Abstract

The ability to manufacture at the point of need in austere environments is a very important concept for the military. Research at the US Army Research Laboratory (ARL) is showing that agile, expeditionary manufacturing could be accomplished through use of materials at or near to the location of operating bases. These materials could include not only organic and inorganic materials naturally occurring in the area but also recycled materials (metals, polymers, etc.) from operating bases as well as battlefield scrap. This idea could potentially reduce the huge logistics tail needed to conduct wars on foreign soil, saving valuable resources and lives, and allowing the warfighter to perform the mission, instead of guarding and securing convoy transports. It would be favorable for our warfighters to have access to technology that uses locally available materials, for the following reasons: improved operational readiness, decreased energy costs related to transportation, reduction of spares inventory needed in-theater, and increased self-sustainability of operating bases. This paper describes ARL’s efforts towards delivering manufacturing operations to the battlefield using recycled, reclaimed, and scrap materials for feedstock.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Background

Shrinking the logistics tail is an important benefit of utilizing materials in-theater.1 The 2012 Army Sustainability Report, released 10/31/12, outlines the Army’s desire to reduce the number of convoys required to resupply troops on the battlefield.2 Reducing vulnerable convoys not only saves materiel and lives, but troops assigned to guard these convoys can actually be utilized for their intended purpose—engaging the enemy. The charter to reduce the tail in the combat zone is deemed critical to the success of the overall Army transformation, with relevance to Army future missions.3 Army research and development (R&D), as well as the sustainment community, should consider reduction in the logistics footprint to be a principal goal. As stated in Ref. 4, “Technology will be one of the primary enablers to reduce the logistic footprint, and the reduction of the logistic footprint is clearly a key element of the future battlefield.” In addition, the armed forces are increasingly playing humanitarian roles in the context of assisting citizens who have lost their assets in a natural disaster and/or live in parts of the world where there is no infrastructure for creating buildings, roads, bridges, or manufacture materials that can clean water, create energy, or repair machines. The ability to build and repair items with materials dually serves both the armed forces and society’s needs.

Challenges

There are many challenges associated with manufacturing with materials found in-theater. First, the materials must be readily available, and in relatively large amounts to be useful. Next, manufacturing process capability must exist at the operating base, and be robust enough to provide a meaningful and reliable method of production, while retaining a small physical and environmental footprint. Scalability of these manufacturing processes must also be taken into account. In addition, power and energy requirements will dictate whether these manufacturing processes will be possible on the operating base. A further concern is the effect that extreme environments (i.e., vibration and thermal and atmospheric conditions) have on the raw materials and the equipment needed for subsequent processing steps.

Impact

Transportation of Army materiel to and from theater is costly in terms of not only the logistic burden but also the time delays associated with replacing, repairing, and upgrading mission-critical equipment, systems, and vehicle platforms. The average soldier alone generates up to 7.5 lbs (3.4 kgs) of waste per day, and often has very limited means to remove the waste, so there is a need to address this from an environmental and health perspective. Water bottles, in particular, are a major problem, representing 200–300 lbs (91–136 kgs)/soldier/year. Multiple waste streams composed of organic and inorganic materials are produced [including meals-ready-to-eat (MRE) trash, cardboard boxes, cellophane and Styrofoam™ packing boxes, used oil and air filters, used motor oil, ammunition dunnage as well as empty brass cartridge casings, medical waste, used batteries, used steel belted off-road tires, etc.,5 offering an opportunity for novel processing technologies to reuse these materials effectively in-theater. Such effort should focus on offering a safe and environmentally responsible way to reduce disposal requirements by turning specific waste streams into value-added products.

The Goal of This Program

The goal of this study is development of technology for use of recycled, reclaimed, and scrap resources for in-theater additive manufacturing, to provide value-added products of use to the warfighter. This paper briefly describes research being performed by ARL in the following areas: production of additive manufacturing (AM)-grade metal powder in a shipping container (intended to supply an operating base with feedstock for metal AM operations) and utilization of waste plastics for three-dimensional (3D) printing applications.

Additive Manufacturing on The Battlefield

The Army has been using 3D printers in forward areas in Afghanistan since 2012.6 These machines are useful for producing parts made of plastic, but to date, no metal additive manufacturing equipment has been introduced into the battlefield, due to various technical challenges. As Dr. Thomas Russell, former director of the ARL, pointed out with respect to having the capability of having metal additive manufacturing in-theater,7 “Logistically there are benefits. One of our biggest challenges in the Army is that there is a huge logistics burden. If we could forward-deploy manufacturing capabilities, we would have the opportunity to manufacture parts in-theater, or repair parts. This is not just about manufacturing a new part, it’s often about how we can repair something that has been damaged. We have the opportunity to do that in-theater and use local materials. It’s an exciting area. I do not think we’ve realized its full potential.”.

Towards Production of Metal Powder on the Battlefield

One of the challenges associated with metal additive manufacturing on a forward operating base is the transport of potentially flammable metal powders for use with these processes. To counter this, ARL submitted a Small Business Innovative Research (SBIR) topic entitled “Production of AM-Grade Metallic Powder on the Battlefield,” which was approved for phase I and II contracts.

The problem with traditional methods (such as gas or water atomization) for production of metal powder in-theater is that too much infrastructure would be needed, including the equipment, utilities (electric power, water, and inert gas), postprocessing of the powder, need for cleanliness, etc.8 This report concluded that it would be more practical to stock an inventory of alloy powder for anticipated needs. Although these are legitimate concerns, it was decided to move forward with this research to determine whether the operations could be optimized to reduce the burden of these hindrances.

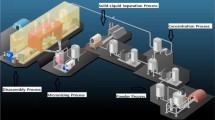

Two companies were awarded a phase I contract: American Engineering and Manufacturing (AEM) teamed with the University of Ohio, and MolyWorks Corporation. AEM proposed to use Lorenz force levitation and melting, while MolyWorks proposed to produce metallic powder in a mobile foundry. Although the companies were only expected to show a proof of concept in the phase I effort, MolyWorks used their existing mobile foundry in a shipping container to actually produce metallic powder, including AISI 4130 steel, titanium 6–4, copper (Cu-101), and 316 stainless steel (Fig. 1) and 6061 aluminum alloy (Supplementary Fig. S1). This mobile foundry is contained within an ISO container, and with further research and development, it is anticipated that the ancillary equipment (controller, power supply, gas supply, etc.) could also all be contained in an ISO container. The process also needs to be optimized, as currently only a small percentage of the powder being made falls within the sweet-spot diameter for metal additive manufacturing (approximately − 325 mesh/45 micron diameter). Within the mobile foundry, the metal is placed into a crucible, melted, and poured over flowing argon gas. The metal powder is formed and collected in the cyclones at the end of the equipment.

To determine the feasibility of using scrap in this process, ARL furnished MolyWorks with pieces of actual battlefield scrap steel and aluminum, to be added to certified steel and aluminum, respectively. MolyWorks was also able to produce aluminum powder made solely from aluminum battlefield scrap (Supplementary Fig. S2), and excess armor steel. It is clear that the particles were, for the most part, spherical, with some satellites.

ARL also wanted to determine whether the powder produced in the mobile foundry could be used with the cold gas dynamic spray (cold spray) process. This is important as it would show that AM-grade metallic powder produced on the battlefield could potentially be used with a portable cold spray machine for repair of parts in situ, extending the lifecycle of these components and reducing the logistics needed to get a spare part back to the theater of operations. The 316 stainless steel powder was placed within the powder feeder of a VRC Gen II portable cold spray system, and sprayed onto 316L stainless-steel substrate panels. For comparison, a sample of Praxair FE-101 316 stainless steel powder (already used by ARL for cold spray applications) was also cold sprayed onto a substrate. The swaths of each run are shown in Supplementary Fig. S3. Supplementary Fig. S4 shows a comparison of the cross-sections of the two cold-sprayed powders. The MolyWorks powder appeared to have less porosity, but more microcracks, indicative of higher residual forces within the deposit. This process would need to be optimized, but it did show that the powder made in the shipping container could be cold sprayed with a portable unit.

The aluminum powder made entirely from aluminum battlefield scrap was also subjected to the cold gas dynamic spray (cold spray) process, being successfully deposited as shown in Supplementary Fig. S5. Supplementary Fig. S6 shows the mechanical mixing that was noted at the interface, which is indicative of a strong adhesive bond.

Waste Plastics for 3D Printing Applications

Although expeditionary AM is a relatively new area for the Army, the Army Rapid Equipping Force (REF) has already deployed polymeric AM fused deposition modeling (FDM) equipment to the battlefield as part of the Expeditionary Laboratory (ExLab).9 The ExLab contains a Stratasys Fortus 250, which is quite limited in terms of the types of polymer feedstock it can print, thus limiting applications. The main drawback of this machine is the requirement to use commercial filament from the original equipment manufacturer (OEM). Logical supply chain issues can again come into play if such filament is not available. Supplementary Fig. S7 shows some parts that were made in the ExLab in-theater out of acrylonitrile butadiene styrene (ABS) polymer, which are to be used as a baseline. Research at ARL was performed to determine the feasibility of trying to 3D-print using recycled polymers (from an operating base) including FDM filament feedstocks of polyethylene terephthalate (PET), polypropylene (PP), high-density polyethylene (HDPE), and polystyrene (PS). The challenges of using recycled materials include the purity of the materials, including additives/fillers/dyes present in many plastic containers and biological and chemical contamination, mixed or unknown feedstocks, and limited power and cleaning materials availability for processing.

Polymer filament was prepared by rinsing plastic containers with ethanol, drying, and cutting into pieces that could be fed either through a cross-cutting paper shredder (PET, HDPE, and PP) or high-speed blender (PS). After shredding, HDPE and PP were further processed by mixing in a high-speed blender to form uniform shred sizes. Shredded polymer was fed into a Filabot or Process 11 extruder at temperatures ranging from 140°C to 270°C to melt the polymers, and the extrudate was collected on a spooler (Filabot). The nozzle diameter was adjusted between 1.75 mm and 3.0 mm to account for die swell and shrinkage. The target diameter was 1.75 mm and 3.0 mm.

Filament was printed into tensile bars (type V, ASTM D63810) on FlashForge Creator Pro and Lulzbot Taz 6 FDM printers. STL files were imported into Simplify 3D for editing. The bed temperature was varied between 60°C and 100°C, while the nozzle temperature was varied between 220°C and 280°C. The build orientation was in the X direction, with the layer height set to 0.2 mm. The infill density, pattern, and outline overlap were optimized for tensile strength with the commercial Stratasys polycarbonate-acrylonitrile butadiene styrene (PC-ABS) filament.

Thermal properties were measured using differential scanning calorimetry (DSC) with a heat–cool–heat program (TA Instruments). All samples were heated at 20°C/min to 300°C, cooled at 20°C/min to − 50°C, then heated again at 20°C/min to 300°C. DSC data were processed using Universal Analysis software. Chemical analysis was performed by Fourier-transform infrared attenuated total reflectance (FTIR-ATR) spectroscopy (Thermo Nicolet Nexus 870 ESP) using 256 averaged scans over the range of 4000–400 cm−1 at resolution of 4 cm−1.

Select forward operating bases have Stratasys FDM printing machines which typically use Stratasys PC-ABS filament. To determine the best mechanical properties that could be achieved with this filament, a series of tensile bars were printed with varied infill density, infill pattern, and outline overlap. Supplementary Fig. S8 displays the effect of the infill density on the tensile strength and stress–strain curves for 25%, 50%, 75%, and 100% infill (grid, 30% overlap). Surprisingly, there was little improvement in tensile strength above 50% infill. The tensile strength was higher for the 50% infill, compared with the 75% infill. Figure 2 displays scanning electron microscopy (SEM) images of the fracture surfaces. All specimens showed a printing defect between layers. The filament shape was partially distorted due to melting into the next layer, but filaments were still distinguishable. Breakage occurred for 25% infill at the void (Fig. 2A). Some filament necking was evident in the 50% infill specimen, while the 75% and 100% samples also showed signs of deformation.

The effect of the infill pattern was also probed (50% infill, 30% overlap) using four common patterns: grid, fast honeycomb, full honeycomb, and triangular. Supplementary Fig. S9 displays the tensile results and a representative stress–strain curve. There was little variation between the different patterns in terms of tensile strength. The triangular and grid patterns showed the best reproducibility, while the honeycomb patterns, particularly the fast honeycomb, had high margins of error.

The outline overlap or percentage of overlap of adjacent filaments was also probed at 50% infill (grid pattern). Overlaps of 10–75% were probed, showing very little change between 30% and 75% overlap (Supplementary Fig. S10).

Recycled polymers contain a variety of different additives, fillers, and dyes, and may have experienced different processing conditions, even for the same polymer type. To get a better understanding of different recycled polymer feedstocks and the best properties to expect from such materials, thermal and mechanical testing was performed. Tensile dogbones were cut out of milk jugs, soda bottles, yogurt containers, and plastic cups (polypropylene) using a die. Plastic water bottles could not be tested due to the ribs in the bottles. Polystyrene materials were too brittle to punch out. (Injection-molded parts for all polymers will be compared in future work.) Representative stress–strain curves are displayed in Supplementary Fig. S11, along with the tensile strength and elastic modulus of each material. The soda bottles (PET) showed the highest tensile strength, nearly five times that of the polyolefin materials. The PET bottles showed two yield points, with a significant amount of stretching before failure.

Table I presents the thermal properties obtained from DSC measurements. The two sources of PP examined, i.e., cups and yogurt containers, showed the same melting temperature and similar percentages of crystallinity, but the crystallization temperatures were 16°C apart. This difference may be due to the dyes and fillers in the yogurt container, in contrast to the cups, which were transparent and likely contained less additives. The thermal characterization of PS only provided information on the glass-transition temperature (Tg), since it is an amorphous polymer, with almost identical values for the two sources of PS. The thermal data for the PET water and soda bottles were markedly different. The PET in the soda bottles showed higher Tg and melting point, but lower crystallization temperature, and was more crystalline. Only one source of HDPE was examined.

Chemical characterization was performed using FTIR spectroscopy (Supplementary Fig. S12). The two sources of PS examined [Petri dishes and utensils (opaque)] appeared chemically identical, despite the presence of fillers in the utensils. The two sources of PET (water and soda bottles) also appeared identical. The PP cups and yogurt containers showed three regions that were notably different, most likely due to dyes in the yogurt containers.

Recycled PS, PET, and PP were fabricated into filaments and printed into tensile bars. Tensile bars were printed from the recycled plastics using either 50% (PS) or 100% (PP, PET) infill, grid pattern, and 30% overlap. The PS tensile bars were quite brittle with mean tensile strength of 19.9 ± 3.9 MPa, or about half that of Stratasys filament (34.0 ± 0.8 MPa). Because the PS filament was very brittle and difficult to spool and feed into the printer, infill and printing parameters were not optimized. PET filament obtained from plastic soda bottles showed tensile strength (36.4 ± 3.1 MPa) comparable to that of Stratasys PC-ABS filament (34.8 ± 0.8 MPa). PP from yogurt containers showed lower mean tensile strength (20.1 ± 2.3 MPa). Printing parameters are currently being optimized to improve the tensile strength of parts printed from recycled filaments. Filament has been made from HDPE but has not yet been printed or tested.

Conclusion

Reducing the dependence of forward operating bases on the logistical supply chain will not only increase operational readiness and the self-sustainability of warfighters in-theater, but also improve the safety of the warfighter by reducing threat vulnerabilities. The ability to fabricate needed parts on demand, in-theater in austere environments with available resources, would be game-changing for the military.

MolyWorks has made great strides in producing powder in a mobile foundry contained within a shipping container. Batches can be made with scrap metal, and the resulting powder can be cold sprayed and additively manufactured using the laser-engineered net-shape (LENS) process. The vision is to have the future capability to produce this powder in-theater for real-time repair of components (for example, with cold spray technology) or building of spare parts.

ARL has also researched use of recycled plastics in 3D printing applications. Studies were conducted to determine the best print parameters to make the strongest part from the least amount of material. Sources of potential plastic waste were characterized to understand their thermal, mechanical, and chemical properties. PET exhibited the highest tensile strength and is likely the best candidate for making strong plastic parts. Tensile bars were printed with recycled filaments and tested. Future work will involve testing tensile specimens made from recycled PP, HDPE, and PET filaments.

Change history

29 May 2020

A significant portion of duplicate content from this article was published as ���Manufacturing at the Point of Need Using Recycled, Reclaimed, and/or Indigenous Materials,��� by Marc Pepi, Nicole Zander, Margaret Gillan, in DSIAC Journal, Vol. 5, No. 3, 2018. DSIAC is a publication of the United States Defense Systems Information Analysis Center, whose content is approved for public release and whose distribution is unlimited.

References

Force projection research and development: the key enabler for army transformation. Strategy Research Project, Col Genaro J. Dellarocco. (US Army War College, Carlisle Barracks, PA, USAWC Class of 2001, 10 April 2001).

US Army Outlines Push to Save Resources, Lives. Defense News (19 Nov 2013).

Shrinking the Logistics Tail in the Combat Zone. Col. Larry W. Jameson (9 April 2002).

Logistics Transformation—Reducing the Logistics Footprint. Strategy Research Project, LTC Darrell S. Ransom, US Army War College, Carlisle Barracks, PA, USAWC Class of 2002 (5 April 2002).

Private Communication with CPT Terry Wilkin, USA (12 Aug 2014)

M. Cox, Army Sees Rapid Prototyping as Key to Rapid Innovation. Defense Tech News, Military.com (1 April 2015).

Dr. Thomas Russell, Research Vision for 3-D Printing. Army Technology Magazine, RDECOM Public affairs (5 July 2014).

J. Strauss, Feasibility study on the deployment of an atomization system contained within conex shipping containers to operate at a forward operating base. Special Report for ARL (25 Nov 2015 unpublished research).

M. Cox, Mobile labs build on the spot combat solutions (2012). http://www.military.com/daily-news/2012/08/17/mobile-labs-build-on-the-spot-combatsolutions.html, Military.com. Accessed Jan 30, 2017.

ASTM D638, Standard Test Method for Tensile Properties of Plastics (West Conshohocken: ASTM International, 2014).

Acknowledgements

The authors wish to thank the following for their contributions to this work: the Army SBIR Office, Chris Eonta and team at MolyWorks Corp., and John Lawmon and team from AEM, Inc. (AM-grade metallic powder from battlefield scrap).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pepi, M., Zander, N. & Gillan, M. Towards Expeditionary Battlefield Manufacturing Using Recycled, Reclaimed, and Scrap Materials. JOM 70, 2359–2364 (2018). https://doi.org/10.1007/s11837-018-3040-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3040-8