Abstract

To determine the frying stability of mid-oleic/ultra low linolenic acid soybean oil (MO/ULLSBO) and the storage stability of food fried in it, tortilla chips were fried in MO/ULLSBO, soybean oil (SBO), hydrogenated SBO (HSBO) and ultra low linolenic SBO (ULLSBO). Intermittent batch frying tests were conducted up to 55 h of frying, and then tortilla chips were aged up to 4 months at 25 °C. Frying oils were analyzed for total polar compounds to determine the frying stability of the oil. Tortilla chips were analyzed for hexanal as an indicator of oxidative deterioration and by sensory analysis using a trained, experienced analytical panel. Results showed no significant differences between the total polar compound levels for MO/ULLSBO and HSBO after 55 h of frying, indicating a similar fry life. However, total polar compound levels for ULLSBO and SBO were significantly higher than for either MO/ULLSBO or HSBO, indicating a lower oil fry life. Hexanal levels in aged tortilla chips fried in SBO were significantly higher than in chips fried in any of the other oils. Tortilla chips fried in MO/ULLSBO and HSBO had significantly lower hexanal levels than in chips fried in ULLSBO. A sensory analysis of rancid flavor intensity showed similar trends to those for hexanal formation. The chips fried in SBO had the highest rancid flavor intensity, with significantly lower hexanal levels in chips fried in HSBO and MO/ULLSBO. Based on these results, MO/ULLSBO not only had a good fry life but also produced oxidatively stable fried food, and therefore would be a healthful alternative to HSBO.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

To eliminate or reduce trans fatty acids in frying oils and fried foods, food manufacturers and restaurants are evaluating alternatives to hydrogenated oils. However, many alternatives do not have the oxidative stability of hydrogenated oils. Stable frying oils usually need to have low linolenic acid (<3%), increased oleic acid (>50%) and decreased linoleic acid (<50%), just as in hydrogenated oil. Some stable oil options exist for frying; however, they vary widely in cost, availability, and oxidative stability. Potential substitutes include naturally stable oils such as corn, cottonseed, peanut, rice bran, palm olein or palm. Other possible oils that have had their fatty acid compositions modified by breeding include high oleic and mid-oleic sunflower, high oleic/low linolenic canola, high oleic safflower, low linolenic soybean and ultra low linolenic soybean. Depending on the type of fried food being prepared and the stability required, many of these oils could be used individually or in blends to achieve suitable frying stability, although not all of these oils have the stability typical of hydrogenated oil. For example, hydrogenated canola oil with 1.2% linolenic acid had better frying stability than modified low linolenic acid canola with 3.4% linolenic acid [1]. Tompkins and Perkins [2] reported that a reduction of linolenic acid to 2.3% in a modified soy oil was not as effective at inhibiting deterioration during frying as hydrogenated soybean oil (HSBO) with 1.4% linolenic acid, as judged by instrumental and chemical analyses of the oil. Soheili et al. [3] reported similar results to those in the previous study [2], but with pan frying studies using low linolenic SBO (LLSBO) (IV = 121) and HSBO (IV = 95). The results of these last two studies are not unexpected because the oxidizability of LLSBO is similar to SBO, since these two oils do not vary much in linoleic acid content. Although reducing the linolenic acid content in soybean oil improved the SBO for frying compared to regular SBO [4, 5], the effect was not as great as it needed to be for the deteriorative conditions characteristic of frying applications. Stable frying oils need more modifications of their fatty acids than just reduced linolenic acid. Previous studies with canola oil showed that a combination of decreasing the linolenic acid to 4.2% and increasing the oleic acid to 78% oil produced better frying stability as measured by total polar compounds than either an unmodified canola oil with 62% oleic acid and 7.7% linolenic acid or a modified canola oil with 64% oleic acid and 3% linolenic acid [6]. Warner and Gupta [7] created a mid-oleic/low linolenic acid SBO from a blend of high oleic SBO (HOSBO) and LLSBO to determine its frying stability, and found that the blended MO/LLSBO with 56% oleic acid and 2% linolenic acid significantly improved the fry life of the oil and the fried food stability of potato chips during storage compared to LLSBO. Although blending oils to create a specific fatty acid profile can provide important information about potentially stable compositions, it is best to evaluate an oil with a naturally occurring composition. Therefore, the objective of this study was to determine the frying stability of modified SBO with both increased oleic acid and decreased linolenic acid [8, 9]. This mid-oleic/ultra low linolenic SBO had 52% oleic, 31% linoleic and 1% linolenic acids and originated from germplasm that had been developed at Iowa State University.

Experimental Procedures

Materials

Soybean oil (SBO), ultra low linolenic acid soybean oil (ULLSBO), and hydrogenated SBO (HSBO) were commercially processed by ConAgra Foods (Omaha, NE, USA); Asoyia (Iowa City, IA, USA); and Columbus Foods (Chicago, Il, USA), respectively. Mid-oleic/ultra low linolenic acid soybean oil (MO/ULLSBO) was obtained from soybean lines developed by Iowa State University. The mid-oleic trait was derived from the line M23 that was developed by Saga University in Japan, whereas the ultra low linolenic acid trait was developed by Iowa State University [8,9]. The soybean seeds of the lines were produced in Iowa and Argentina during 2006 and 2007 and then hexane-extracted, refined, bleached and deodorized at the POS Pilot Plant (Saskatoon, Saskatchewan, Canada). No oils contained additives other than citric acid. Yellow corn tortillas were obtained from a local market.

Instrumental and Chemical Analyses of Oils

Fatty acid compositions of the initial oils were determined by capillary gas chromatographic (GC) analysis with a Hewlett-Packard 5890 GC (Wilmington, DE, USA) equipped with a SP2330 column (30 m, 0.20 mm ID, 0.20 μm film thickness) (Supelco, Bellefonte, PA, USA). Column temperature was held at 190 °C for 5 min and the temperature was programmed to increase to 230 °C at 20 °C/min. Other GC conditions were: injector, 250 °C; detector, 260 °C. Initial oxidation of the fresh oils was measured in duplicate by peroxide value (AOCS method Cd 8-53) [10]. The oxidative stability index of the fresh oils was measured at 110 ºC according to the AOCS method Cd 12b-92 [10]. Total polar compound levels of the fresh and used frying oils were determined in duplicate by the AOCS column chromatography method Cd 20-91 [10]. Tocopherols were measured by high-performance liquid chromatography (HPLC) (Varian, Palo Alto, CA, USA) using a NH2 column with 98:2 hexane:2-propanol and a fluorescence detector set at 298 nm excitation and 345 nm emission.

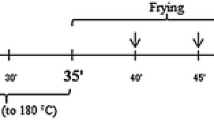

Frying Stability

The frying protocol included intermittent batch frying of tortilla wedges at 180 °C with total heating/frying time of 55 h over a five-day period. Each tortilla (15 cm diameter) was cut into six equal wedges. Each 50 g batch of tortilla chips was fried for 90 s at 180 ± 2 °C in a 2 L capacity fryer (National Presto Industries, Eau Claire, WI, USA) containing 1,200 g oil initially. Tortilla chips were fried every 20 min for 11 h each day for five days. Oil and chip samples were collected every 5 h until a duration of 55 h of frying had been attained. Fresh make-up oil (120 g) was added every 5 h after the oil samples were collected. Tortilla chips were placed in 1 L wide-mouth glass jars with air in the headspace, and the jars were closed with screw lids. Chips were aged in the jars in the dark for 0, 1, 2, 3, and 4 months at 25 °C, and then frozen until later analyses.

Volatile Compound Analyses of Tortilla Chips

Hexanal content of the fresh and aged tortilla chips was analyzed in triplicate with a purge and trap apparatus equipped with a test tube adapter (Tekmar model 3000, Tekmar-Dohrmann Co., Cincinnati, OH, USA) coupled with a Varian model 3400 gas chromatograph (GC) and a Saturn model 3 ion trap mass spectrometer (MS) (Varian, Inc., Walnut Creek, CA, USA). A 50 mg tortilla chip sample was placed in a 1.9 × 7.6 cm test tube and heated at 100 °C for 9 min of preheat time. Volatile compounds were trapped on a 30.5 cm Tenax #1 trap, with 10 min sample purge time, 170 °C for 6 min desorbing, 180 °C MCS desorb temperature, and 160 °C GC transfer line and valve temperature. Volatile compounds were introduced onto a DB-1701 GC capillary column (30 m × 0.32 mm with 1 μm film thickness) (J & W Scientific, Folsom, CA, USA). The column was held at −20 °C for 2 min, and then heated from −20 to 233 °C at 3 °C/min. Column helium flow rate was 2 mL/min with 28 mL/min injector split vent flow. The GC injector was set at 240 °C and the line to the mass spectrometer was set at 230 °C. The ion trap MS operated in EI mode with a mass scan range of 23–400 m/z over 0.8 s. Filament emission current was 25 μA, axial modulation was 2.1 V, manifold heater was set at 160 °C, and the filament/multiplier delay was 2.5 min. Compound structural identifications were made both from spectral comparisons with the NIST 92 mass spectrometry library (Varian, Inc.) and from retention time comparisons with standard compounds.

Sensory Analysis of Tortilla Chips

A 14-member analytical descriptive sensory panel, trained and experienced in evaluating fried foods, was presented with 5 g crushed tortilla chip samples in 59.2 mL (2 oz) plastic souffle cups with snap-on lids (Solo Cup Company, Urbana, IL, USA). Panelists rated the tortilla chips for intensities of individual flavors, including fried food, stale, rancid, and hydrogenated flavors, on a ten-point intensity scale with 0 = no intensity and 10 = strong intensity. Analyses were done in duplicate. All sensory evaluations were conducted in a panel room with individual booths, temperature control and with red lighting to mask color differences between samples [11].

Statistical Analysis

Data were evaluated by analysis of variance [12]. Statistical significance was expressed at the P ≤ 0.05 level unless otherwise indicated.

Results and Discussion

Fatty Acid Composition

The linolenic acid content of the SBO was significantly higher than that of the other three oils (Table 1). Linoleic acid contents were similar for SBO and ULLSBO, but significantly less for MO/ULLSBO and HSBO. Saturated fat levels showed some significant differences between oil types; however, the ranges for the saturates were small. Oleic acid levels were similar for SBO and ULLSBO, but significantly higher for MO/ULLSBO and HSBO.

Initial Oil Quality

All peroxide values were at low levels of 0.4 or less at the beginning of the frying tests. The OSI values of the zero-time oils were 6 h for SBO, 8.7 h for ULLSBO, 13.7 h for MO/ULLSBO and 57.5 h for HSBO. In the fresh oils, total polar compound levels (Fig. 1) were all low, with SBO at 2.0%, ULLSBO at 1.8%, and both MO/ULLSBO and HSBO at 1.7%.

Frying Stability

Total polar compound formation was measured as an indicator of frying stability. After 15 h of frying, polar compound levels increased in all oils from zero-time, but SBO had the highest amount at 5.5%, followed by 4.8% for ULLSBO, 4.7% for HSBO and 4.3% for MO/ULLSBO (Fig. 1). By 35 and 55 h of frying, the SBO had formed significantly more polar compounds than any of the other oils. No significant difference was noted between HSBO and MO/ULLSBO; however, both of these oils had total polar compound levels that were significantly lower than ULLSBO.

Oxidative Stability of the Tortilla Chips

Hexanal, which is an excellent marker for the oxidative stability of linoleic acid-containing oils and foods [13], was used to monitor oxidation in the chips because linoleic acid was a prominent fatty acid in the oils in this study. Volatile compounds from oleic acid were not monitored because the levels were very low because of the stability of oleic acid to decomposition. Volatile compound analysis was conducted on the tortilla chips that were sampled at 15, 35 and 55 h of frying time then aged at 0, 1, 2, 3, and 4 months at 25 °C. The induction periods for hexanal development varied significantly depending on frying oil type. For example, the tortilla chips fried in HSBO showed no induction during the storage times used, except for the sample fried in oil used for 55 h and aged for 4 months at 25 °C, which was the most extreme condition in the study (Fig. 2). Most of this stability can be attributed to the fatty acid composition of the HSBO, which had only 15.5% linoleic acid and 0.7% linolenic acid. The chips fried in MO/ULLSBO had a similar pattern of hexanal formation to that with HSBO. No significant differences were found between the samples fried in either HSBO or MO/ULLSBO for 15 h of frying at any storage time. Significant differences were only noted between the chips fried in HSBO and MO/ULLSBO at 35 h of frying and after 4 months of aging, and at 55 h of frying and after 2, 3 and 4 months of aging. The greater content of linoleic acid in the MO/ULLSBO than in the HSBO was probably the cause of the differences in stability (Table 1). The tortilla chips fried in the ULLSBO had a similar stability to the chips fried in HSBO and MO/ULLSBO for only the first 2 months of aging for the 15 h samples and for only the first month of aging in the 35 and 55 h samples. The lower oxidative stability was not unexpected, because the ULLSBO had approximately 55% linoleic acid. As expected, the chips fried in the SBO had the lowest stability, primarily because of the higher amount of linolenic acid in SBO. The longer the SBO was used for frying, the less stable the chips became. For example, the induction period for hexanal formation was after 3 months in the chips fried in 15 h oil, after 1 month in the 35 h sample and less than 1 month in the 55 h sample. The more deteriorated the SBO, the faster the induction period for hexanal. At 15 h of frying time, the SBO used to fry chips had 5.5% polar compounds, and the levels increased to 12.1% after 35 h and to 16.1% after 55 h of frying.

Sensory Analysis of Tortilla Chips

Sensory analyses were conducted on tortilla chips sampled after the oils were used for 0, 15, 35 and 55 h of frying and then aged for 0, 2, and 4 months. Sensory panelists evaluated the tortilla chips for four flavors—the positive deep-fried attribute; negative descriptors, stale and rancid, as indicators of oxidation; and for hydrogenation flavor. The intensity of the deep-fried attribute in tortilla chips is usually lower than in potato chips fried in similar oil types because tortilla chips have more natural flavors (such as corn) that can mask some of the deep-fried flavor. For example, in a previous study in which potato chips were fried in LLSBO and a 1:1 blend of HOSBO and LLSBO to create a MOSBO, the intensities for deep fried in the unaged potato chips fried in oil used for 5 h were in the 5.0–6.0 range [7], whereas the intensities in this study for the tortilla chips fried in the MO/ULLSBO at 15 or 35 h were in the 4.0–5.0 range (Fig. 3). In most chips, the deep-fried flavor intensity decreases with increasing storage time. Stale flavor is usually evident during early oxidation as the intensity of positive flavors such as deep fried begin to decrease, but before any flavors indicative of greater oxidation (such as rancid) are detected. In this study, the deep-fried flavor intensity of the tortilla chips significantly decreased with increasing storage time in all oils except for HSBO, which maintained a fairly constant—although low—intensity level of deep-fried flavor at all storage times and at all frying times of 15, 35 and 55 h. Deep-fried flavor intensity also decreased with increasing frying time, but differences were only significant between 35 and 55 h (Fig. 3). In previous frying studies, we have reported that oils with high levels of oleic acid and therefore low amounts of linoleic acid, such as high oleic sunflower oil, had low intensities of deep-fried flavor. The deep-fried flavor, which is primarily produced by 2,4-decadienal, a linoleic acid decomposition product, is limited in intensity when the amount of linoleic acid is low [14]. We were therefore interested in the intensity of the deep-fried flavor in the chips fried in mid-oleic soybean oil. Results showed that the chips fried in the MO/ULLSBO had the highest amounts of deep-fried flavor of all the oil types in most trials (at 4 months for 15 h; at all storage times for 35 h, and at 0 and 2 months for 55 h) (Fig. 3). The chips fried in ULLSBO had the second-highest deep-fried intensity in most trials.

Intensity levels for hydrogenation flavor are not presented because the flavor was present only in the chips fried in HSBO and also did not change much over storage time or frying time. The intensities for hydrogenation flavor ranged from 2.5 to 3.5 for all frying times and storage times for the chips fried in HSBO. The intensity levels for stale flavor were also low for all chip samples. The intensity score range was from 0.5 for unaged samples to a maximum of 2.5 for samples aged 2 months. As storage time increased, the intensity levels for stale flavor increased slightly from 0 to 2 months, and then decreased slightly at 4 months or did not change from the second- to the fourth-month levels for chips fried in all oils except for HSBO. The chips fried in HSBO had consistently low stale-flavor intensities. Data is not shown because of the low intensity levels and few incidences of significant differences between oil types. The increase in stale flavor for most chip samples aged between 0 and 2 months corresponded to a decrease in deep-fried flavor intensity between these storage times. The decrease in stale flavor between 2 and 4 months corresponded to an increase in rancid flavor intensity between those storage times. Rancid flavor intensity levels in the tortilla chips were at very low levels (<1.0) in all unaged samples, even after 55 h of oil use (Fig. 4). For chips fried in any of the oils used for 15 and 35 h of frying, this pattern continued; however, in the oils used for 55 h, the chips fried in SBO and ULLSBO had significantly higher rancid intensity levels than chips fried in HSBO or MO/ULLSBO. At 4 months of storage, the chips fried in SBO and ULLSBO had significantly stronger rancid intensities than chips fried in HSBO or MO/ULLSBO at all frying times. At 35 and 55 h of oil use, the chips showed significant differences between all oil types, with the most rancid flavor given by SBO, followed by ULLSBO, then MO/ULLSBO, and HSBO.

The combination of low linolenic acid, moderate oleic acid, and lowered linoleic acid was probably responsible for most of the enhanced frying stability and fried food stability of the MO/ULLSBO. However, the tocopherol content may also have played a role in the differences. Initially, HSBO had significantly more ppm of γ- and δ-tocopherols than the other oils; however, MO/ULLSBO lost the lowest percent of tocopherols of all oils (Table 2). For example, in oils used for 55 h of frying, MO/ULLSBO lost 46% of γ-tocopherol compared to 54% in ULLSBO, 65% in SBO and 76% in HSBO. The pattern for δ-tocopherol loss was similar to that for the γ-tocopherol, with the lowest loss in MO/ULLSBO at 24%, followed by 27% in ULLSBO, 32% in SBO and 36% in HSBO. The higher retention of γ- and δ-tocopherols in the MO/ULLSBO possibly helped to inhibit deterioration in the oil and fried food.

Our previous study on soybean oil with moderate levels of oleic acid was conducted using blends of high oleic soybean oil and low linolenic acid soybean oil to create a mid-oleic oil [7]. In that research, we reported that the mid-oleic blend had significantly lower total polar compound levels and significantly lower hexanal levels in the potato chips fried in the oils than the chips fried in LLSBO. In this study, we found similar results with the polar compound levels and the hexanal contents of tortilla chips. Tortilla chips fried in the MO/ULLSBO were significantly more stable than chips fried in SBO or ULLSBO because of the differences in fatty acid composition and tocopherol retention during frying. Although LLSBO and ULLSBO have good frying stabilities, the stability of MO/ULLSBO is significantly better, and therefore this oil is a more appropriate alternative to HSBO because it has both increased oleic acid and decreased linolenic acid contents rather than just a decreased linolenic acid content.

References

Hawrysh ZJ, Erin MK, Kim SS, Hardin RT (1995) Sensory and chemical stability of tortilla chips fried in canola oil, corn oil, and partially hydrogenated soybean oil. J Am Oil Chem Soc 72:1123–1130

Tompkins C, Perkins EG (2000) Frying performance of low-linolenic acid soybean oil. J Am Oil Chem Soc 77:223–229

Soheili KC, Tippyawat P, Artz WE (2002) Comparison of a low-linolenic and a partially hydrogenated soybean oil using pan-fried hash browns. J Am Oil Chem Soc 79:1197–1200

Warner K, Mounts TL (1993) Frying stability of soybean and canola oils with modified fatty acid compositions. J Am Oil Chem Soc 70:983–988

Mounts TL, Warner K, List GR (1994) Performance evaluation of hexane-extracted oils from genetically modified soybeans. J Am Oil Chem Soc 71:157–161

Warner K, Orr P, Parrott L, Glynn M (1994) Effect of frying oil composition on potato chip stability. J Am Oil Chem Soc 71:1117–1121

Warner K, Gupta M (2005) Potato chip quality and frying oil stability of high oleic acid soybean oil. J Food Sci 70:395–400

Rahman SM, Takagi Y, Kubota K, Miyamoto K, Kawakita T (1994) High oleic acid mutant in soybean induced by X-ray irradiation. Biosci Biotech Biochem 58:1070–1072

Fehr WR, Welke GA, Hammond EG, Duvick DN, Cianzio SR (1992) Inheritance of reduced linolenic acid content in soybean genotypes A16 and A17. J Crop Sci 32:903–906

AOCS (1998) Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press, Champaign, IL

Warner K (1995) Sensory evaluation of oils and fat-containing foods. In: Warner K, Eskin NAM (eds) Methods to assess quality and stability of oils and fat-containing foods. AOCS Press, Champaign, IL, pp 44–75

Snedecor GW (1956) Statistical methods, 5th edn. Iowa State University Press, Ames, IA

Frankel EN (2005) Lipid oxidation. Oily Press, Dundee, UK

Warner K, Orr P, Glynn M (1997) Effect of fatty acid composition of oils on flavor and stability of fried foods. J Am Oil Chem Soc 74:347–356

Acknowledgments

The authors acknowledge the United Soybean Board for their financial support for the development of the MO/ULLSBO lines; production of the seed used for processing; and the extraction and refining of the oil. Thanks also are extended to Asoyia for providing the ULLSBO used in the test, and to L. Parrott, W. Rinsch, and K. Steidley for technical assistance, and the NCAUR sensory panel.

Author information

Authors and Affiliations

Corresponding author

Additional information

Names are necessary to report factually on available data; however, the USDA neither guarantees nor warrants the standard of the product, and the use of the name by the USDA implies no approval of the product to the exclusion of others that may also be suitable.

About this article

Cite this article

Warner, K., Fehr, W. Mid-Oleic/Ultra Low Linolenic Acid Soybean Oil: A Healthful New Alternative to Hydrogenated Oil for Frying. J Am Oil Chem Soc 85, 945–951 (2008). https://doi.org/10.1007/s11746-008-1275-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-008-1275-1