Abstract

Aim of this work is to study the cryoprotective role of extracellular trehalose in the production of bakery products from frozen dough. Therefore, different levels of trehalose (up to 200 ppm) were incorporated in dough/bread samples made from white and whole-wheat flour, and their quality (loaf volume, weight loss during baking, crust and crumb color) and texture characteristics (dough, crust and crumb firmness) were examined during frozen storage. To investigate the role of trehalose on dough behavior, the sugar content (glucose, fructose, and sucrose) of dough samples composed with or without trehalose was monitored, and dough microstructure was also analyzed with scanning electron microscopy. The cryoprotective effect of trehalose was confirmed, and it was found proportional to its level for both flour types. Trehalose can improve dough behavior under freezing conditions in terms of bread volume and texture characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Frozen bakery products have become increasingly popular during the last 50 years due to their high convenience and retainability. However, the application of frozen storage, although it may significantly extend dough products’ shelf-life, generates deteriorative alterations to their physicochemical characteristics. The most important of these is the reduction or loss of yeast’s viability and dough strength. More specifically, yeast viability may affect gassing power, fermentation time, and loaf volume, which is determinant of consumers’ acceptability, whereas dough strength is associated with gluten network’s stability, gas retention ability, and bread’s quality (Anon et al. 2004; Casey and Foy 1995; Giannou et al. 2005).

To restrict the detrimental effects of freezing on dough performance, several methods have been suggested in the literature. More specifically, the development of yeast strains with improved cryoresistance (Tanghe et al. 2000) as well as the modification of process parameters and dough formulation, through the use of suitable additives/ingredients, have been a matter of research during the last decades (Holmes and Hoseney 1987; Neyreneuf and Delpuech 1993; Ribotta et al. 2004; Rouille et al. 2000).

Trehalose is a stable, colorless, odor-free and nonreducing disaccharide consisting of two glucose units linked in an alpha,alpha-1,1-glycosidic bond. It has a widespread occurrence in nature as it is found in many survival forms of organisms, including bacteria, yeasts, fungi, insects, invertebrates, and plants. It can serve as a source of energy and carbon and may participate in the actions of metabolism. However, the most important function of trehalose is its ability to protect biomolecules against environmental stress caused by desiccation, dehydration, heat, cold, and oxidation (Elbein et al. 2003; Gancedo and Flores 2004; Masaru et al. 1995; Schiraldi et al. 2002; Singer and Lindquist 1998; Van Dijck et al. 1995).

Trehalose is already used in several food products, such as bakery, beverages, confectionery, or cereals, to reduce sweetness and moisture absorption and prevent browning reactions and starch retrogradation (Bar 2000; Food Standards Australia New Zealand (FSANZ) 2003). It is also utilized in the drying operations of egg, vegetable, or fruit products as it exhibits increased efficiency in the preservation of the structure and function of food molecules (Roser 1991).

Besides, trehalose is considered a particularly effective cryoprotectant. In general, the action of cryoprotective agents in a food system can be detected by the reduction of the freezing point, which promotes supercooling, or the protection of cell membranes from freeze injury or osmotic dehydration and proteins from denaturation (Diniz-Mendes et al. 1999; Karel and Lund 2003). The mechanism of the cryoprotective action of trehalose is not completely understood but is mainly attributed to its interaction with water and lipid membranes and its ability to induce the glass transition phenomenon and freeze concentration (Conrad and De Pablo 1999; Haines 2003).

In food technology, extensive interest is shown on the physiological effect of trehalose on yeast cryoresistance (Carvalheiro et al. 1999; Meric et al. 1995). However, although it has gained approval as a safe food additive and is considered a novel food ingredient, its cryoprotective role has been sufficiently studied only in the production of frozen fish products (surimi), gelatin desserts, ice creams, and frozen tofu (FSANZ 2003; Fuchigami et al. 2002). The current work focuses on the incorporation of different levels of exogenous trehalose in a dough formula and the study of dough behavior under frozen storage.

Materials and Methods

Raw Materials

Two types of commercially milled wheat flour: strong soft white flour T.70% (expressed as the milling yield) and whole-wheat flour T.90%, were purchased from “Sarantopoulos Flourmill” (Keratsini, Greece) with a protein content of about 12 and 14%, respectively. The purpose of using both types of flour is that these are the most predominant in the food market and that due to their compositional divergence they may exhibit different breadmaking potential. Food-grade ascorbic acid, a-a-trehalose (Merck, Germany) and sugar, salt, instant dry yeast, and vegetable shortening, obtained from the local market, were the ingredients used for the preparation of dough samples.

Dough Formulation

The basic dough formula consisted of 500 g of flour, 300 g of water (60% flour basis), 10 g of dry yeast (2% flour basis), 20 g of sugar (4% flour basis), 15 g of vegetable shortening, 10 g of salt (2% flour basis), and 0.05 g of ascorbic acid (100 ppm flour basis). Samples containing 0, 50, 100, 150, and 200 ppm of trehalose, per flour weight, were prepared to study its influence on the breadmaking properties.

Dough/Bread Preparation

Dough preparation included yeast’s prehydration with the water and mixing of all ingredients in a “Kenwood Chef KM400” (Kenwood, UK) domestic blender for 2 min at a low speed (speed 2) and 8 min at a medium speed (speed 4). Two-speed mixing was performed as it is proposed to yield relatively light loaves with crispy, crackly crusts and keep oxidation (loss of flavors) to minimum (Calvel et al. 2001). Low speed is required for homogeneous ingredient dispersion and flour hydration (brief duration) whereas more extensive mixing for optimum dough development. Mixing time was carefully chosen to provide smooth dough with a dry surface and optimum elastic character (Pyler 1988). Dough was immediately divided in round-shaped samples of 80 g, which were packed in aluminum pans, wrapped with transparent polymer film, weighed, and stored in a freezer (Iberna SCO 50, Iberna, Italy) at −26°C for an overall period of almost 3 months (82 days for samples from white flour and 81 days for those from whole-wheat flour).

At regular intervals during frozen storage, three samples from every flour type and trehalose concentration were withdrawn from the freezer for testing. They were thawed and proofed at an incubation chamber (Bekso EB1N, Bekso, Brussels, Belgium) set at 25°C for 195 min. Thawing conditions were optimized in a separate study, and normal proofing temperatures (above 30°C) were not applied to avoid uneven thawing and surface blistering. One of the samples was used for dough texture examination, and the rest were baked in a laboratory oven with air circulation (Thermawatt TG103, Thermawatt, Peristeri, Greece) at the temperature of 180°C for 35 min.

After cooling of bread samples for 30 min at room temperature (28–30°C), they were weighed to determine weight loss during baking; their specific volume was estimated, and their crust and crumb color as well as crust and crumb texture were also analyzed. All the above measurements were performed in triplicate. Nonfrozen samples were also prepared at different intervals during the sampling period, according to the above procedure, proofed at 25°C for 45 min and baked as previously described.

Analysis of Sugars

To analyze the sugar content of the samples with or without trehalose, 30 g of dough containing 0 and 200 ppm of trehalose were placed in volumetric flasks of 100 ml. About 5 ml of potassium ferrocyanide [K4[Fe(CN)6]·3H2O] (Riedel-de Haen AG, Germany) solution (dissolution of 10.6 g of salt in water with final volume of 100 ml) and zinc acetate [Zn(CH3COO)2·2H2O] (Fluka AG, Switzerland) solution (dissolution of 2.19 g of salt and 3 ml of acetic acid in water with final volume of 100 ml) were added (Egan et al. 1981). The volume was filled at 100 ml with high performance liquid chromatography (HPLC) grade water (Lab-Scan Analytical Sciences). Samples were thoroughly stirred, retained for 10 min, and filtered using Chromafil P-45/25 PVDF filters (Macherey-Nagel, Germany).

The liquid samples occurring from dough extraction were analyzed for their sucrose, glucose, and fructose content using a HPLC instrument (HP 1100-Hewlett Packard, Waldbronn, Germany) equipped with a refractive index detector (HP 1047A). A Nucleosil Carbohydrate EC 250/4 (Macherey-Nagel, Duren, Germany) column was utilized. The mobile phase was acetonitrile/water (HPLC grade) at the ratio of 80:20. Extra pure D(+)-Sucrose, D(−)-Fructose (Riedel-de Haen AG, Germany) and D(+)-Glucose anhydrous (Panreac Quimica SA, Spain) were used as the reference materials (Laaksonen and Roos 2000).

Specific Volume

Rapeseeds displacement method was applied to estimate the specific volume (Hall et al. 2004). Both bread samples from every flour type and trehalose concentration were measured in triplicate, and the mean value was calculated.

Color Measurement

A Minolta CR/200 chromatometer (Minolta Company, Chuo-ku, Osaka, Japan), which displays the L*, a*, b*, color parameters according to the CIELAB system of color measurement, was used to measure the crust and crumb color of baked samples. Each sample was measured in triplicate, and color variation during storage was estimated according to the following equation (MacDougall 2002):

Texture Analysis

Dough and bread texture characteristics were determined using a TA-XT2i (Stable Micro Systems, Godalming, Surrey, UK) Texture Analyser. A compression test was applied, which can yield sample’s firmness (resistance to deformation-maximum force during first compression). Dough samples were subjected to a two-cycle compression test using the SMS P/45C cone probe (test speed 3 mm/s, penetration distance 15 mm). Bread samples’ crust (upper part of the whole sample) was subjected to a cut test using the TA-45 craft knife (test speed 3 mm/s, penetration distance 15 mm). The samples were thereafter sliced in the middle (vertically) using a double blade knife (fabricated in house) of 1 cm thickness. A two-cycle crumb compression test was performed using the Sris P/75 Aluminum Platen probe (test speed 3 mm/s, penetration distance 10 mm).

Sensory Evaluation

Baked samples were subjected to preliminary sensory evaluation by five trained panelists to determine the degree of acceptance using a scale scoring 0–6. Two replicates of each sample were evaluated with Quantitative Descriptive Profile Analysis (QDA). This method relies on statistical analysis to determine the appropriate terms, procedures, and panelists to be used for the analysis of a specific product. It involves the detection (discrimination) and the description of both the qualitative and quantitative sensory aspects (texture, appearance, sound, odor, and flavor attributes) of a product by trained panelists using a linear scale (Meilgaard et al. 1999).

Differential Scanning Calorimetry Studies

The thermal behavior of frozen dough samples, containing 0 and 200 ppm of trehalose, was monitored with a PerkinElmer DSC 6 (PerkinElmer, Wellesley, USA) instrument connected to a computer supplied with the Pyris Manager Thermal Analysis Software. The instrument measures the differential heat flow between the sample and an inert reference sample at atmospheric pressure. The differential scanning calorimetry (DSC) instrument was calibrated using indium as a standard (Tm = 156.6°C, ΔHm = 28.5 J/g). Samples were placed in hermetically sealed aluminum DSC pans of 50 μl (PerkinElmer), and an empty pan was used as the reference sample. Cooling (at a constant rate of 10°C/min) was performed by draining liquid nitrogen through samples’ chamber, whereas nitrogen gas (99.9% purity) was utilized to minimize water condensation in the measuring cell as it removes moisture or oxygen which may accumulate and damage the cell over time (Laaksonen and Roos 2000).

Scanning Electron Microscopy

For scanning electron microscopy analysis, dough samples containing 0 and 200 ppm of trehalose were prior dried overnight at 100°C and then powdered. A Quanta 200 (FEI, Czech Republic) scanning electron microscope was used. Samples containing 0 and 200 ppm of trehalose were observed at a magnification level of 1,000×. Higher levels of magnification could not be applied to the samples as they caused excessive heating and deformation.

Statistical Analysis

Statistical analysis of the data was performed using the software Statistica 6.0 (StatSoft, Tulsa, OK, USA). Multiple regression analysis and principal component analysis (PCA) were performed. Multiple regression involves predicting the values of a dependant variable from values deriving from a collection of other variables (predictors) using linear combinations (Christensen 1996).

For the data collected on P variables (quality parameters) for N cases (trehalose content), PCA performs analyses in the N-dimensional space defined by P variables and P-dimensional space defined by N cases. Mathematically, the computation of factors in PCA basically consists of diagonalizing a symmetric matrix. The result is a new set of variables (principal components) that are linear combinations of the original variables and are uncorrelated. The new variables thus generated are smaller in number and yet account for the inherent variation of the data to the maximum possible extent. In this way, a new space (factor space) is generated onto which the cases and the variables can be projected and classified into categories (Sharma 1996; StatSoft Inc. 2006).

Results and Discussion

To designate the quality characteristics of bread made from frozen dough, weight loss during baking, specific volume, crust and crumb color, and dough, crust, and crumb firmness were measured after different storage-time intervals. Specially, specific volume and crumb texture characteristics are considered to be two of the most important quality indicators in frozen bakery products (Ribotta et al. 2001) since these are both affected by the loss of yeast viability and dough strength.

In Figs. 1 and 2, the specific volume variation during storage is presented for samples from white and whole-wheat flour, respectively. Findings indicate that, in most cases, there is a proportional relation between specific volume and trehalose content. The specific volume of nonfrozen samples (0–200 ppm) prepared at different intervals during the sampling period, using the same experimental procedure, varied between 2.41 and 3.17 ml/g for white samples and 1.76 and 2.15 ml/g for whole-wheat samples.

To determine a relationship between loaf volume (dependant variable) and other quality parameters such as weight loss during baking, dough firmness, crumb firmness during dual compression, and trehalose content (predictors), multiple regression analysis was used. The linear model applied was: Specific volume = A0 + A1*weight loss + A2*dough firmness + A3*crumb firmness + A4*trehalose content. The occurring constants at every experimental point are presented in Table 1 both for samples from white and whole-wheat flour. Analysis of variance (ANOVA) was implemented at these data to examine the impact of storage time on loaf volume variance. It was concluded that storage time had no significant effect (P = 0.996 for white flour and 0.988 for whole-wheat flour samples) on loaf volume during the period (14–82 days) examined in the current study. This is substantiated by the finding of Fik and Surowka (2002), who noted that the most pronounced quality changes were observed at the beginning of the storage period. Their experiments confirmed that the freezing itself has the greatest effect on the quality of frozen bread, whereas the time of storage in optimal conditions affects it only slightly. Therefore samples with trehalose could retain their superior characteristics to some storage time.

The coefficients of the regression analysis indicated that, in almost every case, dough (A2) and crumb (A3) firmness were negatively correlated with loaf volume during the storage period examined in the current work. The opposite trend appeared for trehalose content (A4) and weight loss (A1). Therefore, a rather firm dough is expected to provide bread with decreased loaf volume and harsh crumb, while humidity loss during baking favors ovenspring. Trehalose proved to protect samples against loss of expansion ability during dough freezing. The same trend was confirmed by loaf volume values’ observation (Figs. 1 and 2).

The dual compression of bread crumb using a texture analyzer can imitate food deformation during chewing and define the physical quality of food perceived by the sense of touch in the mouth (mouth feel) (Rosenthal 1999). Figure 3 presents the average crumb firmness during storage for samples with different levels of trehalose. It is apparent that the addition of trehalose in frozen dough samples can proportionally improve their textural characteristics, providing bread with softer and smoother crumb. However, the ameliorative effect of trehalose was more evident in the case of white flour. Results from crust texture analysis indicated no remarkable action by the addition of trehalose (data not shown).

To examine the overall contribution of the parameters examined in the current study in the quality characteristics of samples with different levels of trehalose stored under freezing conditions, principal component analysis was used. In the current study, two components were selected to describe the process.

In Figs. 4 and 5, the PCA scores and loadings plots for components 1 and 2 and samples made from white and whole-wheat flour, respectively, are presented. Loadings plots show that loaf volume and dough firmness had the opposite effect on samples quality for both flour types used in this study (they appear in opposite positions in the plot). Texture characteristics of the baked samples are closely correlated in both cases. Crust color is indicated in the same area for the two flour types, while crumb color presents variable behavior. In score plots, grouping was performed to study the attributes of samples containing different levels of trehalose. The spots with the same trehalose content refer to measurements at different storage times. In both cases, samples with 200 ppm of trehalose were the most finely grouped (closer to each other) and presented a strong influence on loaf volume, since they were spotted at the same area of the loadings and scores diagrams. This confirms all other findings and shows that trehalose can improve dough stability under severe conditions. Samples with 150 ppm of trehalose were also well centered; however, their behavior was more correlated to samples with 50 ppm. The conclusion that can be derived from the above elements is that despite the differences between the breadmaking efficiency of white and whole-wheat flour, the protective role of trehalose is congener.

In Table 2, the mean values of the quality attributes measured during frozen storage in the current study are presented for samples made from white and whole-wheat flour. ANOVA was applied so as to define differences between samples’ flour type and trehalose concentration. The two flour types showed no significant differences as far as weight loss during baking and crumb compression characteristics are concerned. Loaf volume and crumb firmness during compression were more significantly affected (P < 0.05) by the addition of trehalose. This amplifies their selection as the most important quality parameters.

State diagrams provide useful information about food storage stability and ingredients interactions. More specifically, stability is affected by the temperature difference between the storage temperature and the glass transition temperature (Tg′) of the maximally freeze-concentrated matrix and decreases rapidly above Tg′. Moreover, ice melting (Tm′) is related to the dilution of the unfrozen matrix and viscosity decrease, which may increase the rate of diffusion-limited reactions in frozen foods (Roos 1995). It is well known that sugars depress the freezing point of food products. However, trehalose at low concentrations presents a stabilizing effect on biomolecules which has been attributed, among other reasons, to glass formation and attainment of the glassy state (Kalichevsky-Dong 2000; Karel and Lund 2003). Besides, the addition of trehalose to food systems may affect their freezing point and their unfrozen water content or decrease the time required to reach storage temperature.

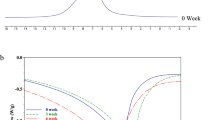

Figure 6 shows the DSC diagrams of samples containing 0 and 200 ppm of trehalose, respectively, which resulted using DSC analysis. Since it was not possible to perform the analysis in all samples, the highest level of trehalose was chosen because it presented the best results in the above measurements. The glass transition temperature was not detected in both cases. However, the addition of trehalose slightly induced the melting peak of ice, facilitating dough freezing and thus minimizing freezing distress.

Low molecular sugar content can be indicative of yeast activity and performance under freezing conditions. Glucose, sucrose, and thereinafter fructose are the sugars most preferably consumed by yeast cells. Glucose and fructose can be readily assimilated by the yeast, while sucrose should be previously enzymatically hydrolyzed to its constituents. High concentrations of glucose or sucrose at certain processing stages can trigger effects such as activation of cellular growth, mobilization of storage compounds, and diminution of cellular stress resistance, which may lead to slow or incomplete fermentation and poor maintenance of yeast viability. Also, as both glucose and fructose are imported to yeast cells through the same carriers, which have a greater affinity for glucose, a delay in fructose uptake is expected (Verstrepen et al. 2004).

Figure 7 represents the glucose, fructose, and sucrose content of samples made from white flour containing 0 and 200 ppm of trehalose at different frozen storage intervals. It is obvious that the addition of trehalose can increase its sugar assimilative activity. Samples with 0 ppm of trehalose presented higher sugar content which, as mentioned before, can be related to poorer fermentation potential. Finally, the levels of fructose, especially in the case of samples with 200 ppm of trehalose, were higher than those of the other two sugar measured.

Scanning electron microscopy showed that the dough sample containing 200 ppm of trehalose (b) was better developed than the one without trehalose, and most of the starch granules were covered with a continuous gluten network (Fig. 8). Starch granules were also better distributed and presented more ordered size. On the contrary, control sample presented both small and large starch granules, which were more densely distributed throughout the protein matrix. Besides, it was found that trehalose can maintain protein structures after thawing, stabilize disulfide bonds, and enhance gluten development (FSANZ 2003; Kim et al. 2003; Shimizu et al. 2003).

Finally, it should be noted that the sensory evaluation of all bread samples pointed no unfavorable effects on their flavor and aroma (0 ppm, almost odorless; 150 and 200 ppm, more intense flavor/aroma at the end of the storage period) by the addition of trehalose. Contrarily, in several cases it amended crust color (0 ppm, 3; 200 ppm, 5) and crumb’s elasticity (0 ppm, 2; 200 ppm, 4), constrained some of the defects in samples’ appearance (fewer fissures), and increased their overall score.

Conclusions

In the current work, the application of trehalose in frozen dough products was studied to investigate its cryoprotective role. Results indicate that it can improve loaf volume and enhance bread’s textural characteristics proportionally to its dough content, providing bakery products with increased cryoresistance and higher-quality attributes. Also, it may affect dough behavior and freeze concentration during freezing and enhance the assimilation of glucose, fructose, and sucrose by yeast cells, improving fermentation ability. However, it is considered important to further study the incorporation of trehalose in frozen dough systems at elevated concentrations to designate its optimum level of use (based on sensory and quality parameters).

References

Anon, M. C., LeBail, A., & Leon, A. E. (2004). Effect of freezing on dough ingredients. In Hui, Cornillon, Legarreta, Lim, Murrell, Nip (Eds.), Handbook of frozen foods. New York, USA: Marcel Dekker.

Bar, A. (2000). Trehalose—produced by a novel enzymatic process. Dossier prepared and submitted on behalf of Hayashibara Co., Ltd., for evaluation pursuant to the EU Novel Foods Regulation (258/97) by the UK Advisory Committee on Novel Foods and Processes, Japan.

Calvel, R., Wirtz, R. L., & MacGuire, J. J. (2001). The taste of bread (p. 32). Maryland, USA: Aspen.

Carvalheiro, F., Roseiro, J. C., & Girio, F. M. (1999). Interactive effects of sodium chloride and heat shock on trehalose accumulation and glycerol production by Saccharomyces cerevisiae. Food Microbiology, 16, 543–550.

Casey, G. P., & Foy, J. J. (1995). Yeast performance in frozen doughs and strategies for improvement. In K. Lorenz & Brummer (Eds.), Frozen and refrigerated doughs and batters. Minnesota, USA: American Association of Cereal Chemists.

Christensen, R. (1996). Multiple regression: Introduction. In Christensen (Ed.), Analysis of variance, design and regression—applied statistical methods (pp. 391–408). London, UK: Chapman & Hall.

Conrad, P. B., & De Pablo, J. J. (1999). Computer simulation of the cryoprotectant disaccharide α,α-trehalose in aqueous solution. Journal of Physical Chemistry, 103, 4049–4055.

Diniz-Mendes, L., Bernardes, E., De Araujo, P. S., Panek, A. D., & Paschoalin, V. M. F. (1999). Preservation of frozen yeast cells by trehalose. Biotechnology and Bioengineering, 65(5), 572–578.

Egan, H., Kirk, R. S., & Sawyer, R. (1981). Pearson’s chemical analysis of foods (pp. 233–236). Essex, UK: Longman.

Elbein, A. D., Pan, Y. T., Pastuszak, I., & Carroll, D. (2003). New insights on trehalose: A multifunctional molecule. Glycobiology, 13(4), 17–27.

Fik, M., & Surowka, K. (2002). Effect of prebaking and frozen storage on the sensory quality and instrumental texture of bread. Journal of the Science of Food and Agriculture, 82, 1268–1275.

Food Standards Australia New Zealand (FSANZ) (2003). Trehalose as a novel food. Final assessment report application (A453), Canberra, Australia.

Fuchigami, M., Ogawa, N., & Teramoto, A. (2002). Trehalose and hydrostatic pressure effects on the structure and sensory properties of frozen tofu soybean curd. Innovative Food Science and Emerging Technology, 3, 139–147.

Gancedo, C., & Flores, C.-L. (2004). The importance of a functional trehalose biosynthetic pathway for the life of yeasts and fungi. FEMS Yeast Research, 4, 351–359.

Giannou, V., Tzia, C., & LeBail, A. (2005). Quality and safety of frozen bakery products. In Sun (Ed.), Handbook of frozen food processing and packaging. New York, USA: Marcel Dekker.

Haines, A. H. (2003). Synthesis of L-trehalose and observations on isomer and by-product formation. Carbohydrate Research, 338, 813–818.

Hall, E., Ibanoglu, S., & Ainsworth, P. (2004). Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. Journal of Food Engineering, 63, 177–184.

Holmes, J. T., & Hoseney, R. C. (1987).Frozen doughs: Freezing ant thawing rates and the potential of using a combination of yeast and chemical leavening. Cereal Chemistry, 64(4), 348–351.

Kalichevsky-Dong, M. T. (2000). The glass transition and microbial stability. In Kilcast & Subramaniam (Eds.), The stability and shelf-life of food. Cambridge, UK: Woodhead and CRC Press LLC.

Karel, M., & Lund, D. B. (2003). Freezing. In Karel & Lund (Eds.), Physical principles of food preservation. New York, USA: Marcel Dekker.

Kim, H.-J., Morita, N., Lee, S.-H., & Moon, K.-D. (2003). Scanning electron microscopic observations of dough and bread supplemented with Gastrodia elata Blume powder. Food Research International, 36, 387–397.

Laaksonen, T. J., & Roos, Y. H. (2000). Thermal, dynamic-mechanical, and dielectric analysis of phase and state transitions of frozen wheat doughs. Journal of Cereal Science, 32, 281–292.

MacDougall, D. B. (2002). Colour measurement of food, principles and practice. In MacDougall (Ed.), Colour in food, improving quality. Cambridge, UK: Woodhead.

Masaru, O., Naoki, U., & Norifumi, O. (1995). Method for producing bread. European Patent Application, EP0688501.

Meilgaard, M. C., Civille, G. V., & Carr, B. T. Descriptive analysis techniques (Ch. 10). In: Sensory evaluation techniques (3rd ed.). New York, USA: CRC Press; 1999.

Meric, L., Lambert-Guilois, S., Neyreneuf, O., & Richard-Molard, D. (1995). Cryoresistance of baker’s yeast Saccharomyces cerevisiae in frozen dough: Contribution of cellular trehalose. Cereal Chemistry, 72(6), 609–615.

Neyreneuf, O., & Delpuech, B. (1993). Freezing experiments on yeasted dough slabs, Effect of cryogenic temperatures on the baking performance. Cereal Chemistry, 70(1), 109–111.

Pyler, E. J. (1988). Baking science & technology, vol II (3rd ed., p. 590–592). Missouri, USA: Sosland.

Ribotta, P. D., Leon, A. E., & Anon, M. C. (2001). Effect of freezing and frozen storage of doughs on bread quality. Journal of Agricultural and Food Chemistry, 49(2), 913–918.

Ribotta, P. D., Perez, G. T., Leon, A. E., & Anon, M. C. (2004). Effect of emulsifier and guar gum on micro structural, rheological and baking performance of frozen bread dough. Food Hydrocolloids, 18, 305–313.

Roos, Y. (1995). Characterization of food polymers using state diagrams. Journal of Food Engineering, 24, 339–360.

Rosenthal, A. J. (1999). Relation between instrumental and sensory measures of food texture. In: Rosenthal (Ed.), Food texture—measurement and perception (pp. 1–13). Maryland, USA: Aspen.

Roser, B. (1991). Trehalose, a new approach to premium dried foods. Trends in Food Science and Technology, 2, 166–169.

Rouille, J., LeBail, A., & Courcoux, P. (2000). Influence of formulation and mixing conditions on breadmaking qualities of french frozen dough. Journal of food engineering, 43, 197–203.

Schiraldi, C., Di Lernia, I., & De Rosa, M. (2002). Trehalose production: Exploiting novel approaches. Trends in Biotechnology, 20(10), 420–425.

Sharma, S. (1996). Principal component analysis. In Sharma (Ed.), Applied multivariate techniques (p. 58–81). New York, USA: Wiley.

Shimizu, Y., Maeda, T., Hidaki, Y., Tani, H., & Morita, N. (2003). Identification and effect of ethyl galactoside on the properties and baking quality of dough. Food Research International, 36, 373–379.

Singer, M. A., & Lindquist, S. (1998). Thermotolerance in Saccharomyces cerevisiae: The Yin and Yang of trehalose. Trends in Biotechnology, 16, 460–468.

StatSoft Inc. (2006). Electronic statistics textbook. Oklahoma, USA: Tulsa.

Tanghe, A., Teunissen, A., Van Dijck, P., & Thevelein, J. M. (2000). Identification of genes responsible for improved cryoresistance in fermenting yeast cells. International Journal of Food Microbiology, 55, 259–262.

Van Dijck, P., Colavizza, D., Smet, P., & Thevelein, J. M. (1995). Differential importance of trehalose in stress resistance in fermenting and nonfermenting saccharomyces cerevisiae cells. Applied and Environmental Microbiology, 61(1), 109–115.

Verstrepen, K. J., Iserentant, D., Malcorps, P., Derdelinckx, G., Van Dijck, P., Winderickx, J., et al. (2004). Glucose and sucrose: Hazardous fast-food for industrial yeast? Trends in Biotechnology, 22(10), 531–537.

Acknowledgments

The present work has been supported by grants from Greek GSRT (General Secretariat of Research and Technology).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Giannou, V., Tzia, C. Cryoprotective Role of Exogenous Trehalose in Frozen Dough Products. Food Bioprocess Technol 1, 276–284 (2008). https://doi.org/10.1007/s11947-007-0008-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-007-0008-z