Abstract

In this study, roasted and unroasted (control) tomato seeds were cold pressed and the seeds, oils, and seed presscakes (meals) were analyzed. Some physicochemical properties, total phenolic content and antioxidant capacity, thermal properties, mineral contents, fatty acids, sterols and tocopherols compositions, volatile compounds and sensory evaluation of the tomato seed oils were determined. The tomato seeds contained 3.3 % of ash, 17.3 % of oil and 27.2 % of protein. The cold press oil recovery rate was 7.2 and 10.28 % for control and roasted seeds, respectively. There were eight sensory terms defining the oils together with 34 different aromatic compounds quantified. The volatile compounds furfural, hexanal, benzaldehyde and 2-isobutylthiazole were found with the highest frequency in the samples. Roasted, green and tomato were defined as characteristic sensory terms for tomato seeds oils. Fifteen different minerals, melting and crystallization temperatures and enthalpies of the oil samples were also quantified. This study provides important data for the tomato seed oils, and proves that pre-roasted tomato seed oils are high quality, nutritious and aromatics oils with higher levels of consumer acceptability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tomato (Lycopersicon esculentum L.) is the most cultivated fruit from Solanaceae family around the world. It has been reported that the annual production of fresh tomatoes reached 100 million tons, with nearly 40 million tons of them being processed for canned tomato, ketchup, tomato juice, sauce, paste, puree and others [1–3]. Nearly 11,820,000 tons of tomatoes were produced in Turkey in 2013. It has been reported that its production increased at a rate of 4.1 % when compared with the previous year [4]. The Çanakkale region takes fourth place in tomato production in Turkey, with 550,000 tons annual tomato production capacity [5].

In the tomato processing industry, large amounts of wastes including tomato skin, pulp, and seeds are generated. These wastes have economical and environmental impacts due to their utilization as sources of protein and vegetable/edible oil and as raw materials for animal feed, and the cosmetic and pharmaceutical industries [2, 6–8]. Several studies [9, 10] have emphasized that tomato byproducts such as peels and seeds could be evaluated as a source of carotenoids and antioxidative additives to inhibit oxidation of refined oils. Shao et al. [11] investigated the cholesterol-lowering effects of tomato-processing wastes such as tomato pomace, defatted seed and seed oil in hamsters fed with high fat diets. The researchers reported that all wastes used, especially tomato pomace, induced decreases in total and LDL cholesterol levels in the hamsters [11]. Tomato peels and seeds constitute 2–5 % of the initial weight of tomatoes [10]. Tomato processing has grown from year to year and this situation leads to a higher release of tomato wastes. Cantarelli et al. [12] compared the physico-chemical properties and fatty acid compositions of oils extracted from tomato seeds obtained from hot and cold break tomato-processing waste. The researchers reported that both oils have close characteristics with respect to the investigated properties [12].

The cold pressing technique, in which excess heating and solvents are not applied to oilseeds during pressing, has a lower oil yield than solvent extraction or hot pressing. However, cold-pressed oils are more attractive in terms of their sensory, nutritional and functional characteristics for consumers. It has been emphasized that the cold press technique is suitable for obtaining seed oils enriched with bioactive components such as flavonoids and phenolic acids and for reducing the use of solvents [13–15]. The effectiveness of some pre-treatments like pre-roasting, enzyme applications and microwave heating on the oil yield of cold-pressed seed oils has been investigated by our research teams in different studies [14, 15], in which it was observed that the applied treatments did not significantly change the oil specifications, while improvements in the oil yield and especially nutrient composition of oils and their sensory-aromatic properties were achieved by pre-treatments prior to the cold press technique.

The objective of the present study was to investigate the physico-chemical and compositional properties, sensory descriptions, consumer preferences and volatile compounds of the cold-pressed oils produced from roasted and unroasted tomato seeds.

Experimental Procedures

Materials

Tomato pomace (containing seeds, peels and remaining flesh) was provided by a tomato paste processing plant (Demko Can, Çanakkale, Turkey). To obtain the tomato seeds used in this study, the peels and other particles were floated in water and the seeds were separated, cleaned from foreign materials and then sun-dried. The general properties of these seeds are summarized in Table 1. All chemicals used were of analytical grade and purchased from Merck (Darmstadt, Germany) and Sigma (St. Louis, MI, USA). The internal standards used in the chromatographic analyses were purchased from Supelco (Bellefonte, PA, USA), Nu-Check (Elysian, MN, USA) and Sigma.

General Properties of the Tomato Seeds

The moisture content (%) of the seeds was determined by an OHAUS MB45 moisture analyzer (Ohaus, Pine Brook, NJ, USA) at 110 °C with 1 g of sample for a 30-min drying program. Total ash content was measured according to the AOCS Ba 5a-49 technique [16]. The oil and crude protein contents of the seeds were measured by the Soxhlet (AOAC 920.39) and the Kjeldahl techniques (AOCS Aa 5-38), respectively [16, 17]. The color of the seeds was measured with a Minolta CR300 colorimeter (Osaka, Japan). Seed dimensions were measured with a digital caliper (CD-15CP; Mitutoyo, Andover, UK). Thousand-seed weight was calculated by counting, weighing and multiplying 100 seeds. All analyses were done in triplicate.

Seed Preparations for Cold Pressing

The cleaned and dried tomato seeds were portioned to two equal amounts for control and roasting treatments. Before cold pressing, each portion was divided again into two equal parts for replication of the cold pressing experiments. Through some pre-experiments, it was determined that optimum oil extraction was achieved, when the moisture of the seeds was 12 %. Hence, seed moisture level was always adjusted in this study according to our previously described technique [14, 15]. Prior to cold pressing, there was a pre-roasting experiment against the control group (no pre-treatment) in this study applied to the seeds. The roasting process was carried out in an air oven (Inoksan FPE 110; Bursa, Turkey) at 150 °C for 30 min according to our previous studies [14, 15].

Cold Pressing of the Tomato Seeds

The cold pressing technique was applied with a laboratory scale (12 kg seed/h capacity, single head, 2 hp, 1.5 kW power) cold press machine (Koçmaksan ESM 3710; İzmir, Turkey). The cold pressing procedure was set by a 10-mm exit die, and 40 rpm of screw rotation speed and 40 °C of exit temperature were used to get the two products: the cold press oil (liquid part) and seed presscake or meal (solid part). After pressing, the cold-pressed oil was centrifuged at 6797g for 10 min at 10 °C to obtain clear oil without suspended materials. The clear oil was placed into amber-colored glasses, flushed with nitrogen and then capped. All oil samples were kept in a refrigerator during the analyses. The seed presscakes were grinded with a Waring blender (7011S; Waring Laboratory, USA) and then put into zipped refrigerator bags, labeled and frozen at −20 °C until the analyses.

Physical Analyses of the Tomato Seed Oils

The refractive indices of the oils were measured by an Abbe 5 (Bellingham and Stanley, UK) refractometer at 20 °C. Apparent viscosities of the oil samples were determined by a Brookfield Viscometer (model DV II + Pro with Rheocalc software; Brookfield, MA, USA) with a LV-SC4-18 spindle and 30 rpm at 20 °C. The specific gravity and turbidity (20 °C) values of the oil samples were analyzed according to the AOCS method Cc 10c-95 [16] and by a Hach 2100 AN Turbidimeter (USA), respectively. The color values of the oils (L, a* and b*) were measured with a Minolta Colorimeter CR-200 (Minolta Camera, Osaka, Japan).

Chemical Analyses of the Tomato Seed Oils

The free fatty acidity, peroxide and iodine number values of the seed oil samples were determined according to AOCS methods Ca 5a-40, Cd 8-53 and Cd 1-25 [16], respectively. The phenolic extracts prepared by the previously described technique [18]. Total phenolic content and antioxidant capacity values were determined by the Folin-Ciocalteu [19] and TEAC assays [20], respectively. Combustion calorie values of the oil samples were measured using a bomb calorimeter (Leco AC-350; St. Joseph, USA).

Thermal Analysis of the Tomato Seeds Oils

The thermal parameters (crystallization and melting temperatures and enthalpies) of the oil samples were determined with a Perkin-Elmer 4000 Series Differential Scanning Calorimeter (DSC) (Groningen, The Netherlands). First, the instrument was calibrated with indium and zinc standards and purged with nitrogen at 50 ml/min flow rate. Then, 5–7 mg of sample was weighed into aluminium pans and sealed hermetically. The applied temperature program was by cooling samples from room temperature to −40 °C at the rate of 5 °C/min, holding at that temperature for 3 min, and then heating again to 40 °C by the rate of 5 °C/min. Pyris 1 Manager Software was used to calculate the thermal parameters [21].

Mineral Composition of the Tomato Seed Oils

The mineral contents of the tomato seed oil samples were determined by ICP-AES (Varian Liberty II AX Sequential, Australia) according to Skujins [22] with minor modifications. Briefly, 2 g of oil samples were weighed into a burning cup with 100 mL HNO3 (65 %). Wet digestion was performed on a hot plate (Velp Scientifica, Italy) at a gradual rise in temperature (90, 100, 150 and 200 °C for 30 min each and 300 °C until the samples were clear). The obtained clear samples were diluted to 25 ml with distilled water. Wet digestion procedure was duplicated for each sample. Appropriate dilutions of AccuTrace reference standard stock (New Haven, USA) were used for the calibration curve procedure.

Fatty Acid, Tocopherol and Sterol Composition of the Tomato Seeds Oils

The fatty acid methyl esters (FAMEs) were prepared from the oil samples according to the AOCS method Ce 2-66 [23]. The quantification of the fatty acid methyl esters was performed with a Gas Chromatograph (Finnigan Trace Ultra, Milan, Italy) equipped with HP 88 capillary column (100 m × 0.25 mm i.d. with 0.2 μm film thickness; Agilent Technologies, Wilmington, DE, USA) and a Mass Spectrometer (Finnigan Trace DSQ; Austin, TX, USA). The GC conditions were described in our previous studies [14, 15].

The sterol compositions of the oil samples were determined by ISO 12228 methods [24]. Briefly, 0.5 g of each oil sample with 1 mL of internal standard (5α-cholestan-3β-ol) was saponified and then extracted with hexane. Dried hexane extracts (0.5 mL) were then silylated with 250 μL bis (trimethylsilyl) trifluoroacetamide/trimethylchlorosilane (4:1) and 250 μL of dry pure pyridine at 60 °C for 15 min. Finally, individual sterols without standards were identified using relative retention time (RRT) of 5α-cholestan-3β-ol. Quantification was performed with a Perkin Elmer AutoSystem XL Gas Chromatography equipped with an FID and a HP-5 (30 m × 0.32 mm × 0.25 μm) column. During the analysis, the following conditions were applied: oven temperature 240 °C for 0.5 min, 240–255 °C (5 °C/min) for 4 min, 255–310 °C (5 °C/min) for 30 min, carrier gas hydrogen (30 cm/s), injector split ratio 1:50, injection volume was 0.2 µL, injector and the detector temperatures were 280 and 300 °C, respectively. Data collection and quantification was done with Total Chrom Navigator of the instrument, and the results of each sterol were expressed as % concentration.

For identification of the tocopherol components, the oil samples were analyzed according to Panfili et al. [25] using an Agilent HPLC series 1200 (Agilent, Wald-bronn, Germany) with ChemStation software equipped with an a ACE 5 SIL normal phase column (150 mm, 4.6 mm i.d., particle size 5 μm). Quantification was performed using tocopherol standards (Merck, Darmstadt, Germany).

Volatile Compounds Determination of the Tomato Seeds Oils

The methodology used in previous studies [14, 15] was used for the determination of the volatile compounds in tomato seed oils. The headspace solid phase microextraction (SPME) (2 cm to 50/30 μm DVB/Carboxen/PDMS; Supelco, Bellafonte) technique [26] was applied to volatile compounds extraction from oil samples. The isolated volatile compounds were quantified by GC/MS (Agilent 6890 N/Agilent 5875C mass spectrometer; Agilent technologies;), equipped with nonpolar HP5 MS column (30 m × 0.25 mm i.d. × 0.25 µm film thickness; J&W Scientific, Folsom, CA, USA) based on the relative abundances calculated positively by the equation given as a footnote in Table 7. Methyl pentanoic acid and 2-methyl-3-heptanone were selected as internal standards (IS) for acidic and neutral-basic characters compounds, respectively. Finally, 10 μL of an internal standard solution containing 0.82 μg of 2-methyl-3-heptanone and 55.2 μg of methyl pentanoic acid was used for GC–MS analysis [27].

Sensory Analysis of the Tomato Seed Oils

Quantitative descriptive analysis (QDA) [28, 29] was used to describe the sensory properties of the oil samples. The sensory analysis was performed by nine trained panelists (five females and four males, aged 28–44) according to Aydeniz et al. [14]. Panelist training was done for 15 h with different sessions in consecutive days. Sensory descriptive terms (eight terms) were developed by the panel shown in Table 2 with the reference standards.

A 10-cm ballot scale anchored from the left end with “absence” to the right end with “maximum intensity” was preferred for QDA evaluation. Tomato seed oils (control and roasted) were coded with 3-digit numbers and put into colorless round-bottom and thinner head glasses closed with lids. Two samples were served to the panelists at room temperature under daylight with a service of water, a slice of apple and unsalted cracker, and an expectoration cup within each session. Different sessions were preferred for random duplication of the samples.

Consumer Test of the Tomato Seed Oils

Sensory attributes (appearance, color, odor, taste/flavor) of the oils were assessed by a 5-point hedonic scale (1 = dislike extremely to 5 = like extremely). Both control and roasted group tomato seed oils were evaluated by 100 different volunteer consumers for each sample.

Statistical Analyses

The differences between control and treatment groups for both oils and seed presscakes were determined by one-way ANOVA, and Tukey’s multiple comparison test was used for separating the means. Sensory data were evaluated with non-parametric Kruskal–Wallis and Dunn’s test. All statistical analyses were done with Minitab v.16.1.1 [30] and SPSS package [31] programs and the level of confidence was selected to be at least 95 % in all analyses. The whole study was duplicated with all analyses and each duplicate performed at least twice.

Results and Discussion

Properties of the Tomato Seed and Seed Presscakes

The physico-chemical properties of the tomato seed and remaining seed presscakes (meal) after the cold pressing are presented in Table 1.

The tomato seeds used in this study contained around 27.24 % of protein, 17.83 % of oil, 3.37 % of ash and 5.28 % of moisture. Knoblich et al. [10] reported that tomato seeds contained 20.2 % of protein, 6.37 % of crude fat and 5.18 % of ash on a dry matter basis. When compared with the findings of Knoblich et al. [10], the tomato seeds used in our study were found to have higher oil and protein content, but lower ash content. Roasting treatment prior to cold pressing was determined to remove oil from the seed more efficiently than that of the control group. Although there is no report to compare seed color values in literature, 1000-seed weights are in good agreement with previous studies [32, 33].

Seed presscakes, one of the major byproducts released after cold pressing, are reported to be rich in protein and crude fiber, but poor in ash content [13]. In our tudy, both seed press cakes obtained by pressing had an average protein content and the roasting treatment led to a slight decrease in protein content and an increase in darkness in color, a*, and b* values of the seed presscakes. The oil remaining in the seed presscakes after the cold pressing was over 50 % of the initial oil measured in the seeds. Unfortunately, this situation is one of the most frequently observed disadvantages of the cold pressing technique. Other pretreatments to enhance oil yield in cold pressing can be searched, but it should also be kept in mind that the sensory quality of cold-pressed oils must be high enough for consumer acceptance, while the bioactive compounds present in the oil must also be kept undegraded during production. The current aim of cold pressing is, in fact, gaining oil with full minor components and bio-active molecules in sacrifice of oil yield. These oil types are preferred for special edible/cuisine purposes and curing applications, and usually have higher commercial values than solvent-extracted and refined oils. Moreover, the oil remaining in the seed prescakes can be later extracted with solvents, if desired.

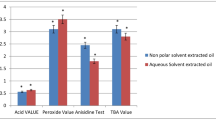

Physico-Chemical Properties of the Tomato Seed Oils

The physio-chemical properties, antioxidant capacity and total phenolics content of the cold pressed tomato seed oils are shown in Table 3. Statistically significant differences were observed in control and roasted seed samples in terms of oil yield, a* value, peroxide value and antioxidant capacity (P ≤ 0.05). Oil yield is calculated as the percent from the total amount of oil gained by cold pressing from a known amount of seeds. Clearly, pre-roasting before cold pressing significantly enhanced the oil yield compared to control. Furthermore, oil from roasted seeds was both clearer (less turbid) and redder (higher a* value). Previously, a similar situation was reported for cold-pressed safflower seed oil [14]. Although the antioxidant capacity and the total phenolics content were at a higher level in the roasted oil sample, the initial peroxide value was also higher in that sample. Similar findings for cold-pressed safflower and poppy seed oils have been reported [14, 15].

There was no significant difference between the control and roasted seeds oil samples in terms of refractive index, viscosity, turbidity, specific gravity, L and b* values, free fatty acidity, iodine number and energy values (Table 3). The refractive index, specific gravity and free fatty acidity values obtained in our study were similar to those reported in the literature [13, 34]. Moreover, the viscosity and peroxide values of our samples were found to be lower, but iodine number was higher compared to the findings of Lazos et al. [34]. The a* (1.57) and b* values (38.08) measured in our samples indicate that tomato seed oil is a yellow-greenish colored oil.

Malecka [9] evaluated the antioxidative effects of tomato seed oils on oxidative stability of refined rapeseed oil. The researcher explained that tocopherol, ∆5-avenasterol and citrostadienol components could contribute to the total antioxidative capacity of the seed oils. The total polyphenol content as well as antioxidant capacity of the roasted sample were found to be nearly 1.5–2 times higher than that of the control group in this study, thus suggesting positive effects of pre-roasting. In a recent study, Eller et al. [8] investigated the antioxidant capacity and phytosterol, tocopherol, carotenoid and lycopene contents of tomato seed oils obtained by several extraction techniques including supercritical CO2 treatment. It was reported that supercritical CO2 extraction has a lower oil yield than that of the hot ethanol and hexane extraction methods, but oils obtained by supercritical CO2 extraction have higher phytosterol content.

Thermal Properties of the Tomato Seed Oils

Thermal properties for the tomato seed oil samples are shown in Table 4.

The enthalpy of crystallization ranged from 11.19 to 11.73 J/g, while the enthalpy of melting ranged from 12.57 to 13.18 J/g, respectively. The crystallization onset temperature, and melting onset and peak temperatures of the roasted oil samples were higher than that of the control samples. Obviously, these oil samples crystallize at around −9 to −6 °C, but fully crystallized oils start melting at around −20 to −15 °C. The shift between crystallization and melting temperature gamut of unsaturated vegetable oils is a well-known phenomenon [35]. Hence, the present study provides important information about the thermal properties of tomato seed oils for the first time in the literature.

Mineral Composition of the Tomato Seed Oils

Fifteen different minerals were quantified in the tomato seed oil samples, and the results are presented in Table 5. The only statistically significant difference between the control and roasted samples was for the iron content being higher in the roasted sample. As far as we have searched, there is no report in literature about the mineral composition of tomato seed oil. On the other hand, Al-Wandavi et al. [6] reported that K, Mg, Na, and Ca were detected as major elemental components in tomato seed flour extracted with hexane. Similarly, Knoblich et al. [10] indicated that Na and K are the macro-minerals in tomato seeds, and that tomato seeds can be accounted as a rich source of iron. This may explain the relatively higher amount of iron in our tomato seed oil samples compared to olive, sunflower, sesame, hazelnut, grape, soy and rice oils [36]. In addition to iron, calcium, potassium, magnesium, sodium and zinc were also quantified in the edible oils mentioned in Cindric et al. [36], but all detected minerals were lower than those quantified in our samples. In another study [37], 18 trace minerals were quantified in eight different virgin olive oils from Italy. The amounts of Mg, Ca, Cr, Fe and Ni present in the olive oil samples were much higher than the quantified amounts in our samples. Hence, this study provides the mineral composition data of the tomato seed oils.

Component Analyses of the Tomato Seed Oils

The fatty acids, sterols and tocopherols composition of the tomato seed oil samples are presented in Table 6. The major fatty acids were linoleic (53 %), oleic (22 %), palmitic (14 %) and stearic (6 %) acid together with ten other fatty acids in less than 1 % quantities.

It has been reported that tomato seed oil is rich in unsaturated fatty acids (mainly linoleic acid) and suitable as cooking and salad oil [13, 34]. Previous reports indicate similar fatty acids composition for this oil [12, 13, 34]. Lazos et al. [34] investigated the physico-chemical properties of tomato seed oils treated with some refining steps as degumming, neutralization and bleaching at laboratory scale. It was observed that treated oils have no difference in fatty acids and sterol profile, although treatment led to an increase in trans-linoleic acid level and decrease in tocopherol content.

Although β-sitosterol, cholesterol, stigmasterol and campesterol were detected as abundant phytosterols, there were 4 other unidentified sterol peaks accounting nearly 50 % of all sterols (Table 6). The relative retention time data for these 4 peaks did not match with any known sterols under the analytical procedures followed. Hence, further analysis with GC/MS can be suggested for identification of those sterols. Eller et al. [8] found out that β-sitosterol, cycloartenol, and stigmasterol were the major phytosterols in tomato seed oils. Similarly, Malecka [9] determined the sterol composition of tomato seed oils and identified mainly β-sitosterol, campesterol and ∆5-avenasterol in their samples. Seven genera of Solanacea family seeds were analyzed for sterols, and cholesterol, 24-methylcholesterol, 24-ethylcholesterol, stigmasterol, 24-methylcholesta-5, 24-dienol, 24-ethylcholesta-5, 24-dienol, 28-isofucosterol, 24-methylenecholesterol, cholestanol, 24-methylcholestanol, 24-ethylcholestanol, cholest-7-enol and 24-ethylcholest-22-enol were identified [38]. The same researchers [39] determined eight triterpene alcohols in the same family plant seeds as lanost-8-en-3β-ol, lanosterol and 24-methylenelanost-8-en-3β-ol in addition to cycloartanol, cycloartenol, 24-methylenecycloartanol, lupeol, β-amyrin, daturaolone and daturadiol. In continuation of the investigations, they [40] identified 17 different sterols in the seeds of eight species of the Solanaceae family. The identified sterols were 31-norlanost-9(11)-enol, 24-methyl-31-norlanost-9(11)-enol, 4α,24-dimethylcholesta-7,24-dienol, 4α-methyl-24-ethylcholesta-7,24-dienol, 31-norcycloartanol, 31-norcycloartenol, cycloeucalenol, 31-norlanost-8-enol, 31-norlanosterol, obtusifoliol, 4α,14α,24-trimethylcholesta-8,24-dienol, 4α-methylcholest-8-enol, lophenol, 24-methyllophenol, 24-ethyllophenol, gramisterol and citrostadienol. It must be kept in mind that these sterols were identified not only in tomato seeds but also in seven other species. Hence, we suggest that unidentified sterols analyzed in the tomato seed oils in our study need further investigations

Gamma and alpha-tocopherols of the oil samples were quantified (Table 6). Eller et al. [8] reported similar values to our results for the gamma-tocopherol content of the tomato seed oils extracted by solvent and supercritical CO2 extraction (0.9–1.03 and 1.05 mg/g), respectively. Total tocopherol content of about 1300 mg/kg oil was reported in enzyme assisted-extracted tomato seed oils with gamma-tocopherol accounting for over 97 % of it followed by alpha and delta-tocopherols [13]. In another study [15], gamma tocopherol was found as the dominant tocopherol and its concentration changed from 0.22 to 0.27 mg/100 g in the roasted and cold pressed poppyseed oil.

Volatile Compounds of the Tomato Seed Oils

The volatile aromatic composition of the tomato seed oils is shown in Table 7. Thirty-four different volatile compounds were identified and quantified in the samples.(Table 7).

The concentration of 2-isobutylthiazole in control group, and furfural in roasted sample were the highest among them all. The volatile compounds hexanal, hexanol, d-limonene, 2-isobutylthiazole, 2-acetyl pyrrole, tetramethyl pyrazine, nonanal, phenylethyl alcohol, methyl-2-hdroxybenzoate, decanal, beta-cyclocitral, phenyl ethyl acetate, (+)-cyclosativene, alpha-copaene, tetradecane and beta-gurjunene were determined in both control and roasted tomato seed oil samples. Moreover, heptanal, furfural, 2,5-dimethyl pyrazine, benzaldehyde, benzene acetaldehyde, corylone pyrazine, 2-phenyl-2-butenal and 3-butyl-2,5-dimethyl pyrazine were only detected in the roasted seed oils. It was observed that roasting treatment contributed to the improvements of aroma active compounds as roasted, nutty, bitter almond, potato, flower, rose leaf, caramellic and sweet. But it also caused a loss of some flavors as green, grass and herbal which were present in the control samples. Although there is information about the volatile and aroma/flavor compounds of different types of tomato and tomato products in the literature, no information on the volatile components of tomato seed oils is present. The data obtained in our study provide a significant contribution to the literature.

Sensory Quality of Tomato Seed Oils

Sensory quantitative descriptive analysis (QDA) results of tomato seed oil is shown in Fig. 1. The panel defined eight sensory descriptive terms (Table 2) and evaluated the two oil samples.

Among eight sensory terms described by panelists in both oil samples, olive, tomato and green terms were found to be higher in the control group, whereas the roasted term was highest in the roasted oil sample, as expected. It was shown that roasting caused a decrease in sensory perceptions of green, tomato, olive and fruity, but induced an increase in roasted, bitter and hay aromas. Spicy aroma was perceived at equivalently lower levels in both oil samples. The sensory descriptions determined by the panel were in good agreement with the sensory descriptions of the volatile compounds determined by GC/MS. These results show that tomato seed oil is similar to virgin olive oil in sensory quality, and mostly positively accepted descriptors (olive, green, tomato, fruity) were determined in the samples, as indicated for the virgin olive oil samples [41].

Consumer hedonic scores for appearance, color, odor and taste/flavor measured with 100 volunteer consumers for each tomato seed oils are presented in Fig. 2. It was observed that roasted seed oils were more appreciated by consumers in terms of the evaluated hedonic properties. Especially, the roasting treatment led to an improvement in the visual properties as appearance and color of the seed oils. These results suggest that cold pressed tomato seed oil is a well-appreciated and liked edible oil by the consumers. Similar findings were reported in our previous studies for cold-pressed safflower and poppy seed oils [14, 15].

Conclusion

Valorization of tomato processing wastes has been an important issue and studied for different purposes. Tomato seeds as process wastes are a rich source of edible oil and protein. In this study, tomato seed oils were produced by the cold pressing technique, and the effect of roasting on some properties of the tomato seed oil was evaluated. The results showed that the cold-pressed tomato seed oils are edible and are high quality and stable oils. Roasting as pre-treatment is a necessary process in the cold pressing technique to increase oil yield and to enhance nutritional value. By applying roasting prior to cold pressing, higher antioxidant activity and tocopherol contents in tomato seed oils were achived whereas this pre-treatment had no effect on the fatty acid and mineral content of the tomato seed oils. It was observed that roasting affected the sterol composition of the tomato seed oils. Furthermore, it was found that roasted seed oils were well-accepted oils in terms of sensory properties and volatile compositions. Consequently, tomato seed oils can be utilized as functional/aromatic ingredients for the development and formulation of new food products. Moreover, knowledge about the thermal properties, volatile aromatic compounds and sensory descriptions of tomato seed oils have been provided as valuable contributions to the literature by this study.

References

Kalogeropoulos N, Chiou A, Pyriochou V, Peristeraki A, Karathanos VT (2012) Bioactive phytochemicals in industrial tomatoes and their processing byproducts. LWT-Food Sci Tech 49:213–216

Botinestean C, Jianu I (2013) Tomato seed oil for industrial use: separation of seeds from tomato pomace using wet fermentation technology. Poster present/Curr Opin Biotech 24:78

WPTC http://www.wptc.to/releases-wptc.php. Accessed April 2014

TurkStat http://www.tuik.gov.tr/PreTablo.do?alt_id=1001. Accessed April 2014

TARYAT (2014) Çanakkale City agricultural investment guide. Republic of Turkey Ministry of Food, Agriculture and Livestock, President of The Strategy Development, Turkey

Al-Wandawi H, Abdul-Rahman M, Al-Shaikhly K (1985) Tomato processing wastes as essential raw materials source. J Agric Food Chem 33:804–807

Topal U, Sasaki M, Goto M, Hayakawa K (2006) Extraction of lycopene from tomato skin with supercritical carbon dioxide: effect of operating conditions and solubility analysis. J Agric Food Chem 54:5604–5610

Eller FJ, Moser JK, Kenar JA, Taylor SL (2010) Extraction and analysis of tomato seed oil. J Am Oil Chem Soc 87:755–762

Malecka M (2002) Antioxidant properties of the unsaponifiable matter isolate from tomato seeds, oat grains and wheat germ oil. Food Chem 79:327–330

Knoblich M, Anderson B, Latshaw D (2005) Analyses of tomato peel and seed byproducts and their use as a source of carotenoids. J Sci Food Agric 85:1166–1170

Shao D, Bartley GE, Yokoyama W, Pan Z, Zhang H, Zhang A (2013) Plasma and hepatic cholesterol-lowering effects of tomato pomace, tomato seed oil and defatted tomato seed in hamsters fed with high-fat diets. Food Chem 139:589–596

Cantarelli PR, Regitano-D’arce MAB, Palma ER (1993) Physico-chemical characteristics and fatty acid composition of tomato seed oils from processing wastes. Sci Agric (Piracicaba, Braz) 50:117–120

Zuorro A, Lavecchia R, Medici F, Piga L (2013) Enzyme-assisted production of tomato seed oil enriched with lycopene from tomato pomace. Food Bioprocess Tech 6:3499–3509

Aydeniz B, Güneşer O, Yılmaz E (2014) Physico-chemical, sensory and aromatic properties of cold press produced safflower oil. J Am Oil Chem Soc 91:99–110

Dündar-Emir D, Güneşer O, Yılmaz E (2014) Cold pressed poppyseed oils: sensory properties, aromatic profiles and consumer preferences. Grasas Aceites 65(3):e029

AOCS (1997) Official methods and recommended practices of the American Oil Chemists Society, 5th edn. AOCS, Champaign

AOAC (2002) Official methods of analysis of AOAC International, 17th edn. Association of Official Analytical Chemists, Gaithersburg

Aydeniz B, Yilmaz E (2012) Enrichment of frying oils with plant phenolic extracts to extend the usage life. Eur J Lipid Sci Technol 14:933–941

Chotimarkorn C, Benjakul S, Silalai N (2008) Antioxidative effects of rice bran extracts on refined tuna oil during storage. Food Res Int 41:616–622

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Yılmaz E, Öğütcü M (2014) Properties and stability of hazelnut oil organogels with beeswax and monoglyceride. J Am Oil Chem Soc 91:1007–1017

Skujins S (1998) Handbook for ICP-AES (Varian-Vista). A short guide to Vista Series ICP-AES Operation. Varian Int. AG, Zug, Version 1.0, Switzerland

AOCS (1998) Official methods and recommended practices of the American Oil Chemists Society, 5th edn. AOCS Press, Champaign

ISO (1999) International Standards Official Methods 12228:1999, animal and vegetable fats and oils—determination of individual and total sterols contents—gas chromatographic method. Genève, Switzerland

Panfili G, Fratianni A, Irano M (2003) Normal phase high-performance liquid chromatography method for the determination of tocopherols and tocotrienols in cereals. J Agric Food Chem 51:3940–3944

Pawliszyn J (2012) Theory of solid phase microextraction. In: Pawliszyn J (ed) Hanbook of solid phase microextraction. Elsevier, Waltham, pp 13–57

Avşar YK, Karagul-Yuceer Y, Drake MA, Singh TK, Yoon Y, Cadwallader KR (2004) Characterization of nutty flavor in cheddar cheese. J Dairy Sci 87:1999–2010

Meilgaard M, Civille GV, Carr BT (1991) Sensory evaluation techniques. CRC, Boca Raton

Brühl L, Matthäus B (2008) Sensory assessment of virgin rapeseed oils. Eur J Lipid Sci Technol 110:608–610

Minitab (2010) Minitab Statistical Software (Version 16.1.1). Minitab, State-College

SPSS (1994) SPSS professional statistics (Version 10.1). SPSS, Chicago

Tabasi A, Nemati H, Tehranifar A, Akbari M (2011) The Effects of shrub pruning and fruit thinning on seed germination and seedling of tomato in the next generation (Lycopersicon esculentum Mill). J Bıol Envıron Sci 5:105–110

Anonymous, 1000-seed weight. http://hazerainc.com/essential-information/1000-seed-weight/. Accessed June 2014

Lazos ES, Tsaknis J, Lalas S (1998) Characteristics and composition of tomato seed oil. Grasas Aceites 49:440–445

Co ED, Marangoni AG (2012) Organogels: an alternative edible oil-structuring method. J Am Oil Chem Soc 89:749–780

Cindric IJ, Zeiner M, Steffan I (2007) Trace elemental characterization of edible oils by ICP-AES and GFAAS. Microchem J 85:136–139

Benincasa C, Lewis J, Perri E, Sindona G, Tagarelli A (2007) Determination of trace element in Italian virgin olive oils and their characterization according to geographical origin by statistical analysis. Anal Chim Acta 585:366–370

Itoh T, Tamura T, Matsumoto T (1977) 4-Desmethylsterols in the seeds of solanaceae. Steroids 30(3):425–433

Itoh T, Tamura T, Matsumoto T (1977) Triterpene alcohols in the seeds of solanaceae. Phytochemistry 16(11):1723–1726

Itoh T, Tamura T, Matsumoto T (1978) Four new and other 4α-methylsterols in the seeds of Solanaceae. Phytochemistry 17(5):971–977

Öğütcü M, Mendes M, Yılmaz E (2008) Sensorial and physicochemical characterization of virgin olive oils produced in Çanakkale. J Am Oil Chem Soc 85:441–456

Acknowledgments

This study is partly funded by Çanakkale Onsekiz Mart University BAP Office (Project no: FYL-2013-42). The authors are grateful for the support. The authors would also like to thank the panel members for their participation and contribution during panel training.

Conflict of interest

The authors have declared no conflict of interests. The authors alone are responsible for the content and writing of this article.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Yilmaz, E., Aydeniz, B., Güneşer, O. et al. Sensory and Physico-Chemical Properties of Cold Press-Produced Tomato (Lycopersicon esculentum L.) Seed Oils. J Am Oil Chem Soc 92, 833–842 (2015). https://doi.org/10.1007/s11746-015-2648-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2648-x