Abstract

We consider a phase field model for the formulation and solution of topology optimization problems in the minimum compliance case. In this model, the optimal topology is obtained as the steady state of the phase transition described by the generalized Cahn–Hilliard equation which naturally embeds the volume constraint on the amount of material available for distribution in the design domain. We reformulate the model as a coupled system and we highlight the dependency of the optimal topologies on dimensionless parameters. We consider Isogeometric Analysis for the spatial approximation which facilitates encapsulating the exactness of the representation of the design domain in the topology optimization and is particularly suitable for the analysis of phase field problems. We demonstrate the validity of the approach and numerical approximation by solving two and three-dimensional topology optimization problems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In engineering it is often desired to apply some optimization techniques to the design of a structure, component or device. Other than sizing [9, 112] and shape optimization techniques [55, 74, 101], a significant contribution is given by topology optimization [10, 11, 13, 15, 89, 90], which represents the fundamental form of optimization; indeed, topology optimization aims at finding the optimal distribution of a material in a design domain such that an objective functional is minimized under certain constraints. The minimum compliance case represents the most common topology optimization problem, for which the goal is to generate the globally stiffest structure by distributing only a limited amount of material in the design domain [11, 13]; additionally, another interesting problem consists in generating the lightest structure under stress constraints, see among the others e.g. [24, 38, 80]. Historically, topology optimization has been used principally for structural static problems based on a linear elastic model, but many other cases have also been successfully considered. For example, this is the case for applications in fluid dynamics [1], heat conduction [48], vibration [61], multiphysics [98] and bioengineering [115]; also topology optimization has been used for shell structures [69, 89] and with different material models as in [93] for elastoplastic structures.

In most cases, topology optimization problems are defined in simplified geometries, typically rectangles, representing the design domain, i.e. the admissible domain that the design can occupy. Even if it is a reasonable starting point to assume the design domain as large as possible to avoid the introduction of spatial constraints on the optimal design, in some cases it would be interesting, if not necessary, to perform topology optimization for a part or component of a structure for which an initial design already exists. This is the case for example when the design domain is obtained as part of a multi step optimization procedure or is defined as a lower-dimensional manifold, like for plates and shells [68, 69]. In such cases, since it is common practice in engineering to represent geometries with Computer Aided Design (CAD) technologies, which are based on NURBS [85] or, more recently, T-splines [94], it is desirable to include the exact representation of the design domain in the topology optimization procedure. However, in current practice, the numerical approximation scheme used for topology optimization, typically the Finite Element Method (e.g. [33, 57, 87]), requires the approximation of the design domain and disconnects the analysis, and hence, the optimization from its geometrical representation.

In general, the capability to embed the CAD geometric representation in the analysis and optimization provides not only accuracy advantages, but also has the potential to considerably improve the efficiency of the overall design procedure. The importance of establishing a suitable link between the optimization and the CAD representation is recognized and discussed in [16] for shape optimization, in particular for shells structures; the authors propose a procedure combining design modeling, structural analysis and optimization, for which these tasks are coordinated by means of a program system named Computer Aided Research Analysis Tool [17] made available to the designer. In [89] shape optimization problems are solved by considering the position of the control points of B-spline [85] as design variables together with adaptive refinement strategies; a similar procedure is extended to topology optimization problems, combining repeated optimization steps with B-spline approximations of the optimal topologies and adaptive refinement. In [74] the relation between CAD and shape parametrization is discussed for shape optimization, especially for fluid dynamics; additionally, in [114] manipulation of the splines is used to generate optimal geometries. Also, in [66] topology optimization problems have been solved by using control points of B-spline curves as design variables in an approach combing shape optimization and hole nucleation.

Isogeometric Analysis, a generalization of Finite Element Analysis for which basis functions are defined by NURBS or T-splines [35, 58], provides the possibility to embed the exact CAD representation of the design domain in topology optimization, in addition to exhibiting several other advantages [8, 34, 41, 50]. Isogeometric Analysis has already been introduced successfully and discussed for shape optimization in [30, 53, 75, 110] and we believe that it also represents a potentially effective numerical approximation method for topology optimization problems. Recently, Isogeometric Analysis has been used in [96] to solve design optimization problems to generate optimal two-dimensional structures by means of a procedure based on trimmed curves; this concept is further extended in [95] for topology optimization problems. In this manner the final optimal structure is represented by NURBS and T-splines and directly linked to the CAD representation without the need of additional postprocessing of the topology optimization result. However, even if this represents a great advantage and ideal situation, the topology optimization results appear to be strongly dependent on the specific approach used to generate the trimmed curves and surfaces. Additionally, B-spline bases are considered in [64] for two-dimensional topology optimization problems.

In general, despite the fact that Isogeometric Analysis allows for the exact representation of the initial (CAD) design domain, the representation of the optimal design is still implicit, in a similar manner for topology optimization strategies with conventional Finite Element methods. For this reason, a comprehensive design optimization procedure based on Isogeometric Analysis should be used to provide an optimized structure starting from an initial design domain and passing through topology optimization and geometry generation of such optimal design. Eventually, the optimal geometry could be further improved by means of shape optimization, while maintaining the centrality of the geometry in the overall optimization procedure by means of Isogeometric Analysis.

In its original formulation, topology optimization is a distributed and discrete valued problem [13], for which only areas of material and void are allowed without intermediate states. However, this formulation leads to many difficulties both from the analysis and the numerical points of view, and it requires efficient discrete optimizers, see e.g. [104]. The most popular approach to overcome this difficulty is based on the material distribution concept, for which the design variable corresponds to a density function smoothly representing the distribution of the material in the design domain, with intermediate values between the pure material and void states allowed. In this framework a possible approach is the homogenization method [3], for which the macroscopic properties of the material are deduced from the microscopic properties of the porous material represented by the density function; the first numerical approximation for an homogenized material was presented in [11]. However, in this approach solutions appear to have an elevated number of microscopic holes and microstructures which are undesired from a manufacturability point of view, when pure material and void states are required. In order to obtain these kinds of optimal topologies, the intermediate states can be penalized by choosing suitable interpolation schemes for the dependency of macroscopic material properties on the density function; in the case of isotropic materials, the Solid Isotropic Material Penalization (SIMP) model is the most successfully used [12, 13, 72, 91]. Typically, topology optimization problems in this approach are solved with suitable constrained optimization techniques and with low-order Finite Element approximation for the density function, often piecewise constant over the elements. However, additional stabilization and filtering techniques need to be introduced at the level of the numerical approximation in order to remove or reduce the well-known mesh dependency and checkerboard phenomena [13, 62] which affect the topology optimization results. Different techniques have been considered to solve topology optimization problems, among these are Evolutionary Structural Optimization (ESO) [116] and Bidirectional ESO methods [118], heuristic procedures based on the identification of regions of material with high and low contributions to the stiffness of the structure; also, other optimization strategies based on the removal of material by the evaluation of topological derivatives have been adopted [76]. However, in general, among the drawbacks of these formulations there is the strong dependence of the optimal solution on the particular optimizer utilized and its settings.

Recently, the use of the level set method [79] has been proposed to solve topology optimization problems [4, 5, 37, 113]. In this approach, the introduction of a level set function, which is associated with the density function, avoids directly tracking the boundaries between the material and the void; the optimal solution is then obtained as the evolution in time of the level set function, for which an optimizer is no longer needed. However, topological changes are uni-directional, in the sense that holes can only be removed in the design domain and inner front creation requires additional numerical techniques [81, 117]; also, similar to other level set methods, repeated reinitializations of the level set function are required while numerically solving the problem.

An alternative approach to topology optimization is provided by the multiphase formulation, where the distribution of two phases, representing the material and void, inside the design domain is described by a smooth function which coincides with the material density function. The geometrical information associated with the optimal topology is then deduced from the sharp interfaces between the two phases, which are represented by thin layers. The definition of topology optimization problems in a multiphase approach has recently been introduced for design dependent loads in [21] (and [22]), for problems with stress constraints in [24] and for the minimum compliance case in [111, 119]; further extensions are also considered in [107]. The concept at the basis of this approach is that the objective functional is penalized by means of a functional approximating the total variation of the material density function, which, in the sharp-interface limit, measures the perimeter of the interfaces between the material and void. The relaxed functional is composed of two terms controlling the thickness of the interfaces and the decomposition of the pure phases, which are typical of multiphase problems [6, 26, 42]. In particular, the introduction of the interface term allows the definition of a well-posed topology optimization problem [24], and it eventually provides optimal solutions at the discrete level not affected by mesh dependency and checkerboard phenomena. However, we observe that in the multiphase approach the optimal value of the penalized objective functional does not correspond in general with the minimum of the compliance, which is the real target of the optimization. Rather, a balance between the compliance and the relaxed functional representing the perimeter of the interfaces is reached at the optimum. Still the problem is formulated as an optimization one, for which the optimal topology depends in general on the optimizer used.

Further, the topology optimization problem in the multiphase approach can be transformed into a phase field problem for which the optimal topology is obtained as the steady state of the phase transition; at the basis of this formulation there is the reinterpretation of the penalized objective functional introduced for the multiphase approach as a total free energy. Traditional phase field models are represented by the Cahn–Hilliard [26–28] and Cahn–Allen [6] equations, which have been introduced in metallurgy to describe phase segregation in binary alloy systems. More recently, phase field approaches have been successfully considered to provide mathematical models for problems in different disciplines; for example, there are models for crack propagation [19, 71], also with Cahn–Hilliard equation [102], image segmentation [109] and cancer and tumor growth [43, 77]. The role of the phase field approach for topology optimization consists in obtaining separated phases, material and void, divided by thin and sharp interfaces for which the distribution of the material in the design domain is determined by the optimization considerations. In this sense, this resembles the case of the Cahn–Hilliard equation with elastic misfit, for which the distribution of the phases partially takes into account the elastic properties of the materials; see e.g. [45]. In topology optimization, this effect has to assume a leading role, and the distribution of the material depends on the objective function of the topology optimization problem. Phase field models for topology optimization have been considered firstly in [111, 119, 120] for the minimum compliance case, also for multimaterials problems; a nonlinear fourth-order generalized Cahn–Hilliard equation is derived and successfully solved for two and three-dimensional problems by using a multigrid algorithm [119, 120] and with an approach which partially decouples the phase and elasticity equations. The mass conservation property of the Cahn–Hilliard equation is conveniently used to naturally take into account the mass/volume constraint associated with the minimum compliance problem. More recently, a similar approach based on the Cahn–Allen equation has been proposed in [107] for shape and topology optimization, even if without the capability to introduce topological changes. In [31, 44] a model based on the diffusion-reaction equation, with analogies with the Cahn–Allen equation, is introduced for minimum compliance problems with an augmented Lagrangian approach to take into account the mass/volume constraint.

Phase field models show many similarities with the level set approach, however, they allow to naturally include hole nucleation in the formulation and avoid reinitializations of level set functions while numerically solving the problem.

In this work we formulate the topology optimization problem for the minimum compliance case by using a phase field approach following [120], since we feel that this kind of formulation provides several advantages. Namely, it has the ability to naturally deal with topological changes, to provide geometrical information, and to completely describe the topology optimization problem at the continuous level, without the necessity of introducing any ad hoc numerical techniques at the discretization stage; also, since the problem of optimization is converted to a phase transition problem, the need to use an optimizer, and hence the dependence of the solution on its settings, is eliminated and replaced with the choice of a suitable time approximation scheme. We rederive the generalized Cahn–Hilliard equation starting from the multiphase approach on the basis of energy considerations, following the usual procedure for the derivation of phase field models, and we highlight the parametric dependency of the problem introduced by the penalization of the objective functional. Also, we rewrite the phase field model as a coupled system of phase and elasticity equations, we provide its dimensionless form, and we characterize it in terms of dimensionless parameters. We discuss the choice of the parameters used to penalize the objective functional and the mesh dependence of the optimal solution, and we extend the continuation method [21, 24, 76], an optimization strategy based on the sequential solution of optimization subproblems, to the phase field case.

For the numerical solution of the topology optimization problem in the phase field approach we consider Isogeometric Analysis for the spatial approximation, since we believe that it provides several benefits for the solution of this kind of problem in analogy with [50, 51] for phase field problems. Firstly, Isogeometric Analysis encapsulates the CAD representation of the design domain in the topology optimization while providing geometric flexibility; also, it ensures robustness, high-order accuracy, and the capability to easily use compactly supported high-order basis functions for the approximation of the nonlinear fourth-order generalized Cahn–Hilliard equation, whose numerical solution necessitates spatially C 1-continuous functions. In addition, the use of Isogeometric Analysis for topology optimization problems allows to properly represent the sharp interfaces between the material and void, and it appears to be resistant to checkerboard and other instability phenomena, even in the multiphase approach. For the time approximation we use the generalized-α method [32] together with a time-adaptive scheme that allows a very efficient solution of the problem, which, in analogy to other phase field models, exhibits fast and intermittent variations in time.

In general, in the phase field approach, Michell type structures [70] are obtained at the early stages and during the phase transition, while the number of holes in the topology tend to reduce as the steady state is approaching. More complicated topologies can eventually be obtained by reducing the relaxation parameter controlling the thickness of the interfaces even if this requires computational meshes sufficiently fine to correctly capture the sharp interfaces. As general consideration, we can conclude that the use of smooth, high-order continuous basis functions, as in Isoegometric Analysis, allows for the proper representation of the interfaces, but necessitates finer meshes than for standard low-order Finite Element approximations; for this reason, we believe that the choice of a suitable material interpolation function may mitigate this effect. In addition, we observe that the topologies obtained at the steady state do not necessarily correspond to the minimum value of the compliance, but rather to the minimum value of the penalized objective functional defined in the multiphase approach. Indeed, while the penalized objective functional monotonically converges to a (local) minimum at the steady state, the evolution in time of the compliance of the system is not monotone and some (local) minima may be obtained at intermediate time steps. However, in the phase field approach, we define a procedure allowing to identify both the optimal topologies corresponding to the minimum values of the penalized objective functional and the compliance simply by tracking the evolution of the compliance during the phase transition to the steady state. Then, we select the optimal topological design as the one corresponding to the minimum value of the compliance achieved during the phase transition for any suitable choice of the relaxation parameters. Nevertheless, different configurations obtained during the phase transition can be selected for further investigation on the basis of the values assumed by the compliance.

We show the effectiveness of the proposed procedure by solving two and three-dimensional topology optimization problems in design domains defined by NURBS geometries. We discuss the influence of the relaxation parameters on the optimal solution and discuss the mesh dependency in relation with the choice of such parameters. In particular, we believe that the mesh dependency effect may be mitigated and eventually eliminated when solving a topology optimization problem in a multiphase or phase field approach.

This work is organized as follows. In Sect. 2 the SIMP and multiphase approaches for topology optimization in the minimum compliance case are recalled. In Sect. 3 the derivation of the standard Cahn–Hilliard phase field model is recalled in anticipation of the presentation in Sect. 4 of the phase field model for topology optimization. In Sect. 4 the generalized Cahn–Hilliard equation is derived, the coupled system presented, and a dimensional analysis performed in order to highlight the dependency of the problem on dimensionless parameters. In Sect. 5 we present the numerical approximation scheme based on Isogeometric Analysis and the generalized-α method with time adaptivity. In Sect. 6 we discuss the dependency of the optimal solution on the initial distribution of material and the choice of the parameters upon which solutions depend; also, we present the continuation method in the context of the phase field approach and we discuss the selection of the optimal topological design. In Sect. 7 we provide and discuss numerical results for two and three-dimensional topology optimization problems. Finally, conclusions are presented in Sect. 8.

2 Topology Optimization in the Minimum Compliance Case

In this section we introduce the topology optimization problem in the minimum compliance case by using the binary original material-void formulation; then, we rewrite the problem with the SIMP and the multiphase approaches, which represent the basis for the definition of the phase transition model of Sect. 4. Standard notation is used through this work to denote the Sobolev spaces of functions with Lebesgue measurable derivatives and norms; see e.g. [2].

2.1 The Material-Void Binary Problem

We start by indicating with x a generic point in a given design domain Ω⊂ℝd of dimension d=2,3. In this design domain, we assume that at any point x∈Ω there is the presence of either material or void; i.e., for any subset Ω mat ⊆Ω, there is a characteristic function χ mat =χ mat (x), with χ mat :Ω→ℝ and χ mat ∈L ∞(Ω), such that:

By convention, χ mat =1 indicates the presence of the material, while χ mat =0 corresponds to regions of Ω where the material is absent, which we will refer to as void. We adopt a formulation based on the linear elastic theory for small displacements with an isotropic material [57], whose properties are fully described by the symmetric elastic tensor ℂ0 which depends on the Young’s modulus E 0, the Poisson ratio ν 0 and the dimension d of the problem (for d=2, both the plane-stress and plane-strain cases can be considered).

The formulation of the continuum topology optimization problem follows from the introduction of the elastic tensor ℂ mat , which is written in terms of the characteristic function χ mat as:

By introducing the displacement u and the associated strain tensor ε(u), we define the stress tensor \(\widetilde{\sigma}_{mat}(\mathbf{u})\) as:

We observe that \(\widetilde{\sigma}_{mat}(\mathbf{u})\) is symmetric and linearly dependent on the displacement u; the superscript “∼” indicates the dependency on the independent variable u.

The associated elastic problem in strong form consists in finding, for a given material distribution Ω mat , the displacement u such that:

where Γ D ⊂∂Ω is the Dirichlet partition of the design domain boundary ∂Ω where the displacement is imposed, while Γ N :=∂Ω∖Γ D is the part of the boundary where the surface force h is applied, with \(\hat{\mathbf{n}}\) the outward directed unit vector normal to ∂Ω; for the sake of simplicity we assume a null displacement on Γ D . Also, f is the body force acting in the domain Ω which we consider independent of the characteristic function χ mat . A sketch is presented in Fig. 1 for a two-dimensional design domain.

Toward the weak form of the elastic problem (4), we introduce the function spaces \(\mathcal{V} := \{ \mathbf{v} \in [H^{1}(\varOmega) ]^{d} : \mathbf{v}|_{\varGamma_{D}} = \mathbf{0} \}\) and \(\mathcal{H}_{mat} := \{ \phi\in L^{\infty }(\varOmega) \}\); moreover, we define the residual R mat,u (u)(v)∈ℝ such that:

where we assume that all the Lebesgue integrals are well defined (this hypothesis holds true for \(\chi_{mat} \in\mathcal{H}_{mat}\), u, \(\mathbf{v} \in\mathcal{V}\), h∈[L 2(Γ N )]d−1 and f∈[L 2(Ω)]d). Then, the elastic problem (4) in weak form reads, for a given material distribution Ω mat :

We observe that the displacement \(\mathbf{u} \in\mathcal{V}\) solving Eqs. (4) and (6) depends on the prescribed Ω mat , for which u=u(χ mat ). In this manner the stress tensor of Eq. (3) associated to the solution of Eq. (6) reads:

We introduce the compliance energy of the system (6), say J mat,E , as:

where ψ E,mat is the strain energy function:

with:

We observe that the standard definition of the strain energy involves a factor of 1/2 which is neglected to maintain consistency with the typical formulation of the topology optimization framework. Also, we notice that following from Eqs. (6) and (8),

In order to introduce the topology optimization problem in the minimum compliance case, we recall that only a limited amount of material can be used, which means that only a limited area/volume of Ω, say V mat <|Ω|, can be covered by the material, with V mat defined as:

In this sense, the topology optimization problem is constrained and the space of admissible controls, say \(\mathcal{H}_{mat,ad} \subset\mathcal{H}_{mat}\), in which we look for the optimal material distribution \(\varOmega_{mat}^{*}\) is defined asFootnote 1

Then, the problem of topology optimization in the minimum compliance case corresponds to

where J E,mat is the compliance energy (8) of the elastic system (6).

2.2 The SIMP Approach

The standard approach to topology optimization consists in replacing the distributed, discrete valued, binary problem of Sect. 2.1 with a problem formulated in terms of a smooth material density function. With this aim, we introduce the material density function ρ=ρ(x) to represent the distribution of a given material at any generic point x of the design domain Ω. By convention, ρ=1 indicates the presence of the material, while ρ=0 corresponds to the void; intermediate states of ρ between 0 and 1 are allowed and indicate regions of “soft” material (ersatz material approach). Also, we require that 0≤ρ≤1, since values outside this range do not correspond to meaningful representations of the material distribution. De facto, the function ρ is a relaxation of the characteristic function χ mat (1) and, in practice, the formulation of the topology optimization problem in terms of the material density function ρ mimics the formulation for the discrete material-void binary problem (12).

The SIMP approach is based on the concept that the properties of the material depend on the density function ρ for which the elastic tensor ℂ(ρ) is a function of ρ; in particular, we can write:

with g(ρ) a suitable function introducing the homogenization of the elastic properties depending on the distribution of the material in Ω. The function g(ρ) assumes a crucial role in the definition of the SIMP method, since the quality of the topology optimization results strongly depend on it; we will return on this point later. It follows that the stress tensor is dependent on ρ as:

Similarly to Eq. (3), the stress tensor \(\widetilde{\sigma}(\rho,\mathbf{u})\) is symmetric and linearly dependent on u and the superscript “∼” is used to indicate the dependency on both ρ and u as independent variables.

By recalling Eq. (4) and Fig. 1, the elastic problem in strong form consists in finding the displacement u, for a given material density function ρ, such that:

We introduce the function space \(\mathcal{H}:= \{ \phi\in L^{\infty} (\varOmega) : g(\phi) \in L^{\infty }(\varOmega) \}\) in addition to the space \(\mathcal{V}\) for the displacement u, and the residual R u (u;ρ)(v)∈ℝ:

The elastic problem (15) in weak form reads, for a given material distribution \(\rho\in\mathcal{H}\):

The displacement \(\mathbf{u} \in\mathcal{V}\) which solves Eqs. (15) and (17) depends on the prescribed material distribution function ρ such that u=u(ρ); as consequence, we define:

By mimicing Sect. 2.1, we define the compliance energy of the system (17), say J E (ρ), as:

with the strain energy function ψ E (ρ):

and

We observe that Eq. (19) can equivalently be written as \({J_{E}(\rho) = \widetilde{J}_{E}(\rho,\mathbf{u}(\rho))}\), where from Eq. (21):

In view of the definition of the topology optimization problem, we define the area/volume covered by the material as:

In addition, we define the space of admissible controls, say \(\mathcal{H}_{ad} \subset\mathcal{H}\), in which we look for the optimal solution ρ ∗ as \(\mathcal{H}_{ad} := \{ \phi\in\mathcal{H} : 0 \leq \phi\leq1 \ \text{and } \int_{\varOmega} \phi\, d\varOmega= V \} \). Then, the problem of topology optimization in the minimum compliance case in the material density formulation reads:

with J E (ρ) the compliance energy (19) of the elastic system (17).

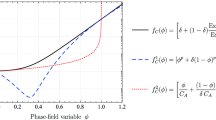

We recall that the elastic properties of the material are introduced in the topology optimization problem by means of the interpolation function g(ρ) of Eq. (13). In general, the topology optimization procedure allows “soft” regions of material in the design domain, since ρ can assume intermediate values between 0 (void) and 1 (material). However, these situations, even if consistent with the mathematical formulation, are in general not desired as output of the optimization problem. Indeed, the goal is to distribute a given material with its full elastic properties for which the desired values of ρ are possibly only 0 (void) and 1 (material). In order to reduce or avoid these situations, the function g(ρ) of Eq. (13) plays a crucial role. In the material interpolation formulation, this function is typically chosen such that intermediate distributions of material correspond to a material with poor stiffness properties; in this manner, due to the area/volume constraint, the material is located to minimize the compliance energy of the system. A typical choice for g(ρ) is based on the SIMP model, for which:

with \(P \geq\max\{\frac{2}{1-\nu_{0}}, \frac{4}{1+\nu_{0}} \}\) if d=2 or \(P \geq\max\{15\frac{1-\nu_{0}}{7-5\nu_{0}}, \allowbreak \frac{3}{2} \frac {1-\nu_{0}}{1-2\nu_{0}} \}\) if d=3; the condition on the power P is to guarantee that the interpolation model represents a material model [12, 13, 72]. Typically, since materials with ν 0=1/3 are often considered, the power is chosen such that P≥3 for both d=2,3; also this value is reasonable even when a minimum value for ρ, say ρ min >0, is introduced. We observe that other choices of g(ρ) can be made, among these are rational functions [103] and B-splines [82], which can be useful for vibration problems; see [13] for a wider discussion.

The continuous topology optimization problem (24) does not admit, in general, the existence of optimal solutions as pointed out and discussed in [13, 63]; moreover, the uniqueness of the solution is also an issue, since multiple minima can be detected due to the non-convex nature of the problem. However, even if in general ill-posed [63, 67, 100], the topology optimization problem is discretized and then solved numerically. Typically, see e.g. [12, 13, 103], low order Finite Element approximations are used to approximate the density function ρ, even if other choices are possible (see [48] for a Finite Volume Method). Then, the problem is solved by means of a suitable optimization method; in this sense, the Method of Moving Asymptotes (MMA) represents one of the most effective optimizers for the solution of topology optimization problems [105, 106]. The fact that the continuous problem is ill-posed reflects on the numerical solution, even if the discrete problem admits the existence of optimal solutions. This is revealed by the so called mesh dependency effect, for which different optimal solutions are obtained with different discretizations of the problem, specifically for different Finite Element meshes. There are several techniques to mitigate or even eliminate this effect, which are introduced as global or local constraints; the most used ones are [13, 100]: local constraints on the density gradient [84], local density and sensitivity filters [20, 84, 97, 99], global control of the minimum length scale [52, 86], and perimeter control or limitation, for which a global constraint (upper bound) in terms of the total variation TV(ρ) of the material density function

with P L >0, is imposed [83].Footnote 2 As pointed out in [7, 54], the total variation of the material density function represents the proper relaxation of the perimeter for designs that interpolate between material and void; moreover, the TV(ρ) converges, in the limit, to the perimeter of designs as the width of the interface between the material and void tends to zero. The imposition of a perimeter constraint limits the number of holes that a solution could exhibit. In practice, the constraint (26) is introduced to make the topology optimization problem well posed, as shown in [7] for the continuous case. An alternative approach to the inequality constraint on the perimeter has been proposed in [54] and consists in perturbing the objective functional (19) with a smooth penalty term for the perimeter P L .

Another undesired, but common, feature that optimal topologies can exhibit is the so called checkerboard phenomenon, which indicates a numerical solution with patterns of alternate 0–1 values (void-material) [13, 100]. As discussed in [62], this represents a form of numerical instability associated with the approximation of the topology optimization problem, which is a nonlinear mixed variational problem in the independent density and displacement variables. Similarly to the case of linear mixed problems [23], stability issues could arise at the discrete level even if the continuous problem is well posed. Even if a comprehensive analysis of the stability properties has not been performed due to the nonlinear nature of the problem, it has been shown in [62] for some particular topology optimization problems, that using suitable pairs of Finite Element spaces for the density and displacement variables eliminates the checkerboard issues.Footnote 3 In general, as pointed out in [13], any of the numerical techniques introduced to limit the mesh dependency effect could be effectively used to avoid this phenomenon.

As a final remark, we observe that in order to properly solve the topology optimization problem (24) in the SIMP approach, it is necessary to introduce additional numerical techniques, which in general depend on the discretization chosen, with respect to the original continuous formulation of the problem; also a suitable constrained optimizer needs to be used.

2.3 The Multiphase Approach

In order to introduce the topology optimization problem in the multiphase approach, we recall that the distribution of the phases, material and void, inside the design domain Ω is represented by the material density function ρ. Also, we define the parameters \(\boldsymbol{\mu}=(\gamma,\lambda) \in\mathcal{D}\), with γ and λ positive and the parameter set \(\mathcal{D} \subset\mathbb{R}^{2}\), in order to introduce a parametrization on the topology optimization problem.

The multiphase approach is based on the introduction of a penalized objective functional J(ρ;μ), which depends on the parameters \(\boldsymbol{\mu}\in\mathcal{D}\), by means of a suitable relaxation of the total variation TV(ρ;λ) of the material density function (26). With this aim, we define the functional J TV (ρ;λ) which represents the relaxation of TV(ρ) with respect to the parameter λ as:

with E 0 a suitable constant and the function ψ TV (ρ;λ) defined as:

where ψ B (ρ) is a suitable bulk energy function and ψ I (ρ) is the interface energy function:

In addition, by recalling Eqs. (19) and (20), we redefine:

In this manner, the penalized objective functional J(ρ;μ) reads:

with the constant E 0 introduced to ensure that all the terms in Eq. (31) have the dimension of an energy density.Footnote 4

The introduction of the functional J TV (ρ;λ;E 0) (27) allows a relaxation of the total variation TV(ρ) constraint (26) and it represents an approximation of the perimeter of the material-void interfaces depending on the parameter λ. The function ψ TV (ρ;λ) (28) defining J TV (ρ;λ;E 0) is obtained as the sum of bulk and interfaces energies ψ B (ρ) and ψ I (ρ). In particular, the bulk energy ψ B (ρ) is a non-convex smooth function chosen in the form of a double-well in the pure phases ρ=0 and ρ=1, for example, as ψ B (ρ)=ρ 2(1−ρ)2 [24]; in this manner, the values assumed by ψ B (ρ) for intermediate values of ρ are larger than for the pure phases, which are preferred in the optimization context. Also, further penalization terms can be added to ψ B (ρ) in proximity of the pure phases ρ=0 and 1 in order to remove the inequality constraints 0≤ρ≤1 from the formulation of the optimization problem; a possibility is to consider ψ B (ρ) a logarithm-type function with singularities in the pure phases. The interface energy function ψ I (ρ) represents a measure of the perimeters of the level sets of the material density function ρ [24] and introduces the capability of controlling the thickness of the interfaces through the parameter λ.

Following the result in [73], it is possible to show that, due to the properties of Γ-convergence (see e.g. [36]), material distributions \(\rho\in\mathcal{H}_{ad}\) minimizing J TV (ρ;λ;E 0) for a fixed value of the area/volume V converge, for λ→0, to characteristic functions χ in the binary form (1) which minimize the perimeter for the same area/volume constraint; see also [24]. This result is particularly important in the context of topology optimization since it allows for the possibility of penalizing the compliance J E (ρ;γ) by means of the relaxed functional J TV (ρ;λ;E 0) approximating the perimeter of the interfaces between material and void with respect to the parameter λ. As a final remark, we observe that, even if the bulk and interface energy functions, ψ B (ρ) and ψ I (ρ), can be considered and investigated separately, it is their combined action which allows for the introduction of the relaxed perimeter constraint J TV (ρ;λ;E 0).

However, since it is more convenient in practice to represent the penalized objective functional (31) explicitly in terms of the strain, bulk, and interface energies, we will consider the following formulation from here on. We rewrite the penalized objective functional J(ρ;μ), dependent on the parameters \(\boldsymbol{\mu}\in\mathcal{D}\), as:

with the function ψ(ρ;μ) defined as:

or, equivalently from Eq. (28), ψ(ρ;μ):=γψ E (ρ)+E 0 ψ TV (ρ;λ). Then, the objective functional J(ρ;μ) (32) reads:

where J E (ρ;γ) is given in Eq. (30) and

We observe that, from Eq. (27), we have equivalently J(ρ;μ)=J E (ρ;γ)+J TV (ρ;λ;E 0). Finally, we notice that the objective functional (32) can be rewritten in terms of the material density function ρ as \(J(\rho;\boldsymbol{\mu})=\widetilde{J}(\rho,\mathbf{u}(\rho);\boldsymbol{\mu})\), where:

with, following from Eq. (21):

Similarly to Eq. (34) we write:

with:

If we consider the penalized objective functional J(ρ;μ) (32) with the bulk energy function ψ B (ρ) embedding the penalization terms for the inequality constrains 0≤ρ≤1, we can take the space of admissible controls as \(\mathcal{H}_{ad} = \{ \phi\in\mathcal{H} : \int_{\varOmega} \phi\, d\varOmega= V \}\), where only the area/volume constraint is explicitly imposed and \(\mathcal{H} = \{ \phi \in L^{\infty}(\varOmega) \cap H^{1}(\varOmega) : g(\phi) \in L^{\infty}(\varOmega) \}\); the extra regularity of \(\mathcal{H}\) with respect to the SIMP approach is due to the presence of the interface energy ψ I (ρ) in the formulation. The topology optimization problem in the multiphase approach corresponds to:

for any given parameter \(\boldsymbol{\mu}\in\mathcal{D}\). We observe that the optimal distribution of material in the design domain is ρ ∗=ρ ∗(x;μ) in the sense that it depends on the parametrization introduced in the penalized objective functional (32).

The parameters \(\boldsymbol{\mu}=(\gamma, \lambda)\in\mathcal{D}\) in Eq. (33) play a crucial role in the optimization problem, since they regulate the balance of the different terms contributing to the penalized objective functional J(ρ;μ). For example, if γ is very large, the optimization problem assumes a similar behavior to the SIMP approach. Conversely, if γ=0, then the optimal result ρ ∗ is dominated by the bulk and interfaces terms only, i.e. by the relaxation of the perimeter constraint associated to J TV (ρ;λ;E 0) (27). This last case corresponds to a pure multiphase problem, where the total free energy of the system is minimized [27, 42] (see Sect. 3 for the Cahn–Hilliard equations).

Remark 1

The material density function ρ ∗ which minimizes J(ρ;μ) for some given \(\boldsymbol{\mu}\in\mathcal{D}\) in Eq. (41) does not correspond, in general, to a (local) minimum of the compliance J E (ρ) (19) which represented the original goal of the optimization. Even if this is an expected result due to the penalization of the objective functionals (31) and (34), we aim at limiting this effect by suitably tuning the parameters \(\boldsymbol {\mu}=(\gamma,\lambda) \in\mathcal{D}\). As a general guideline, the parameter γ should be chosen as large as possible, while λ as small as possible.

Remark 2

A third positive parameter, say κ∈ℝ, can be added to the parameter vector \(\boldsymbol{\mu}\in\mathcal{D}\), such that \(\boldsymbol{\mu}_{\kappa}:=(\gamma,\lambda,\kappa) \in\mathcal{D}_{\kappa}\), with \(\mathcal{D}_{\kappa}\subset\mathbb{R}^{3}\). In this case, the penalized objective functional (32) is redefined as:

with the function ψ κ (ρ;μ κ ):

or, equivalently, in terms of the relaxation of the total variation function ψ TV (ρ;λ) (28) as: ψ κ (ρ;μ κ )=γψ E (ρ)+E 0 ψ TV,κ (ρ;λ;κ) with \(\psi_{\mathit{TV},\kappa}(\rho;\lambda;\kappa):= ( \frac{1}{k} \psi_{B}(\rho) + k \lambda\psi_{I}(\rho) )\). Then, the formulation of the topology optimization problem follows similarly to the previous case. The role of κ is twofold. Firstly, it ensures that the penalized objective functional is convex for κ “sufficiently” large and the topology optimization problem (41) is well-posed, as shown in [24] for a minimum weight topology optimization problem with stress constraints in a relaxed approach. Secondly, it ensures that the optimal topology converges to the pure phases 0 and 1 for κ→0 [24], according to the properties of Γ-convergence [73] for functionals with interface terms [21]. On this basis the parameter κ introduces the possibility to solve the topology optimization problem (41) by means of a continuation method [13, 21, 24, 76]. In this procedure, the optimal topology ρ ∗ is obtained as the last step of a sequence of minimizers of locally convex (or quasi-convex) optimization problems parametrized for decreasing values of κ and initialized with the optimal solution of the previous step; this means that a non-convex topology optimization problem without interface term, which corresponds to the ideal formulation, is obtained as the limit for κ→0.

Finally, we observe that the topology optimization problem in the multiphase approach is completely defined at the continuous level and, eventually, for suitable choices of the parameters, also well-posed. This is not the case of the SIMP formulation, which is in general ill-posed at the continuous level and it requires the introduction of additional numerical techniques at the discrete level. However, a non-convex optimizer is still required to solve the topology optimization problem in the multiphase context.

3 Phase Field Model: The Cahn–Hilliard Equation

In Sect. 2.3 we have considered the topology optimization problem as a multiphase approach for which a penalized objective functional is minimized; the formulation is however still set in an optimal control context, for which an optimization problem needs to be solved to find ρ ∗. However, the penalized objective functional can be interpreted as a total free energy and the topology optimization problem recast in a phase transition setting. Indeed, in this case, the evolution of the phases is such that an energy is minimized in time with respect to the initial configuration. In this section we provide the derivation of the standard Cahn–Hilliard phase field model [26–29] and we highlight its properties in view of the phase field model for topology optimization in Sect. 4. For further details in the analysis of the Cahn–Hilliard equation we refer the interested reader to [25, 39, 40, 42, 92], while e.g. to [39, 50, 108] for its numerical solution.

Let us consider a two phase problem, for which the phase transition is described by the variable ρ=ρ(t,x), which corresponds to the concentration of one of the phases in the domain Ω (the other one is obtained as 1−ρ in the 0–1 binary representation). The total free energy (Ginzburg–Landau free energy), which we indicate with F(ρ;λ) [27, 28, 42], is expressed in the case of interest as:

with the total free energy function ψ F (ρ;λ) defined as:

for a positive parameter \(\lambda\in\mathcal{D} \subset\mathbb{R}\) and the bulk and interface energies given in Sect. 2.3; the parameter C 0 is introduced to ensure that the function ψ F (ρ;λ) assumes the dimension of an energy density. Typically, a double-well logarithm or quartic function is chosen for ψ B (ρ) [27, 40, 42, 108], even if other type of functions can be conveniently used.

The definition of the phase transition model is based on the concept of gradient flow grad F(ρ,λ) of the functional F(ρ;λ) in the norm of a Hilbert space \(\mathcal{Z}\) [29, 42], for which the corresponding equation in strong form reads:

with ρ=ρ 0 for t=0 in Ω. Depending on the choice of the function space \(\mathcal{Z}\), different phase transition models can be obtained; if \(\mathcal{Z} = \{ \varphi \in(H^{1}(\varOmega) )' : \langle\varphi, 1 \rangle= 0 \}\) [42], the Cahn–Hilliard gradient flow and the corresponding equation are obtained [26–28], otherwise, if \(\mathcal{Z}= L^{2}(\varOmega)\), the Cahn–Allen equation is derived [6]. In particular, in the Cahn–Hilliard case, the gradient flow \(\operatorname{grad} F(\rho,\lambda)\) reads:

where M(ρ)≥0 is a sufficiently regular function called the mobility, which is typically a constant M 0 or degenerate M(ρ)=M 0 ρ(1−ρ), and z F (ρ;λ) is the potential associated to the total free energy function ψ F (ρ;λ); in the Cahn–Allen case, the gradient flow would read \(\operatorname{grad} F(\rho;\lambda) = M(\rho) z_{F}(\rho;\lambda)\). The potential z F (ρ;λ), which we introduce for the sake of simplicity, depends specifically on the choice made for the functional (44) and in this case is obtained as the Gâteaux derivative in L 2(Ω) of the total free energy (44):

for some \(\lambda\in\mathcal{D}\); if further we assume that the boundary condition \(\nabla\rho\cdot\hat{\mathbf{n}} = 0\) is imposed on ∂Ω, the potential z F (ρ;λ) simply reads:

where:

for ρ sufficiently regular.

A standard formulation of the Cahn–Hilliard equation in strong form is:

for some \(\lambda\in\mathcal{D}\). We define the function space \(\mathcal{H} := \{ \phi\in H^{2}(\varOmega) : \nabla\phi\cdot \hat{\mathbf{n}} = 0 \}\). Let us assume that \(\rho\in C^{1} ([0,T);\mathcal{H} )\) and so \(\frac {\partial\rho}{\partial t} \in\mathcal{C}^{0} ([0,T);\mathcal{H} )\). That is, ρ is a C 1-continuous mapping from the time interval [0,T) into \(\mathcal{H}\) and \(\frac{\partial\rho}{\partial t}\) is a C 0-continuous mapping from [0,T) into \(\mathcal{H}\). Consequently, for each t∈[0,T), \(\rho\in\mathcal{H}\) and \(\frac {\partial\rho}{\partial t} \in\mathcal{H}\). From Eq. (52), for each t∈[0,T), the residual R CH (ρ;μ)(ϕ)∈ℝ is given by:

Then, the Cahn–Hilliard equation in weak form reads:

with ρ=ρ 0 in Ω, t=0, for some \(\lambda\in\mathcal{D}\). The Cahn–Hilliard equation (54) (or Eq. (52)) is endowed with the following properties:

-

Its solution ρ exists and is unique for the case of constant mobility as shown in [92] for problems in dimensions d=1,2,3 under suitable hypothesis for the bulk function ψ B (ρ) including its smoothness; existence of solutions is discussed in [40] for the case of degenerate mobility.

-

It is mass conservative in the sense that the area/volume covered by the phases in Ω is constant in time; indeed, by using the definition (23), we can easily deduce from Eq. (54) for ϕ=1 that:

$$ \frac{dV}{dt} = 0 \quad\Longleftrightarrow\quad V \equiv \int_{\varOmega}\rho_0 \, d\varOmega\quad\forall t \in [0,T). $$(55) -

The total free energy functional (44) is a Liapunov functional; indeed, it is possible to show from Eq. (54) that:

(56)

(56)This implies that the phase transition occurs in such a manner that the energy associated to the Cahn–Hilliard equation is decreasing or at most conserved in time; this property also holds true for the Cahn–Allen equation, since in general:

$$ \frac{d F}{dt}(\rho;\lambda) = - C_0 \bigl\| \operatorname{grad} F(\rho;\lambda)\bigr\|_{\mathcal{Z}}^2 \leq0, $$(57)in the norm induced by \(\mathcal{Z}\), see [42].

-

Under suitable hypothesis on the function ψ B (ρ) including its analyticity, in [92] it is proved that, for a given ρ 0, the unique solution ρ converges to an equilibrium (steady state) and \({\frac{\partial\rho}{\partial t} \rightarrow0}\) for t→∞ in the topology of the corresponding function spaces. This implies from Eqs. (46) and (57) that the steady state solution is a critical one for the total free energy F(ρ;λ) [39], with \({\frac{d F}{dt}(\rho;\lambda)\rightarrow0}\) for t→∞; it follows that F(ρ;λ) evolves to a local minimum through the phase transition from the initial solution ρ 0.

-

The total free energy F(ρ;λ) (44) represents a reformulation of the relaxed total variation of the material density function J TV (ρ;λ;E 0) introduced in Eq. (27). As a consequence, distributions of phases minimizing the total free energy F(ρ;λ) are approximations of minimizers of the perimeter for a fixed area/volume V.

4 Topology Optimization with the Phase Field Model

We derive now the phase field model for topology optimization similarly to [120]. First, we provide the generalized Cahn–Hilliard equation based on the multiphase approach of Sect. 2.3; then, we reformulate the problem as a coupled system with phase and displacements as independent variables and, finally, we discuss the dimensionless problem highlighting its dependence on dimensionless parameters.

4.1 The Generalized Cahn–Hilliard Equation

In Sect. 3 we derived the Cahn–Hilliard equation starting from a total free energy functional. We have observed that this phase field model is area/volume conservative and the phase transition occurs in such a manner that the energy of the system decreases in time. These two properties are crucial to recast the multiphase approach for topology optimization of Sect. 2.3 in a phase transition model, since an area/volume constraint is set in the minimum compliance case and a penalized objective functional needs to be minimized.

The derivation of the generalized Cahn–Hilliard equation for the topology optimization problem in the minimum compliance case follows in similar manner to Sect. 3 by using the penalized objective functional (32). In particular, we have that:

where ρ=ρ 0 for t=0 in Ω,

and the potential z(ρ;μ) deduced from the Gâteaux derivative in L 2(Ω) of the penalized objective functional (32):

for some \(\boldsymbol{\mu}\in\mathcal{D}\). If we assume that \(\nabla \rho\cdot\hat{\mathbf{n}} = 0\) on ∂Ω, we have from Eq. (33) that:

where z B (ρ) and z I (ρ) are defined in Eqs. (50) and (51), respectively, and:

In order to evaluate z E (ρ), further elaborations are needed since \({\frac{d \psi_{E}}{d \rho}(\rho) = \frac{d \widetilde{\psi}_{E}}{d \rho}(\rho,\mathbf{u}(\rho))}\) from Eq. (20); in particular, we have that:

From Eq. (21) we deduce that:

similarly, by recalling that \(\widetilde{\sigma}(\rho,\mathbf{u})\) depends linearly on u and the elastic tensor ℂ(ρ) is symmetric, we have:

In order to evaluate the term \(\widetilde{\sigma}(\rho,\frac {d\mathbf{u}}{d\rho} )\), we need to differentiate the weak form of the elasticity equation (17) with respect to ρ; by assuming that the function \(\frac{d \mathbf{u}}{d \rho} \in\mathcal{V}\), we obtain:

and hence for v=u:

By replacing the result (67) in Eq. (65), and then Eqs. (64) and (65) in Eq. (63), we obtain:

with:

The potential (61) can also be written as:

where:

and equivalently:

It is now possible to introduce the strong form of the generalized Cahn–Hilliard equation for topology optimization from Eq. (58), which reads:

for some \(\boldsymbol{\mu}\in\mathcal{D}\). By recalling from Sect. 3 that \(\rho\in\mathcal{H}\) for all t∈[0,T), with \(\mathcal{H} := \{ \phi\in H^{2}(\varOmega) : \nabla\phi\cdot \hat{\mathbf{n}} = 0 \}\), we introduce the residual R ρ (ρ;μ)(ϕ)∈ℝ such that:

It follows that the weak form of the generalized Cahn–Hilliard equation is:

with ρ=ρ 0 in Ω, t=0, for some \(\boldsymbol{\mu}\in\mathcal{D}\). We observe that Eq. (75) is obtained with the natural boundary condition \(M(\rho) \nabla z(\rho;\boldsymbol{\mu}) \cdot\hat{\mathbf{n}} = 0\) and the essential one \(\nabla\rho\cdot\hat{\mathbf{n}} = 0\) defined on the boundary ∂Ω; due to its nature, the latter is embedded in the space \(\mathcal{H}\).

Remark 3

The boundary condition \(\nabla\rho\cdot\hat{\mathbf{n}} = 0\) imposes a geometric constraint on the optimal design since it requires that the interfaces between the material and void intersect the boundary ∂Ω only at right angles. This does not have physical meaning in minimum compliance topology optimization and it is introduced only to facilitate the reformulation of the topology optimization problem from the multiphase approach into the phase field model (see in particular Eqs. (60), (61) and (51)). If one wishes to avoid this, an alternative boundary condition may be incorporated in the phase field model. We have not pursued this in this work.

The generalized Cahn–Hilliard equation (75) (or Eq. (73)) represents a model for topology optimization problems in the minimum compliance case, for which the following properties hold similarly to the Cahn–Hilliard equation:

-

The unique solution ρ exists by extending the result of [92] under suitable hypothesis on the bulk and strain energy functions ψ B (ρ) and ψ E (ρ), in the case of constant mobility.

-

The area/volume covered by the material in the design domain Ω is constant during the phase transition; see Eq. (55).

-

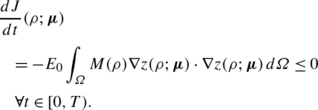

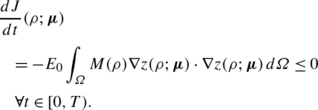

The penalized objective functional J(ρ;μ) (32) is a Liapunov functional which evolves in time by decreasing from the initial value corresponding to ρ 0; indeed, from Eq. (57) in analogy with Eq. (56), we have:

(76)

(76) -

If the functions ψ B (ρ) and ψ E (ρ) satisfy the hypothesis made in [92] for the bulk energy of the Cahn–Hilliard equation, the unique solution ρ converges to a steady state which minimizes the penalized objective functional J(ρ;μ) of the multiphase approach with respect to the initial solution ρ 0; in this manner, the optimization problem is converted to a time dependent one and its optimal solution ρ ∗ is obtained as ρ for t→∞.

-

The topology optimization problem is completely defined in the formulation by choosing the data h, f, ℂ0 and Ω, the function g(ρ) in Eq. (13), the mobility M(ρ), the initial condition ρ 0 (which also introduces the area/volume constraint V) and the parameters \(\boldsymbol{\mu}\in\mathcal{D}\).

In the current work we do not provide a rigorous analysis of the generalized Cahn–Hilliard equation for topology optimization problems. At this point, we only speculate on the possibility that the bulk ψ B (ρ) and especially the strain energy ψ E (ρ) functions could satisfy the hypothesis made in [92] for the existence and uniqueness of the solution ρ and its convergence to a steady state, the minimizer of J(ρ;μ); further limitations on the material interpolation model could be eventually deduced to fit such hypothesis. However, we observe that numerical tests exhibit the convergence of the solution to a steady state for any given initial solution, for which we feel that the validity of the considered phase field model could be shown also from an analytical point of view.

Remark 4

As observed in Remark 1, the minimum value of the penalized objective functional J(ρ;μ) does not coincides in general with the minimum value of the compliance J E (ρ) (19). For this reason, at the steady state of the phase transition, only a (local) minimum of J(ρ;μ) is obtained, while the minimum value of J E (ρ) can be obtained at an intermediate time t∈[0,T).

4.2 The Coupled System

The generalized Cahn–Hilliard equation (75) (or Eq. (73) in strong form) is written in terms of the phase variable ρ. However, in order to solve the problem it is necessary to evaluate the displacement u(ρ) by solving the elasticity equation (17) for a given value of ρ. In practice, for each t∈[0,T), there is a corresponding displacement \(\mathbf{u} \in\mathcal{V}\). For this reason, it is convenient to consider the phase ρ and the displacement u as two independent variables and rewrite the generalized Cahn–Hilliard equation as a coupled system of equations.

By recalling Eqs. (73), (71) and (15), the strong form of the coupled system is:

for some \(\boldsymbol{\mu}\in\mathcal{D}\). Also, for each t∈[0,T), we define the residual \(\widetilde{R}_{\rho}(\rho,\mathbf{u};\boldsymbol{\mu})(\phi) \in\mathbb{R}\) from Eq. (74) by recalling the potential \(\widetilde{z}(\rho,\mathbf{u};\boldsymbol {\mu})\) (71):

similarly, from Eq. (16), for each t∈[0,T), we redefine \(\widetilde{R}_{\mathbf{u}}(\rho,\mathbf{u}; \boldsymbol{\mu })(\mathbf{v}) \in\mathbb{R}\) to highlight the explicit dependency on ρ and u as:

Then, the coupled system of generalized Cahn–Hilliard and elasticity equations in weak form, which we will indicate as TO(μ), reads:

for some \(\boldsymbol{\mu}\in\mathcal{D}\) and the associated energy \(\widetilde{J}(\rho,\mathbf{u};\boldsymbol{\mu})\) defined in Eq. (37). We observe that the displacement u depends on the time t∈[0,T) implicitly trough the variation of the phase ρ. Indeed, in the elasticity equation no time derivatives appear, meaning that the displacement adapts instantaneously to the variation of the phase.

The reformulation of the generalized Cahn–Hilliard equation (75) (or Eq. (73)) into the coupled system TO(μ) (80) provides an approach to analyze the problem in terms of existence and uniqueness. Indeed, we notice that the coupled system (80) shows many analogies with the Cahn–Hilliard equation with elastic misfit, also known as the Cahn–Larchè model [65], for which the phase transition is also driven by elastic interactions of the material [45, 78]. In [45] the existence of a solution of such a system is proved as well as its uniqueness for a specific choice of the elastic energy; in [46] the corresponding discretized problem is analyzed. However, we remark that the Cahn–Larché equations and the coupled system TO(μ) (80) corresponding to the generalized Cahn–Hilliard equations are derived from different concepts. Indeed, the first equations follow from thermodynamical considerations and balance laws for the species and the momentum with ρ and u as independent variables. Conversely, the generalized Cahn–Hilliard equation is developed by considering the displacement variable as dependent on the phase variable u(ρ) and only the balance of the species is taken into account; the coupled system TO(μ) only represents a reformulation of such an equation.

4.3 Dimensionless Form of the Coupled System

We now rewrite the coupled system (80) in dimensionless form. With this aim, we introduce the dimensionless space and time coordinates:

and the phase and displacement variables:

where L 0 and T 0 are representative length and time scales, while the superscript ⋆ indicates dimensionless variables. Also, if we use E 0 as the representative Young modulus, we obtain:

and

while defining the reference surface and body forces  and f

0, we have:

and f

0, we have:

finally, the dimensionless mobility is:

Let us define the following dimensionless parameters which we indicate with the vector D=(D 1,…,D 5) such that:

we observe that the parameter γ is dimensionless, while the parameter λ assumes the same dimension as \(L_{0}^{2}\). Moreover, we define the dimensionless potential:

for which \(\widetilde{z}^{\star}(\rho^{\star},\mathbf{u}^{\star};\mathbf{D}) = D_{2} \widetilde{z}(\rho,\mathbf{u};\boldsymbol{\mu})\) and the dimensionless energy function:

for which \({\widetilde{\psi}^{\star}(\rho^{\star},\mathbf{u}^{\star};\allowbreak\mathbf{D}) = \frac{D_{2}}{E_{0}} \widetilde{\psi}(\rho ,\mathbf{u};\boldsymbol{\mu})}\). With these, we define from Eq. (78) the dimensionless residual \(\widetilde{R}^{\star}_{\rho}(\rho^{\star},\mathbf{u}^{\star};\allowbreak \mathbf{D})(\phi^{\star}) \in\mathbb{R}\ \forall t \in[0,T)\):

for which \(\widetilde{R}^{\star}_{\rho}(\rho^{\star},\mathbf{u}^{\star};\mathbf{D})(\phi^{\star}) = \frac{L_{0}^{4-d}}{\lambda M_{0}} \widetilde{R}_{\rho}(\rho,\mathbf{u};\boldsymbol{\mu})(\phi)\); similarly, from Eq. (79) we define \(\widetilde{R}^{\star}_{\mathbf{u}}(\rho^{\star},\mathbf{u}^{\star};\mathbf{D}) (\mathbf{v}^{\star}) \in\mathbb{R}\ \forall t \in[0,T)\) as:

with  . It follows that the dimensionless topology optimization problem in the phase field approach reads:

. It follows that the dimensionless topology optimization problem in the phase field approach reads:

with \(\rho_{0}^{\star}= \rho_{0}\) and T ⋆=T/T 0. The corresponding dimensionless penalized objective functional (energy) follows from Eq. (89) as:

with \(\widetilde{J}^{\star}(\rho^{\star},\mathbf{u}^{\star};\mathbf{D}) = \frac{1}{E_{0}} \frac{L_{0}^{2-d}}{\lambda} \widetilde{J}(\rho,\mathbf{u};\boldsymbol{\mu})\); the same scaling occurs for \(\widetilde{J}_{E}^{\star}(\rho^{\star},\mathbf{u}^{\star})\), \(J_{B}^{\star}(\rho^{\star})\) and \(J_{I}^{\star}(\rho^{\star})\).

We notice that the topology optimization problem (92) fully depends on the dimensionless parameters D and the initial solution \(\rho^{\star}_{0}\), for which the principle of dimensional similitude can be applied. Also, it is possible to reduce the parametric dependence by setting D 1=1 and hence choosing the representative time scale as \(T_{0} = \frac{L^{4}_{0}}{\lambda M_{0}}\); it follows that the problem TO⋆(D) (92) depends on D=(D 2,…,D 5).

We observe from Eq. (91) that the dimensionless parameters D 4 and D 5 of Eq. (87) only affect the linear elasticity equation. The dimensionless parameters D 2 and D 3 are responsible for changing the optimal solution of TO⋆(D) once the data are set; indeed they control the balance of the strain, bulk and interfaces energies in the penalized objective functional (93). From Eq. (89), we deduce that if D 3 is very large, then the phase field solution is dominated by the minimum compliance term of the penalized objective functional. Conversely, if D 3→0, specifically if due to γ→0, TO⋆(D) solves the standard Cahn–Hilliard equation for the phase problem with the displacement u ⋆ depending on the distribution of ρ ⋆ in Ω ⋆. Also, since from Eq. (87) D 3=γD 2 and D 2∼1/λ, with λ related to the control of the thickness of the interfaces, we have that D 2 and D 3≫1, when sharp interfaces are required.

Remark 5

For the sake of simplicity, we henceforth omit the superscript ⋆ to indicate dimensionless quantities.

5 Numerical Approximation

In this section we discuss the numerical approximation of the topology optimization problem TO(D) (92) by using a similar approach to the one used in [50, 51] for phase field problems. In particular, for the spatial approximation we consider Isogeometric Analysis [35, 58], while for the temporal approximation we use the generalized-α method [32] with time adaptivity.

5.1 The Spatial Approximation

We consider design domains Ω described by a NURBS (or B-spline basis) [85], for both the two and three-dimensional cases. The use of Isogeometric Analysis for the spatial approximation of the PDEs allows us to encapsulate directly the geometry representation in the analysis, by using the same basis functions used to represent the geometry [35, 58]. In this manner, no geometrical approximations are introduced in the analysis of the topology optimization problem TO(D) (92).

Isogeometric Analysis provides a way to easily achieve high-order continuity in the approximated solution without introducing extra degrees of freedom. In particular, for the TO(D) problem, the use of globally C 1(Ω)-continuous basis functions is necessary to approximate the functional space \(\mathcal{H}\) of the phase variable ρ. Specifically, we consider basis functions of degree p≥2 defined by open knot vectors with equally spaced internal knots repeated at most p−1 times; in this manner we ensure that the basis functions are globally C 1(Ω)-continuous. We consider the same basis functions for the phase ρ and the displacement u.

We introduce the finite dimensional spaces \(\mathcal{H}_{h} \subset \mathcal{H}\) and \(\mathcal{V}_{h} \subset\mathcal{V}\), with the above mentioned properties, of dimensions \({n_{h,\rho} := \text{dim} (\mathcal{H}_{h} )}\) and \({n_{h,\mathbf{u}} := \text{dim} (\mathcal{V}_{h} )}\). Due to the properties of the NURBS basis, the essential boundary condition \(\nabla\rho\cdot\hat{\mathbf{n}}=0\) is easily introduced in the space \(\mathcal{H}_{h}\) by imposing equality of two consecutive control values of ρ normal to the boundary. We illustrate strong imposition of the essential boundary condition in Fig. 2 for a one-dimensional B-spline basis of degree 2. This also holds for NURBS and for the multidimensional case. For each t∈[0,T), \(\rho _{h} \in\mathcal{H}_{h}\) and \(\mathbf{u}_{h} \in\mathcal{V}_{h}\) have the representations:

with N A (x) the NURBS basis and n bf the number of basis functions; the corresponding test functions are:

Then the discrete TO h (D) coupled problem for any t∈[0,T) is:

where the discrete initial condition ρ 0,h is obtained as the L 2(Ω) projection of ρ 0 in the space \(\mathcal{H}_{h}\). The total number of degrees of freedom of TO h (D) is n h :=n h,ρ +n h,u . Finally, we introduce from Eq. (94) the vectors of control variables:

and, from Eqs. (90) and (91), the discrete residuals:

where \(\hat{\mathbf{e}}_{i}\), with i=1,…,d, represent the orthonormal basis of the space ℝd; for the sake of simplicity, we neglected the explicit dependency of the discrete residuals on D in Eq. (98).

B-spline basis of degree 2 and knot vector \(\varXi=\{\{0\}_{i=1}^{3},\allowbreak 0.2,0.4,\allowbreak 0.6,0.8,\{1\}_{i=1}^{3}\}\); the two external pairs of basis functions are marked with squares and circles to indicate that the corresponding control variables need to be equal to impose the boundary condition \(\nabla\rho\cdot\hat{\mathbf{n}}=0\) on ∂Ω

5.2 The Time Approximation

The time approximation of the TO(D) problem (92) represents a challenge similar to that for the Cahn–Hilliard equation due to the fourth-order term and significant nonlinearities. We use the generalized-α method; see [32, 60] and also [8, 50]. Moreover, since the solution of the topology optimization problem is obtained as the steady state solution of the coupled system (92), i.e. for t→∞ (or T sufficiently large), we need an adaptive time scheme that reduces the time step size when necessary and increases it as the solution approaches the steady state. We employ the same procedure proposed in [50] for the Cahn–Hilliard equation, which is based on an accuracy criterion and reduces the computational costs of the simulation while maintaining an adequate level of accuracy.

Very recently, a new second-order accurate, provably unconditionally stable, time integration algorithm for phase field models has been developed in [49]. This would provide a viable alternative to the generalized-α method.

5.2.1 Time Step Scheme

Let us subdivide the time interval [0,T) by introducing the discrete time vector \(\{t_{n} \}_{n=0}^{n_{ts}}\), with Δt n :=t n+1−t n the width of the time interval at the step t n , for which the control variables (97) are \(\dot{\mathbf{P}}_{n} = \dot{\mathbf{P}}(t_{n})\), P n =P(t n ) and U n =U(t n ). Then, if we interpret the variables \(\dot{\mathbf{P}}_{n+1}\) and P n+1 as independent, the generalized-α method for the TO h (D) problem at time step t n+1 reads from Eq. (98):

with \(\dot{\mathbf{P}}_{n}\) and P n given; the parameters α m , α f and δ∈ℝ, chosen on the basis of stability and accuracy considerations, define a specific generalized-α method. As described in [57, 60] we select α m , α f and δ as follows:

where ρ ∞∈[0,1] is the spectral radius of the amplification matrix at Δt→∞. See [57, 60] for further details.

The nonlinear system (99) is solved for each time step t n+1, for n=0,…,n ts −1, by means of a two stage predictor-multicorrector algorithm, for which the control variables at the time step t n+1 are obtained iteratively, where \(\dot{\mathbf{P}}_{n+1,(i)}\), P n+1,(i) and U n+1,(i), for i=0,1,…,i max , are the iterates and where i=0 indicates the predictor. At the predictor stage the control variables are initialized as:

At the multicorrector stage the following iteration steps are repeated for i=1,…,i max :

-

1.

Update the control variables following the last two relations of Eq. (99):

(102)

(102) -

2.

Assemble the residuals:

(103)

(103) -

3.

If the following stopping criteria on the relative norms of the residuals:

$$ \frac{\|\mathbf{R}_{\rho,(i)}\|}{\|\mathbf{R}_{\rho ,(0)}\|} < \mathit{tol}_R \quad \text{and} \quad\frac{\|\mathbf{R}_{\mathbf{u},(i)}\|}{\|\mathbf{R}_{\mathbf{u},(0)}\|} < \mathit{tol}_R $$(104)are satisfied for a prescribed tolerance tol R , set the control variables at time step t n+1 as \(\dot{\mathbf{P}}_{n+1}=\dot{\mathbf{P}}_{n+1,(i-1)}\), P n+1=P n+1,(i−1) and U n+1=U n+1,(i−1) and exit the multicorrector stage; else proceed to step 4.

-

4.

Define the consistent tangent matrices from Eq. (98):

(105)

(105)where, by using Eq. (99), we have:

(106)

(106) -

5.

Solve the following linear system in the variables Δ P n+1,(i) and Δ U n+1,(i):

(107)

(107) -

6.

Update the control variables:

(108)

(108)and return to step 1.

5.2.2 Time Adaptivity

We consider an adaptive scheme similar to the one proposed in [50], which is based on the comparison of the solutions obtained with the generalized-α method and the backward Euler method [88]. The backward Euler method can be obtained by setting α m =α f =δ=1 in the generalized-α method.

The adaptive time scheme starts, for each time step t n+1, n=0,…,n ts −1, with the given control variables \(\dot{\mathbf{P}}_{n}\), P n and U n , and a given time step Δt n , typically that used at the previous time step. Then, in the adaptive algorithm the following steps are repeated for l=1,…,l max , starting with Δt n,(0)=Δt n−1 (or, if n=0, with Δt n,(0)=Δt 0):

-

1.

Compute the control variables \(\dot{\mathbf{P}}_{n+1,(l-1)}\), P n+1,(l−1) and U n+1,(l−1) with the generalized-α method of Sect. 5.2.1 for Δt n,(l−1).

-

2.

Compute the control variables \(\dot{\mathbf{P}}^{BE}_{n+1,(l-1)}\), \(\mathbf{P}^{BE}_{n+1,(l-1)}\) and \(\mathbf{U}^{BE}_{n+1,(l-1)}\) by means of the backward Euler method for Δt n,(l−1).

-

3.

If the generalized-α or the backward Euler methods are not converging (i.e. the predictor-multicorrector algorithm of Sect. 5.2.1 is not convergent), reduce the time step by means of a safety coefficient χ NC ∈(0,1), update Δt n,(l) as:

$$ \varDelta t_{n,(l)} = \chi_{NC} \varDelta t_{n,(l-1)}, $$(109)and return to step 1; else proceed to step 4.

-

4.

Evaluate the relative error associated to Δt n,(l−1):

(110)

(110) -

5.

Update the time step size according to the following formula:

$$ \varDelta t_{n,(l)} = \chi_{n,(l-1)} \varDelta t_{n,(l-1)}, $$(111)where:

$$ \chi_{n,(l-1)} := \min\biggl\{ \chi_A \biggl( \frac{\mathit{tol}_A}{e_{n+1,(l-1)}} \biggr)^{1 / 2}, 1+\chi_{GR} \biggr \}, $$(112)with tol A a prescribed tolerance, χ A ∈(0,1) a suitable safety coefficient and χ GR >0 the maximum growth rate admitted.

-

6.

If e n+1,(l−1)≥tol A , return to step 1. Otherwise, update the control variables \(\dot{\mathbf{P}}_{n+1}= \dot {\mathbf{P}}_{n+1,(l-1)}\), P n+1=P n+1,(l−1), U n+1=U n+1,(l−1) and the time step Δt n =Δt n,(l), and exit the loop.

We observe that on the basis of the previous algorithm, one of following three situations occurs after step 6:

-

if \(e_{n+1,(l-1)} < \chi_{A}^{2} \mathit{tol}_{A}\), the time step size is increased, the control variables of step 1 are considered valid and the loop ends;

-

if \(\chi_{A}^{2} \mathit{tol}_{A} \leq e_{n+1,(l-1)} < \mathit {tol}_{A}\), the time step size is reduced, the control variables of step 1 are still considered valid and loop terminates;

-

if e n+1,(l−1)≥tol A , the time step size is reduced, the control variables of step 1 are invalid and the steps 1–6 are repeated.

Since the steps 1 and 2 are computationally expensive, the occurrence of the last case should be minimum; as pointed out in [50], this is the case if good choices for the parameters tol A and χ A are made.

6 Selection of Parameters and Optimal Design

In Sect. 4.3 we provided the dimensionless form of the topology optimization problem (92), which we proposed to solve numerically by means of Isogeometric Analysis and the generalized-α method in Sect. 5. However, as already pointed out, the solution of the TO(D) problem depends on the dimensionless parameters D, which depend on parameters \(\boldsymbol{\mu}\in\mathcal{D}\) introduced in Sect. 2.3. In this section we address the issue of the choice of the parameters \(\boldsymbol{\mu}\in\mathcal{D}\) and the mesh dependency effect, we select the interpolation function g(ρ) (25) and the bulk energy ψ B (ρ) (33), we describe the continuation method which could be used for topology optimization in the phase field approach, and we discuss the choice of the initial solution ρ 0. Finally, we discuss the strategy for the identification and selection of the optimal topological design.

6.1 The Choice of the Parameters \(\boldsymbol{\mu}\in \mathcal{D}\) and Mesh Dependency

The dimensionless parameters D (87) depend both on the data of the problem and the parameters \(\boldsymbol{\mu }=(\lambda,\gamma) \in\mathcal{D}\); in particular, only the dimensionless parameters D 2 and D 3 and the representative time scale T 0 are related to \(\boldsymbol{\mu}\in\mathcal{D}\), since we set D 1=1.

For the choice of the parameter λ we adopt similar considerations to the ones made in [50, 51]. The Cahn–Hilliard equation converges for λ→0 (see Eq. (45)) to a thermodynamically consistent sharp-interface model, for which the representative length scale of the interface is related to \(\sqrt{\lambda}\). Similarly, for the generalized Cahn–Hilliard equation for topology optimization, the value of λ should be sufficiently small in order to provide realistic results with sharp interfaces between the material and the void. Moreover, λ is responsible for the number of holes appearing in the optimal topology, since in general it is associated with the interface energy ψ I (ρ) of Eq. (29).

From a numerical point of view, we observe that the computational mesh used for the spatial approximation should be fine enough to capture the thin layers between the material and void. For these reasons, following from the dimensional considerations of Sect. 4.3, we assume that the thickness of the interfaces depends on the computational mesh and the parameter λ is chosen as [50]:

where h is the characteristic length of the computational mesh, defined as: