (non-equilibrium melting) of granular starch (Biliaderis et al. 1980; Biliaderis 2009). Flour weights were about 8 mg. The samples were scanned from 0 to 110 °C at 5 °C/min using an empty pan as reference. Starch retrogradation was evaluated in the samples which have been previously gelatinized in the DSC oven and stored in the pans at (4 ± 2) °C for 7 days; the staled samples were re-scanned using the same heating protocol as for gelatinization. The enthalpy (∆H) values, expressed in joule per gram, based on dry flour basis, the onset and endset temperatures (T o and T e), and the peak temperature (T p) were established in both scans of gelatinization and retrogradation. Samples were run in duplicate.

Statistical Analysis

Statgraphics Centurion v.6 (Bitstream, Cambridge, MN, USA) was used for multivariate non-linear regression. STATISTICA package (Tulsa, OK, EEUU) v.6, allowed performance of MANOVA analysis, and least significant difference (LSD) test was used to evaluate significant differences (p < 0.05) between samples.

Results and Discussion

β-Glucanase Activity Rice Flours Treated by Microwaves

Endogenous β-glucanase activity of rice flours was estimated by measuring the rate of decrease in specific viscosity of a purified BG solution after addition of the rice flour extract at constant temperature of 20 ± 0.2 °C (Table 1). A pronounced decrease in specific viscosity over time was observed with the untreated rice flours, corresponding to an average activity value of (0.109 ± 0.005)/h, which denotes a high β-glucanase activity in untreated rice flour, only slightly smaller than that reported previously for barley flours, i.e., 0.143 or 0.117 for coarse or fine barley flours, respectively (Lazaridou et al. 2014). However, for the microwave-treated flours, the decline in specific viscosity of the mixed standard BG solution-flour extracts over time was significantly smaller (p < 0.05), implying that the hydro-microwave treatment brought about a large reduction in β-glucanase activity of the rice flours; the effect being more pronounced when the time of the treatment and the moisture content of flours increased (see Table 1). The total inactivation of β-glucanase activity was effected after 8 and 4 min of MW treatment for flours tempered to moisture contents of 19 and 25 %, respectively. For the same periods of MW treatment, residual β-glucanase activities were still measured in flours with 13 and 16 % moisture contents, even though they were reduced by 87 and 91 % with respect to the initial flour enzymatic activity. Lazaridou et al. (2014) also found that increasing the moisture content of barley flours before hydrothermal treatment by autoclaving, resulted in complete inactivation of the endogenous barley β-glucan hydrolyzing enzymes. This behavior could be explained by the large reduction of the denaturation temperature of proteins even with a slight increase of moisture content in low moisture protein systems (Arntfield et al. 1990), such as hydrated flours. In other studies, hydrothermal treatments such as steaming and autoclaving of barley grain and oat groats also led to no detectable β-glucanase activity (Izydorczyk et al. 2000; Zhang et al. 1998). The water content is particularly important when the heating energy is generated by microwave radiation. Microwaves are electromagnetic waves in the frequency range of 300–300,000 MHz. In a MW field, where the polar molecules absorb microwave energy and orient themselves with respect to the applied electric field, the rapid change in their orientation generates heat by molecular friction (Sumnu 2001). This results in bulk heating throughout the sample and a faster heating rate compared with other forms of conventional heating. Because of its dipolar nature, water is the main source of microwave interactions with food materials. Most likely the increase in moisture content of the flour above its monolayer value allows a faster absorption of energy from microwaves during the treatment. As a result, a pronounced reduction in the time needed to inactivate the β-glucanase with microwave energy in comparison to other heating systems is effected; i.e., the time is shortened from 4 h heating the flour in an oven at 130 °C (Rieder et al. 2015) to 20 min, when autoclaving flours at 120 °C (Lazaridou et al. 2014), to only 4 min with microwave heating. These findings imply significant savings of time and energy.

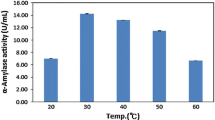

The evolution of temperature versus microwave treatment time is shown in Fig. 1 for flours with 13 to 25 % moisture contents. In the first 20 s of treatment, the flours had got 59 and 72 °C, respectively. After 2 ½ and 2 min (for 13 and 25 % moisture) both flours attained a constant temperature around 95 and 97 °C, respectively, leading to a plateau value as found by other authors (Lewandowicz et al. 1997). Lewandowicz et al. (1997) reported that the plateau interval length increased with the rise in moisture content and also when the sample was introduced in sealed containers instead of open ones; the sealed beakers used were covered by these authors with a perforated polyethylene foil that probably allowed some water loss during heat treatment. As can be concluded from the temperature–time responses, all the attained plateau temperature values were always below 100 °C (presumably due to the “cooling effect” from water evaporation), with water acting as “protector” of the flour constituents. This relatively low temperature probably explains the smaller changes in the physico-chemical properties of the heat-treated flours.

β-Glucanase Inactivation Kinetics in Hydrated Rice Flours by Microwave Heating

Figure 2 shows the regression surface response of the residual β-glucanase activity versus the microwave treatment time and the moisture content of the flour treated. The regression equation obtained was

with k being dependent on moisture content (M) as follows:

leading to the general equation:

where A is the time-dependent β-glucanase activity (t), t is the time of microwave treatment (min) and M is the moisture content of the hydrated flour (% in wet basis) and k (per min) is the apparent rate constant of enzyme inactivation that is dependent exponentially on moisture flour. A 0, k o, and b are constants estimated for this specific system after fitting the 33 data sets to the model (Eq. 3). The estimated value of A o constant was (0.109 ± 0.0027)/h, representing the initial β-glucanase activity of the untreated flour (t = 0); k o (0.0146 ± 0.0033)/min represents the rate of enzyme inactivation when the moisture content of the flour is 0 %; and b (0.212 ± 0.013) is a constant that quantifies the influence of water content of the flour to the inactivation rate. The correlation coefficient of this regression, R 2, was 0.9667 which means that the model explains successfully the variation of β-glucanase activity during the microwave treatment within the range of moistures (13–25 %) and treatment times (0.67–8 min) applied in the present study. The standard error of the estimate was 0.0070/h. The fitting value (estimated) of A o, was very near to the experimental initial β-glucanase activity of the flour, before any treatment, 0.109/h (see Table 1), implying the good agreement of the model to the experimental data. Regarding the correlation equation (Eq. 3) it must be noted the marked effect of flour moisture, M, on β-glucanase inactivation kinetics, as the rate constant, k, depends exponentially on it. The kinetics constant, k, for the completely dry flour, 0.0146/min1, increased to 0.231, 0.438, 0.828, and 2.969/min when the moisture content of the microwave-treated flour increased to 13, 16, 19, and 25 %, respectively. The model can also predict the time of MW treatment needed to completely inactivate the endogenous β-glucanase (to reduce its original activity value in rice flour from ~0.1 to 0.0001/h); this is reduced from more than 30 min at 13 % hydration level to less than 3 min for 25 % moisture.

Pasting Properties of Flours

The impact of microwave treatments on rheological responses of aqueous flour dispersions, i.e., upon cooking (gelatinization and pasting ) and cooling (gelling) of the starch component of the rice flours, was studied to evaluate any side effects that microwave β-glucanase inactivation treatment might have on the flours. As can be seen in Table 2, although some significant differences were found between the pasting properties of the native rice flour and those of the microwave-treated samples, particularly for the highest moisture flours and the longest treatment times, none of them were of great quantitative importance. In general, microwave-treated flours did not show significant differences in peak viscosity compared to the control (untreated) flour. However, the microwave treatment increased trough viscosity (TV) when the two longest treatment times were applied in all the flours, independently of the moisture content. The most important increase in TV, 14 %, was noted for the flour with the highest moisture content, 25 %, and the longest treatment time, 4 min. This increase in TV, concomitant with the decrease in the breakdown, demonstrates that microwave-treated flours are more stable during continuous heating and agitation, which concurs with the findings of Adebowale et al. (2005), Hormdok and Noomhorm (2007), Olayinka et al. (2008), and Watcharatewinkul et al. (2009). The final viscosity (FV) of the gelled flours after the heating/cooling cycle, hardly varied in any of the MW-treated flours with respect to the untreated flour; only flours with 25 % moisture, following a 2–4 min MW treatment, showed a significant, although moderate (<10 %) increase in FV. The setback viscosity (SB) was neither affected by MW treatment, as also happened with the pasting temperature (PT). Only the flour with 25 % moisture and treated for 4 min showed a feeble significant increase in the PT. Some studies have been conducted on the effect of MW on cereals, mainly starches. Lewandowicz et al. (2000) found an increase in gelatinization temperature and a decrease in solubility of microwaved maize and wheat starches. Stevenson et al. (2005) also reported an increase of gelatinization temperature and a decrease of paste viscosity of microwaved maize starch. Anderson and Guraya (2006) and Luo et al. (2006) investigated, respectively, the effect of microwave on rice and maize starches with different proportions of amylose/amylopectin. These authors reported rearrangements of the molecular structure upon microwave heating that could explain the significant changes in viscosity properties of both waxy and non-waxy starches. Pinkrová et al. (2003) have observed that the peak viscosity of rice flour decreased as temperature and microwave power level applied to rice grain increased. On the other hand, Fan et al. (2012) reported that microwave irradiation had no effect on the optical and thermal properties of rice starch during gelatinization compared to conventional heating. Many studies have been carried out on the structural and physical properties of starches after heat moisture treatment (HMT) (Zavareze and Dias 2011). HMT promotes intense changes in starches, thus significantly altering their pasting profile as evidenced by increased pasting temperature and decreased peak viscosity, final viscosity, and breakdown (Watcharatewinkul et al. 2009). According to these researchers, the changes in heat-treated starch’s pasting properties are due to associations between the chains in the amorphous regions of the granule as well to changes in crystallinity during the hydrothermal treatment. Such structural modifications are intensified as the moisture content in the HMT increases (Olayinka et al. 2008). As the forces of the intra-granular chain interactions are strengthened, the starch requires more heat for structural disintegration and paste formation (Olayinka et al. 2008). A high pasting temperature thus indicates that more forces and cross-links exist within the starch granules (Olayinka et al. 2008). Lan et al. (2008) have shown that the retrogradation process is influenced by the amount of leached amylose, granule size, and the presence of rigid, non-fragmented swollen granules. Chung et al. (2009) also found that HMT reduces amylose leaching from starch granules and that this reduction is more significant in starches containing high levels of amylose. They have reported that HMT promotes additional amylose–amylose and/or amylopectin–amylopectin chain interactions, which restrict amylose leaching and decrease retrogradation events. A recent study by Roman et al. (2015) reports on the effects of short-time (0.5 to 4 min) MW treatments of corn flours at 30 % moisture. They found opposite effects on pasting properties depending on the MW treatment time. Treated samples showed increased viscosity during the heating–cooling cycle when a very short time of microwave treatment was applied (0.5 and 1 min). Instead, longer treatments (4 min) induced the opposite effect, and a decrease in the viscosity was noted. A decrease of the maximum (peak) viscosity was also observed by Pinkrová et al. (2003) by increasing temperature of microwave treatment of the rice grain and increasing power output at a moisture content of 30 %. Roman et al. (2015) have examined the effect of MW on flour structure. They found a more disaggregated structure and a less compact matrix, with starch granules being more naked and slightly swollen. Luo et al. (2006) observed even more marked changes on starch granule structure when moistened (30 %) maize starch was treated for 20 min with microwaves at 1 W/g. They have noted some breakage, cracks, and pores on the surface of the starch granules. These observations can be attributed to chain segmental transfers and internal rearrangements in the granular material, facilitated by water plasticization. The absence of such effects in our MW-treated flours could be due to the shorter treatment times employed (lower power) as well as the use of completely airtight bags, where large water transfers within the sample were probably hindered by the vapor pressure raised in the bag headspace. Figure 3 shows the different pasting properties of two aliquots of 30 % moistened rice flour treated with the same MW heating procedure used in all the experiments carried out in this study, and in an opened beaker. Although further studies should be carried out to fully unravel the different effects heat moisture treatments have on the starch granular material using MW, the notable differences in pasting properties shown in Fig. 3 clearly indicate that water plays an important role in starch modifications during MW treatments. Moreover, it is important to note that the flour treated in the close bag maintained its original white color compared to that treated in the open beaker for the same time which showed a visible darker brown color.

X-Ray Diffraction

The diffractograms obtained from the microwave-treated and the untreated 25 % moistened rice flours (Fig. 4) showed that all samples maintained the A-type crystallinity, typical of many cereal starches (Imberty et al. 1991; Zobel 1964) with peaks centered at approximately 15°, 17.1°, 18°, and 23° (2θ), for both native sample and all microwave-treated rice flours. Indeed, the A-type crystalline pattern was conserved in the MW-treated flours with 25 %, for any processing time (0.67, 1, 2, and 4 min), and no significant differences in the relative crystallinity value compared to the native flour (starch) were observed. Luo et al. (2006) and Roman et al. (2015) reported an increase in x-ray intensities for microwave-treated maize starch and flour, respectively. It has been postulated that microwave radiation can lead to formation of additional double helical structures within the starch crystallites, leading to a higher molecular order than that in native starch (Luo et al. 2006). The movement of double helices might be related to the vaporization of water molecules that release positions originally occupied by water molecules, allowing for more compact ordered crystalline arrays (Luo et al. 2006). The use of hermetically sealed bags in our study provided a small positive pressure inside the bags and prevented the loss of water, and this in turn might have resulted in limited molecular reorganization within the starch granules. Different effects of HMT on starch crystallinity have been noted by other authors, however, for more prolonged thermal treatments. Jyothi et al. (2010) observed an increase in crystallinity of sweet potato and arrowroot starches and a slight decrease in the crystallinity of cassava starch, after the three starches were heat moisture treated at 120 °C for 14 h at 20 % moisture. Similar results to our findings were obtained by Maache-Rezzoug et al. (2008). These authors did not find any significant difference in the relative crystallinity when applied a controlled pressure drop (DIC) hydrothermal treatment at 1 bar of pressure (100 °C, 14–15 % moisture) for any processing time (10–60 min) to maize starch, whereas they have noted a significant reduction in relative crystallinity when applied treatments at 2 and 3 bar of pressure (122 and 135 °C, respectively); in the latter case, the A-type crystalline pattern was progressively changing to a V-type crystalline pattern, implying the formation of amylose–lipid complexes in the heat-treated starch granules. Overall, the findings of the present work clearly indicate that it is possible to apply MW treatments for complete inactivation of β-glucanase without modifying starch structure, even at the highest moisture content of 25 %. Maintaining a constant water content of the flour and the flour temperature below 100 °C, throughout the microwave treatment are probably the most important parameters in this respect.

Impact of MW on Thermal Properties

The results of x-ray diffractometry were further confirmed by differential scanning calorimetry. The thermal properties of untreated (control) and microwave-treated 25 % moistened rice flours are summarized in Table 3. In the range of temperatures tested, the aqueous dispersions of flours exhibited two endothermic peaks, corresponding to the gelatinization of starch and the dissociation of amylose–lipid complexes (Biliaderis 2009). After 7-day storage (in the DSC pans) at 4 °C of the gelatinized samples, a second scan also showed two endothermic transitions. The peak corresponding to the melting of the recrystallized amylopectin that appeared at lower temperatures than the gelatinization peak of native starch, and the amylose–lipid complex transition found in the first scan that appeared at the same temperature and had the same enthalpy value. As can be seen, the effect of microwaves on starch gelatinization, amylopectin retrogradation and amylose–lipid complex temperatures and enthalpies was practically negligible, even though the samples tested by DSC were those of the highly moistened flours. The only significant effect (p < 0.01) was obtained in the gelatinization peak temperature (weak annealing, Biliaderis 2009), although the quantitative importance of this change was rather minor. Other authors have also reported an increase in the gelatinization peak temperatures of microwave-treated 30 % moistened maize flours (Roman et al. 2015) when MW energy was applied for 2 and 4 min; the increases observed by these authors were ~3 °C, while that of the present work was less than 1 °C. Lewandowicz et al. (2000) also observed rises in the gelatinization peak temperatures of 30 % moistened starches treated by MW for 60 min at 0.5 W/g, that varied from 13 °C for wheat to 6 °C for waxy corn starch, in comparison to their untreated counterparts. Moreover, these authors have reported an important decrease, ~72 %, in the apparent gelatinization enthalpy value of wheat starch that was only ~50 % for corn, and insignificant for waxy corn compared with the untreated starches. Other authors also found a reduction in starch gelatinization enthalpy for MW-treated corn starches (Luo et al. 2006; Stevenson et al. 2005). In contrast, Roman et al. (2015) have reported an almost double gelatinization enthalpy of all MW-treated corn flour samples with respect to the native one. Consequently, the extent of MW heating effects on thermal behavior of granular starches depends on the starch source, the amylose and moisture content, as well as the intensity and time of the applied microwave treatment (Zavareze and Dias 2011).

Conclusions

Microwave treatment is a useful alternative for inactivation of the endogenous β-glucanase in rice flours when applied to moistened flour samples. The enzyme inactivation process follows a first-order kinetic response (R 2 = 0.97). The constant rate of the thermal inactivation by MW increased exponentially with the moisture content of the flour, so that, the microwave treatment time required for complete β-glucanase inactivation was only 4 min when the initial flour moisture was raised to 25 %. Following the MW treatment, the crystallinity of the starch was unaffected and the side effects of the treatment on flour pasting and thermal properties were rather negligible.

References

AACC, American Association of Cereal Chemists, (2000). Method 44–19. In: Anonymous approved methods of the AACC, (10th ed.). The Association, St. Paul, MN.

Adebowale, K. O., Afolabi, T. A., & Olu-Owolabi, B. I. (2005). Hydrothermal treatments of Finger millet (Eleusine coracana) starch. Food Hydrocolloids, 19, 974–983.

Åman, P., Rimsten, L., & Andersson, R. (2004). Molecular weight distribution of beta glucan in oat-based foods. Cereal Chemistry, 81, 356–360.

Anderson, A. K., & Guraya, H. S. (2006). Effects of microwave heat moisture treatment on properties of waxy and non-waxy rice starches. Food Chemistry, 97, 318–323.

Andersson, A. A. M., Armo, E., Grangeon, E., Fredriksson, H., Andersson, R., & Aman, P. (2004). Molecular weight and structure units of (1–3, 1–4)-β-glucans in dough and bread made from hull-less barley milling fractions. Journal of Cereal Science, 40, 195–204.

Arntfield, S. D., Ismond, M. A. H., & Murray, E. D. (1990). Thermal analysis of foods. In V. R. Harwalkar & C. Y. Ma (Eds.), Thermal analysis of food proteins in relation to processing effects (pp. 51–91). London: NewYork: Elsevier Applied Science.

Biliaderis, C.G. (2009). Structural transitions and related physical properties of starch. In R. L. Whistler, & J. N. BeMiller (Eds.), Starch: Chemistry and Technology, 3rd Ed. (pp. 293–372), Academic Press.

Biliaderis, C. G., Maurice, T. J., & Vose, J. R. (1980). Starch gelatinization phenomena studied by differential scanning calorimetry. Journal of Food Science, 45, 1669–1674.

Brummer, Y., Duss, R., Wolever, T. M. S., & Tosh, S. M. (2012). Glycemic response to extruded oat bran cereals processed to vary in molecular weight. Cereal Chemistry, 89, 255–261.

Chang, Y. K., & El-Dash, A. A. (1998). Effect of microwave energy on lipase inactivation and storage stability of brown rice. Acta Alimentaria, 27(2), 193–202.

Chung, H. J., Liu, Q., & Hoover, R. (2009). Impact of annealing and heat-moisture treatment on rapidly digestible, slowly digestible and resistant starch levels in native and gelatinized corn, pea and lentil starches. Carbohydrate Polymers, 75, 436–447.

Cronin, C., & Shanahan, F. (1997). Insulin-dependent diabetes mellitus and coeliac disease. Lancet, 349(9058), 1096–1097.

EFSA. (2011a). Scientific opinion on the substantiation of a health claim related to barley beta-glucans and lowering of blood cholesterol and reduced risk of (coronary) heart disease pursuant to article 14 of regulation (EC) No. 1924/2006. EFSA Journal, 9(2470), 14.

EFSA. (2011b). Scientific opinion on the substantiation of health claims related to beta-glucans from oats and barley and maintenance of normal blood LDL-cholesterol concentrations (ID 1236, 1299), increase in satiety leading to a reduction in energy intake (ID 851, 852), reduction of post-prandial glycaemic responses (ID 821, 824), and “digestive function” (ID 850) pursuant to Article 13 (1) of Regulation (EC) No. 1924/2006. EFSA Journal, 9(2207), 21.

EFSA. (2011c). Scientific opinion on the substantiation of health claims related to oat and barley grain fibre and increase in faecal bulk (ID 819, 822) pursuant to Article 13 (1) of Regulation (EC) No. 1924/2006. EFSA Journal, 9(2249), 13.

Fan, D., Ma, S., Wang, L., Zhao, J., Zhang, H., & Chen, W. (2012). Effect of microwave heating on optical and thermal properties of rice starch. Starch, 64(9), 740–744.

Hager, A. S., Ryan, L. A. M., Schwab, C., Ganzle, M. G., O'Doherty, J. V., & Arendt, E. K. (2011). Influence of the soluble fibres inulin and oat beta-glucan on quality of dough and bread. European Food Research and Technology, 232(3), 405–413.

Hjerde, T., Kristiansen, T. S., Stokke, B. T., Smidsrod, O., & Christensen, B. E. (1994). Conformation-dependent depolymerization kinetics of polysaccharides studied by viscosity measurements. Carbohydrate Polymers, 24(4), 265–275.

Hormdok, R., & Noomhorm, A. (2007). Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT--Food Science and Technology, 40, 1723–1731.

Imberty, A., Buléon, A., Tran, V., & Perez, S. (1991). Recent advances in knowledge of starch structure. Starch, 43(10), 375–384.

Izydorczyk, M. S., Storsley, J., Labossiere, D., Mac Gregor, A. W., & Rossnagel, B. G. (2000). Variation in total and soluble β-glucan content in hulless barley: effects of thermal, physical and enzymatic treatments. Journal of Agricultural and Food Chemistry, 48, 982–989.

Jiaxun-Tao; Rao, R. & Liuuzo, J. (1993). Microwave heating for rice bran stabilization. Journal of Microwave, Power and Electromagnetic Energy, 28 (3), 156–164, ISSN-0832-7823.

Jyothi, A. N., Sajeev, M. S., & Sreekumar, J. N. (2010). Hydrothermal modifications of tropical tuber starches. 1. Effect of heat-moisture treatment on the physicochemical, rheological and gelatinization characteristics. Starch, 62(1), 28–40.

Lan, H., Hoover, R., Jayakody, L., Liu, Q., Donner, E., Baga, M., et al. (2008). Impact of annealing on the molecular structure and physicochemical properties of normal, waxy and high amylose bread wheat starches. Food Chemistry, 111, 663–675.

Lazaridou, A., & Biliaderis, C. G. (2007). Molecular aspects of cereal β-glucan functionality: physical properties, technological applications and physiological effects. Journal of Cereal Science, 46, 101–118.

Lazaridou, A., Marinopoulou, A., Matsoukas, N. P., & Biliaderis, C. G. (2014). Impact of flour particle size and autoclaving on β-glucan physicochemical properties and starch digestibility of barley rusks as assessed by in vitro assays. Bioactive Carbohydrates and Dietary Fibre, 4(1), 58–73.

Lewandowicz, G., Fornal, J., & Walkowski, A. (1997). Effect of microwave radiation on potato and tapioca starches. Carbohydrate Polymers, 34, 213–220.

Lewandowicz, G., Jankowskib, T., & Fornal, J. (2000). Effect of microwave radiation on physicochemical properties and structure of cereal starches. Carbohydrate Polymers, 42, 193–199.

Luo, Z., He, X., Fu, X., Luo, F., & Gao, Q. (2006). Effect of microwave radiation on the physicochemical properties of normal corn, waxy corn and amylomaize V starches. Starch-Starke, 58, 468–474.

Maache-Rezzoug, Z., Zarguili, I., Loisel, C., Queveau, D., & Buléon, A. (2008). Structural modifications and thermal transitions of standard maize starch after DIC hydrothermal treatment. Carbohydrate Polymers, 74, 802–812.

Moriartey, S., Temelli, F., & Vasanthan, T. (2010). Effect of formulation and processing treatments on viscosity and solubility of extractable barley beta-glucan in bread dough evaluated under in vitro conditions. Cereal Chemistry, 87(1), 65–72.

Olayinka, O. O., Adebowale, K. O., & Olu-Owolabi, B. I. (2008). Effect of heat-moisture treatment on physicochemical properties of white sorghum starch. Food Hydrocolloids, 22, 225–230.

Perez-Quirce, S., Collar, C., & Ronda, F. (2014). Significance of healthy viscous dietary fibres on the performance of gluten-free rice-based formulated breads. International Journal of Food Science and Technology, 49, 1375–1382.

Pinkrová, J., Hubáčková, B., Kadlec, P., Příhoda, J., & Bubník, Z. (2003). Changes of starch during microwave treatment of rice. Czech Journal of Food Sciences, 21, 176–184.

Rieder, A., Ballance, S., & Knutsen, S. H. (2015). Viscosity based quantification of endogenous β-glucanase activity in flour. Carbohydrate Polymers, 115, 104–111.

Roman, L., Martinez, M. M., Rosell, C. M., & Gomez, M. (2015). Effect of microwave treatment on physicochemical properties of maize flour. Food and Bioprocess Technology, 8(6), 1330–1335.

Ronda, F., Perez-Quirce, S., Lazaridou, A., & Biliaderis, C. G. (2015). Effect of barley and oat β-glucan concentrates on gluten-free rice-based doughs and bread characteristics. Food Hydrocolloids, 48, 197–207.

Rosell, C. M., Barro, F., Sousa, C., & Mena, M. C. (2014). Cereals for developing gluten-free products and analytical tools for gluten detection. Journal of Cereal Science, 59, 354–364.

Stevenson, D. G., Biswas, A., & Inglett, G. E. (2005). Thermal and pasting properties of microwaved corn starch. Starch, 57(8), 347–353.

Sumnu, G. (2001). A review on microwave baking of foods. International Journal of Food Science and Technology, 36, 117–127.

Thomson, T. (2009). The nutritional quality of gluten-free foods. In E. Gallagher (Ed.), In: Gluten-free food science and technology (pp. 45–51). Wilet-Blackwell: New Delhi.

Tosh, S. M. (2013). Review of human studies investigating the post-prandial blood-glucose lowering ability of oat and barley food products. European Journal of Clinical Nutrition, 67, 310–317.

Tosh, S. M., Brummer, Y., Wolever, T. M. S., & Wood, P. J. (2008). Glycemic response to oat bran muffins treated to vary molecular weight of β-glucan. Cereal Chemistry, 85, 211–217.

Trogh, I., Courtin, C. M., Andersson, A. A. M., Aman, P., Sorensen, J. F., & Delcour, J. A. (2004). The combined use of hull-less barley flour and xylanase as a strategy for wheat/hull-less barley flour breads with increased arabinoxylan and (1/3, 1/4)- β-D-glucan levels. Journal of Cereal Science, 40, 257–267.

US Food and Drug Administration (USFDA). (2005). Food labeling: SOLUBLE dietary fibre from certain foods and coronary heart disease. Federal Register, 70, 76150–76162.

Vatandoust, A., Ragaee, S., Wood, P. J., Tosh, S. M., & Seetharaman, K. (2012). Detection, localization, and variability of endogenous beta-glucanase in wheat kernels. Cereal Chemistry, 89(1), 59–64.

Watcharatewinkul, Y., Puttanlek, C., Rungsardthong, V., & Uttapap, D. (2009). Pasting properties of a heat-moisture treated canna starch in relation to its structural characteristics. Carbohydrate Polymers, 75, 505–511.

Wolever, T. M. S., Tosh, S. M., Gibbs, A. L., Brand-Miller, J., Duncan, A. M., Hart, V., et al. (2010). Physicochemical properties of oat β-glucan influence its ability to reduce serum LDL cholesterol in humans: a randomized clinical trial. The American Journal of Clinical Nutrition, 92, 723–732.

Zavareze, E. R., & Dias, A. R. G. (2011). Impact of heat–moisture treatment and annealing in starches: a review. Carbohydrate Polymers, 83, 317–328.

Zhang, D., Doehlert, D. C., & Moore, W. R. (1998). Rheological properties of (1–3), (1–4) β-D-glucans from raw, roasted and steamed oat groats. Cereal Chemistry, 75, 433–438.

Zhao, S., Xiong, S., Qiu, C., & Xu, Y. (2007). Effect of microwaves on rice quality. Journal of Stored Products Research, 43, 496–502.

Zhong, Y., Tu, Z., Liu, C., Liu, W., Xu, X., Ai, Y., et al. (2013). Effect of microwave irradiation on composition, structure and properties of rice (oryza sativa L.) with different milling degrees. Journal of Cereal Science, 58(2), 228–233.

Zobel, H. F. (1964). Methods in carbohydrate chemistry. Vol. 4. In R. L. Whistler (Ed.), X-ray analysis of starch granules (p. 109). Orlando, FL: Academic.

Acknowledgments

The authors gratefully acknowledge the financial support of the Spanish Institutions Ministerio de Economía y Competitividad and the European Regional Development Fund (FEDER) (Projects AGL2012-35088 and AGL2015-63849-C2-2-R).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pérez-Quirce, S., Ronda, F., Melendre, C. et al. Inactivation of Endogenous Rice Flour β-Glucanase by Microwave Radiation and Impact on Physico-chemical Properties of the Treated Flour. Food Bioprocess Technol 9, 1562–1573 (2016). https://doi.org/10.1007/s11947-016-1741-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1741-y