Abstract

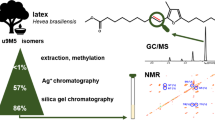

A ~20% CLA-rich soy oil with low saturated fat and no cholesterol was produced by photoisomerizing soy oil linoleic acid. The oil is predominately trans,trans CLA, with the oil containing 17% trans,trans CLA. Recent studies have shown that trans,trans CLA-rich soy oil significantly reduces heart disease and diabetes risk factors in obese rats. However, the positional isomerism of these geometrical isomers has not been identified. The objectives of the study were to determine trans,trans CLA positional isomerism of CLA fatty acids in CLA-rich soy oil and determine the resolution of trans,trans CLA positional isomers by silver ion chromatography. GC–MS studies of 4-phenyl-1,2,4-triazoline-3,5-dione (PTAD) derivatives of CLA-rich oil showed that 9,11 CLA and 10,12 CLA were the major positional isomers. These were hypothesized to be the trans,trans CLA isomers, which was confirmed by silver ion chromatography and subsequent GC–FID fatty acid and ATR-FTIR geometrical isomer analysis of the collected fractions. The identification of 9,11 trans,trans CLA and 10,12 trans,trans CLA as the major CLA isomers in CLA-rich oil then allowed the deduction of the synthetic mechanism of the photoisomerism of soy oil linoleic acid to trans,trans CLA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dietary CLA has been reported to possess health benefits in suppressing cancer [1 , 2], reducing atherosclerosis [3], enhancing immune systems [4], reducing body fat [5], and as an antimutagenic agent, an antioxidant, and in lowering insulin resistance [6]. Furthermore, it has been shown that CLA acts as a growth factor increasing bone mass [7], muscle-mass [8 , 9] and reducing abdominal adipose tissue [10]. However, a healthy diet often does not supply sufficient CLA from dairy and bovine sources to produce a clinical effect.

A pilot plant process was developed for photoisomerization of linoleic acid in soy oil that produced ~20% total CLA [11] with low saturated fat and no cholesterol. The oil contains 17% trans,trans CLA, since trans,trans isomers are predominant. Animal nutrition studies showed that a diet including 0.5% trans,trans CLA, as CLA rich-soy oil, fed to obese Zucker rats over 90 days reduced total serum cholesterol and serum LDL by more than 50%, relative to rats fed on a control diet of 0.5% soy oil [12]. There was also a 35% reduction in liver weight relative to the control which is probably due to prevention of fatty liver. The loss in liver weight was attributed to 39% reduction in liver lipids, which is an important indicator of obesity related liver disease. A significant decrease in serum glycated hemoglobin was observed, which is a diabetes risk factor.

However, the CLA-rich oil trans,trans positional isomerism is not known because the CLA content was determined by GC–FID methyl ester analysis, which does not resolve trans,trans positional isomers [13]. A possible role of the health benefits of trans,trans rich CLA soy oil necessitates the determination of the identity and number of trans,trans CLA isomers in CLA-rich oil. Furthermore, isolation of the trans,trans positional isomers would permit comparison of their biological activity. Therefore, the following objectives were addressed: (1) determination of the positional isomerism of CLA fatty acids in CLA-rich soy oil, (2) determination of the silver ion HPLC chromatographic behavior and resolution of CLA-rich oil trans,trans CLA FAME.

Experimental Procedures

Materials

Refined, bleached, and deodorized (RBD) soy oil (Wesson; ConAgra, Irvine, CA, USA) was obtained from a local grocery store (Fayetteville, AR, USA) with 55% linoleic acid and 6% linolenic acid. Resublimed Iodine was used as a catalyst (EM Science Cheery Hill, NJ, USA). The HPLC solvents, hexane and acetonitrile, were HPLC grade (VWR International, West Chester, PA, USA). 4-Phenyl-1,2,4-triazoline-3,5-dione (Sigma-Aldrich, St. Louis, MO, USA) was used to synthesize CLA derivatives enhancing subsequent MS analysis. Nitrogen gas, oxygen free grade (Scientific Supplies, University of Arkansas, Fayetteville, AR, USA) was also used. Other chemicals used were reagent grade.

Methods

CLA-Rich Soy Oil trans,trans CLA Positional Isomer Determination by GC–MS

CLA-rich soy oil preparation

Approximately 5 g RBD soy oil samples in 7 mL borosilicate glass vials with 0.35% iodine catalyst were attached to an illuminated laminar flow photo-irradiation unit with photon flux (power) set to 3.14 mW for 12 h as described by Lall et al. [13] to produce 15% CLA-rich oil consisting of 11% trans,trans CLA, as determined by GC–FID in duplicate [14] with no other CLA isomers exceeding 3% of total CLA.

CLA derivatization with 4-phenyl-1,2,4-triazoline-3,5-dione (PTAD) to synthesize CLA-PTAD adducts

The positional isomers were determined in the CLA-rich oil by making CLA 4-phenyl-1,2,4-triazoline-3,5-dione (PTAD) derivatives that would enhance MS identification. CLA-rich oil FAME were produced as described by Christie [15]. PTAD adducts of CLA FAME were obtained in duplicate by the modified method of Young et al. [16] as follows. PTAD (165 mg) was added to 140 mg of CLA FAME in 5 mL methylene chloride and stirred for 20 min to form the Diels–Alder CLA adduct as shown in Fig. 1. The excess PTAD was removed by adding the solution to a silica-gel column and eluting CLA-PTAD adducts with 5 mL hexane:ethyl acetate (5:1) solvent.

GC–MS analysis of PTAD adducts to determine positional isomerism

A modified method of Young et al. [16] was used to determine the positional isomerism of CLA isomers by GC–MS in duplicate. GC–MS analysis of CLA-PTAD adducts was performed using a capillary GC-column column ZB-5HT INFERNO (30 m × 0.25 mm i.d, 0.25 mm film thickness). The GC/MS was a Varian 450 GC interfaced to a Varian 320 MS and a Leap Technologies CombiPal autosampler. GC–MS analysis of CLA-PTAD adducts was performed using a 1-µl liquid injection with a 20:1 split. The injector temperature was 250 °C. Helium was used as a carrier gas with a volumetric gas flow rate of 2 mL/min. The column temperature was programmed at 60–325 °C at a rate of 10 °C/min with a 1 min hold at 60 °C and a 7 min hold at 325 °C. GC–MS was operated in electron-impact ionization mode. The GC–MS interface temperature was 250 °C. Data were collected in full scan over the ion range of 125–500. The detector temperature was 250 °C.

Silver Ion HPLC Separation of CLA Rich Oil trans,trans CLA FAME

CLA-rich oil FAME were produced from photoisomerized CLA-rich soy oil by the base-catalyzed methylation method described by Christie [15].

Silver ion HPLC separation of trans,trans CLA isomers

The silver ion HPLC separation method of trans,trans CLA from CLA-rich soy oil was adapted from Sehat et al. [17]. Two ChromSpher five Lipids Analytical silver-impregnated columns (each 4.6 mm i.d. × 250 mm stainless steel; 5 µm particle size (Chrompack, Bridgewater, NJ, USA) in series were used. The column temperature was kept constant at 23 °C using a Temperature Control Module (Waters Corporation, Milford, MA, USA).

About 40 mg CLA-rich oil FAME in 20 µl hexane was injected using the Waters 717 plus autosampler and a Waters model 600 system, equipped with a quaternary pump (Waters Delta 600), pumping at rate of 1 mL/min. A simple solvent system consisting of 0.1% Acetonitrile in hexane was used. The column effluent was connected to a photodiode array (PDA) detector (Waters Model 2996, Waters Corporation, Milford, MA, USA) measuring absorbance at 233 nm. The data output from PDA was integrated by Waters Empower™ 2 Software (Waters Corporation, Milford, MA, USA). The CLA fractions, identified by absorbance peaks at 233 nm, were then collected manually for subsequent GC–FID and ATR-FTIR analysis in duplicate.

Fatty acid analysis of CLA FAME fractions

The CLA FAME fractions obtained by silver ion HPLC were subjected to GC–FID fatty acid analysis by the method of Lall et al. [14] and geometrical isomerism was determined by ATR-FTIR according to the method of Kadamne et al. [18]. Both the analyses were performed in duplicate.

Results and Discussion

CLA Fatty Acids Positional Isomer Determination in CLA-Rich Soy Oil by GC–MS

Figure 2 shows the total ion chromatogram of products from the Diels–Alder reaction of PTAD with CLA FAME from CLA-rich oil. Two peaks eluted very close to each other with retention times of 30.64 min and 30.77 min. The mass spectra of the two peaks are shown in Fig. 3. The fragmentation scheme of CLA-PTAD adducts (Fig. 4) shows that the first peak is derived from 9,11 CLA and the second peak from 10,12 CLA. The ion at 469 of the first GC peak (Fig. 2), 9,11 CLA was identified as the molecular ion (Fig. 3a). The Diels–Alder ring structure enhanced the relative abundance of this ion based on comparison to archival spectra from the parent FAME of similar dienes. Cleavage occurred on either side of the six-member ring, indicating the location of the carbons that originally constituted the conjugated double bond system. In the PTAD derivative of 9,11 CLA isomer, the position of the nitrogen containing ring, between carbon 9 and 12 of the hydrocarbon chain, is indicated by alpha-cleavage to the ring to give m/z = 384 and 312 products. Loss of methanol from the ion containing the carboxyl moiety (with m/z 384) at m/z 352 is also consistent with the structures as shown in Fig. 4.

The mass spectrum of second peak of the total ion GC chromatogram, 10,12 CLA (Fig. 3b) shows an intense ion at 469 m/z that was an easily recognized molecular ion peak. For a PTAD derivative of the 10,12 CLA isomer, the position of the nitrogen containing ring formed by a Diels–Alder reaction with a diene between carbon 10 and 13 is indicated by alpha-cleavage to give ions with m/z values of 298 and 398. The loss of methanol from the ion containing the carboxyl moiety (with m/z 398) gives an additional fragment with m/z = 366. This is consistent with the structures shown in Fig. 4.

It is highly probable that the 9,11 CLA and 10,12 CLA are trans,trans isomers because trans,trans isomers are 75% of the CLA in CLA-rich oil [11]. However, chromatography and FTIR studies were subsequently performed to confirm these results and to demonstrate trans,trans isomer separation.

Silver Ion HPLC Resolution of trans,trans CLA FAME in CLA-Rich Oil

Figure 5 shows the silver ion chromatogram of CLA-rich soy oil FAME using a PDA detector at 233 nm. There are four peaks with first two being much larger than the other two. The control soy oil FAME chromatogram did not show any peaks as conjugated CLA compounds were absent (data not shown). The CLA peaks were identified using the retention times reported by Sehat et al. [17] and Yurawecz et al. [19] under the same chromatographic conditions.

Silver ion HPLC chromatogram obtained by UV-PDA detection at 233 nm of CLA-rich soy oil FAME. The CLA peaks assignments are according to retention times reported by Sehat et al. [17] and Yurawecz et al. [19]. Peak 1 area = 55,808.88 mV s; Peak 2 area = 52,544.04 mV s; Peak 3 area = 21,368.03 mV s; Peak 4 area = 17,814.43 mV s

The FAME GC–FID analysis of silver ion HPLC fractions 1 (trans-10,trans-12 CLA) and 2 (trans-9,trans-11 CLA) showed that they were trans,trans CLA isomers, according to the retention times by Christie[15]. ATR-FTIR spectra (Fig. 6.) showed the characteristic trans,trans peak at 988 cm−1for both the silver ion HPLC peak fractions of fractions 1 (trans-10,trans-12 CLA) and 2 (trans-9,trans-11 CLA) confirmed that they were both trans,trans isomers [18].

The nature of the trans,trans isomers provides an insight into the mechanism of CLA synthesis in CLA-rich oil production. Since there are only two trans,trans CLA positional isomers formed, they must be produced from the two corresponding cis,trans and trans,cis conjugated diene radicals shown in Fig. 7 (Matt McIntosh, personal communication, 29th April 2011). Both conjugated diene radical are derived from the same initial methylene interrupted radical (Fig. 7) and each is just as likely to be formed as the other. Therefore, both t,t CLA positional isomers are present in similar quantities.

High intensity UV-radiation cleaves iodine (I2) to form iodide radicals (I). The iodide radical abstracts a hydrogen radical (H) from C-11 of linoleic acid, which is alpha to two double bonds, to form a carbon radical and HI. Resonance stabilization of the methyl interrupted radical occurs to form more stable conjugated radicals. These are either 9,11 CLA or 10,12 CLA radicals, with carbon radical being at C13 or C9, respectively. A hydrogen radical is then donated from HI to produce trans-10, cis-12 CLA and cis-9, trans-11 CLA. The iodide radicals (I) then combine to regenerate iodine (I2). The cis,trans and trans,cis CLA isomers are then rapidly converted to a more stable trans,trans configuration, as shown in Fig. 7.

Conclusions

CLA-rich oil consists of two major trans,trans CLA positional isomers; trans-9,trans-11 CLA and trans-10,trans-12 CLA. Isolation of the two trans,trans isomers to study their biological activity may be possible by semi-preparative silver ion chromatography. The trans-9, trans-11 CLA isomer has been reported to have nutritional benefits [20, 21] but the biological activity of trans-10,trans-12 CLA has not yet been reported.

Abbreviations

- CLA:

-

Conjugated linoleic acid

- GC:

-

Gas chromatography

- FID:

-

Flame ionization detector

- PDA:

-

Photodiode array detector

- TAG:

-

Triacylglycerides

- Ag-HPLC:

-

Silver ion high performance liquid chromatography

- FAME:

-

Fatty acid methyl esters

- MS:

-

Mass spectrometry

- MeOH:

-

Methanol

- ATR-FTIR:

-

Attenuated total reflectance fourier transform infrared spectroscopy

- t,t :

-

trans,trans

- LA:

-

Linoleic acid

- PV:

-

Peroxide value

References

Ip C, Chin SF, Scimeca JA, Pariza MW (1991) Mammary cancer prevention by conjugated dienoic derivative of linoleic acid. Cancer Res 51:6118–6124

Shultz TD, Chew BP, Seaman WR, Luedecke LO (1992) Inhibitory effect of conjugated dienoic derivatives of linoleic acid and beta-carotene on the vitro growth of human cancer cells. Cancer Lett 63:125–133

Lee KN, Kritchevsky D, Pariza MW (1994) Conjugated linoleic acid and atherosclerosis in rabbits. Atherosclerosis 108:19–25

Cook ME, Miller CC, Park Y, Pariza MW (1993) Immune modulation by altered nutrient metabolism: nutritional control of immune-induced growth depression. Poultry Sci 72:1301–1305

Park Y, Storkson JM, Albright KJ, Liu W, Pariza MW (1999) Evidence that the trans-10,cis-12 isomer of conjugated linoleic acid induces body composition changes in mice. Lipids 34:231–241

Yeong LH, Nancy KG, Michael WP (1989) Newly recognized anticarcinogenic fatty acids: identification and quantification in natural and processed cheeses. J Agric Food Chem 37:75–81

Li Y, Watkins BA (1998) Conjugated linoleic acids alter bone fatty acid composition and reduce ex vivo prostaglandin E2 biosynthesis in rats fed n-6 or n-3 fatty acids. Lipids 33:417–425

Park Y, Albright KJ, Liu W, Storkson JW, Cook ME, Pariza MW (1997) Effect of conjugated linoleic acid on body composition in mice. Lipids 32:853–858

Dugan MER, Aalhus JL, Schaefer AL, Kramer JKG (1997) The effect of conjugated linoleic acid on fat to lean repartitioning and feed conversion in pigs. Can J Anim Sci 77:723–725

Riserus U, Berglund L, Vessby B (2001) Conjugated linoleic acid (CLA) reduced abdominal adipose tissue in obese middle-aged men with signs of the metabolic syndrome: a randomized controlled trial. Int J Obes 25:1129–1135

Jain VP, Proctor A, Lall RK (2008) Pilot-scale production of conjugated linoleic acid-rich soy oil by photoirradiation. J Food Sci 73:E3–E192

Gilbert W, Gadang V, Proctor A, Jain V, Katwa L, Gould A, Devareddy L (2011) trans,trans-Conjugated linoleic acid rich soy bean oil increases PPAR-gene expression and alleviates insulin resistance and cardiovascular risk factors. Lipids 46:961–968

Lall R, Proctor A, Jain VP, Lay JO (2009) Conjugated linoleic acid-rich soy oil triacylglyceride fraction identification. J Agric Food Chem. 57:1727–1734

Lall RK, Proctor A, Jain VP (2009) A rapid, micro FAME preparation method for vegetable oil fatty acid analysis by gas chromatography. J Am Oil Chem Soc 86:309–314

Christie WA (2001) A practical guide to the analysis of conjugated linoleic acid. Inform 12:147–152

Young DC, Vouros P, Holick MF (1990) Gas chromatography—mass spectrometry of conjugated dienes by derivatization with 4-phenyl-1,2-triazoline-3,5-dione. J Chromatogr A 522:295–302

Sehat N, Rickert R, Mossoba MM, Kramer JKG, Yurawecz MP, Roach JAG, Adlof RO, Morehouse KM, Fritsche J, Eulitz KD, Steinhart H, Ku Y (1999) Improved separation of conjugated fatty acid methyl esters by silver ion-high-performance liquid chromatography. Lipids 34:407–413

Kadamne J, Jain VP, Selah M, Proctor A (2009) Measurement of conjugated linoleic acid in CLA rich oil by ATR-FTIR. J Agric Food Chem 57:10483–10488

Yurawecz MP, Morehouse KM (2001) Silver ion HPLC of conjugated linoleic acid isomers. Eur J Lipid Sci Technol 103:594–632

Lee Y, Thompson J, Heuvel J (2009) 9E,11E-conjugated linoleic acid increases expression of the endogenous antiinflammatory factor, interleukin-1 receptor antagonist, in RAW 264.7 Cells. J Nutr 139:1861–1866

Ecker J, Liebisch G, Patsch W, Schmitz G (2009) The conjugated linoleic acid isomer trans-9, trans-11 is a dietary occurring agonist of liver X receptor alpha. Biochem Biophys Res Commun 388:660–666

Acknowledgments

We are grateful to the Arkansas Soybean Promotion Board and the Arkansas Biosciences Institute for providing the funding for this research. We would also like to thank Dr. Matt McIntosh for providing technical support and expertise in elucidating the CLA formation mechanism. The MS facility was supported by Grant Number P20 RR15569 from the National Center for Research Resources (NCRR), a component of the National Institutes of Health (NIH). Its content is solely the responsibility of the authors and does not necessarily represent the official view of NCRR or NIH.

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Shah, U., Proctor, A., Lay, J.O. et al. Determination of CLA trans,trans Positional Isomerism in CLA-Rich Soy Oil by GC–MS and Silver Ion HPLC. J Am Oil Chem Soc 89, 979–985 (2012). https://doi.org/10.1007/s11746-011-2001-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-011-2001-y