Abstract

Psyllium is a source of natural dietary fibre with recognised health benefits that can be used as a hydrocolloid with functional food applications. The purpose of this study was to determine the effect of different levels of Plantago ovata fibres in plant-based sausages on their composition, physicochemical, and mechanical properties. Proximate composition was studied. Water activity (aw), water release, pH, colour measurement, texture profile analysis (TPA), and Warner–Bratzler Shear Force (WBSF) were determined to establish the physicochemical and textural properties of sausages. A plant-based sausages microstructure study and a sensory study were carried out to better understand conformation and to determine their acceptance. The results showed that sausages had high ash and carbohydrate contents but, above all, a low-fat content. The use of psyllium increased water-holding capacity. The results also indicated that employing Plantago ovata white (PW) fibre can minimise mechanical problems and reduce colour changes. However, PW fibre showed less retained water, which was why chickpea starch further developed and was more gelatinised. At the same time, the plant-based sausages with PW fibre obtained the best overall score with the fewest colour changes in the sensory evaluation. Nevertheless, further studies are recommended to improve the texture and acceptability of these plant-based sausages.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, there is an increase in the consumption of veggie diets. The three diets forming part of the veggie world are flexitarian (predominantly plant-based diets with occasional portions of meat or fish), vegetarian (can include egg and dairy products), and vegan diets (excludes all animal-sourced foods) [1, 2]. As the Lantern study [2] indicated, 7.8% of the Spanish population followed one of these diet types in 2017, and the consumption of these diets increased by 27% in 2019. However, this percentage is lower than it is in countries like Germany and England [3], and these diets are on the increase in Europe and other Western countries [4]. Between 2017 and 2018, a report on food consumption in Spain recorded a 2.6% reduction in consumed meat [5]. One of the main reasons for choosing this diet type could be because vegan and vegetarian diets are associated with lower risks of chronic diseases for adults [6], and a wide range of health benefits like improving glycaemic control, blood lipids, body weight, and blood pressure [7]. Vegetarians and vegans describe their motives as “ideological” and primarily mention environmental concerns, animal welfare, and other ethical considerations as their reasons for choosing to eat these diet types [3, 8].

Meat production is mainly responsible for environmental pressures, such as pollution and unsustainable use of resources [9, 10]. According to an FAO report [11], meat is not essential in diet, since a large number of vegetarians have a nutritionally adequate diet. Therefore, Kamani et al. [12] concluded that meat should be substituted for totally vegetable origin food, so that the resulting product would be more similar to the original product in sensorial and textural acceptability terms with an adequate nutritional value. This makes replacing meat with plant-based meat substitutes an interesting alternative [9]. However, meat analogues are not always successful, which is mainly related to their low sensory quality [13]. Consequently, the great challenge for the food industry is to preserve the sensory and texture quality of analogous meat products. Various plant proteins can be used to help to overcome this problem, such as proteins from legumes, cereals, oilseeds, and soya, because these ingredients have functional properties, such as emulsifying, and water and oil absorption capacities, and high nutritional values [14]. Another problem with today's meat substitutes is that they are three-to-four times more expensive than meat products [13]. These proteins are used in different ways as textured proteins, flours, and concentrated or isolated proteins.

Some studies have shown that some hydrocolloids are capable to improve the physical and sensory food properties. It is a well-known fact that dietary fibres (DFs) have technological functions, such as water absorption and water retention, and minimise production costs without affecting the sensory properties of the final product [15]. Furthermore, they have opened possibilities to design new fibre-enriched products and generate new textures for a variety of applications [16]. Psyllium (Plantago ovata) is a source of natural DF [17] with good water absorbability and gelling properties [18]. This means that it can be used as a hydrocolloid with functional applications in new food production [19]. Furthermore, much research has indicated psyllium health benefits for diabetes, constipation, colon cancer prevention, diarrhoea, inflammatory bowel disease (ulcerative colitis), irritable bowel syndrome symptoms, abdominal pain, obesity, and hypercholesterolaemia [19,20,21]. There are several studies in which psyllium is used as a source of DF in the preparation of meat batters and sausages to improve texture and organoleptic properties or reduce fat [22,23,24,25,26]; however, no studies related to the use of this colloid to totally replace meat in sausages have been found. On the other hand, plant-based meat analogues are generally elaborated by extrusion [27,28,29]. In this study, three commercial types of P. ovata DFs, two from husk (one in husk form and other in powder) and one from the seed, were used to elaborate a plant-based sausage without using the extrusion technology due to it high costs. These DFs has been studied in the previous studies and showed different techno-functional properties, highlighting their different particle size and their hydration properties [18, 30].

The main objective of this study was to determine and compare the effect of using three different commercial DFs from P. ovata at concentrations from 0 to 6% on the physicochemical, textural, and sensory characteristics of plant-based sausages.

Materials and methods

Materials

All the ingredients used to prepare samples were supplied by the company Productos Pilarica S.A., Paterna, Spain. The main characteristics of P. ovata DF samples are shown in Table 1.

Preparation of plant-based sausages

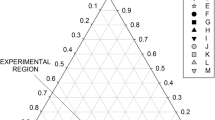

The control sausage formulation was that used by Majzoobi et al. [31] with minor modifications. First, the texturised pea protein was hydrated in a ratio 1:50 during 30 min. Then, the plant-based sausages were prepared by mixing 37% cold water, 32% hydrated texturised pea protein, 13.2% whole chickpea flour, 10.5% olive oil, 4.2% potato starch, 1.3% salt, and 1.8% seasonings in a food mincer (Moulinex Multimoulinette, AT714G32, Moulinex, SEB Group, France) for 10 min. To study the effect of adding psyllium, the three different P. ovata fibres were added to the formulation at 0%, 3%, 4%, 5%, and 6% w/w: Plantago Husk (PH), Plantago Powder (PP), and Plantago White (PW). Table S1 shows the experimental design. The mixture was stuffed inside a 2.5 cm-diameter previously hydrated artificial casing (Productos Pilarica S.A., Paterna, Spain). Samples were cooked in a water bath at 80 °C for 20 min until 75 °C were reached in the centre of the samples. Then, samples were cooled in cold water (8 °C) for 15 min. Finally, samples were stored at 4 °C for 24 h before running further experiments. Figure 1 shows all the plant-based sausage samples herein formulated.

Plant-based sausages analysis

All the samples were analysed in triplicate for each analysis.

Proximate composition of the plant-based sausages

Samples’ moisture (g water/100 g sample) was determined according to AOAC [32]. One gram of each sample was placed in a vacuum oven for drying (Vaciotem, J.P. Selecta, Spain) at 70 °C until constant weight. Crude fat quantification was performed by ether extraction with an Ankom XT10 Extraction System (NY, USA) [33]. The Dumas method in a Leco CN628 Elemental Analyzer (Leco Corporation, St. Joseph, MI, USA) determined the crude protein (nitrogen content × 6.25) according to Method 990.03 of AOAC International [34]. The crude ash content was determined by Method 923.03 [34]. A 1 g sample was incinerated at high pressure in a microwave oven (Muffle P Selecta Mod.367PE) for 3 h at 550 °C, and ash was gravimetrically quantified. Carbohydrates were calculated by difference.

Water activity (aw)

Samples’ water activity (aw) was analysed by the AquaLab PRE LabFerrer equipment (Pullman, USA).

Water release

Plant-based sausages’ water release was determined according to Majzoobi et al. [31]. One gram of each sample was cut into a thin slice and placed between two filter papers (Whatman No. 1) of known weight. Then, the samples between filters were pressed with a 1 kg weight for 20 min at 25 °C. The results were expressed as a percentage of water release.

pH

The pH of the plant-based sausages was measured using a Crison Basic 20+ pH meter (Crison S.A., Barcelona, Spain) with a puncture probe (Crison 5231).

Colour measurement

Samples’ colour was measured using a Konica Minolta CM-700d colorimeter (Konica Minolta CM-700d/600d series, Tokyo, Japan) with a standard D65 illuminate and a 10° visual angle. A measurement was taken for both the powders of the previously ground P. ovata fibre samples (Minimoka GR-020, Coffemotion S.L., Lérida, Spain) to present the same granulometry and plant-based sausages. A reflectance glass (CR-A51, Minolta Camera, Japan) was placed between the sample and the colorimeter lens. The measurement window was 6 mm in diameter. For both powders and plant-based sausages, the results were expressed as in the CIELab system.

The total colour difference (ΔE) was calculated according to: ΔE* = [(ΔL*)2 + (Δa*)2 + (Δb*)2]1/2. For the P. ovata fibre samples, the powder with the same granulometry was placed inside a circular aluminium sample holder (17.7 mm diameter × 9.53 mm high). ΔE1 was determined to observe the colour differences between PH and the other fibres (PP and PW). ΔE2 was performed for the differences between PP and PW.

For plant-based sausage colour, two sausages of each formulation were measured on both the internal and external sides. ΔE1 was used to observe the differences between the internal and external colours at each concentration. To observe the colour difference due to the addition of P. ovata fibres (PH, PP and PW), ΔE2 (internal and external) was determined in relation to the control sample.

Texture analysis

The plant-based sausages’ texture was measured using a TA-XT2 Texture Analyser (Stable Micro Systems Ltd., Godalming, UK) with the Texture Exponent software (version 6.1.12.0). A texture profile analysis (TPA) was performed as described in Kamani et al. [12]. Samples (2 cm long × 2.5 mm diameter) were compressed to 50% strain of their original height using a steel probe (45 mm diameter). A time of 5 s was allowed between the two compression cycles and the test speed was 50 mm/min. The attributes calculated from the force–deformation curve were hardness (N), adhesiveness (N.s), springiness (mm), cohesiveness (dimensionless), resilience (dimensionless), and chewiness (N).

With the same texture analyser, Warner–Bratzler Shear Force (WBSF) was performed according to Jin et al. [35] using a shearing V-shaped blade. The plant-based sausage samples (4 cm long × 2.5 mm diameter) were sheared at a crosshead speed of 100 mm/min. Firmness (N) was measured as the maximum peak force of shearing on the deformation curve.

Microstructure

The microstructural study was carried out by Cryo-field emission scanning electron microscopy (Ultra 55 FESEM, ZEISS, Oberkochen, Germany) (Cryo-FESEM). Cubes (3 mm3) cut by a stainless-steel cutter before being immersed in slush nitrogen (− 210 °C) and transferred to a cryo-trans GeminiSEM 500 (ZEISS, Oberkochen, Germany) linked with a field emission scanning electron microscope that operated below − 130 °C. Samples were cryofractured at − 180 °C and etched at − 90 °C.

Confocal scanning laser microscopy (CLSM) was conducted using a ZEISS 780 microscope coupled to an Axio Observer Z1 inverted microscope (Carl Zeiss, Germany). To visualise samples, the C-Apochromat 20X/1.2 W water immersion objective was used. Images were obtained and stored at a resolution of 1024 × 1024 pixels by the microscope software (ZEN). The employed stains were Rhodamine B and Calcofluor White (Fluka, Sigma-Aldrich, Missouri, USA).

Rhodamine B stained proteins and carbohydrates (starch granules) and was excited with diode line 488 and detected at 580 nm. Calcofluor White stained polysaccharides and was excited with diode line 405 and detected at between 410 and 477 nm.

To observe and study samples, tissue sections (20 μm thick) were obtained using a cryostat (CM 1950, Leica Biosystems, Nussloch, Germany). The portion of tissue was placed on a slide. Then, 20 μL of Rhodamine solution were added and left to rest for 5 min. The same procedure was followed for Calcofluor White, and samples were covered with a glass coverslip.

Sensory analysis

The sensory evaluation of the plant-based sausages was carried out by ten trained panellists. Sensory tests were run to describe differences in the addition of psyllium fibres, and to select the best-valued fibre and concentration. Water was served as ‘flavour cleaners’ to avoid the sense-adaptation effect. Seven attributes of the cooked plant-based sausages were evaluated: general texture, chewiness, juiciness, gumminess, colour, visual aspect, and overall acceptability. Each sausage was cut into 2 cm after removing the casing. The trained panellists were separated by at least 2 m following COVID-19 regulations. The design involved randomising the order that samples were served in. Each sensory attribute was represented with a 9-box scale, where the general texture was labelled from “I do not like” to “I like very much”, chewiness from “tender” to “leathery”, juiciness from “dry” to “juicy”, gumminess from “gritty” to “rubbery”, colour and the visual aspect from “unappetising” to “very appetising”, and overall acceptability from “totally rejectable” to “totally acceptable”. Panellists marked the box at the intensity level that they believed best characterised each sample.

Statistical analysis

All the analytical determinations were made in at least triplicate. Version 17.2.04 of the Statgraphics Centurion XVII Software was applied to perform the analysis of variance (one-way ANOVA), with a 95% confidence level. The LSD test was followed to evaluate differences between samples (p < 0.05). A correlation analysis was run at the 95% significance level among all the studied parameters (Statgraphics Centurion XVII).

Results and discussion

Proximate composition

Samples’ proximate composition is presented in Table 2. The addition of the various levels of psyllium fibres had a significant effect on moisture (p < 0.05). The samples with the highest moisture were control and PH 3%, with no significant differences between them (p > 0.05). A general drop in moisture was shown as the concentration of psyllium fibres rose, and this decrease became more intense for fibres PP and PW. According to Stephan et al. [36], the moisture of vegan meat analogues is higher, because more water is required to produce them than conventional meat products, and also due to the hydration of dried proteins and hydrocolloid powders. For this reason, the moisture values of all the studied meat-free sausages were higher than those found by Stephan et al. [36] for German sausages (56.5%). However, the water content of vegan sausages made with isolated pea protein, as reported by Stephan et al. [36], was higher than for all the samples tested in this study, but similar to that of meat sausages in which animal fat had been replaced, like those studied by Grasso et al. [37], who used sunflower seed flour as a fat replacer in frankfurters.

The highest protein content was obtained for samples PW 6% and, PP 5% and 6%. A fibre-concentration interaction was observed: when concentration rose, so did the protein content for fibres PP and PW, and this increase was intenser with the PP fibre. Nonetheless, no significant differences were found at the 6% concentration for PP and PW (p > 0.05). When adding the PH fibre, protein content significantly lowered (p < 0.05) and protein content lowered as the concentration rose. These results are similar to those by Wang et al. [38] for sausages made with Lentinula edodes as a replacer of pork lean meat at the 50% and 75% replacement levels.

The control exhibited the highest fat content. However, this content was lower than in the meat-free sausages with different hydrocolloids made by Majzoobi et al. [31], but higher than the fat content in the meat emulsion formulated with guar-xanthan gum mixture by Rather et al. [39]. In all the studied samples, fat content dropped as the concentration of psyllium fibres rose, and the fat content of the plant-based sausages was very low.

The lowest ash content was for the control sample, although all these values were higher than not only all the vegan and vegetarian recipes [31, 36], but also for meat products [37, 40]. It is worth noting that the ash content of these sausages was due to the contribution of the minerals that they could represent. This could also be related by the addition of psyllium fibres, because a rise in the fibre concentration resulted in higher ash content. This effect was stronger from the 5% concentration with PP fibre addition, because significant differences were observed between 5 and 6% of the PP fibres, and between 5 and 6% of fibres PH and PW (p < 0.05).

A concentration-used fibre interaction was observed for carbohydrates content. The sample with the lowest carbohydrate content was the control, and carbohydrate content rose as the fibre concentration increased. This increase was greater when PW fibre was added. Therefore, the 5% and 6% PW samples had the highest carbohydrate content, with no significant differences between them (p > 0.05). Nevertheless, the 5% and 6% concentrations of samples PH and PW obtained significantly lower values than the PW samples (p < 0.05).

Water activity, water release, and pH

The water activity, water release, and pH of the plant-based sausages are listed in Table 3. Nasonova and Tunieva [41] indicated that using fat replacer did not significantly affect aw. The results observed in this study also affirmed that a meat-free sausage can display a similar water activity to both meat sausages and sausages formulated with fat replacers. This parameter is vital for food microbial stability. One good result was that the aw of all the studied samples was slightly lower than the results reported by Stephan et al. [36] for different vegan and vegetarian sausages, and those in Wang et al. [38] for sausages formulated with L. edodes as a fat replacer.

The water release of the samples with added psyllium fibres came close to those obtained by Majzoobi et al. [31] for meat-free sausages with different hydrocolloid levels. The water release value was significant for the control sample (p < 0.05). As water release correlates negatively with water-holding capacity, a lower water release value is considered a desirable characteristic in sausages [31], because it can result in a product’s better texture and quality. The present study found an increase in the concentration of the three tested psyllium fibres (PH, PP, and PW), which resulted in decreased water release, which means and water-holding capacity. It is a well-known fact that dietary fibres possess technological functions, such as water absorption and water retention [15, 18].

The range of pH values went from 5.89 to 6.56 (Table 3). A concentration-added fibre interaction took place, and increasing the concentration of all the tested added fibres led to a higher pH for sausages. This increase was greater for fibres PH and PP because of the significant differences between the 6% PP and PH samples and the PW 6% sample (p < 0.05). The pH values in the sausages with the added psyllium fibres were comparable to not only those obtained by Majzoobi et al. [31] for meat-free sausages with different hydrocolloid levels, but also to those found by Stephan et al. [36] for vegetarian sausage analogues and meat sausages like German boiled sausages. Jridi et al. [42] and Majzoobi et al. [31] reported slightly lower pH when adding hydrocolloids. On the contrary, pH increased in our study, which could be due to the pH of the psyllium fibres being between 5.10 and 6.14 [18].

Colour measurement

Table 4 depicts the colour parameters of the psyllium fibre samples. The sample with the significantly highest lightness (L*) value was the PW fibre (p < 0.05). Redness (a*) and yellowness (b*) also significantly differed among the three samples, and the PP fibre obtained the highest a* and b* (p < 0.05). According to Bodart et al. [43], colour differences (ΔE1 and ΔE2) among all samples were humanly appreciable, over 3, and the biggest colour difference was between fibre samples PP and PW.

The colour parameters of our sausage samples appear in Table 5. Figure 1 shows the sausage samples herein prepared. For external colour, the samples with the highest lightness (L*) values were the control and the samples with less added fibre. Adding fibres influenced colour, and the L* values significantly lowered with increasing fibre content. A fibre addition–concentration interaction took place internally and externally as the PP fibre addition more intensely lowered L*. This could be related to the colour of the PP fibre sample which had the highest darkness value (Table 4). These results are comparable to those obtained by Grasso et al. [37], who added sunflower seeds to frankfurters as a fat replacer. Those authors also reported a drop in L* when adding sunflower seeds.

Our redness (a*) values were lower than those reported by Stephan et al. [36] for the vegetarian sausage analogue, but similar to the meat-free sausages made with different gums by Majzoobi et al. [31]. The plant-based sausages with less a* were those samples to which PP fibre was added, but with small differences between samples and the control for all the tested samples for both external and internal colours. In this case, the fibre with the highest a* was PP (Table 4). This result in sausages could be due to a colour change that occurred during cooking and could also be related to the interaction with other sausage ingredients.

The sample with the highest external yellowness (b*) value was the control sausage. A fibre–concentration interaction was observed both internally and externally, and a b* lowered when fibre concentration increased. The drop in the b* value was significantly more marked at the PP fibre concentrations of 4%, 5%, and 6% (p < 0.05). However, the b* value of the PP fibre was the highest (Table 4), which was also the case with the a* value. No significant differences were observed between the samples with 4% and 5% of fibres PW and PH (p > 0.05), but significant differences appeared between the samples with 6% of fibres PW and PH (p < 0.05). These results were slightly higher than those reported by Stephan et al. [36] for vegan sausage analogues, but are comparable to those obtained by Wang et al. [38] for sausages with pork lean meat replaced with L. edodes.

ΔE1 was performed to observe the differences between internal and external colours at each concentration (Table 5). These results generally showed that ΔE1 was higher with a rising fibre concentration, but only for PH 3%, PH 6%, and PP 6% [43].

Figure 2a and b depicts the colour differences (ΔE2) between addition of fibres and the control (internal and external colours). They show that ΔE2 generally increased as the fibre concentration rose. Fibre samples PP had a higher ΔE2 from the 3% concentration (see Fig. 1). However, the samples with a lower ΔE2 value were those formulated with the PW fibre, which was perceptible only at the 5% and 6% concentrations, because the ΔE2 values were above 3 (see Fig. 1) [43]. It should be noted that colour differences were bigger superficially than internally, except for the plant-based sausages with 5% and 6% PH. This could be due to the shape and particle size of the husk fibre (PH), as reported by Noguerol et al. [18]. Authors like Grasso et al. [37], Pintado et al. [44], and Henning et al. [45] have also stated colour alteration when adding different fibres and fat replacers in frankfurters. For all these reasons, and according to Deliza et al. [46], adding fibre minimises colour differences in the food matrix, which is important for avoiding possible consumer rejection, because liking food with an appropriate appearance could favour consumers’ healthier product consumption.

Textural properties

Table 6 indicates the effect of adding different P. ovata fibres levels on the textural attributes of the plant-based sausages. The control sausage obtained the lowest values for all the studied parameters, except adhesiveness. This finding implies that adding psyllium fibres modifies products’ mechanical properties. As for the force required to cut a sausage, the samples with the highest firmness and hardness values were those made with the PW fibre. A concentration–fibre interaction occurred for hardness, cohesiveness, resilience, and chewiness as a higher content of the fibre samples assumedly increases these parameters. With hardness, the increase was significantly greater when PW fibre was added at all the concentrations (p < 0.05). Significant differences were observed for cohesiveness, resilience, and chewiness among all the plant-based sausages (p < 0.05), and adding the PW fibre resulted in significantly higher values for all the studied concentrations of these parameters (p < 0.05). Table 7 depicts the Pearson correlation among mechanical properties (TPA) and physicochemical parameters and carbohydrates’ content. Significant Pearson correlations were observed among carbohydrate content and hardness, cohesiveness, resilience, and chewiness. This result indicates that adding psyllium fibres modifies the textural parameters of sausages. Significant negative correlations were found between the water release and TPA parameters (hardness, cohesiveness, resilience, and chewiness) (Table 7). Hence, plant-based sausage texture is related to the water-holding capacity of added fibres.

All the samples obtained similar springiness values, although significant differences were found among the plant-based sausages (p < 0.05). Stephan et al. [36] reported similar elasticity values for both meat and meat-free sausages, whereas Kamani et al. [12] indicated that non-meat proteins could hold more water and fat, which reduces springiness. Therefore, fibre content could also be included in this statement based on the results herein obtained. However, the elasticity values of Majzoobi et al. [31] for meat-free sausages were slightly higher, but the hardness values of meat-free sausages with xanthan were similar to the samples with PW fibre at the 4%, 5%, and 6% concentrations. According to Grasso et al. [37], sausages’ textural behaviour can be related to composition (mainly protein and fibre content), but, in this case, we examined the mechanical properties of plant-based sausages.

Microstructure

To visualise the structure of the plant-based sausages, the lowest (3%) and highest (6%) concentrations of each psyllium fibre type were selected, as well as the control sample. No differences were found in the microstructural observation between both concentrations. Images correspond to the 6% concentration.

Figures 3 and 4 show the distribution of the ingredients in the plant-based sausages studied by CLSM (confocal scanning laser microscopy). Polysaccharides, such as vegetal walls and fibre, were observed in blue by staining agent Calcofluor (Fig. 3). A very complex matrix is observed in the first row; vegetal tissue, probably from chickpea flour, and is dispersed among the matrix, together with partially gelatinised potato starch granules and oil droplets. Although the different psyllium fibres were not clearly identified, probably because psyllium interacted with other components in the matrix, its presence increased the consistency of the continuous phase, as reflected by the different firmness and hardness values (Table 6). Moreover, Yao et al. [47] indicated that the moisture content had a profound effect on fibre formation, showing that meat analogues extruded at 60.11% moisture had well-defined fibre orientation. Similar value to that shown in this study for sausages made with 5 and 6% PW (Table 2). Stained cell walls surrounding chickpea starch granules are observed in Fig. 3 (second row).

Starch granules and protein were red-stained with staining agent Rhodamine (Fig. 4). Protein is observed in the background and is less intensely stained. In all the samples, potato starch granules are larger and more gelatinised than chickpea granules, which are smaller and surrounded by cell walls. The plant-based sausages with PH fibre showed the most packed and least gelatinised chickpea starch granules, perhaps because PH fibre had the highest WHC and WRC values [18], which means less water available to hydrate starch. Beikzadeh et al. [48] indicated that some gums prevent starch granules from swelling, chain gums avoid the interaction between starch polymers, and also between protein and starch, and results in product texture softening. This falls in line with the results obtained in the present study, because the sausages made with PH fibre had lower firmness values (Table 6). The control and PP sausages presented a similar structure to the PH samples. However, the PW sausages showed the most deformed, broken, and loose chickpea starch granules. In fact, the chickpea tissue in the formulation with PW appeared disintegrated and, consequently, starch granules were more swollen and freely interacted with other matrix components. This might indicate that PW fibre retains less water and the PW samples would have more water available to interact with other components and, therefore, chickpea starch would develops more, which would makes it more gelatinised.

Consequently, this could correlate with samples’ hardness, and the sausages that contained the PW fibre were those with the highest firmness, hardness, and chewiness values (Table 6).

Figure 5 shows the structure of the plant-based sausages using Cryo-FESEM. Once again, a complex matrix was observed with gelatinised potato starch in the matrix (first row). Details of the chickpea starch granules (second row) confirm that granules were packed and almost intact in both the control and PH and PP samples. This was not the case with the PW samples, where the chickpea cell tissue breakdown and granules gelatinisation were once again observed.

Sensory analysis

Figure 6 shows samples’ sensory attributes. The sensory panel gave lower colour and visual aspect scores to the samples made with PP fibre than the samples prepared with fibres PH and PW (Fig. 6a). The samples with the PW fibre scored the best and were perceived to be more similar to the control sample. This scenario could be related to the colour parameters of the fibre and sausage samples (Tables 3 and 4, respectively), where the darkest fibre sample was PP, and the plant-based sausages with lower L*, a*, and b* values were also those made with PP fibre. The highest ΔE2 values were between the control sample and the sausages with PP, generally at high concentrations (5% and 6%) (Fig. 2). This result was expected, because they confirmed that marked colour changes can imply rejection, as indicated by Deliza et al. [35].

Regarding the texture of the plant-based sausages (Fig. 6b), the samples with high juiciness values were the control, PW 3%, PW 5%, PH 5%, PP 3%, and PP 4%. However, samples PW 3% and PW 4% were evaluated as the gummiest samples. The sample with the highest chewiness value was PW 6%, because this parameter was analysed by a TPA (Table 6). Consequently, these results revealed that samples PW 3%, 4%, 5%, and 6% and PP 3% and 6% offered a generally good texture. It was concluded that this texture must be improved to achieve a similar texture to meat products, because it is known that meat replacers or avoiders do not improve product texture, and texture is one of the main reasons why omnivores reject such products.

Finally, the overall acceptability values of the 4% and 6% PW plant-based sausages were higher than for the other samples (Fig. 6c). These PW fibre concentrations seemed suitably desirable, which indicates that this fibre would be acceptable for preparing plant-based sausages, although further research is recommended to improve texture.

Limitations

As these are products mainly address those consumers who wish to reduce or avoid meat consumption, a sensory analysis should be carried out with this diet type. Noguerol et al. [3] indicated that product texture is less important for vegan and vegetarian consumers than for omnivores.

Moreover, in the present study, only psyllium fibres were used as gum to modify texture. General aspect, colour, and gummies were the attributes with the highest scores (> 6 on a scale from 0 to 9). Thus, future studies should include a combination with other ingredients in an attempt to improve general texture.

Conclusions

The plant-based sausages made in this study had high ash and carbohydrate contents due to the addition of P. ovata fibres. Above all, a lower fat content can be highlighted compared to other meat and meat-free sausages. The use of psyllium fibres also increases the water-holding capacity which, as herein observed, improves the texture of plant-based sausages. However, chewability and colour changes could pose major problems for these sausages. The results of this study show that employing PW fibre can minimise these problems, because hardness and chewiness increase and colour changes are almost imperceptible compared to the control. However, PP fibre is rejected, particularly for the colour it confers sausages. The sensory evaluation showed that these three fibres can be used to prepare plant-based sausages. Moreover, PW fibre can be highlighted for obtaining the overall best score and for the fewest colour changes. Nevertheless, it would be desirable for future studies to research with other fibres, gelling agents, or their combination, to improve the texture and acceptability of these plant-based sausages.

References

Chen C, Chaudhary A, Mathys A (2019) Dietary change scenarios and implications for environmental, nutrition, human health and economic dimensions of food sustainability. Nutrients 11(4):856

Lantern study, The Green Revolution, Lantern (2019). https://uploads-ssl.webflow.com/5a6862c39aae84000168e863/5fbd3c9339a23b21188c2bcd_2019_Low_TheGreenRevolution.pdf. Retrieved Nov 2021

Noguerol AT, Pagán MJ, García-Segovia P, Varela P (2021) Green or Clean? Perception of clean label plant-based products by omnivorous, vegan, vegetarian and flexitarian consumers. Food Res Int. https://doi.org/10.1016/j.foodres.2021.110652

Müller P (2020) Vegan diet in young children. Glob Landsc Nutr Chall Infants Child 93:103–110

Ministry of Agriculture, Fisheries and Food, Informe del consumo alimentario en España, 2018. https://www.mapa.gob.es/images/es/20190807_informedeconsumo2018pdf_tcm30-512256.pdf. Retrieved Nov 2021

Segovia-Siapco G, Burkholder-Cooley N, Haddad Tabrizi S, Sabaté J (2019) Beyond meat: a comparison of the dietary intakes of vegetarian and non-vegetarian adolescents. Front nutr 6:86

Viguiliouk E, Kendall CW, Kahleová H, Rahelić D, Salas-Salvadó J, Choo VL, Mejia SB, Stewart SE, Leiter LA, Jenkins DJA, Sievenpiper JL (2019) Effect of vegetarian dietary patterns on cardiometabolic risk factors in diabetes: a systematic review and meta-analysis of randomized controlled trials. Clin nutr 38(3):1133–1145

Sneijder P, Te Molder H (2009) Normalizing ideological food choice and eating practices Identity work in online discussions on veganism. Appetite 52(3):621–630

Elzerman JE, Hoek AC, Van Boekel MA, Luning PA (2011) Consumer acceptance and appropriateness of meat substitutes in a meal context. Food Qual Prefer 22(3):233–240

Smetana S, Mathys A, Knoch A, Heinz V (2015) Meat alternatives: life cycle assessment of most known meat substitutes. Int J Life Cycle Assess 20(9):1254–1267

FAO (1992) Meat and meat products in human nutrition in developing countries. Food and Agriculture Organization of the United Nations. Bender A, ISBN: 92-5-103146-0

Kamani MH, Meera MS, Bhaskar N, Modi VK (2019) Partial and total replacement of meat by plant-based proteins in chicken sausage: evaluation of mechanical, physico-chemical and sensory characteristics. J Food Sci Technol 56(5):2660–2669

Hoek AC, van Boekel MA, Voordouw J, Luning PA (2011) Identification of new food alternatives: how do consumers categorize meat and meat substitutes? Food Qual Prefer 22(4):371–383

Malav OP, Talukder S, Gokulakrishnan P, Chand S (2015) Meat analog: a review. Crit Rev Food Sci Nutr 55(9):1241–1245

Han M, Bertram HC (2017) Designing healthier comminuted meat products: effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci 133:159–165

Rosell CM, Santos E, Collar C (2009) Physico-chemical properties of commercial fibres from different sources: a comparative approach. Food Res Int 42(1):176–184

Ren Y, Linter BR, Foster TJ (2020) Cellulose fibrillation and interaction with psyllium seed husk heteroxylan. Food Hydrocoll 104:105725

Noguerol AT, Igual M, Pagán MJ (2022) Developing psyllium fibre gel-based foods: physicochemical, nutritional, optical and mechanical properties. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2021.107108

Franco EAN, Sanches-Silva A, Ribeiro-Santos R, de Melo NR (2020) Psyllium (Plantago ovata Forsk): from evidence of health benefits to its food application. Trends Food Sci Technol 96:166–175

Belorio M, Marcondes G, Gómez M (2020) Influence of psyllium versus xanthan gum in starch properties. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2020.105843

Ren Y, Yakubov GE, Linter BR, MacNaughtan W, Foster TJ (2020) Temperature fractionation, physicochemical and rheological analysis of psyllium seed husk heteroxylan. Food Hydrocoll 104:105737

Osheba AS, Hussien SA, El-Dashlouty AA (2013) Evaluation of some vegetal colloids on the quality attributes of beef sausage. Adv J Food Sci Technol 5(6):743–751

Mehta N, Ahlawat SS, Sharma DP, Dabur RS, Yadav S (2016) Optimization and quality evaluation of dietary fiber rich chicken meat rolls incorporated with psyllium husk. Fleischwirtschaft Int 3:65–69

Aleshkov A, Zhebo A, Burik M, Ivashkin M (2020) Technology and characteristics of boiled sausages enriched with dietary fibers of plantago psyllium l. Biointerface Res Appl Chem 10(4):5715–5723

Mehta NITIN, Ahlawat SS, Sharma DP, Yadav SANJAY, Arora DEVAN (2013) Development and quality evaluation of chicken patties incorporated with psyllium husk. Haryana Vet 52(2):6–11

Kausar T, Kausar MA, Khan S, Haque S, Azad ZR (2021) Optimum additive composition to minimize fat in functional goat meat nuggets: a healthy red meat functional food. Processes 9(3):475

Wittek P, Ellwanger F, Karbstein HP, Emin MA (2021) Morphology development and flow characteristics during high moisture extrusion of a plant-based meat analogue. Foods 10(8):1753

Kendler C, Duchardt A, Karbstein HP, Emin MA (2021) Effect of oil content and oil addition point on the extrusion processing of wheat gluten-based meat analogues. Foods 10(4):697

Caporgno MP, Böcker L, Müssner C, Stirnemann E, Haberkorn I, Adelmann H, Handschin H, Windhab EJ, Mathys A (2020) Extruded meat analogues based on yellow, heterotrophically cultivated Auxenochlorella protothecoides microalgae. Innov Food Sci Emerg Technol 59:102275

Noguerol AT, Gozalbes A, Pagán MJ (2022) Development of a plant-based spread with psyllium: effect on physico-chemical, nutritional, functional and mechanical properties (Submitted)

Majzoobi M, Talebanfar S, Eskandari MH, Farahnaky A (2017) Improving the quality of meat-free sausages using κ-carrageenan, konjac mannan and xanthan gum. Int J Food Sci Technol 52(5):1269–1275

AOAC (2000) Official methods of analysis. Association of Official Analytical Chemist, Volume I, agricultural chemicals, contaminants, drugs, edited by W. Horwitz. Association of Official Analytical Chemists, Washington, DC

AOCS (2005) Official procedure approved procedure Am 5-04. Rapid determination of oil/fat utilizing high temperature solvent extraction. American Oil Chemists Society, Urbana, IL

AOAC (2002) Official methods of analysis of AOAC international, 16th edn. AOAC International, Gaithersburg

Jin SK, Kim SH, Choi JS, Yim DG (2019) Effect of diverse binder materials and their addition levels on physico-chemical characteristics of sausages. J Food Meas Charact 13(2):1558–1565

Stephan A, Ahlborn J, Zajul M, Zorn H (2018) Edible mushroom mycelia of Pleurotus sapidus as novel protein sources in a vegan boiled sausage analog system: functionality and sensory tests in comparison to commercial proteins and meat sausages. Eur Food Res Technol 244(5):913–924

Grasso S, Pintado T, Pérez-Jiménez J, Ruiz-Capillas C, Herrero AM (2020) Potential of a sunflower seed by-product as animal fat replacer in healthier Frankfurters. Foods 9(4):445

Wang L, Guo H, Liu X, Jiang G, Li C, Li X, Li Y (2019) Roles of Lentinula edodes as the pork lean meat replacer in production of the sausage. Meat Sci 156:44–51

Rather SA, Masoodi FA, Akhter R, Rather JA, Gani A, Wani SM, Malik AH (2016) Application of guar–xanthan gum mixture as a partial fat replacer in meat emulsions. J Food Sci Technol 53(6):2876–2886

Sousa SC, Fragoso SP, Penna CR, Arcanjo NM, Silva FA, Ferreira VC, Barreto MD, Araújo ÍB (2017) Quality parameters of frankfurter-type sausages with partial replacement of fat by hydrolyzed collagen. LWT 76:320–325

Nasonova VV, Tunieva EK (2019) A comparative study of fat replacers in cooked sausages, In IOP Conference Series: Earth and Environmental Science (Vol. 333, No. 1, p. 012085), IOP Publishing

Jridi M, Abdelhedi O, Souissi N, Kammoun M, Nasri M, Ayadi MA (2015) Improvement of the physicochemical, textural and sensory properties of meat sausage by edible cuttlefish gelatin addition. Food Biosci 12:67–72

Bodart M, de Peñaranda R, Deneyer A, Flamant G (2008) Photometry and colorimetry characterisation of materials in daylighting evaluation tools. Build Environ 43(12):2046–2058

Pintado T, Herrero AM, Jiménez-Colmenero F, Ruiz-Capillas C (2016) Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci 114:75–84

Henning SSC, Tshalibe P, Hoffman L (2016) Physico-chemical properties of reduced-fat beef species sausage with pork back fat replaced by pineapple dietary fibres and water. LWT 74:92–98

Deliza R, Saldivar SS, Germani R, Benassi VT, Cabral LC (2002) The effects of colored textured soybean protein (TSP) on sensory and physical attributes of ground beef patties. J Sens Stud 17(2):121–132

Yao G, Liu KS, Hsieh F (2004) A new method for characterizing fiber formation in meat analogs during high-moisture extrusion. J Food Sci 69(7):303–307

Beikzadeh S, Peyghambardoust S, Homayouni RA, Beikzadeh M (2017) Effects of psyllium and marve seed mucilages on physical, sensory and staling properties of sponge cake. J Agric Sci Technol 19:1079–1089

Acknowledgements

The authors acknowledge the financial support of the Generalitat Valenciana (programme FDEGENT 2018) and the company Productos Pilarica S.A. (Paterna, Spain).

Author information

Authors and Affiliations

Contributions

ATN: conceptualization, methodology, investigation, formal analysis, software, data curation, and writing—original draft. VL: methodology, investigation, formal analysis, data curation, and writing—original draft. MJP: conceptualization, writing—review and editing, funding acquisition, project administration, resources, supervision, and validation.

Corresponding author

Ethics declarations

Conflict of interest

John Smith declares that he has no conflict of interest. Paula Taylor has received research grants from Company A. Mike Schultz has received a speaker honorarium from Company B and owns stock in Company C.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Additional informed consent was obtained from all patients for which identifying information is included in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Noguerol, A.T., Larrea, V. & Pagán, M.J. The effect of psyllium (Plantago ovata Forsk) fibres on the mechanical and physicochemical characteristics of plant-based sausages. Eur Food Res Technol 248, 2483–2496 (2022). https://doi.org/10.1007/s00217-022-04063-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04063-2