Abstract

Due to the presence of non-sulfonated residual alkyl ether (AE), sodium alkyl ether sulfonate (SAES) may exhibit clear point-cloud point solubilization behavior in brine. Accordingly, the effect of temperature on the compatibility of iC17EOxS (x = 7 and 10), nC17EO10S, along with their analogous nonionic surfactants iC17EOxH (x = 7 and 10) and nC17EO10, in addition to iC9EO14 in brine has been investigated. Depending on their molecular structures, these surfactants exhibited concentration-dependent clear point and cloud point solubilization behavior. The cloud point was associated with the AE component whereas the clear point was attributed to the sulfonated one. Interestingly, an increase in the cloud point of the nonionic component with respect to the corresponding nonionic AE (100 % active) was observed. Adding iC9EO14 (100 % active) to iC17EO7S (x an = 0.0–0.362) resulted in a significant decrease in the clear point of iC17EO7S from above 100 °C to below 22 °C with a concomitant increase in iC17EO7/iC9EO14 mixture cloud point from 68 °C. (x an = 0) to 72 °C (x an = 0.325). This relatively modest increase by 4 °C was attributed to the interrelationship of different competitive mechanisms, namely an increase in mixed micelle charge with increasing x an, the dehydration of OE groups via ion (SO3 −)-dipole (O → CH2) interactions, and possible shielding of SO3 − groups by iC9EO14 nearby extended EO groups. To the best of our knowledge, this is the first instance where dual anionic-nonionic solubilization behavior of SAES in brine characterized by high salinity and hardness is being reported.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

When a fatty alcohol (ROH) is ethoxylated, the resulting ether still has a terminal –OH group which can be subsequently used to synthesize the corresponding alkyl ether sulfonate (AES). The conversion of the nonionic molecule to an anionic one can be varied by adjusting the process variables (degree of ethoxylation, linear or branched hydrophobic moiety, type of counterion…). All these variables make it possible to adapt chemically the surfactant structure, to the petroleum reservoir conditions (salinity and temperature), rather than the opposite as it is the case with petroleum sulfonates. Thus, by combining the properties of the polyoxylenated nonionic surfactant to an anionic surfactant, chemically and not as a mixture, the so-called modified nonionic surfactants were introduced into enhanced oil recovery (EOR) processes, due to their superior tolerance towards hard water and high salinities [1–4]. Recently [5–7], we investigated the possibility of injecting dilute aqueous solutions of a series of alkyl ether sulfonates (R 1(OCH2CH2) x OC(R 2)CHCH2SO3Na, where x = 6, 8; R 1 = nonylphenol, iso-tridecyl; R 2 = C12/C14) and CH3(CH2) x CH(SO3Na)(CH2) y O–(CH2CH2O) n H (x + y = 15 and n = 2, 5, and 8) in reservoir conditions characterized by high salinity (~200 g/L) and hardness (Ca2+ 12.31 g/L, and Mg2+ 2.01 g/L). These surfactants were compatible with brine up to 0.1 wt% and displayed dynamic interfacial tension behavior, in which ultralow transient minima were observed in the range 10−4–10−3 mNm−1, followed by an increase in the IFT to equilibrium values in the range 10−3–10−1 mNm−1. Ethoxylated sulfonates surfactants were also found to be promising candidates in alkaline-surfactant-polymer (ASP) formulations for EOR in elevated temperature (90 °C) and high salinity (57 g/L) [8]. Measurement of solubility in sea water and phase behavior in mixtures of NaCl and heptane with a water-to-oil ratio WOR = 2, have been conducted for a series of alkyl- and alkylbenzene ether sulfonates with different chain length, branching and degree of ethoxylation. The results showed good brine-surfactant compatibility and favorable phase behavior results [9].

However, the conversion of alkyl ether (AE) nonionic surfactants to sulfonates generally results in a mixture of alkyl ether sulfonate (AES) and a non-sulfonated residue (AE), in which the mixture composition depends on the degree of sulfonation. Accordingly, we should realize that, above the critical micelle concentration of the mixture, we are in fact dealing with AES-AE mixed micelles and not with AES single micelles. The presence of the nonionic species may therefore play a major role when considering technical grade AES for EOR applications. Particularly, the combination of high temperature with high salinity and hardness in a given petroleum reservoir may have a drastic effect on both AES and AE components. For instance, it is well known that when petroleum sulfonates are dissolved in water, especially in the presence of electrolytes, the surfactant solution will appear cloudy or turbid and frequently a gel-like suspension can be seen in the solution. Some turbid solutions turn clear upon heating [10, 11]. This transition from turbid-to-clear occurs over a range of less than one degree centigrade and is defined as the clear point of the surfactant. Some other surfactant solutions may remain turbid even at the boiling point of water, indicating that their clear point is above 100 °C. Salager [12] showed that clear point of petroleum sulfonates can also be reduced to room temperature by adding proper amounts of alcohols. The turbid-to-clear transition was shown to depend on (1) the molecular weight of the alcohol: the heavier the alcohol the less alcohol is required, and (2) salinity: the higher the salinity the higher the amount of alcohol that is needed. From filtration experiments, Salager suggested that the clear point represents the transition at which the liquid crystals or swollen micelles disperse perhaps to form micellar structures which are too small to scatter light. Clear points measurements by Aoudia [11] for a series of cloudy monoisomeric alkylbenzene sulfonate aqueous solutions in the presence of electrolyte (NaCl) seems to support such suggestion. Aoudia showed that plots of the fluorescence depolarization degree (%P) against temperature displayed a critical temperature at which the surfactant solution turns clear and the degree of fluorescence polarization start to decrease sharply. This was attributed to the fact that, below the clear point, the emitted fluorescence from the surfactant molecule used as its own probe (intrinsic probe) include both the “true fluorescence” emitted from the excited singlet state molecules as well as a certain percent degree of scattering induced by the solution turbidity due to the presence of large particles. At the critical temperature, the surfactant solution turns clear and consequently only true fluorescence is contributing to the measured fluorescence depolarization. Nonionic surfactants, on the other hand, are characterized by their cloud points, temperature at which a clear surfactant solution turns turbid and eventually separates into two phases [13]. The upper phase contains the totality of surfactant molecules and is generally called the surfactant-rich phase, whereas the lower clear phase has mostly water with a surfactant concentration around its critical micelle concentration.

Both clear (for pure anionic surfactants) and cloud (for pure nonionic surfactants) points are strongly affected by surfactant structure and additives. Particularly, numerous investigations have shown that the cloud points of nonionic surfactants are drastically increased upon adding small amount of ionic surfactants [14–21]. For instance, the addition of SDS or CTAB at concentrations well below their critical micelle concentrations (1 mM) to 1.0 wt% TX-114 results in an increase in the cloud point from 25 to 74 °C. The occurrence of the cloud point phenomenon in anionic surfactants is rather rare [22], whereas some mixtures of anionic-cationic surfactants were found to exhibit clouding upon heating [23–26]. On the other hand, the clouding phenomenon of alkyl ethoxylated anionic surfactants in brine has not been investigated, in spite of its great significance in EOR.

Our first objective is therefore to investigate the effect of temperature on the compatibility of a series of sodium alkyl ether sulfonates (SAES) with synthetic brine having high salinity (~181,326 ppm), which also have dissolved therein 11,118 ppm Ca2+ and 3,978 ppm Mg2+. Such brine compositions are representative conditions prevailing in many technically challenging reservoir candidates for EOR. Our hypothesis is that in technical grade AES used in EOR processes, dual nonionic (cloud point)-anionic (clear point) can be observed in their solubilization behavior in brine. In addition, AE cloud point is probably influenced by the presence of the AES component, and conversely the AE component may also affect the AES clear point. This issue is of prime importance in EOR by surfactant flooding in which clouding may affect the efficiency of the process. To the best of our knowledge, this is the first instance that a such mutual effect in ethoxylated anionic surfactants is being addressed. Furthermore, attempts will be made to enhance surfactant-brine compatibility by decreasing the anionic component clear point and increasing the nonionic component cloud point using mixed anionic-nonionic mixtures as a suitable alternative to adding alcohols, a costly and technically limited approach.

Experimental

Materials

A series of sodium alkyl ether sulfonate (SAES, 30 wt% active material) were used in this study. They have the following molecular structure: iC17–O–(CH2CH2O)7–SO2Na (iC17EO7S, MW = 650 g/mol and high branching degree), iC17–O–(CH2CH2O)10–SO2Na (iC17EO10S, MW = 782 g/mol and high branching degree), and nC17–O–(CH2CH2O)10–SO3Na (nC17EO10S, MW = 782 g/mol and low branching degree). The nonionic surfactants (100 wt% active) used in this work have the following molecular structures: iC17–O–(CH2CH2O)7–H (iC17EO7, MW = 548 g/mol, HLB ~ 11, and high branching degree; iC17–O–(CH2CH2O)10–H (iC17EO10, MW = 696 g/mol, HLB ~ 13 and high branching degree), nC17–O–(CH2CH2O)10–H (nC17EO10, MW = 696 g/mol HLB ~ 13 and low branching degree), and iC9–O–(CH2–CH2O)14–H (iC10EO14, MW = 760 g/mol, HLB ~ 16 and mid branching degree). All surfactants were kindly supplied by BASF (The German Chemical Company) and used without further purification. The degree of sulfonation is 85 %, meaning that any ethoxylated anionic surfactant with an active content of 30 wt% contains 25.5 wt% sulfonated component (AES) and 4.5 wt% nonionic surfactant (AE). Synthetic brine (Table 1) was used in all our experiments as a standard to simulate high salinity and hardness reservoir conditions.

Methods

For cloud point measurements, surfactant solutions at different concentrations (0.025–1.0 wt%) were prepared in glass tubes which were sealed, shaken and immersed in a constant temperature bath set at 22 °C. These solutions were heated gradually to a temperature of about 95 °C. The cloud point transition temperatures were determined by visual observation. After the samples had been heated to above the clouding temperature, the cloud point was taken as the temperature at which the last visible sign of cloudiness disappears on cooling. At a cooling rate of approximately 1 °C min−1 the measurements were generally reproducible within 0.5 °C. Likewise, the clear point transition temperatures were taken as the temperature at which an initially turbid surfactant solution turns clear. Critical micelle concentrations (CMC) were determined from surface tension measurements using a K9 tensiometer (Krüss, Germany).

Results and Discussion

Alkyl Ether (AE)/Brine Compatibility

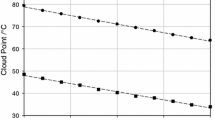

Compatibility of the nonionic surfactants iC17EO7, nC17EO10, and iC17EO10 with synthetic brine are shown in Table 2. As seen in this Table, iC17EO7 and nC17EO10 surfactants form turbid solutions in brine (0.025–1.0 wt%) and eventually separate into two phases, suggesting that their cloud points are below 22 °C. Although the two surfactants are characterized by a relatively high HLB (11 and 13), the observation of cloud points below 22 °C even at very low surfactant concentrations (0.025 wt%) is probably related to a significant decrease in their solubility in the presence of large amount of electrolyte. On the other hand, iC17EO10 forms clear solutions in brine in the entire range of concentration (0.025–0.05 wt%). Upon heating, these clear solutions turn turbid. Figure 1 shows the variation of iC17EO10 cloud point with concentration, suggesting that iC17EO10 cloud point is above 22 °C and varies between 37 °C (0.025 wt%) and 22.6 °C (1.0 wt%). Several trends in the variation of the cloud point with surfactant structure have been observed. In particular, the cloud point generally increases with an increase in the degree of ethoxylation and decreases with increasing alkyl carbon chain length [27, 28]. Indeed, this is well illustrated by the observed cloud points below 22 °C for iC17EO7 and above 22 °C for iC17EO10, two nonionic surfactants having similar alkyl chain length and structure but different degree of ethoxylation. On the other hand, iC17EO10 and nC17EO10 are characterized by similar degree of ethoxylation (10 EO) and similar number of carbon atoms in the alkyl chain, but differ by their alkyl chain structure, a highly branching degree in iC17EO10 and a lower branching degree in nC17EO10. It is well documented that when the hydrophobic group is branched, the carbon atoms on the branches appear to have one-half the effect of carbon atoms on a straight chain. As a result, the alkyl chain in iC17EO10 is more hydrophilic than the corresponding one in nC17EO10 and this may account for the relatively higher solubility of iC17EO10 in brine. Nonionic surfactants are widely used as co-surfactants in EOR applications, thereby cloud point data are of considerable practical interest.

Temperature-total surfactant concentration (wt%) phase diagram for iC17EO10 alone in brine (Filled circles). Inset Temperature-total surfactant concentration (wt%) phase diagram for iC17EO10S (weight fraction 0.15 of nonionic component iC17EO10 in the presence of weight fraction 0.85 of anionic component iC17EO10S in the mixture) in brine (Filled diamonds)

Sodium Alkyl Ether Sulfonate (SAES)/Brine Compatibility

The effect of temperature on surfactant-brine compatibility was investigated for the three sodium alkyl ether sulfonates iC17EO7S (weight fraction 0.15 of iC17EO7 and weight fraction of 0.85 iC17EO7S in the mixture), iC17EO10S (weight fraction 0.15 of iC17E10 and weight fraction 0.85 iC17EO10S in the mixture), and nC17EO10S (weight fraction 0.15 of nC17EO10 and weight fraction 0.85 nC17EO10S in the mixture). For iC17EO7S surfactant, all solutions were turbid at 22 °C and remain turbid upon heating up to 95 °C. Ultimately, phase separation occurs and a gel-like suspension can be observed in the surfactant solution, suggesting a clear point for iC17EO7S above the boiling point of water. On the contrary, a different behavior was observed for iC17EO10S and nC17EO10S. Solutions made with iC17EO10S were clear and stable at 22 °C in the entire range of surfactant concentration investigated (0.025–1.0 wt%). Upon heating, a concentration-dependent clear-to-turbid transition temperature was observed in the concentration range 0.1–1.0 wt%, whereas solutions at 0.025 and 0.05 wt% remain clear up to the boiling point of water (Fig. 1, Inset).

As previously mentioned, the degree of sulfonation in SAES used in this study (iC17EO7S, iC17EO10S, and nC17SEO10S) is 85 %, meaning that 15 wt% of the starting nonionic material (iC17EO7, iC17EO10, and nC17EO10) is not sulfonated. For instance, iC17EO10S (30 wt% active) contains 25.5 wt% sulfonated component (iC17EO10S) and 4.5 wt% nonionic component (iC17EO10). The variation of the clear-to-turbid transition temperature with iC17EO10S concentration displayed in Fig. 1 (Inset) shows that the transition temperature decreases significantly as the total surfactant concentration is increased from 0.1 wt% (T = 62.5 °C) to 0.5 wt% (T = 44 °C). At 0.5 wt% and above, the transition temperature did not vary very significantly. This is a typical variation for the cloud point for a pure nonionic surfactant with concentration. In addition, the trend shown in Fig. 1 (Inset) for iC17EO10S is similar to that shown for iC10EO10 alone (Fig. 1). Hence, the clear-to-turbid transition can be indeed attributed to the variation of the cloud point of the anionic component (weight fraction 0.15 of iC17EO10 in the mixture) in the presence of the anionic component (weight fraction 0.85 of iC17EO10S in the mixture). Furthermore, a close look at Fig. 1 reveals that at 1.0 wt% iC17EO10S (weight fraction 0.15 of iC17EO10 in the mixture), the cloud point is around 42 °C whereas the cloud point of iC17EO10 alone at 0.15 wt% concentration is around 24.5 °C. Likewise, at 0.5 wt% iC17EO10S (weight fraction 0.075 of iC17EO10 in the mixture) the cloud point is 44 °C whereas the equivalent cloud point of iC17EO10 alone at the same concentration (0.075 wt%) is around 28 °C. This is well illustrated in Fig. 2 which displays the variation of the cloud point with nonionic surfactant concentration for iC17EO10 alone (Filled circle) and for the nonionic component (weight fraction 0.15 of iC17EO10 in the mixture) in the presence of the anionic component (weight percent 0.85 of iC17EO10S in the mixture) in a concentration range up to 15 wt% (Filled diamond). Clearly, a similar upward shift (ΔT ~ 17–18 °C) in the cloud point is observed. This increase is generally observed when conventional anionic surfactants (SDS, CTAB,..) are added to polyoxyethylenated surfactant [14–21]. The importance of these observations is that, alkyl ether sulfonates (usually considered as being essentially anionic surfactants) may also display cloud point solubilization behavior due to the presence of the nonionic component. Cloud point occurrence with alkyl ether anionic surfactants in brine have been so far ignored in spite of the great significance of this property in surfactant formulations for EOR oil field applications, where clear and stable surfactant formulations at the injection and reservoir temperature are preferred. For instance, Fig. 1 (Inset) shows that the alkyl ether sulfonate surfactant iC17EO10S can be used to formulate clear and stable solutions at high salinity and hardness (Table 1) at temperatures approaching 100 °C at a surfactant concentration below 0.1 wt% and over a wide range of reservoir temperatures (42–60 °C) over a concentration range of 0.15–1.0 wt%, concentrations usually used in EOR field applications.

Temperature-nonionic (iC17EO10) surfactant concentration (wt%) phase diagram for iC17EO10 alone (Filled circles) and for the nonionic component (weight fraction 0.15 of C17EO10 in the mixture) in the presence of the anionic component (weight fraction 0.85 of iC17EO10S in the mixture in brine (Filled diamonds)

Compared to its isomeric counterpart iC17EO10S, nC17EO10S shows an interesting and different solubilization behavior in brine. This surfactant form turbid solutions at 22 °C over the entire range of concentrations used. Upon heating, a turbid-to-clear transition occurs, followed by a clear-to-turbid one (Fig. 3). The clear-to-turbid transition temperature is similar to that observed with the isomer iC17EO10S and can therefore be associated with the cloud point of the nonionic component nC17EO10 (weight fraction 0.15 in the mixture) in the presence of the sulfonated moiety nC17EO10S (weight fraction 0.85 in the mixture). According to Table 2, the cloud point of pure nC17EO10 alone is below 22 °C in the concentration range 0.025–0.1 wt%, whereas the cloud point of nC17EO10 (weight fraction 0.15) in the presence of nC17EO10S (weight fraction 0.85) is significantly increased to the range 69.5–76 °C, depending on the total surfactant concentration. On the other hand, the turbid-to-clear transition temperature can be attributed to the clear point of the anionic component AES (weight fraction 0.85 of nC17EO10S in the mixture) in the presence of the nonionic component (weight fraction 0.15 of nC10EO10 in the mixture). In the concentration range (0.025–0.5 wt%), clear and cloud points vary in an opposite manner, whereas at 0.5 wt% and above, both remain practically invariant with surfactant concentration. Hence, the temperature-surfactant concentration phase diagram displayed in Fig. 3 is clearly reflecting a dual anionic-nonionic solubilization behavior of nC17EO10S in brine, in which an evident interrelationship appears to exist between the two properties.

Temperature-total surfactant concentration (wt%) phase diagram for nC17EO10S (weight fraction 0.15 of nC17EO10 in the mixture) in the presence of presence of the anionic component (weight fraction 0.85 of nC17EO10S in the mixture) in brine: clear point (Filled diamonds) and cloud point (Filled squares)

At this juncture, it is worth turning our attention to the effect of the surfactant structure on its solubilization behavior in brine. As seen in Fig. 3, nC10EO10S clear point vary from 43 to 49 °C (0.025–1 wt%), whereas clear points for iC17EO7S and iC17EO10S are above the boiling point of water and below 22 °C, respectively, suggesting a strong molecular structure-clear point correlation. Shinoda et al. [32] reported an increase in the clear point of anionic surfactants with the increase in their alkyl chain and attributed this behavior to a decrease in the surfactant solubility. Since iC17EO7S and iC17EO10S are characterized by similar alkyl chain, the observed difference in their compatibility behavior with brine can be attributed to the difference in their degree of ethoxylation. Increasing the number of ethylene oxide (EO) units in the surfactant molecular structure results in an increase in hydrogen bonding of EO groups with water and consequently enhances the surfactant solubility. On the contrary, iC17EO10S and nC17EO10S have similar alkyl chain length as well as similar average degree of ethoxylation, yet they display different clear point property. This is probably due to the difference in the degree of branching in the two isomers, a highly branched chain in iC17EO10S and a lower one in nC17EO10S, thereby conferring a higher hydrophilicity character to iC17EO10S.

Having shown that the cloud points of the intrinsic nonionic component (iC17EO10 and nC17EO10) in sodium alkyl ether sulfonates (SAES) are significantly increased in the presence of the corresponding counterpart anionic component (iC17EO10S and nC17EO10S) with respect to iC17EO10 and nC17EO10 alone, it is also necessary to assess the effect of an extrinsic nonionic surfactant on the clear point of ethoxylated anionic surfactants in brine. Essentially most efforts focused on the effect of ionic surfactants on the cloud point of nonionic surfactants [13–21], and to the best of our knowledge, no work on the effect of nonionic surfactant on the clear point of ionic surfactant has been reported so far. Furthermore, most studies dealt with conventional anionic-nonionic mixtures in which the ionic surfactants were used in small amounts well below their CMC values.

SAES/AE/Brine Compatibility

The effect of an extrinsic nonionic surfactant (iC9EO14, 100 % active) on the clear point of the anionic component iC17EO7S (weight fraction 0.85 of iC17EO7S in the mixture) in the presence of nonionic component (weight fraction 0.15 of iC17EO7 in the mixture) and the concomitant effect of the anionic component iC17EO7S on the cloud point of iC9EO14 were investigated at a total surfactant concentration well above the CMC of the surfactant mixture. CMC values for iC17AE7S, iC9EO14, and iC9EO14 (weight fraction 0.8)/iC17EO7S (weight fraction 0.2) mixture were determined from the variation of the surface tension with surfactant concentration and were found to be 0.019, 0.137, and 0.073 wt%, respectively (Fig. 4). Accordingly, the effect of temperature on the compatibility of iC17EO7S(0.15 wt% iC17EO7)/iC9EO14 system was investigated at a total surfactant concentration of 1.0 wt%, to ensure the presence of anionic-nonionic mixed micelles. In addition, it is important to note that iC17EO7S(iC17EO7)/iC9EO14 system is in fact a pseudo-binary system due to the presence of a small amount of iC17EO7. One should therefore consider the presence of three surfactants in solutions, two nonionics (the intrinsic surfactant iC17EO7 and the extrinsic surfactant iC9EO14) and one anionic (iC17EO7S). Mole fractions were calculated accordingly and are reported in Table 3, where x an, x int, and x ext are the molar fractions of the anionic component iC17EO7S, the nonionic component iC17EO7, and iC9EO14, respectively. iC17EO7S(iC17EO7)/iC9EO14 mixtures in the range composition x an = 0.082–0.325 were clear and stable in the presence of iC9EO14 (x ext = 0.897–0.590) at 22 °C. Upon heating, a concentration-dependent clear-to-turbid transition temperature was observed in the range 68–72 °C (Fig. 5). As previously mentioned, the clear point of the anionic ethoxylated component iC17EO7S (weight fraction 0.85 in the presence of weight fraction 0.15 of the nonionic component iC17EO10) within the total surfactant concentration range 0.025–1.0 wt% is above the boiling point of water. By adding iC9EO14 to iC17EO7S(iC17EO7) a tremendous decrease in the clear point is observed from above 100 °C to the range 68–72 °C, reflecting a remarkable effect of iC9EO14 on the iC17EO7S clear point. Interestingly, there is also a mutual effect of the anionic component iC17EOS on the cloud point of the extrinsic nonionic surfactant iC9EO14, as it is generally known. The plot of cloud point versus xan (Fig. 5) shows a linear increase in iC9EO14(iC17EO7) cloud point from 68 °C (iC10EO14 single micelles) to 72 °C (x an = 0.325). The following correlation was obtained:

where T cp in centigrade. It is well recognized that addition of small amounts of ionic surfactants below their CMC values to nonionic micelles usually results in a significant increase in the nonionic cloud point. For instance, the addition of an anionic surfactant (C14-sarcosinite) used below its CMC to nonionic TX-100 micelles (2 wt%) resulted in an increase in the cloud point exceeding the boiling point of water [16]. This significant increase was ascribed to the incorporation of C14-sarcosinite surfactant molecules to TX-100 nonionic micelles and the formation of charged mixed micelles, thereby causing repulsion between micelles and raising the cloud point. Likewise, the increase in the cloud point by 4 °C in iC17EO7S(iC17EO7)/iC9EO14 system can be attributed to the formation of charged mixed micelles with the nonionic surfactants, in which the repulsion between micelles is enhanced. However, this increase at a total surfactant concentration of 1.0 wt%, well above the CMCs of the individual surfactants and their mixtures, is extremely modest compared to that observed with conventional anionic (SDS, CTAB)-polyoxyethylenated nonionic systems in which such effect becomes more prominent when concentrations of anionic surfactant approaching their CMCs. Li et al. [29] showed that the cloud point of a 1 wt% Tergitol 15-S-7 (mixture of secondary ethoxylated alcohols with 11–15 carbons on hydrophobic alkyl chain and an ethylene oxide number of 7) is drastically increased from around 50 °C in the presence of SDS below its CMC to above the boiling point of water in the presence of SDS at its CMC. Thus, the small effect of iC17EO7S on the cloud point of iC914EO may suggest that electrostatic intermicellar repulsion in (iC17EO7S(iC17EO7)/iC9EO14) system is somehow hindered by other factors.

According to the classical interpretation, the appearance of clouding is attributed to the dehydration of the polyoxyethylene chain that occurs at the cloud point temperature. This dehydration was suggested to be induced by the conformation change of the POE chain with temperature rise [30]. Reduction in the degree of hydration of the EO groups was also attributed to the presence of the sulfate moiety, as evidenced by the measured lipophilic character of the EO groups in a series of alkyl ether groups containing 1–10 EO groups per molecule [31]. Sulfate ion-oxyethylene group interactions has been reported recently by Aoudia et al. [32] in self-aggregation of a series of sodium lauryl ether sulfate (SLES) having 1–3 EO units and in their mixed micellization with TX-100. The authors reported a more hydrophobic character of SLES surfactants (CMC = 0.8 mM) as compared to their homologous non ethoxylated counterpart SDS (CMC = 8.2 mM). They suggested that mixing alkyl ether sulfate and polyoxyethylene-type surfactants may result in an attractive ion–dipole interaction between SO4 − moiety and the nearby O → CH2 dipole in mixed micelles. Such ion–dipole interactions may result in a dehydration of the EO groups as well as in a change in mixed micelle charge, thereby reducing to some extent micelle–micelle repulsion. Furthermore, owing to its molecular structure, the sulfonate group in iC17EO7S is attached to a polyoxyethylene (POE) chain having seven EO units, so that the location of SO3 − is not at the micelle-water interface but within a certain distance from the interface determined by the anionic intrinsic POE chain. On the other hand, the relatively longer POE in iC9EO14 (14 EO units) extends further into the bulk aqueous phase, so that some shielding of the sulfonate groups may occur, thereby reducing to some extent intermicellar coulombic repulsion (Scheme 1) [33, 34]. Thus, there exist three concomitant effects that can be attributed to the variation of the cloud point with x an, namely: (1) an increase in mixed micelle charge with increasing x an (this factor promotes cloud point elevation), (2) a dehydration of EO groups via interactions with the sulfonate groups (this factor promotes cloud point depression), and (3) the possible shielding of SO3 − groups by nearby extended POE chain of iC9EO14 (this factor promotes cloud point depression). The interrelationship of the three mechanisms may result in the small increase in the cloud point (4 °C) shown in Fig. 5. Furthermore, within the molar fraction anionic range x an = 0.082–0.325, mixed micelles are probably predominately composed of iC17EO10 and iC9EO14 (x int + x ext = 0.917–0.668) in which every single anionic component surfactant molecule iC10EO7S in the mixed micelle is surrounded by some nonionic surfactant molecules iC17EO7 and iC9EO14 (Scheme 1). In these nonionic rich mixed micelles, shielding effect of SO3 − by the nonionic POE chain (14 EO) may be expected to play a relatively greater role than intermolecular ion–dipole interactions. It is also worth noting that the addition of the alkyl ether sulfonate surfactant iC17EO10S (weight fraction 0.15 of iC17EO7 in the presence of weight fraction 0.85 of iC17EO7S in the mixture) to C14EO14 will inevitably result in a iC14EO14/iC17EO7 nonionic mixture. Accordingly, as x an increases, the molar fraction of iC17EO (x int) increases at the expense of the molar fraction of iC10EO14 (x ext). Assuming that iC10EO14/iC17EO7 mixture can be described as an equivalent single nonionic surfactant having a average degree of ethoxylation and hydrophobic alkyl chain length given by

where f int and f ext are the calculated molar fractions of iC7EO7 and iC9EO14 in solution by excluding the anionic component contribution to the total number of moles in the solution. Values of 〈EO〉 and 〈C n 〉 are reported in Table 3. From this Table, it can be seen that upon adding iC17EO7S(iC17EO) to iC9EO14, the equivalent ethylene oxide number decreases by 1 unit whereas the equivalent alkyl chain length increase also by about 1 carbon atom. In order to increase the cloud point within a series of homologous nonionic surfactants, the hydrophile-lipophile balance (HLB) must be increased. This is achieved either by increasing the number of ethylene oxide units per molecule or, by reducing the number of carbon atoms in the hydrophobic chain. Consequently, the outcome of adding iC17EO7S(iC17EO7) to iC9EO14 is probably reflected by an overall decrease in the HLB in (iC17EO7)/(iC9EO14) mixture, thereby promoting cloud point depression.

Finally, the significance of our observations is two-fold: (1) alkyl ether sulfonates (AES) display dual anionic-nonionic solubilization behavior in brine due to the residual nonsulfonated alkyl ether (AE) component and (2) adding a nonionic polyoxyethylenated surfactant to AES may result in a concomitant significant decrease in the AES clear point and an increase in the cloud point of the added nonionic surfactant. Thus, in the case that a higher cloud point and a lower clear point are preferred, such as in surfactant flushing operations, a combination of mixed anionic-nonionic surfactant mixtures might be used to prevent clouding and/or gel formations.

References

Miller DJ, von Halasz S-P, Schmidt M, Holst A, Pusch G (1991) Dual surfactant systems for enhanced oil recovery at high salinities. J Petrol Sci Eng 6:63

Ayirala SC, Vijapurapu CS, Rao DN (2006) Beneficial effects of wettability altering surfactants in oil-wet fractured reservoirs. J Petrol Sci Eng 52:261

Carmona I, Schechter RS, Wade W, Weerasooriya U (1985) Ethoxylated oleyl sulfonates as model compounds for enhanced oil recovery. Soc Petrol Eng J 25:351

Abe M, Schechter RS, Wade W, Weerasooriya U, Yiv S (1986) Microemulsion formation with branched tail polyoxyethylene sulfonate surfactant. J Colloid Interface Sci 114:342

Aoudia M, Al-Shibli MN, Al-Kassimi LH, Al-Maamari RS, Al-Bemani AS (2006) Novel surfactants for ultralow interfacial tension in a wide range of surfactant concentration and temperature. J Surfact Deterg 9:287

Aoudia M, Al-Maamari RS, Nabipour M, Al-Bemani AS, Ayatollahi S (2010) Laboratory study of alkyl ether sulfonates for improved oil recovery in high-salinity carbonate reservoirs: a case study. Energy Fuels 24:3655

Aoudia M, Al-Harthi Z, Al-Maamari RS, Christie LC, Berger P (2010) Novel alkyl ether sulfonates for high salinity reservoir: effect of concentration on transient ultralow interfacial tension at the oil-water interface. J Surfact Deterg 13:223

Al-Hashmi HS, Obiora V, Al-Yousef HY, Fernandez F, Nofal W (2005) Alkaline surfactant polymer for carbonate reservoirs. Petrol Sci Technol 23:723

Skauge A, Palmgren O, Norsk Hydro AS (1989) Phase behavior and solution properties of ethoxylated anionic surfactants. In: SPE 18499, SPE international Symposium on Oilfield Chemistry in Houston

Fernandez ME (1978) Adsorption of sulfonates from aqueous solutions on to mineral surfaces. M.Sc. Thesis, UT at Austin

Aoudia M (1980) Spectroscopic investigations of the effect of surfactant structure on aqueous micellar solutions. Ph.D. Dissertation, University of Texas at Austin

Salager JL (1977) Physico-chemical properties of surfactant-water-oil mixtures: phase behavior, microemulsion formation and interfacial tension. Ph.D. Dissertation, UT at Austin

Degiorgio V (1983) Physics of amphiphiles: micelles, vesicles and microemulsions (1983). In: Degiorgio V, Corti M (eds) North-Holland Publisher, Amsterdam

Mata JP (2006) Hydrodynamic and clouding behavior of triton X-100+ SDS mixed micellar systems in the presence of sodium chloride. J. Dispersion Sci Technol 27:49

Panchal K, Desai AT, Nagar T (2006) Physicochemical behavior of mixed nonionic-ionic surfactants in water and aqueous salt solutions. J Dispersion Sci Technol 27:33

Varade D, Bahadur PJ (2005) Interaction in mixed micellization of sodium N-tetradecanoylsarcosinate with ionic and nonionic surfactants. J Dispersion Sci Technol 26:549

Sardar N, Ali, MS, Kamil M, Kabir-ul-Din (2010) Phase behavior of nonionic polymer hydroxypropylmethyl cellulose: effect of Gemini and single-chain surfactants on the energetics at the cloud point. J Chem Eng Data 55:4990

Nascentes CC, Aurelio Z, Aruda Z (2003) Cloud point formation based on mixed micelles in the presence of electrolytes for cobalt extraction and preconcentration. Talanta 61:759

Mukerjee P, Padhan SK, Dash S, Patel S, Mishra BK (2011) Clouding behavior in surfactant systems. Adv Colloid Interface Sci 162:59

Marszall L (1988) Cloud point of mixed ionic-nonionic surfactant solutions in the presence of electrolytes. Langmuir 4:90

Molina-Bolivar JA, Hierrezuelo JM, Carnero Ruiz C (2013) Energetics of clouding and size effects in nonionic surfactant mixtures: the influence of alkyl chain structure and NaCl addition. J Chem Thermodyn 57:59

Smith AM, Holmes MC, Pitt S, Harrison W, Tiddi JLT (1995) Lamellar phases in contact with the lower consolute loop of ionic surfactant-water systems. Langmuir 11:4202

Chinchalikar AJ, Aswal VK, Kohlbrecher J, Wagh AG (2012) Small-angle neutron scattering study of temperature vs. salt dependence of clouding in charged micellar system. Eur Phys J E 35:55

Kumar S, Sharma D, Kabir-ud-Din (2000) Cloud point phenomenon in aqueous surfactant + quaternary bromide systems and its variation with additives Langmuir 16:6821

Kumar S, Aswal VK, Andleeb Z, Naqvi S, Goyal S, Kabir-ud-Din (2001) Cloud point phenomenon in ionic micellar solutions: a SANS study. Langmuir 17(9):2249

Kumar S, Sharma D, Kabir-ud-din (2004) Effect of additives on the clouding behavior of sodium dodecyl sulfate + tetra-n-butylammonium bromide system. J Surfact Deterg 7:271

Rosen MJ (1989) Surfactants and Interfacial Phenomena, 2nd edition, Wiley, New York

Shinoda K, Masakatsu H, Takao H (1872) The Physicochemical properties of aqueous solutions of fluorinated surfactants. J Phys Chem 76:909

Li JI, Bai DS, Chen BH (2009) Effects of additives on the cloud points of selected nonionic linear ethoxylated alcohol surfactants. Colloids Surf A 346:237

Inoue T, Ohmura H, Murata D (2003) Cloud point temperature of polyoxyethylene-type nonionic surfactants and their mixtures. J Colloid Interface Sci 258:374

Sowada R (1981) Lipophilic nature of oxyalkyl groups in alkyl ether sulfates. J. Fuer Practishe Chemie 323:278

Aoudia M, Al-Maamari T, Al-Salmi F (2009) Intramolecular and intermolecular ion-dipole interactions in sodium lauryl ether sulfate (SLES) self-aggregation and mixed micellization. Colloids Surf A 335:55

Anton RE, Anderez JM, Bracho C, Vejar F, Salager JL (2008) Practical surfactant mixing rules based on the attainment of microemulsion-oil-water three-phase behavior systems. In: Narayanan R (ed) interfacial processes and molecular aggregation. Advances Polymer Sci, Springer, 218:83–113

Arandia MA, Forgiarini AM, Salager JL (2010) Resolving an enhanced oil recovery challenge: optimum formulation of a surfactant-oil-water system made insensitive to dilution. J Surfact Deterg 13:119

Acknowledgments

We are very grateful to The Research Council (TRC, Sultanate of Oman) for supporting this research (Grant: ORG/SQU/EI/11/023, RC/SCI/CHEM/12/03).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Al-Faraji, S., Al-Maamari, R.S. & Aoudia, M. Sodium Alkyl Ether Sulfonates (SAES): Dual Anionic-Nonionic Behavior in Synthetic Brine Having High Salinity and Hardness. J Surfact Deterg 18, 113–121 (2015). https://doi.org/10.1007/s11743-014-1593-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-014-1593-2