Abstract

This investigation is aimed at developing a new cereal-based product, with increased nutritional quality, by using Bifidobacterium pseudocatenulatum ATCC 27919 as starter in whole wheat sourdough fermentation and evaluating its performance. Four different sourdough levels (5%, 10%, 15%, and 20% on flour basis) in bread dough formulation were analysed. The effects of the use of bifidobacteria in sourdough bread were comparatively evaluated with controls (yeast and/or chemically acidified sourdough with antibiotics). The sourdough and dough fermentative parameters analysed were pH, total titratable acidity, d/l-lactic and acetic acids. Bread performance was evaluated by specific volume, slice shape, crumb structure and firmness, crust and crumb colour, pH, total titratable acidity, and d/l-lactic and acetic acids, phytate, and lower myo-inositol phosphate contents. The sourdough breads showed similar technological quality to the control sample, with the exception of specific bread volume (decreased from 2.46 to 2.22 mL/g) and crumb firmness (increased from 2.61 to 3.18 N). Sourdough inoculated with bifidobacteria significantly increased the levels of organic acids in fermented dough and bread. The Bifidobacterium strain contributed to the fermentation process, increasing phytate hydrolysis during fermentation owing to the activation of endogenous cereal phytase and its own phytase, resulting in bread with significantly lower phytate levels (from 7.62 to 1.45 μmol/g of bread in dry matter). The inclusion of sourdough inoculated with bifidobacteria made possible the formulation of whole wheat bread with positive changes in starch thermal properties and a delay and decrease in amylopectin retrogradation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cereal grains are grown in greater quantities and provide more food energy worldwide than any other type of crop. Cereal foods produced and consumed in different ways are an essential component of daily diet. Health experts advise that whole grains are a healthy necessity in every diet, the consumption of at least half of the cereal servings as whole grains being the recommendation for adults (Whole Grains Council, USA). Epidemiological findings have indicated a protective role of whole grain foods against several diseases. Medical evidence clearly shows that whole grains reduce risks of certain diseases such as colorectal cancer, type 2 diabetes, coronary heart disease and obesity (Pereira et al., 2002; Mellen et al., 2008). Cereal goods, especially whole grain products, are source of fibre, vitamins, minerals and other biologically active compounds as phenolic compounds, lignans, phytosterols, tocopherols, tocotrienols and phytic acid, and processing may modify the amount and bioavailability of some of them (Slavin, 2004; Katina et al., 2005). In fact, the whole grain or fractions of cereal grain could be modified by sourdough fermentation to improve nutritional value or promote healthiness of cereal by-products (Katina et al., 2005). The use of sourdough is a common practice in many countries around the world. Sourdough fermentation can modify the flavour of products, stabilise or increase levels of various bioactive compounds, retard starch bioavailability, extend the shelf life of bread and improve mineral bioavailability (Katina et al., 2005). Texture, taste and smell of bread are the main characteristics taken into account by consumers to determine its quality. In this sense, there are numerous examples of improved texture and palatability in sourdough fermentation processes due to peptide, lipid and carbohydrate metabolism (Thiele et al., 2002; Gänzle et al., 2007). Although sensory quality is the basis for any successful bakery product, consumers are aware of nutrition/health interactions and consequently society demands healthier and more nutritious foods. The effect of sourdough and cereal fermentation could enhance delivery of nutrients to the bloodstream (Poutanen et al., 2009). As was mentioned above, sourdough has great potential to modify the digestibility of starch, lowering the glycemic index of the products mainly due to increased lactic and acetic acid levels (Katina et al., 2005; De Angelis et al., 2009). Whereas lactic acid lowers the rate of starch digestion in bread, acetic acid would delay the gastric emptying rate (Liljeberg et al., 1995; Liljeberg & Björck, 1998).

On the other hand, phytic acid (myo-inositol [1,2,3,4,5,6]-hexakisphosphate, InsP 6) or phytates (its salts), which are considered to be the major factor causing negative effects on mineral uptake in humans and animals, is a precursor of generation of bioactive compound (Fretzdorff & Brümmer, 1992; Lopez et al., 2001; Nielsen et al., 2007; Haros et al., 2009). The phytates are capable to form complexes that strongly reduce the absorption of many minerals as iron, zinc, calcium, magnesium, manganese and copper (Lopez et al., 2002; Konietzny & Greiner, 2003). However, the phytate hydrolysis decreases the negative effects on mineral absorption and generates lower myo-inositol phosphates that have been suggested to be compounds with specific biological activity and may positively affect human health (Shi et al., 2006; Haros et al., 2009). The phytase is the enzyme that catalyses the hydrolysis of InsP 6 to a mixture of myo-inositol pentakis-, tetrakis-, tri-, di-, monophosphates (InsP 5, InsP 4, InsP 3, InsP 2, InsP 1, respectively) and orthophosphate. The reduction of InsP 6 content during the breadmaking process depends on phytase action, which in turn depends on many factors including bran content, pH, temperature, water content, particle size distribution, fermentation time, exogenous phytase addition and process (Haros et al., 2001; Lopez et al., 2002; Sanz Penella et al., 2008, 2009; Rosell et al., 2009). The cereal has an endogenous phytase, which its optimal pH of action is around 4.5 in wheat and rye doughs; hence, the use of sourdough or acidified sponges increases the InsP 6 hydrolysis (Fretzdorff & Brümmer 1992; Lopez et al., 2001; Reale et al., 2004). Phytases could be produced by a wide range of plants, bacteria and fungi; and some of them are commercially used for animal nutrition, although are not considered of food grade (Haros et al., 2009). It was reported that strains of Bifidobacterium show phytase activity, suggesting their possible utility in producing bakery products (Haros et al., 2005, 2007). Sanz Penella et al. (2009) investigated the use of bifidobacteria with high phytate-degrading activity as starter cultures in two formulations of bread (100% and 50% of whole wheat flour) resulting in breads with significantly lower levels of phytates. Palacios et al. (2008) investigated the use of Bifidobacterium strains as starter during long fermentation process of whole wheat dough, which showed a good adaptation to the dough ecosystem and contributed to different acidification degrees promoting the phytate hydrolysis. Many new interesting applications for sourdough still remain to be explored, such as the use of Bifidobacterium starter cultures for improving phytate hydrolysis, or the production of organic acids and novel bioactive compounds. This research is aimed at developing new cereal-based products of increased nutritional quality and containing lower amounts of InsP 6, by using bifidobacteria of human origin, Bifidobacterium pseudocatenulatum ATCC27919, as a starter in whole wheat sourdough fermentation.

Materials and Methods

Materials

Commercial Spanish whole wheat flour was purchased from the local market. The characteristics of flour were (grammes per kilogramme in dry matter): moisture 141.6 ± 0.3, protein (N × 5.7) 111.7 ± 0.6, lipids 17.6 ± 0.2 and ash 8.4 ± 0.1. Compressed yeast (Saccharomyces cerevisiae, Levamax, Spain) was used as a starter for the breadmaking process, whereas B. pseudocatenulatum ATCC 27919, originally isolated from faeces of infants, was used as starter in sourdough fermentation.

Microbial Growth Conditions

Bifidobacteria were grown in Garche broth in which inorganic phosphate (K2HPO4 and NaH2PO4) was replaced by 0.74 g/L phytic acid dipotassium salt (Sigma-Aldrich, St. Louis, MO, USA) and 0.1 M 3-[N-morpholino] propanesulphonic/acid buffer (Sigma-Aldrich, St. Louis, MO, USA; Haros et al., 2007). The medium was inoculated at 5% (v/v) with 18-h old cultures, previously propagated under the same conditions. Cultures were incubated at 37°C in anaerobic conditions (AnaeroGen™, Oxoid, England) until the beginning of the stationary phase of growth (∼14–18 h). Bacterial cells were harvested by centrifugation (10,000×g, 15 min, 4°C, Sorvall RC-5B, DuPont Instruments), washed twice, and suspended in 0.085% NaCl solution (Sanz Penella et al., 2009). The obtained cell suspensions were used to inoculate the sourdough. Microbial counts in sourdough and dough samples were determined by plate count on selective media. Sourdough and dough samples from each formulation (1 g) were homogenised with 9 mL of peptone water (Scharlau Chemie, Barcelona, Spain), serially diluted, and plated on agar. Bifidobacteria counts were determined after sourdough incubation and dough fermentation periods in Garche agar, using the double-layer technique, after anaerobic incubation at 37°C for 48 h (Haros et al., 2005). Yeast counts were determined in Rose Bengal Agar (Scharlau Chemie, Barcelona, Spain) after aerobic incubation at 30°C for 72 h (Sanz Penella et al., 2009).

Breadmaking Process

The control bread dough formula consisted of whole wheat flour (500 g), compressed yeast (2.5% flour basis), sodium salt (1.8% flour basis), tap water (up to optimum absorption, 500 Brabender Units, 65.0%) and ascorbic acid (0.01% flour basis). The ingredients were mixed for 4.5 min, rested for 10 min, divided (100 g), kneaded and then rested (15 min). Doughs were manually sheeted and rolled, proofed (up to optimum volume increase, at 28°C, 85% relative humidity), and baked (165°C, 30 min) according to Haros et al. (2001).

Whole wheat sourdough without yeast were prepared and added in five levels to bread doughs formula, 0%, 5%, 10%, 15% and 20% in flour basis (control, WDS-5, WDS-10, WDS-15 and WDS-20, respectively). The sourdough formulation consisted in a mixture of flour and water (1:2, v/v) with an inoculum ∼5.5 × 108 CFU of B. pseudocatenulatum per gramme of flour, incubated for 18 h at 37°C in anaerobic conditions. The control acid sourdough consisted of the same formulation and conditions as described above without the addition of Bifidobacterium strain, including a mixture of antibiotics at 1% v/v (penicillin, 50 U/mL; streptomycin, 0.05 mg/mL; neomycin, 0.1 mg/mL; and cycloheximide, 0.5 mg/mL from Sigma-Aldrich Steinheim, Germany). The control acid sourdough pH was adjusted at 4.17 with a mixture of lactic and acetic acids (1:2 v/v), to reach the same pH of sourdough biologically acidified with using bifidobacteria. Fermentation was monitored by measuring pH, temperature and volume increase of the dough at regular period times. After the fermentation step, doughs were baked in an electric oven and cooled at room temperature for 75 min for their subsequent analysis (Sanz Penella et al., 2009).

Bread Performance

The technological parameters analysed were: loaf specific volume (cubic centimetre per gramme), width/height ratio of the central slice or slice shape (centimetre/centimetre), moisture content (percent) and crumb firmness, determined by a texture profile analysis using the Texture Analyser TA-XT Plus (Stable Micro Systems, Surrey, UK; Sanz Penella et al., 2009). Each parameter was measured at least per triplicate.

Digital image analysis was used to measure the bread crumb structure. Images were previously squared at 240 pixels per centimetre with a flatbed scanner (HP ScanJet 4,400 C, Hewlett Packard, USA) supported by the HP PrecisionScan Pro 3.1 Software. Two 10 × 10 mm squares field of view of central slice (10-mm thick) of each of three loaves were used, thereby yielding six digital images per baking. Data was processed using Sigma Scan Pro Image Analysis Software (version 5.0.0, SPSS Inc., USA). The crumb grain features chosen were: cell area/total area, square centimetre/square centimetre; wall area/total area, square centimetre/square centimetre; number of cells per square centimetre; and mean cell area, square millimetre (Sanz Penella et al., 2009).

The tristimulus colour parameters L* (lightness), a* (redness to greenness), and b* (yellowness to blueness) of the baked loaves (crumb and crust) were determined using a digital colorimeter (Chroma Meter CR-400, Konika Minolta Sensing, Japan), previously calibrated with the white plate supplied by the manufacturer. The instrument settings were illuminant C, display L* a* b*, and observer angle 10º. From the parameters determined, hue angle (h*), chroma (C*) and total colour difference (∆E*) were calculated by the equations: h* ab = arctan (b*/a*); C* ab = (a* 2 + b* 2)1/2; ∆E* = [(∆L*)2 + (∆a*)2 + (∆b*)2]1/2. Each sample was measured 18 times in different sample points to minimise the heterogeneity produced by the bran.

Initial InsP 6 concentration in whole wheat flour, InsP 6 residual amount and lower myo-inositol phosphates generated after fermentation and baking in bread were measured by using the high-pressure liquid chromatographic method described by Türk and Sandberg (1992), later modified by Sanz Penella et al. (2008).

Preliminary sensory analysis of fresh breads was performed by a panel of 20 non-trained tasters, who usually consume whole wheat bread, using a simple scale of acceptation (dislike very much, dislike, like, like very much).

Total Titratable Acidity (TTA) Determination, D/L-Lactic and Acetic Acids

Ten grammes of sourdough, dough or bread, blended with 100 mL of acetone/water (5:95, v/v) under constant agitation, were titrated against 0.1 N NaOH until a final pH of 8.5. The results were expressed as the volume (millilitre) of NaOH 0.1 N needed for titrating 10 g of sourdough, fermented dough or bread. Concentrations of d-lactic acid, l-lactic acid and acetic acid were analysed using the specific enzymatic methods of Boehringer Mannheim/R-Biopharm by UV method (Polar Star Omega BMG LABTECH, Germany). The results were expressed as μmoles of d/l-lactic or acetic acid per gramme of sourdough, fermented dough or bread.

Differential Scanning Calorimetry Analysis

The thermal properties of starch flour during the baking of fermented dough (gelatinization) and changes induced during the bread storage (amylopectin retrogradation) were carried out on a calorimeter (DSC-7, Perkin-Elmer). Indium (enthalpy of fusion 28.41 J/g, melting point 156.4°C) was used to calibrate the calorimeter. Fermented dough samples (30–40 mg) were weighted directly into differential scanning calorimetry (DSC) stainless steel pans (LVC 0319–0218, Perkin-Elmer) and hermetically sealed (Quick-Press, 0990–8467, Perkin-Elmer). Calorimeter scan conditions were used according to the methodology described by Leon et al. (1997), later modified by Sanz-Penella et al. (2010). Briefly, to simulate the temperature profile in the centre of the bread crumb during baking, the samples were kept at 30°C for 1 min, were heated from 30°C to 110°C at 11.7°C/min, were kept at this temperature until 5 min, and cooled to 30°C at 50°C/min. To analyse amylopectin retrogradation, heated-cooled pans were stored at 4°C for 0, 1, 2, 4, 7, 10 and 15 days, and heated again in the calorimeter from 30°C to 110°C, at 10°C/min (Sanz-Penella et al., 2010). An empty pan was used as a reference and three replicates of each sample were analysed.

The parameters recorded were onset temperature (T o), peak temperature (T p) and conclusion temperature (T c) of gelatinization and retrogradation. Straight lines were drawn between T o and T c, and the enthalpies associated with starch gelatinisation and retrogradation (ΔH g and ΔH r, respectively) were calculated as the area enclosed between the straight line and the endotherm curve. The enthalpies were expressed in Joules per grammes of dry matter.

Statistical Analysis

Multiple sample comparison of the means and Fisher’s least significant differences were applied to establish statistical significant differences between treatments. All statistical analyses were carried out with the software Statgraphics Plus 7.1 (Bitstream, Cambridge, MN) and differences were considered significant at p < 0.05.

Results and Discussion

Characteristics of Sourdough

The sourdough inoculated with bifidobacteria used in this study became more acidic at the end of the incubation period (from initial pH 5.4 to final pH 4.2) owing to fermentative activity of the microbial metabolism. As observed in the literature, the values of pH in ripe sourdoughs using typical starters such as Lactobacillus sanfranciscensis, Lactobacillus plantarum and/or Lactobacillus brevis can vary between 3.5 and 4.3, depending on the type of flour, the process and the starter cultures used (Collar et al., 1994; De Angelis et al., 2009; Thiele et al., 2002; Robert et al., 2006). During the incubation period there was a considerable production of organic acids (mainly acetic and lactic acids) reaching TTA values around 17.0 mL, with the production of lactic acid exclusively in its levorotatory form (Table 1). Robert et al. (2006) reported lower values of TTA in sourdoughs inoculated with L. plantarum or Leuconostoc sp. In the current study, the molar ratio between lactic and acetic acids was 0.37. It should be pointed out that acetic acid production is greater than lactic acid production in bifidobacteria. This value corresponds to typical molar ratios found as the result of sugar catabolism in bifidobacteria, 0.40–0.70, mainly depending on the strain and the sugar (Van der Meulen et al., 2006). Metabolism of carbohydrates varies depending on the species of Bifidobacterium and even the strains, the type of soluble sugars and the processing conditions. The metabolite production for B. pseudocatenulatum after growing in synthetic medium containing different energy sources showed a molar ratio between 0.38 and 0.74 (results not shown). Although the optimum in industrial sourdough fermentation of wheat is considered around 2.5 (Röcken 1996; Hammes & Gänzle, 1998), this value can vary over wider ranges (Barber et al., 1991). Lactic and acetic acid production was considered the main reason for the decrease in the value of pH after sourdough fermentation. Lactic acid bacteria (LAB) counts showed 4.0 × 109 CFU per gramme of flour after the incubation period, which represented a considerable increase from the initial value. The LAB population was in the range of counts found in mature sourdoughs (Hammes et al., 2005; Robert et al., 2006). The pH value reached at the end of sourdough fermentation and the colony counts indicated that the inoculated bifidobacterial strain could adapt to the dough environment, increasing its viability.

Characteristics of Fermented Dough

The inclusion of sourdough in the bread formulation caused a significant decrease in the dough pH, from 5.38 to 4.57, as was expected (Table 1). However, the dough pH remained unchanged during the yeast fermentation process until the optimum volume increase was reached. Similar pH values were found by Collar et al. (1994) when sourdough was added in a proportion of between 10% and 25% on flour basis. Dough volume showed a constant increase during the fermentation period, reaching a maximum after approximately 60 min at 28°C. The presence of sourdough in the bread formulation did not significantly modify the optimum dough volume. However, the addition of sourdough to the formulation significantly increased the LAB counts (from 2.2 × 104 CFU/g to 1.1 × 107 CFU/g, control and WDS-20 samples, respectively), whereas the yeast counts remained almost constant (3.7–5.0 × 107 CFU/g). These LAB and yeast counts were consistent with previous reports shown by other authors (Palacios et al., 2006, 2008). TTA values in fermented dough ranged from 4.60 to 9.23, showing a constant and significant increase mainly due to the production of lactic and acetic acid during sourdough fermentation (Table 1). This highlights the considerable acidic production of the Bifidobacterium strain used in this study, which may be important for enhancing flavour and delaying bread staling. The d-lactic acid content decreased with the rise in the sourdough percentage added to the formulation, whereas the l-lactic and acetic acids presented a significant increase. The molar ratio between the d/l-lactic and acetic acids remained between 0.45 and 0.47 in all formulations with sourdough inoculated with bifidobacteria (Table 1). L. plantarum, L. brevis and Leuconostoc sp. were reported to produce greater amounts of lactic acid (5.5–13.3 μmol/g) than the culture used in this study, and lower amounts of acetic acid (1.66–5.82 μmol/g) in fermented dough made with sourdough (Collar et al., 1994; Robert et al., 2006).

Acidic Characteristics of Bread

TTA values in the bread were recorded from 4.19 to 10.60 (Table 1). These results were in the range found by other researcher in bread with sourdough inoculated with lactobacilli (Katina et al., 2009), although this parameter could vary over a wider range. The d/l-lactic and acetic acids showed the same tendency as was found in the fermented dough: the amount of d-lactic acid decreased with the increase in sourdough in the formulation, whereas the l-lactic and acetic acids showed an opposite behaviour (Table 1). L. plantarum and L. brevis resulted in lower acetic acid production (1.2–2.3 μmol/g) than the levels found in this study, whereas the amount of lactic acid was significantly higher, reaching values up to 40.9 μmol/g (Collar et al., 1994). The molar ratio between d/l-lactic and acetic acids registered an increase from 0.91 in the control sample to 1.29–1.45 with the addition of 15–20% of sourdough in the bread formula. During the breadmaking process, there is a weight loss, 95% of which is due to water evaporation and 5% due to organic acid loss, mainly in crust and outside crumb of the bread, the loss of acetic acid during baking being greater than that of lactic acid (Spicher, 1983). This greater loss of acetic acid was responsible for the increase in the molar ratio between the d/l-lactic and acetic acids of the bread compared with the values recorded in the fermented dough. It is important to note that the increase in the amount of these organic acids caused by the use of sourdough has been shown to lower the glycemic index of bread products (Liljeberg et al., 1995; Liljeberg & Björck, 1998).

Bread Performance

The effect of the addition of sourdough on bread quality was analysed (Table 2). In general, technological parameters did not show significant differences between samples. The loaf moisture ranged between 34.74 and 36.04 without significant changes. The sample with 20% sourdough content (WDS-20) showed a significantly lower loaf specific volume than the control, whereas the slice shape remained without significant differences, but tended to decrease (Table 2). There is considerable consensus with regard to the positive effects of the addition of sourdough on bread volume and crumb structure (Arendt et al., 2007). Despite this, Collar et al. (1994) developed lower volume breads when using a high percentage of sourdough with L. plantarum and L. brevis as starters. The acidification of the sourdough and partial acidification of the bread dough impact on structure-forming components like gluten and starch. During incubation of sourdough and dough fermentation, biochemical changes occur in the carbohydrate and protein components of flour owing to the action of microbial and endogenous enzymes. The possible proteolytic activity associated with the Bifidobacterium strain, which would take place during the incubation period of sourdough incubation and dough fermentation, would attack gluten-associated proteins and weaken the gluten network, leading to breads with a lower specific volume. This proteolytic activity has been observed in several lactobacilli strains found in different sourdoughs, which might contribute an improvement in bread flavour (Rollan et al., 2005).

The crumb textural profile of samples to which sourdough had been added showed no significant difference compared with the control (data not shown). However, the crumb firmness showed a constant increase from 2.61 in the control sample to 3.18 N in the formulation with 20% sourdough (Table 2). Increased firmness with addition of sourdough was at least partly due to the lower specific volume found in these samples. Softer breads were found after the inclusion of mature sourdough in the bread formulation, which might depend on the number of stages used in sourdough preparation (Barber et al., 1991).

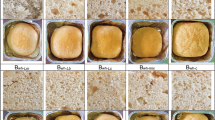

The parameters that describe crumb grain features did not show any significant difference between samples (Table 2). Despite this, the cell area and number of cells showed a slight correlation, with the value decreasing when a greater percentage of sourdough was added to the formulation (15–20%). The technological parameters (loaf specific volume, width/height ratio and firmness) could corroborate this tendency (Fig. 1). However, although these differences were statistically significant, they were unimportant in the sensory analysis (results not shown). The values of the mean cell area ranged from 0.95 to 1.32, with no differences appearing between breads made with sourdough and the control (without sourdough).

The effect of the addition of sourdough inoculated with bifidobacteria on the crust and crumb colour was determined (Table 3). Generally, the sourdough did not present significant changes in the crust or crumb colour of the bread in comparison to the control. The total colour difference in bread crust and crumb, which represents the total colour difference between the samples with sourdough and the control sample, was less than 5 units (from 0.67 to 3.16), indicating that no differences were detectable by visual observation. So, although some significant changes were recorded in a few colour parameters, they were not perceptible to consumers by visual observation (Fig. 1).

In general, the breads made with sourdough (5–15%) had high consumer acceptance (82–93% of tasters), but with lower scores than the control breads. Bread made with 20% sourdough showed the lowest degree of acceptance, mainly because of its higher acidity, being accepted by 40% of the tasters.

Degradation of Phytate and Generation of Lower Myo-inositol Phosphates

The phytate content in the control bread was reduced by 28% over baseline in the flour (Table 4). Its reduction and the generation of lower myo-inositol phosphates were mainly due to endogenous cereal phytase, since it is known that phytates decrease during the breadmaking process as a consequence of the activity of this enzyme (Haros et al., 2001). The addition of sourdough to the bread formula produced a significant decrease in the amount of InsP 6. This reduction was greater when the amount of sourdough increased in the formulation, from 7.62 μmol/g (control sample) to 1.45 μmol/g (WDS-20). Leenhardt et al. (2005) reported that slight acidification of dough (pH 5.5) with sourdough containing L. brevis allowed a significant phytate breakdown, up to 70% of the initial flour content compared with 40% in the control sample. Sourdough fermentation with a multi-species starter including L. plantarum and Lactobacillus mesenteroides was more efficient than yeast fermentation in reducing phytate content in whole wheat bread, reaching values around 25% hydrolysis after 1 h of fermentation (Lopez et al. 2001).

The acidified control, which was supplemented by the amount of acids (lactic and acetic acids) required to mimic the pH reached by sourdough fermented by bifidobacteria, showed an intermediate concentration of InsP 6 (Table 4). This indicated that the endogenous phytase was also activated by the reduction of pH during the fermentation period. As mentioned above, the addition of sourdough produced a decrease in pH from 5.38 (control dough) to 4.57 (WDS-20). A similar observation was obtained in the dough with 20% acid control sourdough, which reached a pH of 4.58. Given that endogenous phytase acts during the breadmaking process and its optimum pH is around 4.1–4.5, acidification of dough due to microbial metabolism could activate this enzyme (Leenhardt et al., 2005). However, hydrolysis of InsP 6 of samples containing 20% sourdough inoculated with bifidobacteria (WDS-20) was significantly higher than samples with chemically acidified sourdough in the same percentage of addition. This suggests that the additional hydrolysis was due to phytase activity of B. pseudocatenulatum, which has already been studied in previous investigations (Haros et al., 2005, 2009; Sanz Penella et al., 2009).

The amount of lower myo-inositol phosphates showed a significant increase with the addition of sourdough inoculated with the Bifidobacterium strain, mainly in the amounts of InsP 4 and InsP 3. The intake of breads with a higher amount of lower myo-inositol phosphate could have positive effects on human health by increasing the bioavailability of minerals or as a result of their bioactive functions in the body, especially InsP 3 (Shi et al., 2006; Haros et al., 2009). Although the Bifidobacterium strain showed phytase activity, cereal activity was the predominant activity compared with the microbial enzyme during the breadmaking process. The additional InsP 6 hydrolysis by Bifidobacterium during sourdough incubation and dough fermentation might change the myo-inositol phosphate profile in the final product (results not shown).

Thermal Parameters of Wheat Starch in Bread

The differential scanning calorimeter was used as an oven to bake the bread dough inside the capsules. This procedure allows determination of the thermal behaviour of wheat starch during the baking process using hermetic capsules. When the temperature of the fermented dough increased from 30°C to 110°C, the thermograms obtained from all the samples showed two different endotherms. The first peak of the thermogram corresponds to the gelatinization process of the amorphous phase of the starch. It was observed between 67.3°C and 80.8°C, reaching enthalpy values from 0.45 to 0.57 J/g (control and WDS-20, respectively). The addition of sourdough produced a slight but significant decrease in onset temperature (67.4°C) compared with the control dough (68.1°C), although there were no significant differences between treatments adding from 5% to 20% of sourdough. With regard to the peak temperature (T p), all samples remained constant with no significant differences. A similar observation was recorded in the conclusion temperature (T c). Regarding the enthalpy of gelatinization, the addition of sourdough provided a slight increase, from 0.45 to 0.57 J/g (control and WDS-20, respectively). This increase was significant compared with the control sample when 15–20% sourdough was added to the dough (WSD-15 and WSD-20). Both samples had higher ΔH g values and similar gelatinization temperatures compared with other samples, suggesting better starch hydration during the period of fermentation (Leon et al., 1997).

The effect of the addition of sourdough on the retrogradation kinetics during storage was analysed (Fig. 2). During the first days of storage, no significant differences between samples were found. After the seventh day, there was a significant reduction in enthalpy with the increase in the amount of sourdough in the formulation (Fig. 2). After 15 days of storage, retrogradation enthalpy achieved an asymptotic behaviour, reaching a value of 1.44 J/g (control sample), whereas the samples with sourdough showed significantly lower values (between 1.24 and 1.00 J/g). The phenomenon of retrogradation is closely related to the ageing of bread (Barcenas et al., 2003a), which depends on the formulation, among other factors. The inclusion of sourdough in the breadmaking process could delay ageing, which is related to the physical changes that take place in starch retrogradation (Barcenas et al., 2003b).

Conclusions

Sourdough inoculated with bifidobacteria could make possible the formulation of whole wheat bread that allows an increase in phytate hydrolysis, enhancement of organic acid levels that modify starch digestibility, and a delay/decrease in amylopectin retrogradation, with high acceptance by consumers. Bifidobacterium strains are GRAS/QPS microorganisms (Generally Regarded as Safe/Qualified Presumption of Safety), do not significantly affect bread performance and increase its nutritional value, and could therefore be used as starters in sourdough formulations, producing a quality similar to the control sample.

References

Arendt, E. K., Ryan, L. A. M., & Dal Bello, F. (2007). Impact of sourdough on the texture of bread. Food Microbiology, 24, 165–174.

Barber, S., Báguena, R., Benedito de Barber, C., & Martinez-Anaya, M. A. (1991). Evolution of biochemical and rheological characteristics and breadmaking quality during a multistage wheat sour dough process. Zeitschrift fur Lebensmittel-Untersuchung und -Forschung, 192, 46–52.

Barcenas, M. E., Haros, M., Benedito, C., & Rosell, C. M. (2003). Effect of freezing and frozen storage on the staling of part-baked bread. Food Research International, 36, 863–869.

Barcenas, M. E., Haros, M., & Rosell, C. M. (2003). An approach to studying the effect of different bread improvers on the staling of pre-baked frozen bread. European Food Research and Technology, 218, 56–61.

Collar, C., Benedito de Barber, C., & Martinez-Anaya, M. A. (1994). Microbial sourdoughs influence acidification properties and breadmaking potential of wheat dough. Journal of Food Science, 59, 629–633.

De Angelis, M., Damiano, N., Rizzello, C. G., Cassone, A., Di Cagno, R., & Gobbetti, M. (2009). Sourdough fermentation as a tool for the manufacture of low-glycemic index white wheat bread enriched in dietary fibre. European Food Research and Technology, 229, 593–601.

Fretzdorff, B., & Brümmer, J. M. (1992). Reduction of phytic acid during breadmaking of whole-meal breads. Cereal Chemistry, 69, 266–270.

Gänzle, M. G., Vermeulen, N., & Vogel, R. F. (2007). Carbohydrate, peptide and lipid metabolism of lactic acid bacteria in sourdough. Food Microbiology, 24, 128–138.

Hammes, W. P., & Gänzle, M. G. (1998). Sourdough breads and related products. In Woods (Ed.), Microbiology of fermented foods (pp. 199–216). London: Blackie Academic and Professional.

Hammes, W. P., Brandt, M. J., Francis, K. L., Rosenheim, J., Seitter, M. F. H., & Vogelmann, S. A. (2005). Microbial ecology of cereal fermentations. Trends in Food Science and Technology, 16, 4–11.

Haros, M., Rosell, C. M., & Benedito, C. (2001). Use of fungal phytase to improve breadmaking performance of whole wheat bread. Journal of Agricultural and Food Chemistry, 49, 5450–5454.

Haros, M., Bielecka, M., & Sanz, Y. (2005). Phytase activity as a novel metabolic feature in Bifidobacterium. FEMS Microbiology Letters, 247, 231–239.

Haros, M., Bielecka, M., Honke, J., & Sanz, Y. (2007). Myo-inositol hexakisphosphate degradation by Bifidobacterium infantis. International Journal of Food Microbiology, 117, 76–84.

Haros, M., Carlsson, N.-G., Almgrem, A., Larsson Alminger, M., Sandberg, A.-S., & Andlid, T. (2009). Phytate degradation by human gut isolated Bifidobacterium pseudocatenulatum ATCC27919 and its probiotic potential. International Journal of Food Microbiology, 135, 7–14.

Katina, K., Arendt, E., Liukkonen, K. H., Autio, K., Flander, L., & Poutanen, K. (2005). Potential of sourdough for healthier cereal products. Trends in Food Science and Technology, 16, 104–112.

Katina, K., Maina, N. H., Juvonen, R., Flander, L., Johansson, L., Virkki, L., et al. (2009). In situ production and analysis of Weissella confusa dextran in wheat sourdough. Food Microbiology, 26, 734–743.

Konietzny, U., & Greiner, R. (2003). Encyclopedia of Food Science and Nutrition (2nd ed., pp. 4555–4563). London: Elsevier.

Leenhardt, F., Levrat-Verny, M. A., Chanliaud, E., & Remesy, C. (2005). Moderate decrease of pH by sourdough fermentation is sufficient to reduce phytate content of whole wheat flour through endogenous phytase activity. Journal of Agricultural and Food Chemistry, 53, 98–102.

Leon, A., Duran, E., & Benedito de Barber, C. (1997). A new approach to study starch changes occurring in the dough-baking process and during bread storage. Zeitschrift für Lebensmittel-Untersuchung und -Forschung A—Food Research and Technology, 204, 316–320.

Liljeberg, H., & Björck, I. (1998). Delayed gastric emptying rate may explain improved glycaemia in healthy subjects to a starchy meal with added vinegar. European Journal of Clinical Nutrition, 52, 368–371.

Liljeberg, H., Lönner, C., & Björck, I. (1995). Sourdough fermentation or addition of organic acids or corresponding salts to bread improves nutritional properties of starch in healthy humans. The Journal of Nutrition, 125, 1503–1511.

Lopez, H. W., Krespine, V., Guy, C., Messager, A., Demigne, C., & Remesy, C. (2001). Prolonged fermentation of whole wheat sourdough reduces phytate level and increases soluble magnesium. Journal of Agricultural and Food Chemistry, 49, 2657–2662.

Lopez, H. W., Leenhardt, F., Coudray, C., & Remesy, C. (2002). Minerals and phytic acid interactions: Is it a real problem for human nutrition? International Journal of Food Science & Technology, 37, 727–739.

Mellen, P., Walsh, T., & Herrington, D. (2008). Whole grain intake and cardiovascular disease: A meta-analysis. Nutrition, Metabolism, and Cardiovascular Diseases, 18, 283–290.

Nielsen, M. M., Damstrup, M. L., Dal Thomsen, A., Rasmussen, S. K., & Hansen, A. (2007). Phytase activity and degradation of phytic acid during rye bread making. European Food Research and Technology, 225, 173–181.

Palacios, M. C., Sanz, Y., Haros, M., & Rosell, C. M. (2006). Application of Bifidobacterium strains to the breadmaking process. Process Biochemistry, 41, 2434–2440.

Palacios, M. C., Haros, M., Sanz, Y., & Rosell, C. M. (2008). Selection of phytate-degrading human bifidobacteria and application as starter cultures in whole-wheat dough fermentation. Food Microbiology, 25, 169–176.

Pereira, M., Jacobs, D., Pins, J., Raatz, S., Gross, M., Slavin, J., et al. (2002). Effect of whole grains on insulin sensitivity in overweight hyperinsulinemic adults. The American Journal of Clinical Nutrition, 75, 848–855.

Poutanen, K., Flander, L., & Katina, K. (2009). Sourdough and cereal fermentation in a nutritional perspective. Food Microbiology, 26, 693–699.

Reale, A., Mannina, L., Tremonte, P., Sobolev, A. P., Succi, M., Sorrentino, E., et al. (2004). Phytate degradation by Lactic Acid Bacteria and Yeasts during the wholemeal dough fermentation: A P-31 NMR study. Journal of Agricultural and Food Chemistry, 52, 6300–6305.

Robert, H., Gabriel, V., Lefebvre, D., Rabier, P., Vayssier, Y., & Fontagne-Faucher, C. (2006). Study of the behaviour of Lactobacillus plantarum and Leuconostoc starters during a complete wheat sourdough breadmaking process. LWT Food Science and Technology, 39, 256–265.

Röcken, W. (1996). Applied aspects of sourdough fermentation. Advances in Food Science, 18, 212–216.

Rollan, G., De Angelis, M., Gobbetti, M., & De Valdez, G. F. (2005). Proteolytic activity and reduction of gliadin-like fractions by sourdough lactobacilli. Journal of Applied Microbiology, 99, 1495–1502.

Rosell, C. M., Santos, E., Sanz Penella, J. M., & Haros, M. (2009). Wholemeal wheat bread: A comparison of different breadmaking processes and fungal phytase addition. Journal of Cereal Science, 50, 272–277.

Sanz Penella, J. M., Collar, C., & Haros, M. (2008). Effect of wheat bran and enzyme addition on dough functional performance and phytic acid levels in bread. Journal of Cereal Science, 48, 715–721.

Sanz Penella, J. M., Tamayo Ramos, J. A., Sanz, Y., & Haros, M. (2009). Phytate reduction in bran-enriched bread by phytase-producing Bifidobacteria. Journal of Agricultural and Food Chemistry, 57, 10239–10244.

Sanz-Penella, J. M., Wronkowska, M., Soral-Smietana, M., Collar, C., & Haros, M. (2010). Impact of the addition of resistant starch from modified pea starch on dough and bread performance. European Food Research and Technology, 231, 499–508.

Shi Y, Azab AN, Thompson MN & Greenberg ML (2006) Inositol phosphates and phosphoinositides in health and disease. In: Majumder & Biswas (ed) Biology of Inositols and Phosphoinositides, pp 265–292. Springer Press, Subcellular Biochemistry

Slavin, J. (2004). Whole grains and human health. Nutrition Research Reviews, 17, 99–110.

Spicher, G. (1983). Baked goods. In D. Rehm & D. Reed (Eds.), Biotechnology. Food and feed production with microorganisms (pp. 1–115). Weinheim: Verlag Chemie.

Thiele, C., Gänzle, M. G., & Vogel, R. F. (2002). Contribution of sourdough lactobacilli, yeast and cereal enzymes to the generation of amino acids in dough relevant for bread flavour. Cereal Chemistry, 79, 45–51.

Türk, M., & Sandberg, A. S. (1992). Phytate degradation during breadmaking - effect of phytase addition. Journal of Cereal Science, 15, 281–294.

Van der Meulen, R., Adriany, T., Verbrugghe, K., & De Vuyst, L. (2006). Kinetic analysis of bifidobacterial metabolism reveals a minor role for succinic acid in the regeneration of NAD+ through its growth-associated production. Applied and Environmental Microbiology, 72, 5204–5210.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by grants AGL2006-09613/ALI, CSIC-200870I229, and Consolider Fun-C-Food CSD2007-00063 from the Ministry of Science and Innovation, Spain (MICINN). The scholarship of J.M. Sanz Penella and the contract of J.A. Tamayo Ramos from MICINN are greatly acknowledged.

Rights and permissions

About this article

Cite this article

Sanz-Penella, J.M., Tamayo-Ramos, J.A. & Haros, M. Application of Bifidobacteria as Starter Culture in Whole Wheat Sourdough Breadmaking. Food Bioprocess Technol 5, 2370–2380 (2012). https://doi.org/10.1007/s11947-011-0547-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0547-1