Abstract

The thermal and structural behavior of four industrial lauric fats, sold under the same commercial description, were investigated by using pulsed nuclear magnetic resonance (pNMR), differential scanning calorimetry (DSC), and X-ray diffraction (XRD) in order to obtain more basic information about their physical properties and particularly, about their polymorphism. The four fats have been classified into two groups based on their fatty acid (FA) and triacylglycerol (TAG) compositions: group 1 was characterized by its high concentration of stearic acid and group 2 by its high concentrations in lauric and myristic acids. After cooling and 24 h tempering at 4 °C, groups 1 and 2 crystallized in the β′2 and β′1 forms, respectively. These crystalline varieties corresponded to double-chain-length organizations (2 L) with the long spacing (LS) values around 36.48, 37.43, and 37.65 Å for group 1, and 33.89, 34.00, 35.04, 37.64, and 37.76 Å for group 2. During heating from 5 to 50 °C at 5 °C/min, the two groups evolved, respectively, from the 2Lβ′2 or 2Lβ′1 forms to liquid state without going through the 2Lβ form, indicating their great β′ polymorph stability. However, after rapid cooling (−25 °C/min), all fats exhibited the same polymorphic evolution; they evolved from the α form between −30 and −10 °C to a mixture of α and β′2 forms with the vanishing of α crystal between 10 and 20 °C and that of β′2 polymorph at the temperatures above 35 °C. The passage to liquid state was also realized without the occurrence of β transition. The XRD data were in accordance with DSC melting profiles or with solid fat content (SFC) melting profiles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Melting and crystallization behavior are two of the most important properties of vegetable oils and fats that mainly influence functionality in many manufactured food products (Tan and Che Man 2002a, b). Triacylglycerols (TAGs), which constitute the main components of oils and fats, can usually crystallize into three polymorphic forms: the hexagonal α-form, the orthorhombic β′-form, and the triclinic β-form (D'Souza et al. 1990; Larsson 1966). Among the three forms, the β′ polymorph reveals the most optimal functional physical properties in terms of crystal density, morphology, network formation of microcrystals, flexibility, and molecular conformations (Che Man et al. 2003; Jin et al. 2008; Precht 1988; Sato et al. 2001) compared with the thermodynamically least stable α forms as well as the more stable β forms. For instance, the β′ form is desired in butter, margarine, and shortenings because it confers a smooth texture to the products (Ishikawa et al. 1997; Jin et al. 2008; Lai et al. 2000). The β polymorph is not desirable in large amounts in most applications because it is often responsible of rough texture occurrence in the products (Ishikawa et al. 1997; Jin et al. 2008), but it is desirable in other applications such as chocolate (Toro-Vazquez et al. 2005; van Mechelon et al. 2006).

Lauric fats are commonly used in the food industry and oleochemical industry (Traitler and Dieffenbacher 1985). Palm kernel oil (PKO), one of the two typical examples of lauric fats, is extracted from the seeds of palm fruits and is characterized by high contents of lauric and myristic acids (Awad and Sato 2002; Traitler and Dieffenbacher 1985). Because of their high content in oleic acid, PKO and its fractions can be hydrogenated to different degrees to produce a wider range of PKO-based products with different oil compositions and properties for food industry (Nazaruddin et al. 2005; Pantzaris and Basiron 2002; Siew 2001). In fact, these products have many food applications such as aerated food emulsion products, shortening, margarine, confectionery, cocoa butter substitute, frying, and bakery products (Jin et al. 2008; Pantzaris and Basiron 2002; Podmore 2002; Traitler and Dieffenbacher 1985; Timms 1997; Ransom-Painter et al. 1997; Siew 2001; Zhou et al. 2010). The chemical composition of some of these PKO products has been documented (Pantzaris and Basiron 2002; Traitler and Dieffenbacher 1985; Rossell 1985; Siew 2001). Numerous studies were also conducted on melting and crystallization properties of these oils in bulk system (Che Man et al. 2003; Md Ali and Dimick 1994; Pantzaris and Basiron 2002; Tan and Che Man 2000; Noordin and Chung 2009) or in emulsified system (Awad and Sato 2002; Cornacchia and Roos 2011a, b; Relkin et al. 2003a, b; Relkin and Sourdet 2005) or in blendings with others fats (Che Man et al. 2003; Chu et al. 2002; Jin et al. 2008; Md Ali and Dimick 1994; Zhou et al. 2010). Most of these studies compared the thermal properties of the nonemulsified fat with those of emulsified fat or other fats. In contrast, there are few reports about the comparison of melting and crystallization characteristics of several lauric fats established in the same conditions, especially about their polymorphism. Therefore, this work examines the crystallization and melting behavior of some PKO products using pulsed nuclear magnetic resonance (pNMR), differential scanning calorimetry (DSC), and X-ray diffraction (XRD) techniques in order to gain more comprehensive understanding of their phase behavior for food applications.

Materials and Methods

Four industrial lauric fats (coded A, B, C, and D), known under the same commercial description, were used in this study. These fats were kindly provided by Puratos Group (Groot-Bijgaarden, Belgium) and used as received.

Fatty Acid Compositions

Fatty acid (FA) compositions were determined by gas chromatography (GC) on a HP 6890 Series GC System (USA) apparatus fitted with a HP 7683 Series Injector (splitless mode) and a flame ionization detector (FID, temperature 250 °C). FA methyl esters (FAMEs) were made by transesterification of oils in methanol. The operating conditions were as follows: 25 m × 0.32 mm × 0.25 μm HP INNOwax polyethylene glycol capillary column; temperature program, from 50 to 150 °C at 30 °C/min and from 150 to 240 °C at 4 °C/min, 240 °C for 10 min; and injector temperature 240 °C. Helium at 75 kPa was used as carrier gas. FAMEs were identified on the basis of their retention data compared with those of a standard mixture (Supelco 37 component FAME Mix) injected in the same conditions.

TAG analyses were carried out with a gas chromatograph model TRACE GC-2000 (Interscience SPRL, Belgium) equipped with a FID (temperature 270 °C, H2 25 ml/min) and an on-column injector (cold-on-column injection). A Restek TAG application-specific column (Restek Rtx-65TAG capillary column, 65 % diphenyl polysiloxane, 35 % dimethyl siloxane; 30 m × 0.32 mm × 0.1 μm) was used. Experimental chromatography conditions were an initial oven temperature of 80 °C, a first ramp to 180 °C at 30 °C/min, and a second ramp to 340 °C at 5 °C/min; this end temperature was maintained for 25 min. The various TAGs of fats were separated according to their carbon numbers (CN) and expressed as equivalent CN in weight percentage of the total TAGs.

Solid Fat Content

A pNMR spectrometer (Minispec MQ20, Bruker, Germany) was used to measure the solid fat content (SFC) of the fat samples according to the IUPAC 2.150(a) nontempered serial method, slightly modified. The fats were melted at 70 °C during 1 h and tempered at 0 °C for 1 h prior to determination. The relative proportions of solid and liquid fats were measured in 5 °C increments between 0 and 55 °C, after holding the sample at each temperature for 45 min instead of 30 min. Automatic calibration was made daily by using three standards (supplied by Bruker) containing, respectively, 0.0, 31.1, and 74.8 % of solid. Data are reported as averages of three measurements.

Thermal Analysis by Differential Scanning Calorimetry

The DSC melting profiles of the samples were analyzed using a Q1000 DSC (TA Instruments, New Castle, DE, USA) with a refrigerated cooling system (TA Instruments) using aluminium SFI pans. Before use, the DSC instrument was calibrated with indium (m.p. 156.6 °C) and n-dodecane (m.p. −9.56 °C) standards. Nitrogen was used as the purge gas in order to prevent condensation in the cells. Around 2–4 mg of sample was used for each analysis. An empty aluminium SFI pan was used as reference.

The melting properties of fats were studied under two different conditions, namely, either after rapid cooling (−25 °C/min) or after cooling and tempering for 24 h in a temperature-controlled cold chamber at 4 ± 0.5 °C. The calorimeter temperature program used for samples that underwent rapid cooling is: heating to 80 °C, 80 °C isotherm for 5 min, cooled at −25 °C/min to −50 °C, held for 5 min, and heated to 80 °C at 5 °C/min. Precrystallized samples (cooled and tempered during 24 h at 4 °C) were subjected to the following temperature program: isotherm at 4 °C for 30 min followed by heating to 80 °C (heating rate: 5 °C/min). All the DSC analyses were carried out in triplicate.

The temperatures of characteristic peaks and the area integration of peaks were carried out using the Universal Analysis Software version 4.2 (TA Instruments). The melting peaks were integrated with a linear baseline.

X-ray Diffraction Analysis

The polymorphic forms of the fat crystals in the samples were determined by powder XRD spectroscopy using a Bruker D8 Advance Diffractometer (Bruker, Germany) (λ Cu = 1.54178 Å, 40 kV, 30 mA) equipped with a Anton Paar temperature control system composed of a TTK450 low-temperature chamber, heating device (TCU 110 Temperature Control Unit) and liquid nitrogen cooling system (LNC Nitrogen Suction Equipment) (Anton Paar, Graz, Austria). XRD analyses were performed at short spacings (15–27° 2θ; 0.02° 2θ s−1) and long spacings (LS, 1–10° 2θ; 0.02° 2θ s−1) with a LynxEye detector (Bruker, Germany) in order to identify the crystalline forms and TAG longitudinal stacking, respectively.

The thermal histories of the samples before XRD analyses were exactly the same as those used for DSC melting measurements (rapid cooling or cooled and tempered for 24 h at 4 °C) and heating rate (5 °C/min). XRD measurements were carried out at several temperatures ranging from −30 °C or 5 °C to a temperature just below the melting point of the samples. Selection of the temperatures at which the XRD patterns were recorded was in function of the DSC melting profiles.

Results and Discussion

Fatty Acid and Triacylglycerol Compositions

The FA and TAG profiles of the fats are shown in Tables 1 and 2, respectively. As all lauric fats (FAO 2001; Pantzaris and Basiron 2002), the fats used in this work presented a high content of lauric acid (41–47 %). Unlike an original lauric fat that presents a high oleic acid content (12–19 %) (FAO 2001), the fats used for this study contained very low oleic acid levels (0.2–0.5 %). They are, therefore, not native but probably fully hydrogenated. The FA compositions of fats C and D and fats A and B were quite similar to those reported by Siew (2001) on hydrogenated PKO (HPKO) and hydrogenated palm kernel olein (HPKOO), respectively. This suggested that these fats have probably been hydrogenated from standard PKO and of its olein fraction, respectively.

Although all the studied lauric fats are totally saturated (above 99 % of saturated FA) and have roughly the same types of FA, they showed differences in the concentration of certain FAs. Indeed, fats A and B were distinguished by their high stearic acid (C18:0) content, while fats C and D by their high lauric and myristic acids (C12: 0 and C14: 0, respectively) contents. These differences have been confirmed by the TAG profiles (Table 2). The concentration of TAGs, with CN ranging between 26 and 42, was superior for fats C and D (around 65 %), particularly for C36, C34, and C38 TAGs, reflecting thus their greater richness in medium chain TAGs. By cons, fats A and B were characterized by a higher content of long-chain TAGs, particularly for TAGs with CN at 42, 44, and 48. It is also useful to note that fats C and D contained a slightly higher level of TAGs with 52 and 54 CN (between 2.4 and 2.9 % against 1.5–1.6 % for fats A and B).

Solid Fat Content

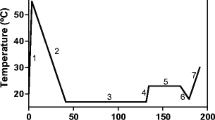

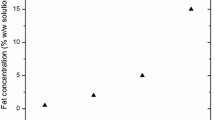

The SFC curves obtained for the four fats are illustrated in the Fig. 1. All fats showed practically similar SFC profiles that covered the same range of temperatures (Fig. 1a) but with differences which were principally marked in the domain of temperatures between 20 and 40 °C (Fig. 1b). Fats A and B presented higher solid content in this range of temperatures. This is linked to their higher concentration in long-chain TAGs (48–50 % of TAGs with CN between 42 and 54 against 34–35 % for fats C and D). It is well established in the literature that the melting point of TAGs increases with their chain length (Braipson-Danthine and Gibon 2007; Himawan et al. 2006). Nevertheless, it is important to note that fats C and D contained a little more solid lipid at 40 °C, probably because of their slightly higher content in TAGs with C52 and C54.

As reported for other lauric fats (Jin et al. 2008; Nazaruddin et al. 2005; Traitler and Dieffenbacher 1985; Siew 2001; Zhou et al. 2010), the SFC versus temperature profile of all the four lauric fats clearly showed a sharp melting curve. This effect was more pronounced for fats C and D than for fats A and B. As these fats could have a pronounced cooling effect in the mouth, they can be used in confectionery as fillings fats or in toffees and coatings (Traitler and Dieffenbacher 1985). This is in accordance with industrial applications expected of lauric fats. Most substitute chocolate for biscuit fillings, coatings, cakes, ice cream, and so on are made from hydrogenated PKO products (Pantzaris and Basiron 2002).

Thermal Behavior

After Rapid Cooling (−25 °C/min)

The DSC melting thermograms obtained after a rapid cooling of the fats (−25 °C/min) are shown in Fig. 2. This figure shows that each fat presented a major thermal event. A single melting peak covering a variable temperature domain (with a temperature peak above 33 °C) is detected for all the samples, depending on the type of fat. The presence of a peak at a temperature above 33 °C is due to the high melting point (HMP) TAG contents of the studied lauric fats. Besides, each different fats presented a limited melting range (from ±15 to 38 °C or 45 °C with the type of fat) that generally constitutes one of the main characteristics of lauric fats such as PKO, HPKO, palm kernel stearin, hydrogenated palm kernel stearin, coconut stearin, babassu oil, and hydrogenated babassu oil (Jin et al. 2008; Pantzaris and Basiron 2002; Renata and Lireny 1999; Rossell 1985; Siew 2001). This is related to the lesser diversity of FAs which compose them compared to the milk fat (for example) that contains more than 400 FAs (Jensen et al. 1991) and is characterized by a wide melting range (from −30 °C to 35 °C) (Danthine 2012). Despite the fact that all these fats are characterized by a single melting peak with a narrow domain, they showed, however, differences in the temperatures of melting peak and the domain of melting (especially for offset temperatures). Indeed, as in the case of SFC curves, fats A and B showed quite similar melting profiles and exhibited the highest peak temperatures (33.8 and 34.3 °C, respectively) and the lowest offset temperatures (38.5 and 39.1 °C, respectively). Fats C and D also displayed quite similar melting profiles but with the lowest peak temperatures (32.8 and 33.2 °C, respectively) and offset temperatures above 43 °C. Their higher end melting temperatures can be explained by their higher concentration in C52 and C54 TAGs. TAGs with C54 and C52 CN such as tristearin (SSS) and 1-palmitoyldistearin (PSS) are, for example, characterized by a range of fusion between 55 and 73 °C (Sato 2001) and 50.4 and 60.6 °C (Gibon 1984), respectively, according to their polymorphic forms.

Although the crystallization conditions prior to obtaining SFC and DSC melting profiles are not rigorously the same, these two results were consistent and gave an idea of the intrinsic properties of various fats. For example, fats C and D which contained a little more solid at 40 °C (~2.5 %) presented here the highest offset temperatures, while fats A and B which had practically no solid at that temperature (~0.7 and ~0.4 %, respectively) displayed the lowest temperatures for the end of fusion.

After Cooling and 24 h Tempering at 4 °C

In addition to the classical method (“After Rapid Cooling (−25 °C/min)”), tempering was applied because it is more in relation with the industrial processes involving this type of fat. Figure 3 shows the DSC melting curves of fats obtained after slow cooling (~ − 0.5 °C/min) and a tempering during 24 h at 4 °C. Unlike the melting profiles obtained after rapid cooling which displayed a single peak, those observed after cooling and 24 h tempering at 4 °C, showed two main melting peaks of equal importance for fats C and D and a medium and a large one for fats A and B, respectively. The temperature at the top of the first peak was noted for fats A, B, C, and D at 26.3 °C, 28.5 °C, 26.8 °C, and 26.2 °C, respectively, and for the second peak at 35.3 °C, 35.5 °C, 34.3 °C, and 34.7 °C, respectively. The first peak could correspond to the fusion of TAGs with lower and middle melting points (LMP and MMP, respectively) (CN ranging between 26 and 42), and the second could correspond to the fusion of TAGs with HMP (CN from 42 to 50). The small peak observed between 40 and 45 °C for fats C and D probably represented the fusion of very HMP TAGs (CN 52 and 54 TAGs).

It is important to notice that the differences in the melting profiles between the two groups of fats (A and B, C and D) were here more accentuated. The differences which were minor without tempering can become major in the industrial processes where tempering is often applied and have great repercussions on the physicochemical properties of the end products. The great differences observed between the two groups of fats are probably due to a better organization of lipid crystals after the cooling and 24 h tempering at 4 °C. Indeed, cooling and tempering at 4 °C during 24 h probably favored the formation of more stable crystals such as β′ or β forms (D’Souza et al. 1990; Sato et al. 1999; Sato 2001). In contrast, rapid cooling (−25 °C/min) from 80 to −5 °C probably led to the formation of unstable crystals such as α forms (D’Souza et al. 1990; Sato et al. 1999; Sato 2001). In order to verify this hypothesis, the polymorphism of the four fats was studied under the same thermal conditions.

Structural Behavior

Polymorphic Forms and Triacylglycerol Longitudinal Stacking

The diffractograms are obtained after cooling of fats at 4 °C followed by 24 h tempering at this temperature (Fig. 4). The analysis of wide-angle XRD (WAXD) (Fig. 4b) shows that fats A and B presented two peaks of diffraction at 4.23 Å and 3.80 Å, characteristic of β′2 polymorph (Braipson-Danthine and Gibon 2007; Desmedt 1993; Gibon 1984; Riiner 1970), while fats C and D displayed four peaks at 4.43 Å, 4.23 Å, 4.05 Å, and 3.80 Å indicating the presence of β′1 form (Braipson-Danthine and Gibon 2007; Desmedt 1993; Gibon 1984; Hagemann et al. 1972; Riiner 1970). Thus, the fats studied in the present work crystallized in the same polymorphic form, i.e., the orthorhombic chain packing (β′) but under two different variants. These two types of β′ crystals were distinguished by their degree of compactness, i.e., the orientation of the orthorhombic chain packing subcell in relation to the end group plane, the β′1 form being more compact (Larsson 1994). The β′ polymorph observed in this work was in agreement with the polymorphic characteristic of lauric fats. Lauric fats tend to possess a stable β′ polymorph owing to their mixed chain length TAGs (Jin et al. 2008; Nazaruddin et al. 2005; Siew 2001; Zhou et al. 2010). In the case of the industrial lauric fats studied, it contains 3.1–3.5 % short-chain FAs (<C10), 58.2–66.1 % medium-chain FAs (C10–C14), and 30.7–38.9 % long-chain FAs (C16–C18) (Table 1). According to Larsson (1994), variation in chain length of FAs may cause packing near the methyl end to become looser and, therefore, cut down the chance for the formation of tight crystal structures. Since β crystal has the most well-arranged structure, smaller variation in chain length of FAs of a particular blend may promote the formation of this polymorph. Moreover, based on the results of several authors (Chu et al. 2002; deMan and deMan 1994; Zhou et al. 2010), fats with high levels of C48 or C54 TAGs are usually in the β form, while fats consisting of relatively higher levels of C40 to C46 TAGs or rich in C50 and C52 TAGs promote β′ crystals formation. The fats studied were comprised from 35.8 to 49.3 % of C40 to C50 TAGs, and it is easy to understand why these fats crystallized preferentially in the β′form. It is also worth noting that the proportion of medium-chain saturated FAs and long-chain saturated FAs seems to determine the formation of the type of β′ crystals. Thus, the ratio lauric acid/stearic acid (C12:0/C18:0) can be taken as an indicator to describe or to predict the crystalline behavior of lauric fats. When this ratio tends to 1.4 (the case of fats A and B), it favors the formation of β′2 crystals, whereas when this ratio tends to 2.2 (the case of fats C and D), the formation of β′1 crystals seems to be privileged. To our knowledge, this is the first time that such a relation is attempted to be made between the composition of lauric fats and the variant of β′ crystals.

These results of polymorphism explained, at least in part, why fats C and D had higher offset temperatures and more solid fat at temperatures above 38 °C compared to fats A and B. According to the literature, the β′1 crystals are thermodynamically more stable and have, therefore, higher melting points than the β′2 crystals (Braipson-Danthine and Gibon 2007; D’Souza et al. 1990).

The small-angle XRD (SAXD) patterns presented in Fig. 4a also show that fats A and B displayed similar XRD profiles, as well as fats C and D. In fact, while fats A and B were characterized by three diffraction peaks around 2.40° (very intense peak), 4.70°, and 7.10°, fats C and D exhibited globally peaks in the same angle values with two additional peaks near 5.20° and 7.80°. The values of LS and the type of TAGs longitudinal stacking are summarized in Table 3. The LS values observed (between ~34 and 38 Å) corresponded to lamellar structures with double-chain-length organizations (2 L) of TAGs. According to the literature, the structures of type 2 L are characterized by values comprising 30 and 50 Å (Desmedt 1993; Hagemann 1988; Larsson 1994; Lopez et al. 2000; Ollivon and Perron 1992). The occurrence of 2 L stacking was not surprising since the different fats contained almost exclusively trisaturated TAGs. It is well known that 2 L structures are generated mostly by long-chain, high-melting, trisaturated TAGs (Hagemann 1988; Larsson 1994; Lopez et al. 2000; Ollivon and Perron 1992). It is also easy to note that the mean values of LS of the fats A and B (around 37 Å) are greater than those observed for the fats C and D (around 35.5 Å), probably due to their higher content in long-chain TAGs. Indeed, it is well demonstrated in the literature that the values of LS increase with the length of the FA in TAG (Larsson 1994).

Polymorphic Evolution During Heating

Once the crystalline forms and TAG longitudinal stacking were characterized, we also studied the polymorphic behavior during the heating of different fats after the rapid cooling or after the cooling and tempering at 4 °C during 24 h in relation with the DSC thermal analysis. The polymorphic evolutions of fats A and D during the heating from 5 to 50 °C at 5 °C/min are illustrated in Figs. 5 and 6.

After Rapid Cooling

The WAXD patterns presented in Fig. 5 show that all the fats followed the same polymorphic evolution during the heating when they have previously underwent rapid cooling from 70 °C to −30 °C at −25 °C/min. In fact, as expected, all fats crystallized under the α form (one diffraction peak around 4.15 Å); it is well known that the rapid cooling generally leads to the formation of unstable polymorphs like the α crystals (D’Souza et al. 1990; Himawan et al. 2006; Sato et al. 1999). During the heating, the crystals of each fat evolved from the α form between −30 and −10 °C to the mixture of α and β′2 between −10 and 10 °C. The α to β′2 transition is completely achieved between 10 and 20 °C, which is followed by the progressive melting of the β′2 crystal from 20 to 35 °C with its whole melting between 35 and 40 °C. The evolution from the β′2 crystal to liquid state occurred without going through the β forms. Indeed, a signal at 4.6 Å, typical of a transition to the β form (D’Souza et al. 1990), was not found in the spectra, indicating that polymorphic transition had not occurred. These results are in accordance to the only no tempering dynamic study recorded in the literature about a fat belonging to the same group after rapid cooling followed by heating (Riiner 1970), thus confirming the β′ form stability of the lauric fats used in this work. On the contrary, there is no dynamic study in the literature on the tempered samples of this type of fat.

After Cooling and 24 h Tempering at 4 °C

The WAXD patterns recorded after cooling and 24 h tempering at 4 °C (Fig. 6b) for fats A and B showed the progressive melting of the β′2 form from 5 to 35 °C and the whole melting of this form between 35 and 40 °C. From 40 °C, the scattering signal observed corresponded to the organization of TAGs in their liquid state (Larsson 1997). For fats C and D (Fig. 6d), we observed an evolution from the β′1 form between 5 and 40 °C to the liquid state at 45 °C. The passage to the liquid state during the heating was each time performed without the occurrence of β form. These results were in perfect harmony with the DSC melting profiles obtained in the same thermal conditions.

The evolution of LS during the heating from 5 to 50 °C at 5 °C/min after cooling and 24 h tempering at 4 °C are given in Fig. 6a and c. Fats A and B (Fig. 6a) evolved from the 2Lβ′2 form between 5 and 35 °C to the liquid state at 40 °C. Similarly, fats C and D (Fig. 6c) evolved from the 2Lβ′1 form between 5 and 40 °C to the liquid state at 45 °C. Moreover, the progressive disappearance of the peaks corresponding to the LS around 33.9 and 34 Å between 5 and 30 °C could be attributed to the progressive fusion of the LMP and MMP TAGs. This would permit to associate these TAGs to LS around 34 Å.

Conclusion

Up to now, limited data are available in the literature comparing the thermal and structural behavior of lauric fats, especially concerning their polymorphism. The present work contributed to an establishment of these basic informations on lauric fats by analyzing four industrial lauric fats, which are sold under the same commercial description. As expected, it was confirmed that the melting and crystallization characteristics of fats, even belonging to the same group, were strongly dependent on the FA and TAG compositions. All fats showed a sharp melting behavior with a slight advantage for fats C and D. That propriety is closely related to the cooling effect in the mouth and could render them as good candidates for cocoa butter substitution in different functional applications or for filling fats in confectionery. As expected, the lauric fats considered in this study presented a β′ polymorph characteristic, due to their mixed chain length TAGs. However, our investigations highlighted that the proportion of medium-chain FAs to long-chain FAs (especially lauric and stearic acids) seems to determine the variant of existing β′crystals. When the lauric acid/stearic acid ratio is smaller (e.g., in this study, 1.4), the β′2 crystals are preferentially formed, while when this ratio is greater (e.g., in this work, 2.4), the formation of β′1 crystals is favored. This is the first time that such a relationship is established between FA composition and polymorphism of lauric fats. Our results have additionally showed great stability of the β′ polymorph during heating whatever the crystallization conditions used prior to heating. Those β′-tending fats could be particularly interesting in the production of industrial products such as shortenings, margarines, spreads, and ice cream.

References

Awad, T., & Sato, K. (2002). Acceleration of crystallisation of palm kernel oil in oil-in-water emulsion by hydrophobic emulsifier additives. Colloids and Surfaces. B, Biointerfaces, 25, 45–53.

Braipson-Danthine, S., & Gibon, V. (2007). Comparative analysis of triacylglycerol composition, melting properties and polymorphic behavior of palm oil and fractions. European Journal of Lipid Science and Technology, 109, 359–372.

Che Man, Y. B., Shamsi, K., Yusoff, M. S. A., & Jinap, S. (2003). A study on the crystal structure of palm oil-based whipping cream. Journal of the American Oil Chemists’ Society, 80, 409–415.

Chu, B. S., Ghazali, M. H., Lai, O. M., Che Man, Y. B., & Yusof, S. (2002). Physical and chemical properties of a lipase-transesterified palm stearin/palm kernel olein blend and its isopropanol-solid and high melting triacylglycerol fractions. Food Chemistry, 76, 155–164.

Cornacchia, L., & Roos, Y. H. (2011a). Solid–liquid transition and stability of HPKO-in-water systems emulsified by dairy proteins. Food Biophysics, 6, 288–294.

Cornacchia, L., & Roos, Y. H. (2011b). Lipid and water crystallization in protein-stabilised oil-in-water emulsions. Food Hydrocolloids, 25, 1726–1736.

D’Souza, V., deMan, J. M., & deMan, L. (1990). Short spacings and polymorphic forms of natural and commercial solid fats: a review. Journal of the American Oil Chemists’ Society, 67, 835–843.

Danthine, S. (2012). Physicochemical and structural properties of compound dairy fat blends. Food Research International, 48, 187–195.

deMan, L., & deMan, J. M. (1994). Functionality of palm oil, palm oil products and palm kernel oil in margarine and shortening. Lipid Technology, 6, 5–10.

Desmedt A. (1993). Etude des propriétés structurales et thermiques de triacylglycérols purs et en présence d’émulsifiants. Influence de la nature de la chaîne en C18 et application au phénomène de blanchiment. Thèse de doctorat, Facultés Universitaires Notre-Dame de la Paix, Namur, Belgique.

FAO (2001). Codex alimentarius: Fats, oils and related products. Vol. 8, 2nd ed. (revised 2001), Rome, Italy.

Gibon V. (1984). Etude du polymorphisme et de l’intersolubilité des triacylglycérols constitutifs des matières grasses végétales. Thèse de doctorat, Facultés Universitaires Notre-Dame de la Paix, Namur, Belgique.

Hagemann, J. W. (1988). Thermal behaviour and polymorphism of acylglycerides. In N. Garti & K. Sato (Eds.), Crystallization and polymorphism of fats and fatty acids (pp. 177–210). New York: Marcel Dekker.

Hagemann, J. W., Tallent, W. H., & Kolb, K. E. (1972). Differential scanning calorimetry of single acid triglycerides: effect of chain length and unsaturation. Journal of the American Oil Chemists’ Society, 49, 118–123.

Himawan, C., Starov, V. M., & Stapley, A. G. F. (2006). Thermodynamic and kinetic aspects of fat crystallization. Advances in Colloids and Interface Science, 122, 3–33.

Ishikawa, H., Shiota, M., Murakami, M., & Nakajima, I. (1997). Polymorphic behaviour of palm oil and modofoed palm oils. Journal of Food Science and Technology International Tokyo, 3(1), 77–81.

Jensen, R. G., Ferris, A. M., & Lammi-Keefe, C. J. (1991). The composition of milk fat. Journal of Dairy Science, 74(9), 3228–3243.

Jin, Q., Zhang, T., Shan, L., Liu, Y., & Wang, X. (2008). Melting and solidification properties of palm kernel oil, tallow, and palm olein blends in the preparation of shortening. Journal of the American Oil Chemists’ Society, 85, 23–28.

Lai, O. M., Ghazali, H. M., Cho, F., & Chong, C. L. (2000). Physical properties of lipase-catalyzed transesterified blends of palm stearin and anhydrous milk fat. Food Chemistry, 70, 215–219.

Larsson, K. (1966). Classification of glyceride crystal forms. Acta Chemica Scandinavica, 20, 2255–2260.

Larsson, K. (1994). Lipids: Molecular organization, physical functions and technical applications. Dundee: Oily Press.

Larsson, K. (1997). Molecular organization in lipids. In S. E. Friberg & K. Larsson (Eds.), Food emulsions (3rd ed., pp. 111–139). New York: Marcel Dekker.

Lopez, C., Lesieur, P., Keller, G., & Ollivon, M. (2000). Thermal and structural behavior of milk fat: 1. Unstable species of cream. Journal of Colloid and Interface Science, 229, 62–71.

Md Ali, A. R., & Dimick, P. S. (1994). Melting and solidification characteristics of confectionery fats: anhydrous milk fat, cocoa butter and palm kernel stearin blends. Journal of the American Oil Chemists’ Society, 71(8), 803–806.

Nazaruddin, R., Mamot, S., & Neoh, T. L. (2005). Physicochemical characteristics of binary mixtures of hydrogenated palm kernel oil and goat milk fat. Journal of Food Lipids, 12, 243–260.

Noordin, M. I., & Chung, L. Y. (2009). Thermostability and polymorphism of theobroma oil and palm kernel oil as suppository bases. Journal of Thermal Analysis and Calorimetry, 95(3), 891–894.

Ollivon, M., & Perron, R. (1992). Propriétés physiques des corps gras. In A. Karleskind, J. P. Wolff, & J. F. Guttmann (Eds.), Manuel des corps gras (pp. 433–442). Paris, France: Lavoisier.

Pantzaris, T. P., & Basiron, Y. (2002). The lauric (coconut and palm kernel) oils. In F. D. Gunstone (Ed.), Vegetable oils in food technology: Composition, properties and uses (pp. 157–202). Oxford: Blackwell.

Podmore, J. (2002). Bakery fats. In K. K. Rajah (Ed.), Fats in food technology (pp. 30–68). Sheffield: Sheffield Academic.

Precht, D. (1988). Fat crystal structure in cream and butter. In N. Garti & K. Sato (Eds.), Crystallization and polymorphism of fats and fatty acids (pp. 305–361). New York: Marcel Dekker.

Ransom-Painter, K. L., Williams, S. D., & Hartel, R. W. (1997). Incorporation of milk fat and milk fat fractions into compound coatings made from palm kernel oil. Journal of Dairy Science, 80, 2237–2248.

Relkin, P., & Sourdet, S. (2005). Factors affecting fat droplet aggregation in whipped frozen protein-stabilized emulsions. Food Hydrocolloids, 19, 503–511.

Relkin, P., Ait-Taleb, A., Sourdet, S., & Fosseux, P.-Y. (2003). Thermal behavior of fat droplet as related to adsorbed milk proteins in complex food emulsions. A DSC study. Journal of the American Oil Chemists’ Society, 80(8), 741–746.

Relkin, P., Sourdet, S., & Fosseux, P.-Y. (2003). Fat crystallization in complex food emulsions. Effects of adsorbed milk proteins and of a whipping process. Journal of Thermal Analysis and Calorimetry, 71, 187–195.

Renata, T. N., & Lireny, A. G. G. (1999). Determination of melting point of vegetable oils and fats by differential scanning calorimetry (DSC) technique. Grasas y Aceites, 50(1), 16–22.

Riiner, U. (1970). Investigation of the polymorphism of fats and oils by temperature programmed X-ray diffraction. Lebensmittel-Wissenschaft und Technologie, 3, 101–106.

Rossell, J. B. (1985). Fractionation of lauric oils. Journal of the American Oil Chemists’ Society, 65(2), 385–390.

Sato, K. (2001). Molecular aspects in fat polymorphism. In N. Widlak, R. Hartel, & S. Narine (Eds.), Crystallization and solidification properties of lipids (pp. 1–15). Champaign: AC0S.

Sato, K., Ueno, S., & Yano, J. (1999). Molecular interactions and kinetic properties of fats. Progress in Lipid Research, 38, 91–116.

Sato, K., Goto, M., Yano, J., Honda, K., Kodali, D. R., & Small, D. M. (2001). Atomic resolution structure analysis of β′ polymorph crystal of a triacylglycerol: 1,2-Dipalmitoyl-3-myristoyl-sn-glycerol. Journal of Lipid Research, 42, 338–345.

Siew, W. L. (2001). Crystallisation and melting behaviour of palm kernel oil related products by differential scanning calorimetry. European Journal of Lipid Science and Technology, 103, 729–734.

Tan, C. P., & Che Man, Y. B. (2000). Differential scanning calorimetric analysis of edible oils: comparison of thermal properties and chemical composition. Journal of the American Oil Chemists’ Society, 77(2), 143–155.

Tan, C. P., & Che Man, Y. B. (2002a). Recent developments in differential scanning calorimetry for assessing oxidative deterioration of vegetable oils. Trends in Food Science & Technology, 13, 312–318.

Tan, C. P., & Che Man, Y. B. (2002b). Differential scanning calorimetric analysis of palm oil, palm oil based products and coconut oil: effects of scanning rate variation. Food Chemistry, 76, 89–102.

Timms, R. E. (1997). Fractionation. In F. D. Gunstone (Ed.), Lipid technologies and applications (pp. 199–222). Marcel Dekker: New York.

Toro-Vazquez, J. F., Rangel-Vargas, E., Dibildox-Alvarado, E., & Charó-Alonso, M. A. (2005). Crystallization of cocoa butter with and without polar lipids evaluated by rheometry, calorimetry and polarized light microscopy. European Journal of Lipid Science and Technology, 107, 641–655.

Traitler, H., & Dieffenbacher, A. (1985). Palm oil and palm kernel oil in food products. Journal of the American Oil Chemists’ Society, 65(2), 417–421.

van Mechelon, J. B., Peschar, R., & Schenk, H. (2006). Structures of mono-unsaturated triacylglycerols. II. The β2 polymorph. Acta Crystallographica. Section B, 62, 1131–1138.

Zhou, S. L., Zhang, F. Q., Jin, Q. Z., Liu, Y. F., Shan, L., Zhang, T., Zou, X. Q., & Wang, X. G. (2010). Characterization of palm kernel oil, pal stearin, and palm olein blends in isosolid diagrams. European Journal of Lipid Science and Technology, 112, 1041–1047.

Acknowledgments

The authors would like to acknowledge Ms. Lynn Doran for agreeing to improve the quality of the English of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anihouvi, P.P., Blecker, C., Dombree, A. et al. Comparative Study of Thermal and Structural Behavior of Four Industrial Lauric Fats. Food Bioprocess Technol 6, 3381–3391 (2013). https://doi.org/10.1007/s11947-012-0980-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0980-9