Abstract

Highly pure n-3 polyunsaturated fatty acids (PUFA)-enriched triacylglycerols (TAG) have attracted considerable attention due to their nutritional benefits and pharmacological effects. In this study, an alternative approach to the conventional method for the synthesis of highly pure n-3 PUFA-enriched TAG by using a multi-step process was reported. First, glyceride mixtures were synthesized through Novozym 435 [Novozymes A/S (Bagsvaerd, Denmark)] catalyzed esterification of n-3 PUFA-enriched FA and glycerol. Second, partial glycerides in the resulting glyceride mixtures were hydrolyzed to FA by immobilized partial glycerides-selective lipase from Malassezia globosa. The purity of TAG reached 99.84% under the optimized conditions: buffer solution of pH 6.0, water content of 100% (w/w, with respect to the oil mass), enzyme loading of 120 U/g (U/w, with respect to oil mass) and reaction temperature of 30 °C. During hydrolysis, the immobilized SMG1-F278N exhibited good reusability and TAG purity of over 94% was maintained after being used for six cycles. Subsequently, purification of TAG was accomplished by molecular distillation at low temperature (150 °C) and highly pure (99.85%) TAG with 88.73% n-3 PUFA was obtained. The final glyceride mixtures with low acid, peroxide and anisidine value were promising products for medical and dietetic purposes. Compared with the conventional one-step synthesis of n-3 PUFA-enriched TAG by enzymatic esterification or glycerolysis or the two-step method by combined transesterification and ethanolysis, this improved process allows for higher purity of n-3 PUFA-enriched TAG and significant reduction in reaction time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Eicosapentaenoic acid (EPA, C20: 5), docosapentaenoic acid (DPA, C22: 5) and docosahexaenoic acid (DHA, C22: 6) are long chain omega-3 fatty acids (FA) which have biochemical and pharmacological benefits on human health and can be applied to treatment/prevention of some diseases [1–3]. In the past few decades, EPA and DHA as triacylglycerols (TAG) have attracted considerable attention due to their higher oxidation stability and bioavailability than EPA and DHA as ethyl esters or FA [4, 5]. Therefore, there is a growing demand to produce highly pure n-3 PUFA-enriched TAG in the food and pharmaceutical industries.

Enzymatic synthesis of n-3 PUFA-enriched TAG has been recognized as an alternative approach for chemical methods due to its environmental friendliness, mild reaction conditions and the high efficiency [6, 7]. However, the purity of TAG produced through lipase-catalyzed esterification or glycerolysis was usually less than 90% due to the presence of partial glycerides [diacylglycerol (DAG), monoacylglycerol (MAG)] [8–11]. Therefore, high temperature (230–260 °C) molecular distillation was required for further purification of n-3 PUFA-enriched TAG which would lead to the oxidation and isomerization of PUFA. Besides, another interesting two-step enzymatic method was reported to synthesize n-3 PUFA-enriched TAG by transesterification and ethanolysis combined with lower temperature (140 °C) molecular distillation [12]. Although, highly pure (98.75%) n-3 PUFA-enriched TAG could be easily obtained at lower temperature, the ethanolysis step for removal of partial glycerides is time consuming (96 h). To overcome the drawbacks of the current methods, it is necessary to further explore alternative methods.

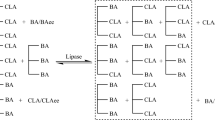

MAG and DAG lipases have attracted much attention in oils and fats modification due to their capability of synthesizing health beneficial partial glycerides [13–19]. However, to our knowledge, only two literatures have utilized this kind of lipase to remove partial glycerides by hydrolysis. A 1,3-specific MAG and DAG lipase MAJ1 from marine Janibacter sp. strain HTCC2649 was reported to remove partial glycerides by hydrolysis from camellia oil and the content of partial glycerides decreased from 98.83 to 27.9% after 12 h hydrolysis [20]. Another non-specific MAG and DAG lipase SMG1 from Malassezia globosa was also employed to hydrolyze partial glycerides from conjugated linoleic acids-enriched glyceride mixtures and the content of partial glycerides decreased from 45.2 to 0.3% [19]. Although MAG and DAG lipases exhibited great application potential in removing partial glycerides, no one has reported the removal of n-3 PUFA-enriched partial glycerides through hydrolysis using MAG and DAG lipases.

In this study, we aimed to develop a multi-step process for the preparation of highly pure n-3 PUFA-enriched TAG. First, glyceride mixtures were synthesized by Novozym 435-catalyzed esterification of glycerol and n-3 PUFA-enriched FA. Then, SMG1-F278N from M. globosa, a non-specific MAG and DAG lipase, with a 6-fold increased hydrolytic activity compared with SMG1 wild type [21] was immobilized and employed to hydrolyze partial glycerides from glyceride mixtures. Effect of different reaction conditions on the hydrolytic reaction including pH of buffer, water content, enzyme loading and reaction temperature were studied in detail and the reusability of immobilized SMG1-F278N was also assessed. Subsequently, molecular distillation at relatively low temperature (150 °C) was employed to purify n-3 PUFA-enriched TAG from hydrolytic products and the physicochemical indices of the obtained glyceride mixtures were analyzed. Finally, 13C NMR was used to characterize the positional distribution of FA in n-3 PUFA-enriched TAG.

Materials and Methods

Materials

Novozym 435 (Candida antarctica B lipase immobilized on a macroporous resin, enzyme activity 12,000 propyl-laurate units/g) was purchased from Novozymes A/S (Bagsvaerd, Denmark). DHA/EPA-enriched ethyl esters were provided by Sinomega Biotech Engineering Co., Ltd. (Zhejiang, China). ECR8285 resin was supplied by Purolite Co., Ltd. (Zhejiang, China). Standards of 1(3)-monooleoyl-rac-glycerol, dioleoyl glycerol (15% of 1,2-dioleoyl glycerol, 85% of 1,3-dioleoyl glycerol), trioleoyl glycerol, EPA ethyl, DHA ethyl, tricosanoic acid (23:0) ethyl esters, and the 37 fatty acid methyl esters for analysis were acquired from Sigma-Aldrich. n-Hexane, 2-propanol and methanoic acid were of HPLC grade from Kermel Chemical Reagent Co., Ltd. (Tianjin, China). All other solvents and reagents for analyses were of chromatographic or analytical grade.

Immobilization of SMG1-F278N

SMG1-F278N was prepared following the procedure of Xu et al. [22] and then it was concentrated by a 10 kDa molecular mass membrane (Vivaflow 200, Sartorius, Germany). The crude fermentation broth of SMG1-F278N was immobilized according to the method of Li et al. [23]. In short, lipase solution (ca. 0.4% protein) was mixed with an equal volume of 1.5 M phosphate buffer (pH 6.0). Subsequently, the mixed enzyme solution (200 mL) was added to a 500-mL conical flask containing 20.0 g of epoxy resin (ECR8285) and then the flask was placed in thermostatic water bath shaker (200 rpm) at 30 °C for 8 h. After immobilization, the immobilized SMG1-F278N was recovered and washed with 1.5 M phosphate buffer (pH 6.0) until the protein was undetectable in the eluate. Finally, the immobilized SMG1-F278N was dried in a vacuum oven at room temperature for 8 h and kept at 4 °C for subsequent use. During immobilization, the protein content was determined according to Bradford assay [24]. A calibration curve was established using bovine serum albumin as the standard protein to calculate the protein content of the enzyme solution before and after immobilization. The hydrolytic activity of immobilized SMG1-F278N was determined according to the method of Wang et al. [14]. One unit (U) of lipase was defined as the amount of immobilized SMG1-F278N which released 1 μmol FA per minute. Specific activity of immobilized SMG1-F278N was expressed as units per mg protein (U/mg). In this study, the hydrolytic activity and specific activity of immobilized SMG1-F278N were 665 U/g and 12.62 U/mg, respectively.

Preparation of n-3 PUFA-Enriched FA

A slightly modified version of the method of Gámez-Meza et al. was employed to prepare n-3 PUFA-enriched FA [25]. First 100 g n-3 PUFA-enriched ethyl esters [containing 0.02% t-butyl hydroquinone (TBHQ)] was saponified using 300 mL of 1.5 mol/L KOH in 80% ethanol by refluxing at 75 °C for 1 h. Then, 200 mL distilled water was added to the saponified mixture before unsaponifiable matter was extracted twice with n-hexane (400 mL) and discarded. Subsequently, the aqueous layer containing saponified matter was acidified to pH 1.0 with 4 mol/L HCl. The mixture was transferred into a separatory funnel and 200 mL n-hexane was added to extract the released FA. Then, the n-hexane layer was dried over anhydrous sodium sulfate and n-hexane was removed by a rotary evaporator at 30 °C under vacuum. The obtained FA were stored under nitrogen at −20 °C until use.

Synthesis of n-3 PUFA-Enriched Glycerides

In this study, n-3 PUFA was defined as the sum of EPA, DPA and DHA. n-3 PUFA-enriched glycerides were synthesized by Novozym 435-catalyzed esterification of glycerol and n-3 PUFA-enriched FA under vacuum. Reaction was conducted in a water-jacketed glass vessel, with volume of 5 L, diameter of 215 mm (inner)/241 mm (outer), and height of 256 mm, containing glycerol (200 g, 2.175 mol) and n-3 PUFA-enriched FA (2035.8 g, 6.525 mol) and initiated by the addition of 44.716 g Novozym 435 (2% of the total weight of substrates) with stirring at 400 rpm, 0.2 kPa and 60 °C. Samples were withdrawn periodically to monitor the composition of the reaction mixture. All procedures were performed in triplicate.

Removal of Partial Glycerides from Glyceride Mixtures by Immobilized SMG1-F278N-Catalyzed Hydrolysis

In order to obtain highly pure n-3 PUFA-enriched TAG, immobilized SMG1-F278N was used to further hydrolyze partial glycerides from glyceride mixtures. Reactions were carried out in a 100-mL conical flask containing 10 g of the glyceride mixtures with stirring at 200 rpm. The reaction conditions were: pH of buffer solution (5.0, 5.5, 6.0, 6.5, 7.0), water content [50, 75, 100, 125 and 150% (w/w, with respect to the oil mass)], enzyme loading of 30, 60, 90, 120 and 150 U/g (U/w, with respect to the oil mass), and temperature (25, 30, 35 and 40 °C) were varied to study their effects on hydrolysis. Buffer solutions used in the hydrolytic reactions were as follows: 0.1 M NaH2PO4/Na2HPO4 (pH 5.0, 5.5, 6.0, 6.5, 7.0). Samples (0.1 mL) were withdrawn at periodic intervals and dried over 0.5 g anhydrous sodium sulfate before diluted with 1 mL mixture of n-hexane, 2-propanol and methanoic acid (18:1:0.003, v/v/v). After being centrifuged at 10,000×g for 2 min, 0.8 mL supernatant was withdrawn for HPLC analysis.

Reusability of Immobilized SMG1-F278N

The reusability of the immobilized SMG1-F278N was determined via hydrolysis of glyceride mixtures under the optimized conditions: enzyme loading of 120 U/g (U/w, with respect to the oil mass), buffer solution of pH 6.0, water content of 100% (w/w, with respect to the oil mass), temperature of 30 °C and 15 h of reaction. After each batch, the immobilized SMG1-F278N was recovered by centrifugation at 10,000×g for 5 min and washed with 20 mL n-hexane three times. Then, the recovered immobilized SMG1-F278N was dried in a desiccator for 24 h at room temperature before being used for the next cycle. TAG purity of 99.84% for the first reaction was set as 100% and TAG purity of subsequent reactions was calculated accordingly.

Purification of TAG by Molecular Distillation

A scaled-up hydrolytic reaction, about 100-fold [1000 g glyceride mixtures, (66.21% TAG, 8.7% FA, 24.67% DAG and 0.42% MAG)] was carried out under the optimized conditions. After the reaction, the reaction mixture was centrifuged at 10,000×g for 5 min. The upper layer oil phase [976.4 g, (67.64% TAG, 32.22% FA, 0.11% DAG, 0% MAG)] was collected for molecular distillation (MD-S80 short path falling film distiller with a heating area of 0.066 m2, Guangzhou Hanwei, China). Molecular distillation of the upper layer oil phase was carried out under the conditions: a feeding temperature of 60 °C, an evaporating temperature of 150 °C, a condenser temperature of 35 °C, a feed flow rate of 2 g/min, a pressure of 2.9 Pa and a scraper speed of 250 rpm. After molecular distillation, the distillates (310.23 g) and residues (653.12 g) were collected for acylglycerol composition analysis, respectively.

The recovery of n-3 PUFA-enriched TAG together with the yield of n-3 PUFA-enriched TAG was calculated according to the method of Li et al. [12].

Analysis of Reaction Mixture by HPLC

The esterification and hydrolytic products were analyzed by Normal Phase HPLC (NP-HPLC, refractive index detector) using a phenomenex Luna column (4.6 mm i.d. × 250 mm, 5 μm particle size, Phenomenex Corporation, Torrance, CA, America). The mobile phase was a mixture of n-hexane, 2-propanol and methanoic acid (18:1:0.003, v/v/v) and elution was carried out at 30 °C with a flow rate of 1 mL/min. Peaks in HPLC were identified by comparison with the reference standards. Acquisition and processing of data was accomplished by Waters Breeze 2 software (Waters Corporation, Milford, MA, America).

TAG purity was defined as Eq. (1) in this study:

Analysis of FA Composition by Gas Chromatography (GC)

Prior to analysis FA composition of n-3 PUFA-enriched TAG by GC, the molecular distillation residues (30 mg) were applied to a thin layer chromatography (TLC) plate (100 × 200 mm) coated with silica gel and developed in a sealed TLC tank using a mixture of n-hexane/ethyl ether/acetic acid (80:20:1, v/v/v) as developing solvents. After developing and drying in a fume hood, the TLC plate was sprayed with 0.1% 2,7-dichlorofluorescein in methanol and visualized under ultraviolet light at 254 nm to identify the TAG band. The identified TAG band was scraped off and methylated to FA methyl esters according to the method of ISO 5509:2000(E) [26]. The FA methyl esters were then analyzed on an Agilent 7890A GC equipped with a capillary column CP-Sil 88 (60 m × 0.25 mm × 0.2 μm; Dikma Technologies, Beijing, China) using nitrogen as the carrier gas with a flow rate of 1.1 mL min−1. The column temperature was initially held at 140 °C for 5 min before being programmed to reach 220 °C at a rate of 4 °C and was then maintained isothermally for 15 min. The temperatures for the injector and detector were set at 250 and 280 °C, respectively. The split ratio of 30:1 was used. The FA composition of prepared n-3 PUFA-enriched FA was analyzed according to the same method.

Positional Distribution of FA in n-3 PUFA-enriched TAG by 13C NMR

The positional distribution of FA in n-3 PUFA-enriched TAG was analyzed by 13C NMR according to the method of Li et al. [12]. Briefly, 50 mg distillation residues were applied to TLC plate to separate n-3 PUFA-enriched TAG as described above. The obtained mixture of silica gel and n-3 PUFA-enriched TAG was added to a 50 mL centrifuge tube for the extraction of n-3 PUFA-enriched TAG using 30 mL chloroform and methanol (2:1, v/v) as solvent. Subsequently, the mixture was sonicated with an ultrasonic wave (200 W) for 10 min and centrifuged at 10,000×g for 5 min. The extracted n-3 PUFA-enriched TAG in the supernatant was transferred into a 50-mL round-bottom flask for removal of chloroform and methanol using a rotary evaporator at 30 °C under vacuum. Finally, the obtained n-3 PUFA-enriched TAG were dissolved in 0.5 mL deuterated chloroform and transferred into a 5-mm NMR tube for 13C NMR analysis.

Other Analyses

The acid value was analyzed according to the method of Qin et al. [27]. The peroxide value (POV) was determined spectrophotometrically by the International Dairy Federation (IDF) method [28]. The anisidine value (AnV) was determined according to the method of Hashemi et al. [29].

Statistical Analysis

All experiments were repeated for triplication. Significant differences among means were accomplished by using of an ANOVA procedure (p < 0.05).

Results and Discussion

Synthesis of n-3 PUFA-Enriched TAG

n-3 PUFA-enriched TAG were synthesized through Novozym 435-catalyzed esterification of glycerol and n-3 PUFA-enriched FA under vacuum. Figure 1 shows the time course of the esterification reaction. As the time proceeded, the TAG content increased and then remained stable at around 66%. However, DAG content increased during the first 3 h and then slightly decreased to 24.67%. Across the whole reaction process, MAG content was below 3%. After 24 h of reaction, the reaction mixture was composed of 66.31% TAG, 24.67% DAG, 0.42% MAG and 8.7% FA.

Synthesis of n-3 PUFA-enriched glycerides through Novozym 435-catalyzed esterification of glycerol and n-3 PUFA-enriched FA. Reaction conditions were as follows: n-3 PUFA-enriched FA/glycerol molar ratio, 3:1; enzyme loading, 2% (with respect to total substrates); temperature, 60 °C; pressure, 0.2 kPa; reaction time, 24 h

Removal of Partial Glycerides from Glyceride Mixtures by Immobilized SMG1-F278N-Catalyzed Hydrolysis

To achieve highly pure n-3 PUFA-enriched TAG, the partial glycerides selective lipase of immobilized SMG1-F278N was employed to remove partial glycerides by hydrolysis from the glyceride mixtures. Effects of reaction parameters such as pH of buffer solution, water content, enzyme loading and temperature on TAG purity were evaluated.

Effect of pH of Buffer Solution on the Purity of TAG

The pH of the reaction system is one of the important parameters which significantly affects the catalytic activity of the lipase. Each enzymatic reaction with an optimum pH and the rate of the enzymatic reaction will be reduced above or below the optimum pH. This is mainly because the dissociation group in the active center of enzyme varies with the pH changes of the reaction system and thus influencing the catalytic activity of the enzyme [30]. The effect of pH of the buffer solution on the purity of TAG was investigated and the results are shown in Fig. 2. Figure 2 shows that TAG purity increased with increasing reaction time and the optimum hydrolysis pH of immobilized SMG1-F278N was 6.0. When the hydrolytic reaction was performed at pH 5.5, TAG purity reached 99.54% after 15 h of reaction. Further increases in the pH of reaction system from 5.5 to 6.0, caused TAG purity to increase significantly (p = 0.012) from 99.54 to 99.84%. However, TAG purity decreased significantly (p < 0.001) when the pH of the reaction system increased from 6.0 to 7.0. The maximum TAG purity was 99.84% at pH 6.0 after 15 h of hydrolysis. TAG purity increased with increasing pH and then decreased when the pH was above 6.0. Therefore, the pH of the buffer solution was fixed at 6.0 for the succeeding experiments.

Effect of Water Content on the Purity of TAG

Water played an important role in the hydrolytic reactions which are reversible and governed by water content of the reaction mixture. The reaction could not be completed if the water content was too low. However, excessive water would add the difficulties of the subsequent product separation. Therefore, appropriate water content is necessary for lipase-catalyzed hydrolysis. In this study, the effect of water content on the purity of TAG was studied and the results are shown in Fig. 3. TAG purity kept rising with increasing water content. However, when the water content exceeded 100% (w/w, with respect to the oil mass), there was no significant difference (p = 0.61) in TAG purity. Although excessive water content promoted the hydrolytic reaction equilibrium to the right, a large amount of water may reduce the concentration of the enzyme at the oil–water interface, thus causing a reduction in catalytic efficiency. Hence, a water content of 100% (w/w, with respect to the oil mass) was determined suitable for the subsequent studies.

Effect of Enzyme Loading on the Purity of TAG

The amount of enzyme used in the reaction determined the initial velocity of the reaction and thus influenced the time to reach equilibrium. The effect of enzyme loading on the purity of TAG was investigated and the results are shown in Fig. 4. Of the whole reaction process, TAG purity increased with increasing enzyme loading. When enzyme loading increased from 90 to 120 U/g, after 15 h of reaction, the purity of TAG increased significantly (p = 0.002) from 98.45 to 99.84%. However, further increase in enzyme loading from 120 to 150 U/g, after 15 h of reaction, made no significant difference (p = 0.78) in TAG purity. The obtained results indicated that the combination between enzyme and substrates reached saturation when enzyme loading was more than 120 U/g. Therefore, out of economic considerations, an enzyme loading of 120 U/g was chosen for the following experiments.

Effect of Temperature on the Purity of TAG

Temperature is an important factor which affects the reaction rate as well as the stability of the enzyme. Figure 5 showed the effect of reaction temperature on the purity of TAG. As illustrated in Fig. 5, TAG purity increased with increasing the temperature from 25 to 30 °C while it decreased when the temperature rose over 30 °C. Lower TAG purity was observed at 40 °C (96.78%) due to the inactivation of immobilized SMG1-F278N. The highest purity (99.84%) of TAG was obtained at 30 °C which was significantly (p < 0.002) higher than those obtained at other temperatures. Therefore, a temperature of 30 °C was selected for hydrolysis of partial glycerides from glyceride mixtures. EPA and DHA contain five and six cis-form double bonds, respectively. Low temperatures for removing partial glycerides might be favorable for preventing the oxidation of EPA and DHA.

Reusability of Immobilized SMG1-F278N

The reusability of immobilized SMG1-F278N was assessed by hydrolysis of partial glycerides from glyceride mixtures under the optimized conditions. TAG purity of 99.84% for the first reaction was taken as 100% and TAG purity in the subsequent reactions was calculated accordingly. As shown in Fig. 6, immobilized SMG1-F278N exhibited high operational stability in hydrolysis of partial glycerides and TAG purity of over 94% was maintained after immobilized SMG1-F278N was used for six cycles. The obtained results indicate that immobilized SMG1-F278N is a prospective enzyme which could be used for purification of TAG from glyceride mixtures.

Purification of n-3 PUFA-Enriched TAG by Molecular Distillation at Lower Temperature (150 °C)

A scale-up hydrolytic reaction, about 100-fold, was carried out under the optimized conditions: enzyme loading of 120 U/g (U/w, with respect to the oil mass), buffer solution of pH 6.0, water content of 100% (w/w, with respect to the oil mass) and a reaction temperature of 30 °C. After the reaction, the reaction mixture was centrifuged at 10,000×g for 5 min and then the upper layer oil phase was collected for molecular distillation. The acylglycerol profile of residues (final product), the FA composition of n-3 PUFA-enriched TAG and recovery of n-3 PUFA-enriched TAG together with the yield of n-3 PUFA-enriched TAG are shown in Table 1. After molecular distillation, the FA produced in the hydrolytic reaction were effectively removed and most of n-3 PUFA-enriched TAG was successfully collected. The final glyceride mixtures contained 99.85% of n-3 PUFA-enriched TAG and 0.15% DAG. No significant difference in FA composition was observed between n-3 PUFA-enriched FA and n-3 PUFA-enriched TAG which indicated that the FA composition was not affected during the processes of enzymatic esterification, hydrolysis and molecular distillation. Similar results were also observed by Li et al. [12] and Wang et al. [31]. Besides, the recovery of n-3 PUFA-enriched TAG and the yield of n-3 PUFA-enriched TAG were 98.49 and 65.31%, respectively.

The physicochemical indices of the glyceride mixtures obtained were analyzed and the results are shown in Table 2. The results showed that the obtained glyceride mixtures had low acid, peroxide and anisidine value which could be used for medical and dietetic purposes. From the above data, purification of n-3 PUFA-enriched TAG from glyceride mixtures by immobilized SMG1-F278N-catalyzed hydrolysis combined with low temperature molecular distillation proved feasible. Therefore, this multi-step process is a promising method for the synthesis of highly pure n-3 PUFA-enriched TAG.

Compared with the synthesis of n-3 PUFA-enriched TAG by Novozym 435-catalyzed transesterification combined with immobilized SMG1-F278N-catalyzed ethanolysis [12], the proposed method in this study by Novozym 435-catalyzed esterification combined with immobilized SMG1-F278N-catalyzed hydrolysis allows a higher purity (99.85 vs 98.75%) of the final product to be achieved. Most importantly, through hydrolysis, the reaction time for removal of partial glycerides was greatly reduced (15 vs 96 h) which is of great significance for industrial application. Overall, the proposed improved multi-step process proved to be a prospective approach for the synthesis of n-3 PUFA-enriched TAG.

Analysis of FA Positional Distribution in n-3 PUFA-Enriched TAG via 13C NMR

In order to get a better understanding of the obtained product, we analyzed the positional distribution of FA in n-3 PUFA-enriched TAG by 13C NMR and the results are shown in Fig. 7. The carbonyl region of 13C-NMR spectra was used to analyze the positional distribution of FA in n-3 PUFA-enriched TAG. The integrated area percentages (mol%) of different FA and their positional distribution in n-3 PUFA-enriched TAG are shown in Table 3. The area percentages of FA in the sn-2 position were compared with half of the area percentages of sn-1,3 position to determine the difference between these two positions in n-3 PUFA-enriched TAG. From the obtained results we found that saturated FA (SFA), monounsaturated FA (MUFA), EPA, DPA, DHA and also other FA were almost distributed evenly at the sn-2 and sn-1,3 positions. Similar results were also observed by Li et al. [12] who found FA in the synthesized n-3 PUFA-enriched TAG were almost equally distributed in sn-2 and sn-1,3 positions.

Conclusions

During synthesis of n-3 PUFA-enriched TAG, due to the thermal instability of n-3 PUFA, high temperature (230–260 °C) molecular distillation was not suitable for removing partial glycerides from glyceride mixtures which would cause oxidation and isomerization of PUFA. Moreover, large amounts of DAG will still exist in the final products after high temperature (230–260 °C) molecular distillation thus resulting in a low TAG purity.

In this study, partial glycerides in glyceride mixtures were removed by immobilized SMG1-F278N-catalyzed hydrolysis. Partial glycerides in glyceride mixtures were hydrolyzed to FA and further purified by molecular distillation at a lower temperature (150 °C). Finally, highly pure (99.85%) TAG with high content (88.73%) of n-3 PUFA was obtained. Compared with the conventional one-step method or the two-step approach by combined transesterification and ethanolysis, this multi-step process offers considerable advantages such as higher purity of the final product and a significant reduction in reaction time.

References

Chakraborty K, Raj RP (2009) Selective enrichment of n-3 polyunsaturated fatty acids with C18–C20 acyl chain length from sardine oil using Pseudomonas fluorescens MTCC 2421 lipase. Food Chem 114:142–150

Larsson SC, Kumlin M, Ingelman-Sundberg M, Wolk A (2004) Dietary long-chain n-3 fatty acids for the prevention of cancer: a review of potential mechanisms. Am J Clin Nutr 79:935–945

Ward OP, Singh A (2005) Omega-3/6 fatty acids: alternative sources of production. Process Biochem 40:3627–3652

Wang WF, Li T, Ning ZX, Wang YH, Yang B, Ma YJ, Yang XQ (2012) A process for the synthesis of PUFA-enriched triglycerides from high-acid crude fish oil. J Food Eng 109:366–371

Lin TJ, Chen SW, Chang AC (2006) Enrichment of n-3 PUFA contents on triglycerides of fish oil by lipase-catalyzed trans-esterification under supercritical conditions. Biochem Eng J 29:27–34

Lyberg AM, Adlercreutz P (2008) Lipase specificity towards eicosapentaenoic acid and docosahexaenoic acid depends on substrate structure. BBA-Biomembranes 1784:343–350

Akanbi TO, Barrow CJ (2015) Lipase-catalysed incorporation of EPA into emu oil: formation and characterisation of new structured lipids. J Funct Foods 19:801–809

Rosu R, Iwasaki Y, Shimidzu N, Doisaki N, Yamane T (1998) Enzymatic synthesis of glycerides from DHA-enriched PUFA ethyl ester by glycerolysis under vacuum. J Mol Catal B Enzym 4:191–198

Cerdán LE, Medina AR, Giménez AG, González MJI, Grima M (1998) Synthesis of polyunsaturated fatty acid-enriched triglycerides by lipase-catalyzed esterification. J Am Oil Chem Soc 75:1329–1337

Liu SC, Zhang CH, Hong PZ, Ji HW (2007) Lipase-catalysed acylglycerol synthesis of glycerol and n-3 PUFA from tuna oil: optimisation of process parameters. Food Chem 103:1009–1015

Moreno-Perez S, Luna P, Señorans FJ, Guisan JM, Fernandez-Lorente G (2015) Enzymatic synthesis of triacylglycerols of docosahexaenoic acid: transesterification of its ethyl esters with glycerol. Food Chem 87:225–229

Li DM, Wang WF, Qin XL, Li XX, Yang B, Wang YH (2016) A novel process for the synthesis of highly pure n-3 polyunsaturated fatty acid (PUFA)-enriched triglycerides by combined transesterification and ethanolysis. J Agric Food Chem 64:6533–6538

Watanabe Y, Yamauchi-Sato Y, Nagao T, Negishi S, Terai T, Kobayashi T, Shimada Y (2005) Production of MAG of CLA by esterification with dehydration at ordinary temperature using Penicillium camembertii lipase. J Am Oil Chem Soc 82:619–623

Wang WF, Xu Y, Qin XL, Lan DM, Yang B, Wang YH (2014) Immobilization of lipase SMG1 and its application in synthesis of partial glycerides. Eur J Lipid Sci Technol 116:1063–1069

Watanabe Y, Shimada Y, Yamauchi-Sato Y, Kasai M, Yamamoto T, Tsutsumi K, Tominaga Y, Sugihara A (2002) Synthesis of MAG of CLA with Penicillium camembertii lipase. J Am Oil Chem Soc 79:891–896

Watanabe Y, Yamauchi-Sato Y, Nagao T, Yamamoto T, Ogita K, Shimada Y (2004) Production of monoacylglycerol of conjugated linoleic acid by esterification followed by dehydration at low temperature using Penicillium camembertii lipase. J Mol Catal B Enzym 27:249–254

Xu D, Sun LJ, Chen HY, Lan DM, Wang YH, Yang B (2012) Enzymatic synthesis of diacylglycerols enriched with conjugated linoleic acid by a novel lipase from Malassezia globosa. J Am Oil Chem Soc 89:1259–1266

Wang WF, Li T, Qin XL, Ning ZX, Yang B, Wang YH (2012) Production of lipase SMG1 and its application in synthesizing diacylglycerol. J Mol Catal B Enzym 77:87–91

Cao Y, Wang WF, Xu Y, Yang B, Wang YH (2013) Enzymatic synthesis of extremely pure triacylglycerols enriched in conjugated linoleic acids. Molecules 18:9704–9716

Yuan DJ, Lan DM, Xin RP, Yang B, Wang YH (2014) Biochemical properties of a new cold-active mono- and diacylglycerol lipase from marine member Janibacter sp. strain HTCC2649. Int J Mol Sci 15:10554–10566

Guo SH, Xu JX, Pavlidis IV, Lan DM, Bornscheuer UT, Liu JS, Wang YH (2015) Structure of product-bound SMG1 lipase: active site gating implications. FEBS J 282:4538–4547

Xu TT, Liu L, Hou SL, Xu JX, Yang B, Wang YH, Liu JS (2012) Crystal structure of a mono- and diacylglycerol lipase from Malassezia globosa reveals a novel lid conformation and insights into the substrate specificity. J Struct Biol 178:363–369

Li XX, Li DM, Wang WF, Durrani R, Yang B, Wang YH (2016) Immobilization of SMG1-F278N lipase onto a novel epoxy resin: characterization and its application in synthesis of partial glycerides. J Mol Catal B Enzym 133:154–160

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram 342 quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Gámez-Meza N, Noriega-Rodríguez JA, Medina-Jaárez LA, Ortega-GarCía J, Monroy-Rivera J, Toro-Vázquez FJ, García HS, Angulo-Guerrero O (2003) Concentration of eicosapentaenoic acid and docosahexaenoic acid from fish oil by hydrolysis and urea complexation. Food Res Int 36:721–727

Wang YH, Mai QY, Qin XL, Yang B, Wang ZL, Chen HT (2010) Establishment of an evaluation model for human milk fat substitutes. J Agric Food Chem 58:642–649

Qin XL, Lan DM, Zhong JF, Liu L, Wang YH, Yang B (2014) Fatty acids specificity of T1 lipase and its potential in acylglycerol synthesis. J Sci Food Agric 98:1614–1621

Shantha NC, Decker EA (1994) Rapid, sensitive, iron-based spectrophotometric methods for determination of peroxide values of food lipids. J AOAC Int 77:421–424

Hashemi SMB, Brewer MS, Safari J, Nowroozi M, Sherahi MHA, Sadeghi B, Ghafoori M (2016) Antioxidant activity, reaction mechanisms, and kinetics of Matricaria recutita extract in commercial blended oil oxidation. Int J Food Prop 19:257–271

Harris TK, Turner GJ (2002) Structural basis of perturbed pKa values of catalytic groups in enzyme active sites. IUBMB Life 53:85–98

Wang XM, Li DM, Wang WF, Yang B, Wang YH (2016) A highly efficient immobilized MAS1 lipase for the glycerolysis reaction of n-3 PUFA-rich ethyl esters. J Mol Catal B Enzym 134:25–31

Acknowledgements

This work was supported by National High Technology Research and Development Program of China (863 program, 2014AA093514, 2014AA093601) and Science and Technology Planning project of Guangdong province (2013B090200015, 2014CX01).

Author information

Authors and Affiliations

Corresponding author

Additional information

D. Li and W. Wang contributed equally to this work.

About this article

Cite this article

Li, D., Wang, W., Li, X. et al. Preparation of Highly Pure n-3 PUFA-Enriched Triacylglycerols by Two-Step Enzymatic Reactions Combined with Molecular Distillation. J Am Oil Chem Soc 94, 225–233 (2017). https://doi.org/10.1007/s11746-016-2928-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2928-0