Abstract

The aim of this study was to evaluate the effect of the addition of tiger nut fibre (TNF) as a carrier of unsaturated fatty acids (UFA) rich oil on some quality parameters in a dry-cured sausage. Nine formulations of “Longaniza de Pascua”, a traditional Spanish dry-cured fermented sausage, were manufactured under normal industrial conditions but incorporating different combinations of TNF (1–2%) as a source of fibre and walnut oil (WO; 2.5–5%) as a source of UFA. The addition of TNF improved WO incorporation into the meat batter: the higher the amount of TNF added, the more WO incorporated. Sausages with TNF + WO had a higher moisture content than the control (hence lower weight loss), lower pH values, higher water activity, similar L* values and higher a* and b* values than the control. The only microorganisms that were affected by the formula were mould and yeasts, but in all cases the counts at the end of ripening were comparable to the results of the most studies on fermented sausages. The increase in lipid oxidation in sausages due to the addition of WO was controlled by the TNF, probably due to the antioxidant compounds (phenolics) it contains. The samples with 1% TNF + 2.5% WO and 2% TNF + 5% WO scored the same in terms of overall liking as the control.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The importance of the link between nutrition and health is a hot topic. Like other food-related sectors, the meat industry is undergoing major transformations, driven by among other things changes in consumer demands (Jiménez-Colmenero 2007). There exist varying possibilities to improve the different categories of processed meat. For ground products, ingredients with a “healthy perception” can be added, such as different sources of dietary fibre (DF) and unsaturated fatty acids (FAs).

Tiger nut fibre (TNF), obtained by upgrading by-products from tiger nut milk production, was reported as a suitable fibre source by Sánchez-Zapata et al. (2009). TNF has a high proportion of total DF (59.71 g/100 g), composed mainly of insoluble DF (99.8%). The intake of this kind of fibre is linked to a sensation of satiety since the fibre absorbs water and takes up space in the stomach and diminishes the need to consume more food. Well-documented studies acknowledge that diets enriched with DF play a significant role in the prevention of several disorders such as colon cancer, constipation, obesity and cardiovascular diseases (Viuda-Martos et al. 2010). TNF also has good functional (water holding capacity, 8.01 g/g; oil holding capacity, 6.92 g/g; emulsifying ability, 70.33 ml/100 ml and emulsifying stability, 100 ml/100 ml) and antioxidant properties (polyphenols content, 0.139 mg gallic acid/g) (Sánchez-Zapata et al. 2009).

Traditional meat products possess certain negative aspects from the nutritional point of view as a consequence, among other reasons, of their high animal fat content (de Paula et al. 2011). The relatively high cholesterol level and low polyunsaturated/saturated (PUFA/SFA) ratio shown by this type of fat are negative factors in relation to the development of some pathologies like coronary heart diseases (Özvural and Vural 2008; Webb and O’Neill 2008). More recently, nutritionists have focused on the type of PUFA and the balance in the diet between n-3 PUFA and n-6 PUFA (Ospina et al. 2011; Williwams 2000;). The n-6/n-3 PUFA ratio is also a risk factor in cancers and coronary heart disease (Pelser et al. 2007; Webb and O’Neill 2008).

Vegetable oils have a positive impact on nutritional aspects as a result of reduced cholesterol content and improved PUFA/SFA and n-6/n–3 ratios (Ospina et al. 2011). Among vegetable oils, walnut oil contains one of the highest levels of PUFAS (up to 78% of the total FA content). The FA composition of walnut oil resembles that of soybean oil, but walnut oil contains a greater concentration of linolenic acid (n–3; 10–15%) (Crews et al. 2005). Some vegetable oils have been used as ingredients in different cooked and fermented meat products, giving rise to products with FA profiles and cholesterol levels more adequate than the traditional (Severini et al. 2003; Muguerza et al. 2001; Martínez et al. 2011). However, negative effects from the technological point of view (for example, that the oil cannot remain into the meat matrix, oil oxidation etc.), and impaired sensory quality are a great limitation on the concentration of oil that can be added. The unsaturated nature of these compounds makes them susceptible to oxidation. This deterioration causes quality changes in the product and is of major concern, both nutritionally and from a safety viewpoint (Fernández-López et al. 2005). In this respect, strategies to enhance food quality involving the control of lipid oxidation are of great importance.

For all these reasons, the use of TNF as a carrier of unsaturated FAs in meat product processing could be a suitable alternative for avoiding the problems related with its incorporation in the meat matrix and for controlling lipid oxidation (due to the antioxidants properties of TNF). At the end it will be obtained a meat product enriched in two healthy ingredients: DF from TNF and PUFA from walnut oil.

The aim of this study was to evaluate the effect of the addition of TNF as a carrier of unsaturated FAs rich oil on some quality parameters in a dry-cured sausage.

Materials and Methods

Materials

Sausages were prepared using fresh lean pork meat and backfat obtained from local processors. The following non-meat ingredients were also used in the sausage formula: analytical grade sodium chloride, sodium nitrite and sodium ascorbate, cold distilled water (4 °C) and food-grade commercial sugar, white pepper and aniseed (Prosur S.A., Murcia, Spain).

“Horchata” (tiger nut milk) by-products (protected designation of origin, “Chufa de Valencia”) were obtained directly from a local manufacturer (Horchatería Navia; Pilar de la Horadada, Alicante, Spain) and processed following the recommendations of Sánchez-Zapata et al. (2011b). TNF was prepared following the procedure described by Sánchez-Zapata et al. (2009). TNF was vacuum packed in vacuum pouches (2 kg) and immediately frozen at −30 °C. When required, pouches were left at 4 °C for 24 h to thaw. Before incorporation into sausage, TNF was dehydrated at 50 °C in a vacuum oven and ground.

Walnut oil (63–80% PUFA, 14–22% MUFA and 7–15% SFA; Berinoix, Guenard Ets, Noyes sur Cher, France) was purchased in a local supermarket.

Sausages Formulation and Processing

Three independent replicates of each batch were prepared at the IPOA Research Group Pilot Plant facilities. A traditional formula for “Longaniza de Pascua” was used to obtain a “base” batter as follows (only meat percentages add up to 100% and percentages of others ingredients are related to meat): 60% lean pork meat, 40% pork backfat, 5% (w/w) water, 2% (w/w) sodium chloride, 0.2% (w/w) sugar, 0.2% (w/w) white pepper, 0.05% (w/w) sodium ascorbate, 0.01% (w/w) sodium nitrite and 0.01% (w/w) aniseed. This mixture was divided into 9 batches depending on the TNF (0%, 1% and 2%), walnut oil (0%, 2.5% and 5%) concentrations and their combinations used (Table 1). Finally, the mince was stuffed into lamb casings (15–25-mm diameter) and all the batches were ripened for 7 days at 15 ± 2 °C and 75 ± 5% relative humidity in a ripening chamber. Figure 1 describes the flowchart of the “Longaniza de Pascua” production process. “Longaniza de Pascua” is a traditional Spanish dry-fermented sausage, which has been recognised by the Valencian regional authorities with a quality distinction (Diario Oficial de la Generalitat Valenciana DOGV 2003).

Chemical Parameters

Moisture, ash, protein, fat and total dietary fibre (TDF) content were determined by AOAC methods (AOAC 1997).

Lipid oxidation was assessed in triplicate by the 2-thiobarbituric acid (TBA) method of Buege and Aust (1978). Thiobarbituric acid reactive substances (TBARS) values were calculated from a standard curve of malonaldehyde (MA) and expressed as milligrammes MA per kilogramme sample.

Physicochemical Parameters

The pH was measured in a suspension resulting from blending a 15-g sample with 150-mL deionized water for 2 min using a pH meter (Mod. pH/Ion 510, Eutech Instruments Pte Ltd., Singapore).

Water activity (a w) was measured at 25 °C using a Novasina TH-500 hygrometer (Novasina, Axair Ltd., Pfaeffikon, Switzerland).

The percentage of weight loss during dry-curing was calculated as weight difference before and after dry-curing.

Colour was evaluated using a spectrophotometer (CM-2600D, Minolta Camera Co., Osaka, Japan) with illuminant D65, 10° observer angle, diffuse/O mode, 8-mm aperture of the instrument for illumination and 8 mm for measurement. Colour was described as coordinates: lightness (L*), redness (a*, ±red–green) and yellowness (b*, ±yellow–blue). Nine replicate measurements were taken for each sample, following the guidelines for colour measurements from the American Meat Science Association (Hunt et al. 1991).

Microbial Counts

Microbial analysis of the sausages included determinations of the number of total viable cells, lactic acid bacteria, Micrococcus and yeasts and molds. Samples (25 g) were excised from the interior of the sausages with a sterile scalpel and forceps, and then homogenized with sterile 1.5% peptone water (Panreac, Barcelona, Spain) in a Stomacher 400 (Colworth, London, UK) for 1.5 min. Serial dilutions of samples were prepared in sterile peptone water (Panreac, Barcelona, Spain). Total viable counts were determined by plating the diluted samples on 3 M Petrifilm™ plates (3M Microbiology, St. Paul, MN, USA) and incubating at 35 °C for 48 h; lactic-acid bacteria by plating on Lactobacilli MRS Agar (Scharlau, Barcelona, Spain) double-layered plates at 37 °C for 48 h in an anaerobic atmosphere; Micrococcus on Mannitol Salt Agar (Scharlau, Barcelona, Spain) incubated at 35 °C for 48 h; molds and yeasts on Rose Bengal Agar with chloramphenicol (Scharlau, Barcelona, Spain) incubated at 28 °C for 5 days.

Sensory Evaluation

Sensory evaluation was carried out by an experienced ten member trained panel. Panel members were either faculty of graduate students of the AgroFood Technology Department of Miguel Hernández University, Alicante, Spain. Three training sessions were held to familiarize the panellists with the dry-cured sausage characteristics, so that each panellist could thoroughly discuss and clarify each attribute to be evaluated in the sausages. Testing was initiated after the panellist agreed on the specifications. A Quantitative Descriptive Analysis was carried out (IFT (Institute of Food Technologists) 1981). All sensory work was carried out in the sensory laboratory at the University, which fulfils requirements according to the international standards (ASTM 1986; ISO 2010). During evaluation the panellists were situated in private booths under fluorescent light, with an intensity of approximately 350 lux. The sample consisting of slices (2 mm thick) was served at room temperature (ASTM 1988). Each panellist evaluated three replicates of all the formulas; the order of presentation being random for each panellist. Tap water was provided between samples to cleanse the palate. The sensory attributes were measured in unstructured scales with descriptors at both ends, no standards were provided. The attributes measured and their descriptors were as follows: for “external evaluation”, easy peeling capability (from very difficult to very easy) and colour intensity (from extremely light to extremely dark). For “odour”, rancidity (from imperceptible to extremely intense). For “taste”, fattiness (from imperceptible to extremely intense). For “texture”, firmness (from extremely soft to extremely tough), juiciness (from extremely dry to extremely moist) and granularity (from absence of granules to extremely gritty).

At the end of the test, panellists were asked to give a score for overall liking of the product from 0 to 7 (from dislike extremely to like extremely).

Statistical Analysis

Data from proximate composition, physicochemical analysis, lipid oxidation and microbial counts were analysed by means of one-way ANOVA test the formula being the main effect (nine levels, see Table 1). Data from sensory evaluation were also analysed by means of ANOVA test but the model included the formula, the assessor and the session nested to the assessor as fixed effects. The interaction assessor × formula was tested and dropped from the model since it was not significant (P > 0.05). Differences between formulas were also tested (Tukey’s test).

Statistical analyses were carried out using SPSS 16.0 for Windows (SPSS Inc., Chicago, USA).

Results and Discussion

Proximate Composition

A proximate analysis of all the sausage formulations is presented in Table 2. WO and TNF increased (P < 0.05) the moisture content. Sausages with added WO showed the highest (P < 0.05) moisture content (increasing with increasing WO concentration). The TNF effect upon moisture was the same but less strong than the effect of WO. However, when WO and TNF were added together, the resultant effect was antagonist: sausages with added TNF + WO showed lower moisture content than samples with only WO (at the same concentration) but higher than samples with only TNF (at the same concentration). Control samples showed the lowest (P < 0.05) moisture content. Several authors have reported that the addition of different sources of DF in meat products increases the water retention (Alesón-Carbonell et al. 2003; Fernández-López et al. 2008; Sánchez-Zapata et al. 2011). This effect has been attributed to the high water holding capacity of the TNF added. The measurements of moisture seem to indicate that WO addition obstructed moisture loss during the dry-curing process perhaps due to the formation of an impermeable film between the meat batter and the sausage skin. Muguerza et al. (2001) also reported that sausages with added olive oil had higher water content than the corresponding control. The addition of WO increased (P < 0.05) sausage fat content, an effect that was expected from the direct addition of oil to the control meat batter. TNF addition (at any concentration) did not modify the sausage fat content. Only when the TNF was added together with the WO the fibre showed an evident effect on the fat content. The highest fat content (P < 0.05) was observed in sausages with 5% WO + 2% TNF added. The increase in fat content in sausages with TNF + WO can be attributed to the oil holding capacity of this fibre (Sánchez-Zapata et al. 2009). Several authors have reported that some FAs (mainly UFAs) are lost in the “drip” observed during the ripening of sausages (Muguerza et al. 2001). These authors also reported that the FAs mostly involved in this loss are the PUFA because the high degree of unsaturation of these FAs makes them more fluid. These reasons could explain the high fat content of sausages with TNF + WO: the oil holding capacity of TNF would decrease WO loss during sausage ripening. The variation observed in sausage protein content (decrease) was attributed to the increase in the fat content due to WO addition. TNF addition (at any concentration) did not modify the sausage protein content. The highest protein content was observed in sausages with the lowest fat content and vice versa. The increase in ash content in sausages with added TNF can be attributed to the fibre mineral content. In contrast, WO addition decreased sausage ash content, mainly due to the increase in the fat content. The addition of 1% and 2% TNF significantly increased (P < 0.05) the total dietary fibre content of longaniza, depending on the amount of TNF added (1.36% in sausages with 1% TNF and 1.84% in sausages with 2% TNF). When the TNF was added together with WO the sausages fibre content decreased slightly due to the presence of WO, but in all cases this content was higher than 1%.

Physicochemical Parameters

The physicochemical parameters of sausages are presented in Table 3. The pH of sausages was only affected (P < 0.05) by TNF addition. Sausages with added TNF (without or with WO at any concentration) showed lower pH values (P < 0.05) than sausages without TNF. WO addition had no effect on final pH. Similar pH behaviour has been reported by other authors (Muguerza et al. 2002) in fermented sausages with different types of vegetable oil added. “Longaniza de Pascua” is a fermented sausage but, due to its small diameter, it is subjected to a very short fermentation-ripening period (7 days) compared with other fermented sausages (approx. 30 days). Long fermentation-ripening periods result in more acidic sausages, with pH values below 5.1 (Incze 1992; Spaziani et al. 2009). In this case, the pH of “Longaniza de Pascua” ranged from 5.11 ± 0.02 to 5.29 ± 0.01. Acid pH favours protein coagulation, as pH approaches its isoelectric point, and thus also favours water release. Acid pH also contributed to safety by contributing to the inhibition of undesirable pathogenic or spoilage bacteria. Another important factor for sausage safety is the reduction of water activity (a w below 0.93) (Toldrá 2006). All sausage formulations showed final a w values below 0.93. The highest aw values (P < 0.05) were found in sausages with added WO. In contrast, the lowest aw values (P < 0.05) were found in sausages with TNF added (lower at higher TNF concentration). When both ingredients were added together, the predominant effect was that of WO. All sausages with 5% WO and TNF added (independently of the TNF concentration added) did not show significant differences in aw values (P > 0.05). Moreover, all sausages with 2.5% WO and TNF added (independently of the TNF concentration added) did not show significant differences in aw values (P > 0.05), which were lower than those at 5% WO and TNF. Drying determines the final moisture content (Table 2), which is closely related with water activity values, because the dehydration results in an increase in sodium chloride concentration in the aqueous phase. Severini et al. (2003) reported that the increase in olive oil content in salami products caused a lower a w reduction because of slower dehydration during ripening, which was explained by the production of a better water in oil emulsion in the samples containing oil.

Weight losses were significantly affected by both TNF and WO addition. Both ingredients reduced (P < 0.05) weight losses with respect to the control sausages. The reduction of weight losses due to TNF addition (with no differences between TNF concentrations) could be related to the water holding capacity of the fibre, which favours the water retention. Control sausages showed the lowest moisture content and the highest weight losses (Table 2). Increasing WO addition produced a higher reduction in sausages weight loss than increasing TNF addition. Sausages with 5% WO showed the highest moisture content (Table 2) and the lowest weight losses. Sausages containing WO + TNF showed weight loss values inversely related to their moisture content. Weight losses depend on many factors, including the temperature and relative humidity of the ripening room, air movement, ripening time, the degree of comminution of the meat mixture, the diameter of the casings and the material of which the casings are made (Roedel and Klettner 1981; Stiebing and Roedel 1987). All these factors were the same in all sausages under study, so that the variations observed in weight losses can only be attributed to the capacity of the meat mixture to retain water and oil.

Colour is one of the most important characteristics for consumers when selecting and purchasing foods, which must be borne in mind when attempting to modify or add new ingredients to a traditional product (Fernández-López et al. 2002). The colour coordinates of sausages are shown in Table 3. The highest lightness values (P < 0.05) were found in sausages only with WO added (at any concentration) and the lowest (P < 0.05) in sausages with TNF added (at any concentration). Muguerza et al. (2002) reported that the inclusion of olive oil in fermented sausages produced lighter coloured sausages. The vegetable oils made the products more brilliant, which could be responsible for the increase in L* values (García et al. 2002; Salazar et al. 2009). This effect was not detected when WO was added together with TNF, probably due to the water holding capacity of TNF, which retained these compounds in the meat batter so that they could not be detected by surface colour measurements. Sausages containing TNF and/or WO showed higher (P < 0.05) a* and b* values than the control. Both coordinates were more strongly affected by WO than by TNF. When both ingredients (TNF and WO) were added together, redness and yellowness also increased, reaching values similar to those when they were added separately. Bloukas et al. (1997) also found that fermented sausages with olive oil were lighter and more yellow than controls.

Lipid Oxidation

The oxidation of FAs and other lipid compounds during the ripening of dry fermented sausages can give rise to rancidity, which may negatively affect their quality, especially when a source of PUFA is included in the formulation. TBARS has been used as an indicator of oxidation and the results are shown in Fig. 2. Georgantelis et al. (2007) reported that rancid flavour is detected in meat products with TBARS values higher than 0.6 mg MA/kg. The sausages with TNF (at any concentration) showed similar TBARS values (P > 0.05) to the control. All sausages containing WO showed higher TBARS (increasing with concentration) (P < 0.05) than control or sausages with only TNF. TBARS was strongly affected (P < 0.05) by 5% WO addition, the highest TBARS values being found in sausages with 5% WO. When this amount of WO was added together with TNF (at any concentration) the TBARS values showed a decrease of approximately 50%. However, sausages with 2.5% WO + TNF (at any concentration) showed similar TBARS values to sausages with only 2.5% WO. These results suggest that the addition of 5% WO accelerates the rate of lipid oxidation, which could be partially controlled by the addition of TNF. The results agree with those of Severini et al. (2003) for “salami” type sausage containing 5% extra-virgin olive oil and with those of Ansorena and Astiasarán (2004) in dry-fermented sausages with linseed oil. Only the TBARS content in the formulation with 5% WO exceeded the level of lipid oxidation which produces a rancid odour and taste.

The effect of different ingredients on TBARS of “Longaniza de Pascua”. For sample denomination see Table 1. a–d Values with different letters differ significantly (P < 0.05)

Microbiological Counts

WO and TNF had no effect (P > 0.05) on total viable counts, lactic acid bacteria or Micrococcus counts. At the end of ripening, sausages showed counts of 6.62 ± 1.12 log CFU/g for total viable bacteria, 6.11 ± 0.66 log CFU/g for lactic acid bacteria and 3.13 ± 1.62 log CFU/g for Micrococcus. The microbiota of fermented sausage during fermentation and ripening changes as a result of the combined effects of lowering the pH, increasing the salt content and decreasing the water activity due to drying, resulting in high populations of lactic acid bacteria (Muguerza et al. 2002). Higher amounts of lactic acid bacteria (7–8 log CFU/g) have been found in Italian and Spanish fermented sausages (Bruna et al. 2001; Casaburi et al. 2007) but it is important to remember that Longaniza de Pascua has a short fermentation-ripening period and so represents a low acid sausage. Bruna et al. (2001) and Lisazo et al. (1999) reported Micrococcus counts of 3–5 log CFU/g in fermented sausages. Muguerza et al. (2002) also reported that the inclusion of olive oil in fermented sausages had no effect on lactic acid bacteria counts. Fernández-López et al. (2008) reported that the addition of different amounts of orange fibre (1–2%) to a Spanish fermented sausage had no effect on the final total viable counts or lactic acid bacteria. However, these authors found that the addition of orange fibre favoured micrococcus growth. In this case, the TNF addition to “Longaniza de Pascua” had no effect on Micrococcus growth, which may be due to the short fermentation-ripening period, because, in the case of sausages with orange fibre added, the differences in micrococcus growth were evident from day 9.

The only microbiological group that showed differences (P < 0.05) between formulations was moulds and yeasts. TNF and WO addition (at any concentration, whether added alone or in combination) increased (P < 0.05) the mould and yeast counts. Counts of moulds and yeasts in control sausages were 3.92 ± 0.61 log CFU/g compared with 4.50 ± 0.81 log CFU/g obtained with the other formulas. These counts of moulds and yeasts compare well with most studies on fermented sausages (Encinas et al. 2000; Moretti et al. 2004). The increase in mould and yeast counts observed in sausages with TNF added could be attributed to the high amount of this microbiota presents in TNF (Sánchez-Zapata et al. 2009). The increase attributed to WO addition could be related with slower dehydration during ripening as has been previously described.

Sensory Characterisation

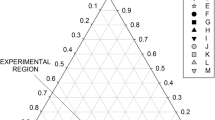

Figure 3 shows the sensory profile of each formula. Sausages with only TNF added (at any concentration) showed similar scores (P > 0.05) for firmness and colour intensity as the control. Sausages with added WO (with or without TNF) were perceived as significantly (P < 0.05) less firm and with less colour intensity. The decrease in firmness perception observed in sausages with WO added would probably be due to the lower weight losses (Table 3). In some cases, colour intensity perception in meat products has been closely related to redness values. In our study, this relation was not found; on the contrary, the higher the a* value, the lower the colour intensity perception. This could be attributed to other factors (other than redness) involved in sausage colour intensity perception: for example, brightness, homogeneity, wrinkled surface etc. Sausages with only 5% WO added were perceived as the most fatty, juicy and rancid (P < 0.05). Sausages with only TNF added showed similar scores (P > 0.05) for juiciness and rancidity as the control but were found to be less fatty than the control. Some authors have reported that the addition of different sources of DF to sausages decreases fatness perception (Alesón-Carbonell et al. 2003; Fernández-Ginés et al. 2003). Sausages with only TNF added were perceived as more granular (P < 0.05) than the others (depending on the concentration). When the TNF was added together with WO, the perception of granularity decreased, reaching scores similar to the control or sausages with only WO. It is also interesting to note that casings could be more easily removed (P < 0.05) from sausages with WO added compared to sausages with added TNF and the control.

Results of the sensory evaluation (quantitative descriptive analysis) carried out in “Longaniza de Pascua” formulated with different TNF and WO concentrations. For sample denomination, see Table 1. Easy peeling capability, 0 (very difficult) to 7 (very easy); colour intensity, 0 (extremely light) to 7 (extremely dark); rancidity, 0 (imperceptible) to 7 (extremely intense); fattiness, 0 (imperceptible) to 7 (extremely intense); firmness, 0 (extremely soft) to 7 (extremely tough); juiciness, 0 (extremely dry) to 7 (extremely moist); granularity, 0 (absence of granules) to 7 (extremely gritty); overall liking, 0 (dislike extremely) to 7 (like extremely)

Overall liking scores depended on the type and concentration of ingredient. Sausages with only TNF added (1 and 2%), sausages with 1% TNF + 2.5% WO and sausages with 2% TNF + 5% WO obtained the highest scores (P < 0.05), and similar to control samples.

Conclusions

The use of TNF as a carrier of walnut oil in dry fermented sausages is feasible. Both are healthy ingredients due to their contribution of DF and unsaturated FAs, respectively. Fibre addition allows the concentration of walnut oil in the sausage formula to be increased (with no technological problems) and also increases oxidation stability, probably due to the contribution of the bioactive compounds with antioxidant properties (polyphenols) present in the TNF. Sensory analyses showed that the differences between samples containing fibre + walnut oil, and the basic formulation were not necessarily negative. The samples with 1% TNF + 2.5% walnut oil and 2% TNF + 5% walnut oil obtained the same score for overall liking as the control.

References

Alesón-Carbonell, L., Fernández-López, J., Sayas, E., Sendra, E., & Pérez-Alvarez, J. A. (2003). Utilization of lemon albedo in dry-cured sausages. Journal of Food Science, 68, 1826–1830.

American Society for Testing and Materials (ASTM). (1986). Physical requirements. Guidelines for sensory evaluation laboratories, STP 913. Pennsylvania: ASTM.

American Society for Testing and Materials (ASTM). (1988). Standard and sensory evaluation of materials and products. In R. C. Storer (Ed.), ASTM Manual Series. Philadelphia: ASTM.

Ansorena, D., & Astiasarán, I. (2004). Effect of storage and packaging on fatty acid composition and oxidation in dry-fermented sausages made with added olive oil and antioxidants. Meat Science, 67, 237–244.

Association of Official Analytical Chemists (AOAC). (1997). Official methods of analysis (16th ed.). Washington, DC: AOAC.

Bloukas, J. G., Paneras, E. D., & Fournitzis, G. C. (1997). Effect of replacing pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Science, 45, 133–134.

Bruna, J. M., Ordoñez, J. A., Fernández, M., Herranz, B., & De la Hoz, L. (2001). Microbial and physicochemical changes during the ripening of dry-fermented sausages superficially inoculated with or having added and intracellular cell-free extract of Penicillium aurantiogriseum. Meat Science, 59, 87–96.

Buege, J. A., & Aust, S. D. (1978). Microsomal lipid peroxidation. Methods in Enzymology, 52, 302–310.

Casaburi, A., Aristoy, M. C., Cavella, S., Di Monaco, R., Ercolini, D., Toldrá, F., & Villani, F. (2007). Biochemical and sensory characteristics of traditional fermented sausages of Vallo di Diano (Southern Italy) as affected by the use of starter cultura. Meat Science, 76, 295–307.

Crews, C., Hough, P., Godward, J., Brereton, P., Lees, M., Guiet, S., & Winkelmann, W. (2005). Study of the main constituents of some authentic walnut oils. Journal of Agricultural and Food Chemistry, 53, 4853–4860.

de Paula, R., Colet, R., de Oliveira, D., Valduga, E., & Treichel, H. (2011). Assessment of Different packaging structures in the stability of frozen fresh Brazilian Toscana sausage. Food and Bioprocess Technology, 4, 481–485.

Diario Oficial de la Generalitat Valenciana (DOGV) (2003). Reglamento de Calidad para la Longaniza de Pascua, para su Distribución con la Marca de Calidad CV. 24/11/2003.

Encinas, J. P., López-Díaz, T. M., García-López, M. L., Otero, A., & Moreno, B. (2000). Yeast populations on Spanish fermented sausages. Meat Science, 54, 203–208.

Fernández-Ginés, J. M., Fernández-López, J., Sayas-Barberá, M. E., Sendra, E., & Pérez-Alvarez, J. A. (2003). Effects of storage conditions on quality characteristics of bologna sausages made with citrus fiber. Journal of Food Science, 68, 710–715.

Fernández-López, J., Pérez-Alvarez, J. A., Sayas-Barberá, E., & López-Santoveña, F. (2002). Effect of paprika (Capsicum annum) on color of Spanish-type sausages during the resting stage. Journal of Food Science, 67, 2410–2414.

Fernández-López, J., Zhi, N., Alesón-Carbonell, L., Pérez-Alvarez, J. A., & Kuri, V. (2005). Antioxidant and antibacterial activities of natural extracts: application in beef meatballs. Meat Science, 69, 371–380.

Fernández-López, J., Sendra, E., Sayas, E., Navarro, C., & Pérez-Alvarez, J. A. (2008). Physicochemical and microbiological profiles of “salchichón” (Spanish dry-fermented sausage) enriched with orange fiber. Meat Science, 80, 410–417.

García, M. L., Domínguez, R., Gálvez, M. D., Casas, C., & Selgas, M. D. (2002). Utilization of cereal and fruit fibre in low fat dry fermented sausages. Meat Science, 60, 227–236.

Georgantelis, D., Blekas, C., Katikou, P., Ambrosiadis, L., & Fletouris, D. J. (2007). Effect of rosemary extract, chitosan and α-tocopherol on lipid oxidation and colour stability during frozen storage of beef burgers. Meat Science, 75, 256–264.

Hunt, M. C., Acton, J. C., Benedict, R. C., Calkins, C. R., Cornforth, D. P., Jeremiah, L. E., Olson, D. P., Salm, C. P., Savell, J. W., & Shivas, S. D. (1991). Guidelines for meat color evaluation (pp. 1–12). Chicago: American Meat Science Association and National Live Stock and Meat Board.

IFT (Institute of Food Technologists). (1981). Sensory evaluation guide for testing food and beverage products. Journal of Food Science, 11, 50–59.

Incze, K. (1992). Raw fermented and dried meat products. Fleischwirtschaft International, 2, 3–12.

International Organization for Standardization (ISO) (2010). International Standard 8589. Sensory analysis general guidance for the design of test rooms. Ref. no ISO 8589:2010 (E). Genevè: ISO.

Jiménez-Colmenero, F. (2007). Healthier lipid formulation approaches in meat-based functional foods. Technological options for replacement of meat fats by non-meat fats. Trends in Food Science and Technology, 18, 567–578.

Lisazo, G., Chasco, J., & Beriain, M. J. (1999). Microbiological and biochemical changes during ripening of salchichón, a Spanish dry cured sausage. Food Microbiology, 16, 219–228.

Martínez, B., Miranda, J.-M., Vázquez, B.-I., Fente, C.-A., Franco, C.-M., Rodríguez, J.-L., Cepeda, A. (2011). Development of a hamburger patty with healthier lipid formulation and study of its nutritional, sensory and stability properties. Food and Bioprocess Technology. doi:10.107/s11947-009-0268-x.

Moretti, V. A., Madonia, G., Diaferia, C., Mentasti, T., Paleari, M. A., & Panseri, S. (2004). Chemical and microbiological parameters and sensory attributes of a typical Sicilian salami ripened in different conditions. Meat Science, 66, 845–854.

Muguerza, E., Gimeno, O., Ansorena, D., Bloukas, J. G., & Astiasarán, I. (2001). Effect of replacing pork backfat with pre-emulsified olive oil on lipid fraction and sensory quality of Chorizo de Pamplona—a traditional Spanish fermented sausage. Meat Science, 59, 251–258.

Muguerza, E., Fista, G., Ansorena, D., Astiasarán, I., & Bloukas, J. G. (2002). Effect of fat level and partial replacement of pork backfat with olive oil on processing and quality characteristics of fermented sausage. Meat Science, 61, 397–404.

Ospina-E., J.C., Sierra-C-, A., Ochoa, O., Pérez-Álvarez, J.A. & Fernández-López, J. (2011). Substitution of saturated fats in processed meat products: review. Critical Reviews in Food Science and Nutrition. doi:10.1080/10408398.2010.493978.

Özvural, E. B., & Vural, H. (2008). Utilization of interesterified oil blends in the production of frankfurters. Meat Science, 78, 211–216.

Pelser, M., Linssen, J., Legger, A., & Houben, J. (2007). Lipid oxidation in n-3 fatty acid enriched Dutch style fermented sausages. Meat Science, 75, 1–11.

Roedel, W., & Klettner, P. G. (1981). Beitrag zum einfluss des huellenkalibers auf die rohhwurstreifung. Fleischerei, 31, 1101–1103.

Salazar, P., García, M. L., & Selgas, M. D. (2009). Short-chain fructooligosaccharides as potential functional ingredient in dry fermented sausages with different fat levels. International Journal of Food Science and Technology, 44, 1100–1107.

Sánchez-Zapata, E., Fuentes-Zaragoza, E., Fernández-López, J., Sendra, E., Sayas, E., Navarro, C., & Pérez-Alvarez, J. A. (2009). Preparation of dietary fiber powder from tiger nuts (Cyperus sculentus) milk (“horchata”) by-products and its physicochemical properties. Journal of Agricultural and Food Chemistry, 57, 7719–7725.

Sánchez-Zapata, E., Fernández-López, J., Peñaranda, M., Fuentes-Zaragoza, E., Sendra, E., Sayas, E., & Pérez-Alvarez, J. A. (2011). Technological properties of date paste obtained from date by-products and its effect on the quality of a cooked meat product. Food Research International, 44, 2401–2407.

Sánchez-Zapata, E., Fuentes-Zaragoza, E., Viuda-Martos, M., Fernández-López, J., Sendra, E., Sayas, E. & Pérez-Alvarez, J.A. (2011b). Reclaim of the by-products from “horchata” elaboration process. Food and Bioprocess Technology. doi:10.1007/s11947-010-0486-2.

Severini, C., De Pilli, T., & Baiano, A. (2003). Partial substitution of pork backfat with extra-virgin oil in “salami” products: effects on chemical, physical and sensorial quality. Meat Science, 64, 323–331.

Spaziani, M., Del Torre, M., & Stecchini, M. L. (2009). Changes of physicochemical, microbiological and textural properties during ripening of Italian low-acid sausages. Proteolysis, sensory and volatile profiles. Meat Science, 81, 77–85.

Stiebing, A., & Roedel, W. (1987). Einfluss der relative luftgeschwindigkeit auf den reifungsverlauf bei rohwurst. Fleischwirtschaft, 67, 1020–1030.

Toldrá, F. (2006). Biochemistry of fermented meats. In Y. H. Hui (Ed.), Food biochemistry and food processing (pp. 641–658). Ames: Blackwell.

Viuda-Martos, M., López-Marcos, M., Fernández-López, J., Sendra, E., López-Vargas, J. H., & Pérez-Alvarez, J. A. (2010). Role of fiber in cardiovascular diseases. Comprehensive Reviews in Food Science and Food Safety, 9, 240–258.

Webb, E. C., & O’Neill, H. A. (2008). The animal fat paradox and meat quality. Review. Meat Science, 80, 28–36.

Williwams, C. M. (2000). Dietary fatty acids and human health. Annales de Zootechnie, 49, 165–180.

Sources of Support

The authors wish to thank Caja Mediterráneo for supporting the pre-doctoral grant of one of the authors (Elena Sánchez-Zapata) and the research project CYTED-IBEROFUN (110AC0386). They also wish to thank Consejo Regulador de la Denominación de Origen “Chufa de Valencia” and Heladería-Horchatería Navia, for kindly providing “horchata” by-products.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sánchez-Zapata, E., Díaz-Vela, J., Pérez-Chabela, M.L. et al. Evaluation of the Effect of Tiger Nut Fibre as a Carrier of Unsaturated Fatty Acids Rich Oil on the Quality of Dry-Cured Sausages. Food Bioprocess Technol 6, 1181–1190 (2013). https://doi.org/10.1007/s11947-011-0733-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0733-1