Abstract

A study on the guar seeds (Cyamopsis tetragonoloba) was performed to investigate the effect of moisture content on the selected physical properties. Moisture contents of seeds were varied from 5.2% to 25.0%, dry basis (d.b.). Seed geometric parameters, such as average length, width, thickness, geometric-mean diameter, surface area, volume, increased but sphericity decreased with increase in moisture content. The 1,000-seed mass increased linearly with moisture content. Bulk density of guar seeds decreased linearly when moisture content was raised from 5.2% to 25.0% d.b. On the other hand, true density decreased till moisture content was increased up to 20%. Further increase in seed moisture resulted in increased true density, which has not been observed in other food grains. The porosity decreased till seed 15.3% moisture and then increased with further addition of moisture. Angle of repose, coefficients of static friction on three different surfaces (plywood, mild steel, and galvanized iron), and terminal velocity increased linearly with seed moisture content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The guar (C. tetragonoloba), also known as cluster bean, is one of the important leguminous commercial crop of India, which is grown successfully in semi-arid and arid regions. India is the world’s largest producer and accounts for 80% of total guar produced in the world (Kumar and Singh 2002). In 2007–2008, the guar production in India was 0.8 MT (Anon 2009). Green pods of the guar are used as vegetable for human consumption. It is also used as cattle feed and green manure.

Guar seed is oval-to-round-shaped dicotyledonous seed with light pale to brown in color. The seed contains 24.5%–34.0% protein, 3.1%–7.5% lipid, and 35%–45% carbohydrate (Joshi et al. 1990). The endosperm of the guar contains about 78%–82% galactomannan gum, also known as guar gum (Goldstein et al. 1973). Guar gum is economically important due to its various uses in industrial applications such as food processing, textiles, paper, oil well drilling mud, explosives, ore floatation, coal mining, tobacco, electrical and telephone, jute, varnish and coatings, ceramics, fire fighting, building construction material, water purifier, photography, pharmaceuticals, agriculture, cosmetics, soap industries, etc. (Vishwakarma et al. 2009b).

The processing steps, for the production of guar gum, include cleaning and grading, splitting, separation of germ from unhulled splits, hulling of the splits after heating, and grinding of the dehulled endosperm splits into powder. Recently, Vishwakarma et al. (2009a) developed a new method for dehulling of guar seeds in which seeds were soaked into the aqueous solution of aliphatic compounds of the non-toxic hydroxyl group, which weakened the bond between hull and cotyledon resulting in easy removal of hull using compression and shear force-based dehulling machine. Change in size, shape, and color was observed while moisture content of guar seeds increased to about 25% during soaking operation. Information on moisture-dependent physical properties such as spatial dimensions, bulk density, true density, and porosity of guar seeds is essential for design of storage structures, processing equipments, and processes. The frictional and aerodynamic properties of guar seeds are important for the design of efficient dehulling and hull separation machines.

Physical properties of various crop seeds such as pumpkin (Joshi et al. 1993), cumin (Singh and Goswami 1996), sunflower seed (Gupta and Das 1997), green gram (Nimkar and Chattopadhyay 2001), pigeon pea (Baryeh and Mangope 2002), okra seed (Sahoo and Srivastava 2002), groundnut kernels (Olajide and Igbeka 2003), caper seed (Dursun and Durson 2005), sweet corn (Coskun et al. 2006), red kidney beans (Isik and Unal 2007), chickpea seeds (Nikoobin et al. 2009), rice (Shittu et al. 2009), and locust bean seed (Sobukola and Onwuka 2010) have been reported in the literature. Selected engineering properties of soybean (Deshpande et al. 1993), locust bean seed (Olajide and Ade-Omowage 1999), sakiz faba bean (Haciseferogullari et al. 2003), cocoa (Bart-Plange and Baryeh 2003), faba bean (Altuntas and Yildiz 2007), and barbunia seed (Cetin 2007) have also been studied in the moisture content range of 18.3%–32.4% (d.b.).

No published literature is available on the physical properties of guar seed as a function of moisture content. The present study was, therefore, aimed to determine moisture-dependent physical properties such as spatial dimensions, geometric-mean diameter, sphericity, surface area, volume, 1,000-seed mass, bulk density, true density, porosity, angle of repose, static coefficient of friction, and terminal velocity of guar seeds (variety RGC-936) between 5% and 25% (d.b.) moisture content.

Material and Methods

The guar seeds (Cyamopsis tetragonoloba) of variety RGC-936 were procured from Central Arid Zone Research Institute, Jodhpur (Rajasthan), India. Seeds were cleaned manually and stored in metal bins at room temperature (25 ± 2 °C). Initial moisture content of the seed was determined using a standard hot air oven drying method at 105 ± 1 °C for 24 h (AOAC 1980). Test samples of the desired moisture contents were prepared by adding measured amount of distilled water followed by thorough mixing and sealing in LDPE bags. The quantity of distilled water to be added was calculated using Eq. 1:

where Q is the mass of water to be added (kg); W 0 is the initial mass of the sample (kg); M 0 is the initial moisture content of the sample (%, d.b.); and M f is the desired moisture content of the sample (%, d.b.).

The conditioned samples were kept at 5 °C in a refrigerator for 7 days to allow uniform distribution of moisture throughout the sample. Desired quantity of the conditioned seeds was taken out and held at room temperature for 2 h before conducting the test (Carman 1996; Deshpande et al. 1993; Singh and Goswami 1996; Cetin 2007). The physical properties were determined at 5.2%, 10.1%, 15.3%, 20.2%, and 25.0% moisture content (d.b.). All the experiments were replicated five times (except measurement of dimensions for which 100 seeds were taken randomly at each moisture content), and the average values were used in the analysis.

To determine the average size, 100 seeds were randomly selected, and length (L), width (W), and thickness (T) of the seeds were measured using a digital micrometer (least count 0.01 mm) (Mitutoyo Corporation, Japan). The arithmetic mean diameter (D a ), geometric-mean diameter (D g ), sphericity (φ), and volume (V) were calculated by using the following relationships (Mohsenin 1986; Jain and Bal 1997):

where

The surface area (A s ) was determined by analogy with a sphere of the same geometric-mean diameter using Eq. 7 (Mohsenin 1986; Tunde-Akintunde and Akintubde 2004):

To determine the mass of 1,000 seeds (M t ), about 250 seeds were taken randomly and weighed (M) on an electronic balance (least count 0.001 g). Then the number of seeds (n) in the sample was counted (Deshpande et al. 1993). The mass of 1,000 seeds was calculated as

Bulk density (ρ b ) was determined following the procedure reported by Singh and Goswami (1996) and Gupta and Das (1997) by filling a 0.5-L cylinder with seeds from a height of 0.15 m at a constant rate and then weighing the contents. The seeds were not compacted during the test.

True density (ρ t ) was determined using the toluene displacement method. Toluene was used in place of water because of its low surface tension, and the seeds absorbed toluene to a lesser extent than that of water (Mohsenin 1986). Toluene (0.5 L) was poured in a 1-L graduated measuring cylinder, and 0.3-kg seeds were immersed in it. The amount of displacement was recorded. The true density was estimated as the ratio of sample mass to the volume of displaced toluene (Mohsenin 1986; Singh and Goswami 1996).

The bed porosity (ε) was calculated using Eq. 9 (Mohsenin 1986).

A plywood box of 0.1 × 0.1 × 0.1 m size with a removable front panel was used to determine the angle of repose (θ). The box was filled with seeds, and the front panel was quickly removed allowing the seeds to flow and assume a natural slope (Joshi et al. 1993; Paksoy and Aydin 2004). The diameter (D) and height (H) of the slope were recorded. The angle of repose (θ) was calculated by using Eq. 10.

The static coefficient of friction (μ) was determined on three different surfaces: plywood, mild steel, and galvanized iron. These materials are commonly used for handling and processing of guar seeds and construction of storage and drying bins. A wooden box of 0.1-m length, 0.1-m width, and 0.04-m height without base and lid was filled with the sample and placed on an adjustable tilting plate, faced with the test surface. The box was raised slightly (0.5–1.0 mm) so as not to touch the surface, and inclination of the test surface was increased gradually with a screw device until the box just started to slide down and the angle of surface (α) was read from a graduated scale. The μ was computed using Eq. 11 (Dutta et al. 1988; Joshi et al. 1993; Singh and Goswami 1996)

Terminal velocity was measured using a cylindrical column in which the material was suspended in the air stream (Nimkar and Chattopadhyay 2001). The minimum air velocity, which held the seeds under suspension, was recorded using a digital anemometer (±0.1 m/s) (Joshi et al. 1993).

The data analysis was carried out by using the Statistca 6 software. The differences between the mean values of physical characteristics of guar seeds were tested for significance using the t-test.

Results and Discussion

Geometrical Parameters

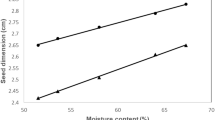

Dimensional characteristics, surface area, and volume of guar seeds at selected moisture contents are reported in Table 1. The L, W, T, D a , D g , and V values increased linearly with moisture content. The reason for this increase was probably due to swelling of gum present in the seeds. This indicated that drying of guar seeds of higher moisture contents may result in shrinkage due to decrease in seed dimensions. Linear increase in seeds dimensions for soybeans and pigeon pea have been reported by Deshpande et al. (1993) and Baryeh and Mangope (2002), respectively. The geometric-mean diameter of the seed was found to be more than that of its thickness. The relationships between L, W, T, and D g with moisture content can be represented as

where m is the moisture content (%, d.b.) Table 1.

The sphericity of the guar seeds decreased linearly from 0.78 to 0.76 (2.57% decrease) with increase in moisture content (Table 1). It was contrary to the published results on soybean (Deshpande et al. 1993) and locust bean seed (Sobukola and Onwuka 2010). The reason could be attributed to the comparatively more expansion of endosperm (lateral expansion) than the germ portion (thickness). This suggested that seed kernels should slide rather than roll in the hoppers and separators with increase in moisture content. The relationship between sphericity (φ) and moisture content is expressed as

Surface Area

The surface area (A s ) of guar seeds increased significantly (p < 0.05) from 35.84 to 40.67 mm2 (13.48% increase) when the moisture content was increased from 5.2% to 25.0% (d.b.) (Fig. 1), and the variation was found to be linear (Eq. 17):

The ratio between volume and surface area is usually called the characteristic length. Characteristic length in irregular-shaped objects plays an important role to determine the projected area of the objects moving in turbulent air stream, and is useful in designing seed cleaners, separators, and pneumatic conveyors. As the ratio between surface area and volume increases, the heat and mass transfer rates from kernels increases, facilitating drying, cooling, and heating operations.

1,000-Seed Mass

The 1,000-seed mass increased linearly from 27.31 to 31.02 g (13.55% increase) with increase in moisture content from 5.2% to 25.0% (Fig. 2). Similar results have been reported for barbunia beans (Cetin 2007) and locust bean seed (Sobukola and Onwuka 2010). The relationship between 1,000-seed mass and moisture content is expressed as

Bulk Density

Bulk density of guar seeds decreased from 848.85 to 775.39 kg/m3 (8.65% decrease) with increase in moisture content from 5.2% to 25.0% (Fig. 3). This decrease was due to greater increase in volume relative to that of mass. Variation of bulk density with moisture content is expressed as

Similar relationships have been reported for chickpea (Konak et al. 2002) and locust bean seed (Sobukola and Onwuka 2010). However, increase in bulk density with moisture content was reported for sunflower (Gupta and Das 1997) and cashew nut (Balasubramanian 2001).

True Density

True density of guar seeds varied from 1422.46 to 1317.31 kg/m3 at different moisture contents. The ρ t decreased with increase in moisture content up to 20% and then increased at 25% moisture content (Fig. 4). The decrease in true density with increase in moisture content was mainly due to the increase in volume (due to swelling of gum containing endosperm present in the seed), which was higher than the corresponding increase in the mass of the material. The variation of true density with moisture content can be expressed as

The behavior of true density of guar seed is different from the other seeds reported in the literature. Increase in true density with moisture content has been reported by Gupta and Das (1997) and Altuntas and Yildiz (2007) for sunflower and faba bean, respectively. These seeds have a lower volume change in comparison to the change in mass with moisture content. However, Tunde-Akintunde and Akintubde (2007) and Cetin (2007) have reported that the true density of beniseeds and barbunia seeds decreased with increased moisture content. This change will affect the flow ability and aerodynamic properties of guar seeds.

Bed Porosity

Bed porosity of guar seeds decreased from 40.33% to 39.43% up to 15.3% moisture content and then increased to 41.75% at 25.0% moisture content (d.b.) as shown in Fig. 5. The variations in ε with moisture content were significant (p < 0.05). The variation of porosity with moisture content can be expressed as

Variation of porosity with moisture content of guar seed was different from other seeds reported in the literature. Increase in porosity with moisture content has been reported by Gupta and Das (1997) and Altuntas and Yildiz (2007) for sunflower and faba bean. However, Tunde-Akintunde and Akintubde (2007), Joshi et al. (1993), and Shepherd and Bhardwaj (1986) have reported decrease in porosity of beniseeds, pumpkin, and pigeon pea seeds, respectively with increasing moisture content. The decrease in porosity of guar seeds up to 15.3% moisture may be attributed to the fact that the increase in moisture content resulted in increased swelling of the seeds, thus reducing inter granular spaces leading to more compact arrangement of the seeds. The increase in porosity beyond 15.3% moisture attributed by higher degree of expansion of gum containing endosperm in comparison to germ of the seed and hence, the sphericity decreased which led to higher porosity. Higher porosity values provide better aeration and water vapor diffusion during deep bed drying, and the data may be utilized for design of aeration systems.

Angle of Repose

The angle of repose of guar seeds increased linearly from 25.1° to 31.9° with moisture content (Fig. 6). Similar behavior has been observed for squash, sunflower, and pumpkin seeds (Joshi et al. 1993; Gupta and Das 1997; Paksoy and Aydin 2004). Variation of angle of repose with moisture content can be expressed as

At higher moisture content, seeds tend to stick together, causing impeded flowability and higher angle of repose. The data would be useful for design of hoppers, and storage bins for the guar seed.

Coefficient of Static Friction

Variation of static coefficient of friction for guar seeds on three surfaces (plywood, mild steel, and galvanized iron) with moisture content is shown in Fig. 7. The static coefficient of friction increased significantly with moisture content for all the surfaces. This was due to the increased adhesion between the seed and the material surfaces at higher moisture contents leading to higher μ values. Similar results have been reported for squash, sunflower, and faba bean (Paksoy and Aydin 2004; Gupta and Das 1997; Altuntas and Yildiz 2007).

The static coefficient of friction ranged from 0.43 to 0.63, 0.51 to 0.65, and 0.36 to 0.45, respectively for plywood, mild steel, and galvanized iron surfaces in the experimental moisture content range. Variation of static coefficient of friction with moisture content of guar seed is expressed as

where μ pb, μ ms, and μ gi are static coefficient of friction of guar seeds against plywood, mild steel, and galvanized surfaces, respectively.

The coefficient of friction at all moisture contents was highest on mild steel followed by plywood and galvanized iron. This was due to the smoother surface of galvanized iron as compared to plywood and mild steel. The order reported for cumin seeds (Singh and Goswami 1996), karingda seeds (Suthar and Das 1996), sunflower seeds (Gupta and Das 1997), and locust bean seed (Sobukola and Onwuka 2010) is plywood followed by mild steel and galvanized iron sheet. However, Amin et al. (2004) have reported that no variation existed between plywood and galvanized iron for lentil seeds.

Terminal Velocity

Terminal velocity exhibited linear significant increase (p < 0.05) from 4.86 to 5.49 m/s as the moisture content increased from 5.2% to 25% (d.b.) (Fig. 8). The relationship between terminal velocity and moisture content is represented as

Singh and Goswami (1996), Gupta and Das (1997), Baryeh and Mangope (2002), Cetin (2007), and Isik and Unal (2007) have reported a linear increase in terminal velocity with moisture content for cumin seed, sunflower, pigeon pea, kariga, and white speckled kidney beans respectively. The increase in terminal velocity with increase in moisture content within the study range can be attributed to the increase in mass of the individual seed per unit frontal area presented to the airflow.

Conclusions

Effects of moisture content on physical properties of the guar seeds were studied. In this study, the average length, width, thickness, geometric-mean diameter, surface area, volume, 1,000-seed mass, angle of repose, static coefficient of friction, and terminal velocity increased with moisture content, while sphericity of guar seeds (variety RGC-936) decreased. Bulk density decreased linearly with increase in moisture content whereas the true density decreased up to 20% moisture content and then increased. The porosity of guar seed decreased from 40.33% to 39.43% till 15.3% moisture content and then increased to 41.75% at 24.97% moisture content. The changes in the physical properties of guar with moisture content may be used in seed-processing machines design and operations. This study provides information for guar processing industries that will help in selection of proper material handling and processing machines.

References

Altuntas, E., & Yildiz, M. (2007). Effect of moisture content on some physical and mechanical properties of faba bean (Vicia faba L.) grains. Journal of Food Engineering, 78(1), 174–183.

Amin, M. N., Hossain, M. A., & Roy, K. C. (2004). Effect of moisture content on some physical properties of lentil seeds. Journal of Food Engineering, 65(1), 83–87.

Anon (2009) National commodity and derivatives exchange limited: (www.ncdex.com). Exchange Plaza, C-1, Block G, Bandra Kurla Complex, Mumbai, India

AOAC. (1980). Official methods of analysis (13th ed.). Arlington: Association of Official Analytical Chemists.

Balasubramanian, D. (2001). Physical properties of raw cashew nut. Journal of Agricultural Engineering Research, 78, 291–297.

Bart-Plange, A., & Baryeh, E. A. (2003). The physical properties of category B cocoa beans. Journal of Food Engineering, 60(3), 219–227.

Baryeh, E. A., & Mangope, B. K. (2002). Some physical properties of QP-38 variety pigeon pea. Journal of Food Engineering, 56, 59–65.

Carman, K. (1996). Some physical properties of lentil seeds. Journal of Agricultural Engineering Research, 63(2), 87–92.

Cetin, M. (2007). Physical properties of barbunia bean (Phaseolus vulgaris L. cv. ‘Barbunis’) seed. Journal of Food Engineering, 80, 353–358.

Coskun, M. B., Yalcin, I., & Ozarslan, C. (2006). Physical properties of sweet corn seed (Zea mays saccharata Sturt.). Journal of Food Engineering, 74(4), 523–528.

Deshpande, S. D., Bal, S., & Ojha, T. P. (1993). Physical properties of soybean. Journal of Agricultural Engineering Research, 56(2), 89–98.

Dursun, E., & Durson, I. (2005). Some physical properties of caper seed. Biosyst Eng, 92(2), 237–245.

Dutta, S. K., Nema, V. K., & Bhardwaj, R. J. (1988). Physical properties of gram. Journal of Agricultural Engineering Research, 39, 259–268.

Goldstein, A. M., Alter, E. N., Seaman, S. K. (1973). Industrial gums. In Whistler, R. L., Bemiller, J. E. (eds). Academic Press, New York, p 303

Gupta, R. K., & Das, S. K. (1997). Physical properties of sunflower seed. Journal of Agricultural Engineering Research, 66, 1–8.

Haciseferogullari, H., Gezer, I., Bahtiyarca, Y., & Menges, H. O. (2003). Determination of some chemical and physical properties of Sakiz faba bean (Vicia faba L. Var. major). Journal of Food Engineering, 60(4), 475–479.

Isik, E., & Unal, H. (2007). Moisture-dependent physical properties of white speckled red kidney bean grains. Journal of Food Engineering, 82, 209–216.

Jain, R. K., & Bal, S. (1997). Physical properties of pearl millet. Journal of Agricultural Engineering Research, 66, 85–91.

Joshi, D. C., Das, S. K., & Mukherjee, R. K. (1993). Physical properties of pumpkin grains. Journal of Agricultural Engineering Research, 54(3), 219–229.

Joshi, U. N., Arora, S. K., & Arora, R. N. (1990). Differential chemical composition of guar species. Guar Res Annals, 6, 38–40.

Konak, M., Carman, K., & Aydin, C. (2002). Physical properties of chick pea seeds. Biosyst Eng, 82, 73–78.

Kumar D, Singh NB (2002) Guar in India. Scientific Publishers (India), Jodhpur, chap 1

Mohsenin, N. N. (1986). Physical properties of plant and animal materials. New York: Gordon and Breach.

Nikoobin, M., Mirdavardoosti, F., Kashaninejad, M., & Soltani, A. (2009). Moisture-dependent physical properties of chickpea seeds. J Food Proc Eng, 32, 544–564.

Nimkar, P. M., & Chattopadhyay, P. K. (2001). Some physical properties of green gram. Journal of Agricultural Engineering Research, 80(2), 183–189.

Olajide, J. O., & Ade-Omowage, B. I. O. (1999). Some physical properties of locust bean seed. Journal of Agricultural Engineering Research, 74, 15–22.

Olajide, J. D., & Igbeka, J. C. (2003). Some physical properties of groundnut kernels. Journal of Food Engineering, 58, 201–204.

Paksoy, M., & Aydin, A. (2004). Some physical properties of edible squash (Cucurbita pepo L.). Journal of Food Engineering, 65, 225–231.

Sahoo, P. K., & Srivastava, A. P. (2002). Physical properties of okra seeds. Biosyst Eng, 83(4), 441–448.

Shepherd, H., & Bhardwaj, R. K. (1986). Moisture dependent physical properties of pigeon pea. Journal of Agricultural Engineering Research, 35, 227–234.

Singh, K. K., & Goswami, T. K. (1996). Physical properties of cumin seed. Journal of Agricultural Engineering Research, 64(2), 93–98.

Shittu, T. A., Olaniyi, M. B., Oyekanmi, A. A., & Olkeleye, K. A. (2009). Physical and water absorption characteristics of some improved rice varieties. Food Bioproc Technol.. doi:10.1007/s/11947-009-0288-6.

Sobukola, O. P., Onwuka, V. I. (2010). Effect of moisture content on some physical properties of locust bean seed (parkia fillicoidea L.). J Food Proc Eng. doi:10.1111/j.1745-4530.2009.00511

Suthar, S. H., & Das, S. K. (1996). Some physical properties karingda seeds. Journal of Agricultural Engineering Research, 64, 93–98.

Tunde-Akintunde, T. Y., & Akintubde, B. O. (2004). Some physical properties of sesame seed. Biosyst Eng, 88(1), 127–129.

Tunde-Akintunde, T. Y., Akintubde, B. O. (2007). Effect of moisture content and variety on selected properties of beniseed. Agric Eng Int: CIGR Ejournal. Manuscript FP 07021. 9, 1–14

Vishwakarma, R. K., Nanda, S. K., Shivhare, U. S. (2009a) Process for dehulling guar seed for refined guar gum split production. Indian patent application no. 1283/DEL/2007. Publication date: 03/04/2009. Journal no. 14/2009

Vishwakarma, R. K., Nanda, S. K., Shivhare, U. S., & Patil, R. T. (2009b). Status on post harvest technology of guar (Cyamopsis tetragonoloba) in India. Agric Mechan Asia, Africa Latin Amer, 40(1), 65–72.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vishwakarma, R.K., Shivhare, U.S. & Nanda, S.K. Physical Properties of Guar Seeds. Food Bioprocess Technol 5, 1364–1371 (2012). https://doi.org/10.1007/s11947-011-0514-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0514-x