Abstract

Palm fatty acid distillate (PFAD) is the by-product obtained during physical refining of crude palm oil, which mainly consists of free fatty acids along with minor amounts of glycerides, bioactive compounds such as tocopherols, tocotrienols, phytosterols, squalene, other hydrocarbons. In the present work, an eco-friendly alkyd resin was prepared using sustainable feedstock such as PFAD along with rosin. The various physico-chemical properties of PFAD-based alkyd resin (PFAD-AR) such as acid value, saponification value, viscosity and volatile matter were determined and compared to palm oil based alkyd resin (PO-AR). The structural properties of the alkyd resins were investigated using Fourier transform infrared (FTIR) and proton nuclear magnetic resonance (1H NMR) spectroscopic techniques. The study presents the utilization of PFAD-based alkyd resin with sodium lauryl sulfate (SLS) and sodium lauryl ether sulfate (SLES) in the liquid detergent formulation. The performance properties of the PFAD-based alkyd resin liquid detergent formulations such as surface tension, wetting power and detergency were comparable with palm oil based alkyd resin liquid detergent formulations and with commercial liquid detergent (CLD). Surface tensions of liquid detergent formulations varied from 20 to 30 mN/m with decrease in concentration. The foaming properties of alkyd resin based liquid detergents are reduced with the increase in the amount of alkyd resin polymer in the formulations. Therefore, it has potential application as a foam reducer in detergent for washing machines.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industrial waste or by-product management is one of the environmental challenges faced by many scientist, technologists and R & D personnel. Some by-products of low commercial value are produced during the refining processes of vegetable oil [1, 2]. Important amount of by-products such as phospholipids, soapstocks, acid oil and fatty acid distillates are obtained during the oil refining processes which are harmful to the environment if they cannot be used for any valuable or industrial activity. As a result of the rising world population, the use of refined vegetable oil has increased, which results in an increase in the production of by-products [3]. The vegetable oil industry is gradually looking into the value addition of the by-products of the oil processing industry. Therefore, researchers and technologists are slowly attempting to explore the utilization of the by-products of the vegetable oil industry, which will not only enhance the efficiency and productivity but also reduce waste in terms of environmental concern.

Detergent consists of chemical agents, which provide cleaning performance by the removal of soil from the surface and by the dispersion of soil in washing liquid. New formulations have been developed which possess better flexibility, improved performance, cost-efficiency and compatibility with the environment [4]. In the formulation of detergent, generally mixtures of surfactants, rather than individual surfactants, are employed to improve the performance properties of the final product [5]. Polymeric additives and surfactants have been used in detergent formulations for over 25 years [6].

India has a large number of alkyd resin production plants, which are used to supply surface coating industries. Alkyd resins are polyesters synthesized by polycondensation reaction of fatty oils or fatty acids, dibasic acids and polyols [7]. Oils such as soya bean oil, palm oil, castor oil, linseed oil, sunflower oil, coconut oil, tobacco seed oil, nahar seed oil, rubber seed oil, karanja oil, karawila seed oil, jatropha seed oil and African locust bean seed oil were used as potential sources for alkyd resin synthesis in coating industries [8]. The per capita consumption of detergents is higher than that consumed by the surface coating industry, therefore alkyd resins could conceivably be utilized for preparation of liquid detergent.

Polymeric surfactants are used as an additive to replace polyphosphates in eco-friendly detergents. Starch and sorbitol-based polymers have been used in liquid and powder detergent [9, 10]. Generally petroleum-based active substances such as linear alkyl benzene sulfonate (LABS) and alpha olefin sulfonate (AOS) are used in heavy and light duty liquid detergent formulations [11]. Rosinated alkyd resins have been synthesized from soybean oil. By-products of oil processing such as oil recovered from spent bleaching earth and acid oil have also used to synthesize alkyd resin, which were used in liquid detergent formulation [12–14]. Effective formulatory trials are required to achieve readily biodegradable, cost-effective and environmentally friendly polymeric surfactants from renewable vegetable resources. Not much work has been carried out using by-products of vegetable oil refinery as an alternative and inexpensive raw material in alkyd resin synthesis for use in liquid detergents.

Palm oil is one of the edible oils. Refined, bleached and deodorized (RBD) palm oil is obtained by physical refining of crude palm oil. Palm fatty acid distillate (PFAD) is one of the by-products obtained during physical refining of crude palm oil. PFAD mainly comprises free fatty acids with minor amounts of glycerides, bioactive compounds such as tocopherols, tocotrienols, phytosterols, squalene and other hydrocarbons [15]. Generally PFAD is used as a free fatty acid source for non-food industries mainly the oleochemical, soap and animal feed industries [16]. PFAD is also esterified and used in biodiesel production [17–19]. The cost of PFAD is lower than palm oil. The present work investigates the utilization of PFAD for the synthesis of rosinated alkyd resins. For comparative study, this cost-effective PFAD-based alkyd resin (PFAD-AR) was also synthesized using palm oil (PO-AR). The structure of the resulting alkyd resins was elucidated by FTIR and 1H NMR spectroscopy. In liquid detergent formulation, alkyd resins act as polymeric surfactant along with sodium lauryl sulfate (SLS) and sodium lauryl ether sulfate (SLES) which were used as highly effective and inexpensive anionic surfactants. SLS and SLES were used with alkyd resins in liquid detergent because they have good wetting and foaming properties which are very effective in removing oil and dirt from cloths and surfaces. Therefore, the performance properties such as surface tension, foamability, wetting capacity and detergency of PFAD-AR-based liquid detergent formulations were compared with PO-AR-based liquid detergent formulations and commercial liquid detergent.

Experimental Methods

Materials

All materials used in this study were obtained from the stated suppliers and used without any further treatment. PFAD and palm oil were obtained as gift samples from M/s Godrej Industries Ltd., Mumbai, India. Glycerine, sodium hydrogen sulfate, sodium hydrogen sulfite, benzoic acid, maleic anhydride, phthalic anhydride, sorbitol, EDTA, urea, sodium hydroxide, sodium carbonate and polyvinyl alcohol (PVA) were of laboratory grade, obtained from Thomas Baker. Other solvents such as methanol, ethanol, toluene and xylene were received as commercial solvents. Mineral turpentine oil (MTO, a mixture of saturated aliphatic and alicyclic C7–C12 hydrocarbons with a maximum content of 25% of C7–C12 alkyl aromatic hydrocarbons) used as solvent was procured from M/s Deep Enterprises, Mumbai. Commercial surfactants such as sodium lauryl sulfate (SLS) and sodium lauryl ether sulfate (SLES) were obtained as gift samples from M/s Godrej Industries Ltd., Mumbai, India.

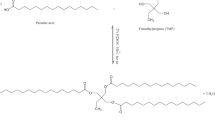

Synthesis of Alkyd Resin From PFAD and Palm Oil

A two-stage alcoholysis–polyesterification process was used to synthesize alkyd resins. Two reactions were carried out separately, one with PFAD and the other with palm oil as fatty raw materials. The reaction was carried out in a 1-L four-necked round-bottom flask equipped with a thermometer, mechanical stirrer, nitrogen gas inlet and Dean–Stark apparatus with a reflux condenser. The flask was charged with 13.3 g of PFAD or palm oil and 12.7 g of glycerol. A catalytic amount of sodium hydrogen sulfate (0.5 g) and sodium hydrogen sulfite (1.5 g) were added at 230 °C (±5 °C) with continuous stirring under nitrogen atmosphere for 60 min until monoglyceride formation was confirmed by methanol solubility test: one part of the resin was mixed with three parts of methanol, and complete solubility of the resin in methanol indicates the formation of monoglyceride [20]. Then the reaction mixture was cooled to 120 °C and 10.5 g of phthalic anhydride and 2 g of maleic anhydride in finely divided form were added along with excess glycerol (27%w/w), 2 g of benzoic acid and 30 g of rosin. The flask was charged with xylene (5% v/w on raw materials) as reflux solvent. The reaction temperature was then raised to 230 °C (±5 °C) and the heating was continued until it reached an acid value in the range of 35–40 mg KOH/g. The acid value of the reaction mixture was measured by taking aliquots of samples after every 0.5-h interval. The resin was diluted by adding mineral turpentine oil (50% w/w of alkyd resin) and the viscosity was examined [13]. Synthesized alkyd resins were melted and cooled to 80 °C and subsequently neutralized with the required amount of 30% NaOH with continuous stirring [13].

Preparation of Detergent Formulation

Different liquid detergent formulations were prepared using different concentrations of neutralized PFAD-AR and PO-AR. The details of the ingredients are listed in Table 1. Detergent samples were prepared using alkyd resins along with SLS, SLES, PVA, sorbitol, urea, EDTA, sodium hydroxide, sodium carbonate and distilled water, and prepared formulations were stirred for 30 min at room temperature [12]. Clear solutions of liquid detergents were obtained and analysed by using detergent tests in comparison with commercially available Surf Excel liquid detergent (CLD) [21].

Instrumental Measurements

Physico-chemical properties of PFAD and palm oil such as the acid value (ASTM D974), saponification value (ASTM D5558-95), free fatty acid content (ASTM D5555), iodine value (ASTM D5554-15), unsaponifiable matter (ASTM D1965-87) and moisture content (ASTM D4928) were determined according to ASTM standard methods.

Physico-chemical properties of the alkyd resins such as acid value (ASTM D1639-96), saponification value, viscosity, volatile matter and specific gravity (ASTM D1475-08) were also determined.

The fatty acid compositions of PFAD and palm oil were determined using a gas chromatograph (Chemito 1000, Thermo Scientific, Nasik, India.) equipped with a flame ionization detector. Analysis was carried out on a BPX-5 column (30 m length, 0.25 mm i.d.) under the following temperature program and conditions: solvent, hexane; sample concentration, 1%; amount of sample injected, 1 µL; 100 °C for 2 min; from 100 to 200 °C at 10 °C/min; at 200 °C for 1 min; from 200 to 300 °C at 10 °C/min; at 300 °C for 20 min; injector temperature at 260 °C; flame ionization detector temperature at 290 °C with nitrogen as the carrier gas at a flow rate of 0.8 mL/min; split ratio of 1:50.

Characteristic FTIR spectra of the PFAD, palm oil and synthesized alkyd resins were evaluated by Shimadzu IR affinity–1S FTIR spectrometer using an ATR sampling accessory.

1H NMR spectra of the PFAD, palm oil and alkyd resins were recorded in CDCl3 at 300 MHz using a Bruker Advance II 400 NMR spectrometer.

Surface Tension Measurements

The surface tension for different concentrations of solution (0.1%, 0.25%, 0.5%) of liquid detergent samples were measured at 25 °C using a Krüss K-100 tensiometer with standard platinum plate (PL O3) as a probe [22]. All the surface tension values are the averages of the three measurements.

Foamability

Foaming power was measured by using a Ross & Miles apparatus for different concentrations of solution (0.1%, 0.25%, 0.5%) of liquid detergent samples [23]. For each sample solution, the experiment was repeated three times and the mean value of three of the results was calculated.

Wetting Power

The wetting test of the liquid detergent formulations was determined by the canvas disc method [24]. The solutions of liquid detergent formulations of different concentrations (0.1%, 0.25%, 0.5%) were prepared. In this method, 500 mL of the solution was kept in a 600-mL beaker. A circular piece of canvas disc was placed in a funnel and was held in an inverted position in the beaker. The canvas disc was allowed to sink to the bottom of the beaker through the detergent solution. The wetting power was determined as the time interval Δt = t−t 0, where t 0 is the time of release and t is the time required for the disc to sink to the bottom. The smaller the Δt was, the better the wetting was.

Detergency Test

Coconut oil (35.8 g) was slowly added to a mixture of carbon black (28.4 g), lauric acid (17.9 g) and mineral oil (17.9 g) in a pestle and mortar to form a thick paste. All the components were ground in the pestle and mortar for 1–2 h till a finely ground mixture was obtained as indicated by the smooth feel of the paste medium. The soil solution was prepared by adding 2 g of this paste to 500 mL of carbon tetrachloride and used for soiling of cloths [12, 13]. White cotton fabrics (10 × 10 cm) were immersed in this soil solution for 10 min [12]. The soiled fabrics were then dried overnight in a drying oven (temperature 50 °C).

The washing was done using a Terg-O-Tometer (Wadegati Labequip Private Limited) equipped with a controlled temperature bath system as follows: speed, 100 rpm; water hardness, 250 ppm; washing detergent solution, 1000 mL; washing time, 15 min; rinsing time, 10 min; temperature, 50 °C; each liquid detergent formulation with 0.1%, 0.25%, 0.5% concentrations were used for washing. The commercial liquid detergent with same concentrations was also used for washing [12–14]. Soil removal from the washed fabrics was determined by reflectance measurement (Premier Colorscan Instrument). After washing, the detergency (%) was calculated using the formula

where Rw, Rs, and Ro are the reflectance measured on washed fabrics, soiled fabrics (before washing) and unsoiled fabrics, respectively.

Results and Discussion

Physico-Chemical Properties of PFAD and Palm Oil

The comparison of physico-chemical properties of the PFAD and palm oil are listed in Table 2. As a result of the presence of higher amounts of free fatty acids in PFAD as compared to palm oil, PFAD has a higher acid value than palm oil. Both fatty raw materials have low iodine values, which indicates the presence of a low degree of unsaturation, and therefore they show non-drying nature. The fatty acid compositions of PFAD and palm oil are given in Table 3. Both contain large amounts of palmitic acid and oleic acid followed by other constituents such as stearic, linoleic, myristic and linolenic acid.

Synthesis of PFAD-AR and PO-AR

PFAD-AR and PO-AR were prepared according to the general alcoholysis–polyesterification reaction. In this reaction, nitrogen gas was applied as the inert blanket and xylene was used to remove water produced during condensation. Maleic anhydride helps to enhance the degree of cross-linking and benzoic acid acts as chain-terminating agent to prevent gel formation. Rosin which consists of resinous acids (mainly abietic acid) is used to aid the progress of the polymerization reaction without gelation and water dispersibility [13]. The reaction was monitored by acid value as shown in Fig. 1. As the reaction progresses, the initial decrease in acid value was more rapid than during the later stages of the reaction. The reactions were carried out until the acid value was in the range of 35–40 mg KOH/g.

Physico-Chemical Properties of PFAD-AR and PO-AR

As shown in Table 4, the physico-chemical properties of PFAD-AR such as acid value, saponification value, viscosity, volatile matter, moisture content, specific gravity and physical appearance were similar to those of PO-AR, which were determined by ASTM standard methods [25]. In this reaction, the initial decrease in acid value was more rapid than during the later stages of the reaction, which indicates the beginning of formation of a three-dimensional network as a result of cross-linking of alkyd resin [26].

Characterization and Evaluation of Alkyd Resins

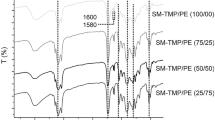

PFAD, palm oil, PFAD-AR and PO-AR were characterized by FTIR and 1H NMR spectroscopic analysis. The FTIR spectra of the PFAD and palm oil are shown in Fig. 2. Both spectra show very similar absorbance; however, they revealed slight differences in terms of absorption bands, especially at 1707 cm−1 (a) and 1745 cm−1 (b) owing to the different nature of PFAD and palm oil. In the FTIR spectra of the PFAD and of palm oil, characteristic peaks are found at 3005 cm−1 due to cis double bond stretching vibration and at 2851–2925 cm−1 due to aliphatic C–H stretching vibration. Peaks for bending vibrations of −CH2 and −CH3 aliphatic group appears at 1462 cm−1. Also peaks at 1290–1090 cm−1 correspond to C–O–C stretching vibration of ester and that at 723 cm−1 correspond to the overlapping of the methylene rocking vibration. Figure 3 shows the FTIR spectra of the synthesized PFAD-AR and PO-AR which indicate the presence of an ester group, olefinic double bonds and other important linkages. For PFAD, the peak for C=O appears at 1707 cm−1, whereas in the case of PFAD-AR, it appears at 1730 cm−1; similar results were observed for PO-AR. Table 5 summarizes the characteristic peaks of alkyd resin and the corresponding functional groups responsible for IR absorption.

1H NMR spectra of the PFAD and palm oil have similar characteristic peaks which are shown in Figs. 4 and 5, respectively. The peaks at 0.81–0.89 ppm are due to the protons of a terminal methyl group. For all the protons of internal –CH2– groups present in the fatty acid chain, peaks appear at 1.2–1.31 ppm. Characteristic peaks at 1.5–1.63 ppm correspond to the protons of –CH2– groups adjacent to the aforementioned terminal methyl group and at 2.7–2.8 ppm for –CH2 of double allylic protons. Characteristic peaks at 1.9–2.1 ppm are for allylic protons of –CH2 and at 2.28–2.35 ppm for α-protons of ester groups. Characteristic peaks at 4.14–4.3 ppm are for protons of the glyceride moiety. For the olefinic protons of the –CH=CH– moiety, the characteristic peaks appear at 5.3–5.4 ppm [27].

1H NMR spectra of PFAD-AR and PO-AR have similar characteristic peaks which are shown in Figs. 6 and 7, respectively. As a result of the deshielding effect of the anhydride group possessing one unsaturation unit (MA) or aromatic ring (PA), the protons for –CH– of the glycerol moiety appear at 6.7–6.9 ppm for alkyd resins which are absent in the 1H NMR spectrum of the PFAD. The PFAD-AR and PO-AR show aromatic protons of phthalic anhydride at 7.1–7.9 ppm which are absent in the PFAD spectrum [27].

Liquid Detergent Formulation

Synthesized PFAD-AR and PO-AR were neutralized with 30% NaOH solution to produce slightly alkaline polymer. Because of the low cost of PFAD, synthesized PFAD-AR was used in liquid detergent formulations and compared with PO-AR-based liquid detergent formulation. Liquid detergent based on different combinations of SLS and the synthesized neutralized alkyd resin were formulated (Table 1). In association with SLS and SLES, PFAD-AR and PO-AR were used as polymeric surfactants in liquid detergent formulations. In combination with alkyd resin, SLS and SLES were used as highly efficient and economical anionic surfactants to enhance the cleaning performance of the detergent. SLES and SLS are widely used as wetting and foaming agents in detergent which can aid the remove oil and dirt from fabrics and surfaces. PVA was used as an anti-redeposition agent and EDTA was used as water softener or a preservative. Urea was used as a hydrotrope to prevent gel formation in the liquid detergent formulary. Sodium carbonate and sodium hydroxide were used as alkali to maintain the pH. All the prepared PFAD-AR and PO-AR-based liquid detergent formulations were evaluated for surfactant properties, foamability, wetting power, percentage detergency and compared with a commercial liquid detergent (CLD) as given in Tables 6, 7 and 8.

Surface Tension Measurements

The study of the influence of the alkyd resin along with SLES/SLS showed reduction in surface tension of water. Surface tension of PFAD-AR-based liquid detergent decreases as a result of the adsorption of polymer–surfactant complex at the air–water interface. The results in Tables 6, 7 and 8 show that the surface tension of PFAD-AR-based liquid detergent decreases with increase in concentration of alkyd resin as compared to PO-AR-based liquid detergent formulation where LD4 and LD5 show better surface tension reduction than CLD. LD5 also showed a decrease in surface tension as compared to LD6, owing to the absence of both SLS and SLES in the formulation. Therefore, the presence of SLES/SLS with higher amounts of alkyd resin increases surface active properties of liquid detergent.

Foamability

Dispersion of gas bubbles in liquid or solid phase is known as foam. Dynamic foam formation was assessed by the Ross–Miles technique in which foam height was measured with respect to time for 20 min at 5-min intervals. Generally foam height for surfactants increases gradually as a function of concentration. Data on foamability is presented in Tables 6, 7 and 8 for the three different concentrations (0.1%, 0.25%, 0.5%) of PFAD-AR-based liquid detergents which were compared with PO-AR-based liquid detergents and CLD. As the concentration of alkyd resin increases, the foamability of the solutions decreases abruptly. All PFAD-AR and PO-AR-based liquid detergents at different concentration show similar foaming characteristics as compared to LD0 and CLD. LD4 and LD5 of PFAD-AR-based liquid detergent formulation at 0.1%, 0.25% and 0.5% concentration generated less foam than LD1, LD2 and LD3 formulations. Thus, the alkyd resin concentration plays an important role in the foamability of the solutions. The polymer alkyd resin addition at the air–liquid interface and the formation of the polymer–surfactant complexes could give rise to a reduction in foamability [28]. Therefore, PFAD-AR acts as a polymeric surfactant that can be used as a foam reducer in liquid detergent. These low foaming characteristics suggest that PFAD-AR-based liquid detergent may be used in the washing machine laundry applications because laundry washing requires low foam.

Wetting Power

Wetting results from intermolecular interactions when liquid and solid surfaces are in contact. The wetting capacity of the PFAD-AR and PO-AR-based liquid detergent formulations were compared with the standard CLD as shown in Tables 6, 7 and 8. SLS and SLES are good wetting agents. Wetting power in liquid detergent was enhanced owing to the presence of higher amounts of alkyd resin along with SLS/SLES. The higher the concentration of the formulation is, the better the wetting power is. Therefore, LD5 and LD4 of PFAD-AR-based liquid detergent formulations showed better wetting power than other formulations. Wetting power of LD6 was lower than LD5 because LD6 contained alkyd resin only without SLS/SLES. Wetting capacity of liquid detergent also determines the efficiency of a detergent solution in soil removal [29].

Detergency

Detergency is the removal of an unwanted soiled liquid or solid substance from a solid surface when a solid surface is brought into contact with a liquid [30]. The cleaning performance (detergency) of different liquid detergent formulations is given in Figs. 8, 9 and 10. As shown in Table 9, the results of detergency of PFAD-AR liquid detergent formulations were comparable with those of CLD and PO-AR-based liquid detergent formulations at 0.1, 0.25 and 0.5% concentration. LD5 and LD4 show better percentage detergency as compared to LD1, LD2, LD3 and LD6 of PFAD-AR-based liquid detergent formulations. In this study, presence of alkyd resin along with SLS/SLES not only enhances the cleaning power but also increases the efficiency of detergents which helps in soil removal. As a result of the reduction of surface tension, better wetting and low foaming properties, the detergency of LD4 and LD5 was higher than that of LD6 and CLD. In liquid detergent formulations, alkyd resin polymer which was synthesized from PFAD was used as a polymeric surfactant. Therefore, liquid detergents formulated by using PFAD-AR are biodegradable, environmentally friendly and cost-effective as compared to CLD.

Conclusion

In this study, PFAD, a sustainable, low-cost and eco-friendly by-product of palm oil refining, was utilized in the synthesis of alkyd resin with rosin as a polymeric surfactant in order to access the feasibility of its application in liquid detergent formulation. In liquid detergent formulation the synthesized PFAD-based alkyd resin was used as an active agent in association with SLS. The results of the performance properties of the PFAD-AR-based liquid detergent were comparable to those of the PO-AR-based liquid detergent and commercial liquid detergent. In PFAD-AR-based liquid detergent formulation, LD5 and LD4 showed low foaming properties, effective reduction in surface tension, better detergency and wetting power as compared to LD1, LD2 and LD3. Owing to low foaming characteristics, PFAD-AR-based liquid detergent can be commercially employed as an ingredient for washing machine laundry which is cost-effective, biodegradable and eco-friendly.

Abbreviations

- AOS:

-

Alpha olefin sulfonate

- CLD:

-

Commercial liquid detergent

- FTIR:

-

Fourier transform infrared

- 1H NMR:

-

Proton nuclear magnetic resonance

- LABS:

-

Linear alkyl benzene sulfonate

- MTO:

-

Mineral turpentine oil

- PFAD:

-

Palm fatty acid distillate

- PFAD-AR:

-

PFAD-based alkyd resin

- PO-AR:

-

Palm oil based alkyd resin

- PVA:

-

Polyvinyl alcohol

- SFT:

-

Surface tension

- SLES:

-

Sodium lauryl ether sulfate

- SLS:

-

Sodium lauryl sulfate

References

Hou CT, Shaw J, Luxem FJBK. Biodiesel from acidulated soapstock (acid oil). Biocatalysis and bioenergy. New York: Wiley; 2008. p. 11.

Haslenda H, Jamaludin MZ. Industry to industry by-products exchange network towards zero waste in palm oil refining processes. Resour Conserv Recycl. 2011;55:713–8.

Piloto-Rodríguez R, Melo EA, Goyos-Pérezl L, Verhelst S. Conversion of by-products from the vegetable oil industry into biodiesel and its use in internal combustion engines: a review. Braz J Chem Eng. 2014;31:287–301.

Jadidi N, Adib B, Malihi FB. Synergism and performance optimization in liquid detergents containing binary mixtures of anionic–nonionic and anionic–cationic surfactants. J Surfact Deterg. 2013;16:115–21.

Rosen MJ. Surfactants and interfacial phenomena. New York: Wiley; 1989.

Bertleff W, Neumann P, Baur R, Kiessling D. Aspects of polymer use in detergents. J Surfact Deterg. 1998;1:419–24.

Turner GPA. Introduction to paint chemistry and principles of paint technology. London: Chapman & Hall; 1988. p. 168.

De Silva SHUI, Amarasinghe ADUS, Premachandra BAJK, Prashantha MAB. Effect of karawila (Momordica charantia) seed oil on synthesizing the alkyd resins based on soya bean (Glycine max) oil. Prog Org Coat. 2012;74:228–32.

Gogate BB, Agrawal RS. Starch-sorbitol based co-polymer (a substitute for LABS). J Soaps Deterg Toilet Rev. 2003;34:25–8.

Gogate BB, Agrawal RS. Sorbitol based polymeric surfactant for detergent powder. J Soaps Deter Toilet Rev. 2003;34:19–22.

Parasuram KS. Soaps and detergent. New Delhi: Tata McGraw-Hill; 1995.

Kharkate SK, Karadbhajne VK, Gogate BB. Some resin based ecofriendly liquid detergents. J Sci Ind Res. 2005;64:752–5.

Toliwal SD, Patel D, Patel JV, Jadhav K. Utilization of byproducts of oil processing industry in liquid detergent. Indian J Chem Technol. 2009;16:373–6.

Toliwal SD, Patel D, Patel JV, Jadhav K. Liquid detergent from acid oil based polymer. J Appl Chem Res. 2010;14:14–22.

Gapoor A, Hassan WHW, Sulong M. Phytochemical for nutraceutical from the by product of palm oil refining. Palm Oil Develop. 2002;36:13–9.

Nang HLL, Wafti NSA, May CY. Palm fatty acid distillate. MPOB Information Series. 2009; MPOB No. 471.

Cheah KY, Toh TS, Koh PM. Palm fatty acid distillate biodiesel: next generation palm biodiesel. Inform. Champaign: AOCS; 2010.

Deshmane VG, Gogate PR, Pandit AB. Ultrasound-assisted synthesis of biodiesel from palm fatty acid distillate. Ind Eng Chem Res. 2009;48:7923–7.

Chabukswar DD, Kaur HP, Gaikar VG. Esterification of palm fatty acid distillate using heterogeneous sulfonated microcrystalline cellulose catalyst and its comparison with H2SO4 catalyzed reaction. Ind Eng Chem Res. 2013;52:7316–26.

Paul S. Surface coating. New York: Wiley; 1985. p. 70–134.

Harris JC. Detergency evaluation and testing. New York: Wiley; 1954.

Rosen MJ. Surfactants and interfacial phenomena. New York: Wiley; 2004. p. 277–302.

Ross J, Miles GD. An apparatus for comparison of foaming properties of soaps and detergents. J Am Oil Chem Soc. 1941;18:99–102.

Seyferth H, Morgan OM. The canvas disc wetting test. Am Dyestuff Rep. 1938;27:525–9.

ASTM. Annual book of ASTM standard. Philadelphia: American Society for Testing Materials; 1973.

Aigbodion AI, Okieimen FE. Kinetics of the preparation of rubber seed oil alkyds. Eur Polym J. 1996;32:1105–8.

Pavia DL, Lampman GM, Kriz GS, Vyvyan JR. Introduction to spectroscopy. Belmont: Brooks/Cole, Cengage Learning; 2008.

Cervantes-Martinez A, Maldonado A. Foaming behaviour of polymer–surfactant solutions. J Phys Condens Matter. 2007;19:246101.

Moulay S, Zenimi A, Dib MJ. Rosin/acid oil-based liquid soap. J Surfact Deterg. 2005;8:169–74.

Kissa E. Wetting and detergency. Pure Appl Chem. 2009;53:2255–68.

Acknowledgements

The authors gratefully acknowledge the Institute of Chemical Technology and financial support under the University Grants Commission (UGC), New Delhi, Government of India.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Chiplunkar, P.P., Shinde, V.V. & Pratap, A.P. Synthesis and Application of Palm Fatty Acid Distillate Based Alkyd Resin in Liquid Detergent. J Surfact Deterg 20, 137–149 (2017). https://doi.org/10.1007/s11743-016-1905-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-016-1905-9