Abstract

The main production mechanism during water flooding of naturally fractured oil reservoirs is the spontaneous imbibition of water into matrix blocks and resultant displacement of oil into the fracture system. This is an efficient recovery process when the matrix is strongly water-wet. However, in mixed- to oil-wet reservoirs, secondary recovery from water flooding is often poor. Oil production can be improved by dissolving low concentrations of surfactants in the injected water. The surfactant alters the wettability of the reservoir rock, enhancing the spontaneous imbibition process. Our previous study revealed that the two main mechanisms responsible for the wettability alteration are ion-pair formation and adsorption of surfactant molecules through interactions with the adsorbed crude oil components on the rock surface. Based on the superior performance of surfactin, an anionic biosurfactant with two charged groups on the hydrophilic head, it was hypothesized that the wettability alteration process might be further improved through the use of dimeric or gemini surfactants, which have two hydrophilic head groups and two hydrophobic tails. We believe that when ion-pair formation is the dominant wettability alteration mechanism, wettability alteration in oil-wet cores can be improved by increasing the charge density on the head group(s) of the surfactant molecule since the ion-pair formation is driven by electrostatic interactions. At a concentration of 1.0 mmol L−1 a representative anionic gemini surfactant showed oil recoveries of up to 49% original oil-in-place (OOIP) from oil-wet sandstone cores, compared to 6 and 27% for sodium laureth sulfate and surfactin, respectively. These observations are consistent with our hypothesis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

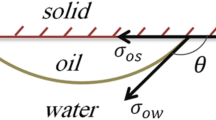

Much of the world’s oil is in reservoirs which contain high conductivity fractures surrounding low-permeability matrix blocks that are oil-wet/mixed-wet [1, 2]. Water flooding recoveries are typically low from such reservoirs. In fractured reservoirs, oil recovery depends on spontaneous imbibition of water to expel oil from the matrix into the fracture system, provided that the matrix blocks are water-wet. To enhance the spontaneous imbibition process in fractured reservoirs, low concentrations of surfactants in injected fluids are used to modify the wettability of the reservoir rock [3, 4]. The surfactant alters the wettability of the reservoir rock to a more water-wet state, enhancing the spontaneous imbibition process [5]. A previous study by the present authors revealed that ion-pair formation and adsorption of surfactant molecules through interactions with the adsorbed crude oil components on the rock surface are the two main mechanisms responsible for the wettability alteration [6]. It was hypothesized that the wettability alteration process might be improved through the use of dimeric (gemini) surfactants, which have two hydrophilic head groups and two hydrophobic tails. Berea cores aged in crude oil were used as porous media in imbibition studies to test this hypothesis. An anionic gemini surfactant (a xylene di C14/C16 sulfonate) was tested against sodium laureth sulfate and surfactin, a biosurfactant with two negative charges on the oligopeptide head group.

Experimental Procedures

In this study, we used 1.5-inch-diameter Berea sandstone cores with permeabilities of 490–590 mD and porosity of 21% (pore volume = 14.9 to 17.3 cm3 ). Crude oil from the Lansing Kansas City C zone (density (ρ) = 0.82 g cm−3; viscosity (μ) = 4.58 mPa s at 45 °C) was centrifuged and then filtered through a 2.7-μm cellulose filter before being used to age the cores to an oil-wet state. The crude oil had acid and base numbers of 0.12 and 2.38 mg KOH/g oil, respectively. Soltrol 130 (Chevron Phillips Chemical Company, The Woodlands, TX), a commercial mixture of C10–C13 isoalkanes, was used as the oil phase in all interfacial tension (IFT) measurements, imbibition and flow tests. Soltrol 130 density and viscosity at 25 °C were 0.754 g cm−3 and 1.42 mPa s, respectively. Synthetic brine (10 g L−1 NaCl, pH 6.96) was used in all experiments with sandstone cores. Sodium laureth sulfate (SLS, STEOL CS-330, MW = 395) was obtained from the Stepan Chemical Company (Northfield, IL), and was used as received as an aqueous solution with a purity of 24%, and diluted as required. Surfactin, a biosurfactant produced by growing Bacillus subtilis on a high-starch medium (MW = 1047) was provided and characterized by Idaho National Laboratory (INL, Idaho Falls, ID). Xylene di-C14/C16-sulfonate (MW = 746), an anionic gemini surfactant, was obtained from Oil Chem Technologies (Sugar Land, TX). It was provided in 100% active acid form and was dissolved in water and neutralized with sodium hydroxide to form the water soluble salt before use. Molecular structures of surfactants used are shown in Fig. 1. Addition of the surfactant at a concentration of 1.0 mmol L−1 did not significantly change the pH of the brine.

IFT was measured between equal volumes of 1.0 mmol L−1 surfactant solution and Soltrol 130 using a Fisher Model 20 ring tensiometer. IFT values versus Soltrol were: SLS, 6.4 mN m−1; surfactin, 4.0 mN m−1; and gemini, 8.0 mN m−1. The base number was obtained following the ASTM nonaqueous potentiometric titration method (D-2896) [7]. The acid number was initially inferred using the correlation between acid number and API gravity of crude oil published by Fan and Buckley [8], and later confirmed by titration [9] according to Stan McCool (personal communication).

Berea sandstone cores were characterized (porosity, permeability, homogeneity) using 10 g L−1 NaCl brine and then initial water saturations were established by flooding the cores with Soltrol 130. The Soltrol 130 was displaced with Lansing Kansas City crude oil and cores were aged under crude oil at 90 °C for 1 month to render them oil-wet. The crude oil was displaced with multiple pore volumes of Soltrol 130 prior to imbibition testing. Aged cores had a typical Amott–Harvey index (I A–H) of −0.4.

To allow multiple tests on the same core, a cleaning protocol was used based on a method developed by Hirasaki et al. [10] Core cleaning was performed in a Hassler-Type core holder (Temco, Tulsa, OK) in a fume hood. The Viton® sleeves used in the core holder were sensitive to the solvents used, so the cores, along with the distribution plugs, were wrapped using fluorinated ethylene polymer (FEP) Teflon® heat-shrinkable tubing (Zeus Industrial Products Inc., Orangeburg, SC) and placed in an oven at 190 °C to allow the FEP to shrink before cooling and placing in the core holder sleeve. Solvents were delivered from glass transfer cylinders with a Teflon® piston. Water from a ConstaMetric pump (LDC Analytical, Stoke, UK) was used to drive the piston, which displaced the solvent through PEEK™ tubing into the core. For each core, approximately two pore volumes (PV) of tetrahydrofuran (THF) was injected daily until the effluent was no longer visibly discolored. THF was then displaced by injecting at least two PV chloroform (CHCl3) daily for several days. Finally, the chloroform was displaced with several PV of methanol (CH3OH) and the methanol was displaced with several PV of water. The core was then oven dried at 90 °C. A full Amott-Harvey wettability test on cores that were cleaned and aged multiple times was not performed; however spontaneous imbibition of brine was not observed in any of the cores so treated.

Imbibition tests were performed by placing cores in an Amott cell (Custom Lab Glass Service, Peculiar, MO) filled with brine with or without surfactant and monitoring oil production over time at room temperature.

Results and Discussion

Surfactants were used at a concentration of 1.0 mmol L−1 in 10 g L−1 NaCl brine. The critical micelle concentration (CMC) was not determined in brine but the CMCs of surfactin in 0.05 M Tris buffer is 24.7 μmol L−1 [11], SLS in water is 8,200 μmol L−1 [12] and the gemini surfactant 14.7 μmol L−1 [from manufacturer information]. Li et al. [11] report that the addition of sodium ions reduces the CMC of surfactin. The surfactin and gemini were therefore above the CMC, while SLS was below. To test the effect of the initial water saturation, core B07 (Pore volume (PV) = 17.3 mL, porosity (ϕ) = 0.21, permeability (k) = 480 millidarcy (mD)) was aged to an oil-wet state as described and adjusted to an initial water saturation of 0.37, then placed in an imbibition cell in contact with brine solution. Oil production was monitored for a few days to confirm that the core was oil wet, and then the brine was replaced by 1.0 mmol L−1 gemini surfactant in brine and oil production was monitored. When oil production ceased the core was cleaned, returned to an oil-wet state with no initial water saturation, and placed in an imbibition cell with 1.0 mmol L−1 gemini surfactant in brine. Figure 2 shows that the presence of initial water saturation had no significant effect either on the rate or on final oil production, though there was a delay of several days before production was observed in the core with initial water consistent with previous studies [6]. It has been reported that initial water saturation can increase the initial rate of imbibition [13], however, this was not observed in this work, possibly because of the disconnected nature of the water saturation in the strongly oil-wet core. This indicates that the results of imbibition tests on cores with no initial water saturation can be extrapolated to those with initial water.

The effect of different surfactants on oil production was investigated by taking additional Berea sandstone cores B03 (PV = 14.9 mL, ϕ = 0.21, k) = 510 mD) and B06 (PV = 16.7 mL, ϕ = 0.21, k = 512 mD), cleaning and aging then exposing them to brine, and then 1.0 mmol/L sodium laureth sulfate and surfactin, respectively. Production data are plotted for all three surfactants in Fig. 3.

The initial rate of oil production by the gemini surfactant was less than that for surfactin; however, the final oil recovery was almost twice that from surfactin after 150 days of imbibition. Ultimate production by surfactin and gemini surfactant were, respectively, approximately four and eight times that from SLS at 1.0 mmol L−1. This higher performance is thought to be due to the presence of two negative charge groups per surfactant molecule, and since the head groups on the dimeric surfactant are smaller than the surfactin’s heptapeptide head, it achieves better packing and hence interaction of the surfactant molecules with the adsorbed materials on the rock surface (Fig. 4).

Conclusions

A representative dimeric surfactant was shown to be appreciably more effective than either a monomeric surfactant (SLS), or surfactin, a biosurfactant with a doubly charged oligopeptide head, at displacing oil from a Berea core by spontaneous imbibition of NaCl brine at a surfactant concentration of 1.0 mmol L−1. These observations are consistent with our hypothesis that when ion-pair formation is the dominant wettability alteration mechanism, wettability alteration in oil-wet cores can be improved by increasing the charge density on the head group(s) of the surfactant molecule. This may have significant implications for oil production from naturally fractured, oil-wet reservoirs. However, more work is required to identify whether this translates to more complex brines containing e.g. divalent ions.

References

Allan J, Sun SQ (2003) Controls on recovery factor in fractured reservoirs: lessons learned from 100 fractured fields. Paper SPE 84590 presented at the SPE annual technical conference and exhibition. Denver, CO, USA

Roehl PO, Choquette PW (1985) Carbonate petroleum reservoirs. Springer-Verlag, New York

Austad T, Matre B, Milter J, Saevareid A, Oyno L (1998) Chemical flooding of oil reservoirs 8. Spontaneous oil expulsion from oil-and water-wet low permeable chalk material by imbibition of aqueous surfactant solutions. Colloids Surf A 137:117–129

Standnes DC (2001) Enhanced oil recovery from oil-wet carbonate rock by spontaneous imbibition of aqueous surfactant solutions, Ph.D. Thesis, Stavanger College, p 115

Standnes DC, Austad T (2000) Wettability Alteration in Chalk 2. Mechanism for wettability alteration from oil-wet to water-wet using surfactants. J Petroleum Sci Technol 28:123–143

Salehi M, Johnson SJ, Liang J-T (2008) Mechanistic study of wettability alteration using surfactants with applications in naturally fractured reservoirs. Langmuir 24:14099–14107

ASTM International (2007) ASTM D2896-07a standard test method for base number of petroleum products by potentiometric perchloric acid titration, in annual book of ASTM Standards. ASTM International, West Conshohocken

Fan T, Buckley JS (2007) Acid number measurements revisited. Soc Petroleum Eng J 12:496–500

ASTM International (2007) D664-07 standard test method for acid number of petroleum products by potentiometric titration. Annual Book of ASTM Standards. ASTM International, West Conshohocken

Hirasaki GJ, Rohan JA, Dubey ST, Niko H (1990) Wettability evaluation during restored state core analysis. Paper SPE 20506 presented at the SPE 65th annual technical conference and exhibition. New Orleans, pp 361–375

Li Y, Ye R-Q, Mu B-Z (2009) Influence of sodium ions on micelles of surfactin-C16 in solution. J Surf Deterg 12:31–36

Mukerjee P, Mysels KJ (1971) Critical micelle concentration of aqueous surfactant systems. US Department of Commerce, National Bureau of Standards, Washington, DC

Morrow NR, McCaffrey F (1978) Displacement studies in uniformly wetted porous media. In: Padday GF (ed) Wetting, spreading and adhesion. Academic Press, New York, pp 289–319

Acknowledgments

The authors would like to thank the US Department of Energy (DOE) for funding this work through Contract NO. DF-FC26-04NT15523. Thanks also to Mr. Gregory Bala and Ms. Sandra Fox at Idaho National Laboratory, Idaho Falls, for providing and characterizing surfactin, and to Dr. Wenyu Zhang (SINOPEC), visiting scholar at the Tertiary Oil Recovery Project, for acid number measurement. We extend our thanks to the Department of Chemical and Petroleum Engineering at the University of Kansas.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Salehi, M., Johnson, S.J. & Liang, JT. Enhanced Wettability Alteration by Surfactants with Multiple Hydrophilic Moieties. J Surfact Deterg 13, 243–246 (2010). https://doi.org/10.1007/s11743-010-1193-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-010-1193-8