Abstract

Low salinity water (LSW) flooding alters rock surface wettability toward more water wetness, and consequently, oil recovery will be increased from a carbonate oil reservoir. Surfactant flooding and polymer flooding enhance oil recovery by oil–water interfacial tension (IFT) reduction and water–oil mobility ratio change, respectively. In this study, a combination of LSW and two non-ionic natural surfactants for enhanced oil recovery was evaluated. Four types of salts (CaCl2, MgCl2, Na2SO4, and MgSO4) at different concentrations in distilled water were used to find optimal LSW based on contact angle (CA) reduction. Two non-ionic natural surfactants (a new natural surfactant from Gemini surfactants (GS) family and Tribulus terrestris surfactant) were applied to obtain their optimum concentration based on IFT reduction. The minimum IFT was achieved in 2000 ppm of GS (4.06 mN/m) and 3000 ppm of TTS (6.21 mN/m). Experimental results showed that the presence of GS in low salinity surfactant solution (1000 ppm of MgSO4 and 2000 ppm GS) is capable to reduce IFT (to 1.02 mN/m) and CA (to 31.25°). Therefore, GS showed good results in IFT improvement and wettability alteration. Finally, the optimal LSS was combined with different concentrations of PHPA polymer and injected into cores. Core flooding results demonstrated 69.7% oil recovery for LSW injection, 82.2% for low salinity GS injection (an increase of 12.5%) and 87.9% for low salinity GS-polymer injection (an increase of 5.7%).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Enhanced oil recovery (EOR) techniques are used to improve oil recovery (OR) from oil reservoirs when reservoir pressure drops. Water flooding is widely applied to displace residual oil and consequently increases OR. In recent years, many studies have focused on injected water salinity and ions composition. Results of these studies showed that low salinity water (LSW) injection enhances OR compared to high salinity water injection (Xie et al. 2016; Pooryousefy et al. 2018). Moreover, the effect of specific ions concentration on LSW performance was investigated and the results reveal that there should be an optimal LSW composition to achieve better results in oil recovery factor (RF) (Yildiz and Morrow 1996). The presence of Ca2+, Mg2+ and SO42− ions in seawater (SW) improves OR. An increase in the sulfate ion concentration in SW and formation water (FW) leads to an increase in OR. SO42− ion in SW is an important factor in wettability modification of carbonate rocks (mix wet to water wet) (Strand et al. 2006; Zhang et al. 2007; Puntervold et al. 2015). Furthermore, the results of several studies indicate that higher concentrations of divalent cations, specifically Ca2+ in FW, generally lower the LSW flooding performance in sandstone reservoirs. In addition, the effect of diluted Mg2+ on LSW performance was either zero or small. When both Ca2+ and Mg2+ were diluted, there was a positive LSW effect on OR. However, the presence of Mg2+ inhibited the full benefit of Ca2+ dilution (Al-Saedi and Flori 2019; Al-Saedi et al. 2019a, b). It is important to note that LSW is more effective on contact angle (CA) alteration and has less effect on interfacial tension (IFT) reduction.

Surfactant flooding (as a chemical EOR technique) increases OR by simultaneously decreasing the IFT and modifying the wettability of the carbonate rock surface (Jia et al. 2017). In the oil wet carbonate reservoirs, surfactant flooding has a high effect on wettability alteration (Karimi et al. 2016). The combination of surfactant flooding and LSW flooding significantly reduces IFT and CA, which enhance OR consequently (Alagic and Skauge 2010; Alagic et al. 2011; Johannessen and Spildo 2013). Low salinity surfactant (LSS) flooding reduces surfactant retention (due to surfactant adsorption on the carbonate rock surface in the reservoir). Therefore, it allows surfactant to be injected at lower concentrations in EOR process (Johannessen and Spildo 2013; Spildo et al. 2014).

Recently, the effect of natural surfactants (because of their cost-effectiveness and renewability) on EOR has been examined and discussed in EOR processes. The studies declare that natural surfactants have a great effect on IFT reduction, and consequently, OR can be improved (Moradi et al. 2019). Plant-based Saponin surfactants were applied in some works to evaluate their effect on IFT and OR in EOR processes (Chhetri et al. 2009). Other studies have investigated the potential of some natural surfactants including Seidlitzia rosmarinus, Zizyphus spina-christi, Glycyrrhiza and Matricaria chamomilla for EOR scheme (Chhetri et al. 2009; Deymeh et al. 2012; Ahmadi et al. 2014; Shadizadeh and Kharrat 2015). Gemini surfactants (GS) are another kind of natural surfactants, which can reduce IFT and alter wettability. GSs consist of two hydrophilic heads and two hydrophobic tails. They can reduce oil–water IFT to the desired value at a lower concentration in comparison with monomeric surfactants. Some studies demonstrated that GSs have great potential for enhancing OR (Jiang et al. 2014; Chang et al. 2016; Zhou et al. 2017, 2018).

Polymer flooding, as a chemical EOR technique, has been applied in carbonate and sandstone reservoirs to improve OR. Polymer flooding is effective on OR improvement at different wetting conditions. Polymer injection increases the viscosity of the injected water (displacing fluid), which leads to water relative permeability decline. The decrease in water relative permeability causes an increase in vertical and areal sweep efficiencies, and OR will be enhanced. In other words, polymer injection improves the oil–water mobility ratio (Kamal et al. 2015a, b; Saboorian-Jooybari et al. 2016).

A combination of surfactant and polymer flooding has a major effect on rock wettability alteration, IFT reduction and oil–water mobility ratio improvement. It was reported that a significant increase in OR can be achieved by surfactant-polymer injection in low chemical concentration (Austad et al. 1994). In addition, it was observed that synergy of LSW and polymer injection can provide a favorable mobility ratio (by polymer) and carbonated rock wettability alteration (by LSW) and EOR efficiency will be increased (Shiran and Skauge 2013; Khorsandi et al. 2017). Moreover, LSW increases polymer stability by decreasing polymer degradation due to reduction in injected water salinity (desalination). Besides, LSW reduces the quantity of polymer, which is needed to obtain the target viscosity, decreases the cost remarkably and solves the chemistry issues of production (Zaitoun et al. 2012).

Some of the aforementioned researches presented experimental results of cationic and anionic surfactants flooding. The main aim of this study is to investigate the effect of two new non-ionic natural surfactants (a new oil-based Gemini surfactant and plant-based Tribulus terrestris surfactant) at low salinity on oil–water IFT, wettability alteration and OR in an oil wet carbonate oil reservoir. The combination of the new surfactants, LSW and PHPA polymer has not yet been investigated experimentally in a strongly oil wet carbonate oil reservoir. In addition, four types of salts were used at different concentrations to obtain the optimum concentration of each salt (as LSW) based on wettability changes. After that, different concentrations of the surfactants were applied to find the optimum concentration of each surfactant based on IFT reduction. To evaluate the integrated effects of IFT reduction and wettability alteration on OR, the optimal LSWs and two natural surfactants were combined and injected into cores. Finally, different concentrations of PHPA polymer were added to the optimal low salinity surfactant solution to examine the polymer effect on OR.

Experimental Methodology

Materials

Crude Oil

The crude oil sample was taken from a carbonate oil reservoir in southwestern Iran. Crude oil compositions were obtained by SARA (saturate, aromatic, resin and asphaltene) analysis and GC/MS (gas chromatography/mass spectrometry). The crude oil sample properties and its compositions are given in Tables 1 and 2, respectively.

Brine

To prepare LSW, four types of salts including magnesium chloride (MgCl2), calcium chloride (CaCl2), sodium sulfate (Na2SO4) and magnesium sulfate (MgSO4) were used. In addition, before the core flooding tests, original FW was injected into the cores to prepare the core samples for core flooding tests. The geochemical analysis of FW is given in Table 3.

Surfactants and Polymer

Two non-ionic natural surfactants, including a new Gemini surfactant (GS) and Tribulus terrestris surfactant (TTS), were used. Partially hydrolyzed polyacrylamide (PHPA) polymer (av. mol. wt. = 3,000,000 g/m, from SNF Floerger, France) was chosen for the experiments because of its low cost and resistance to bacterial attack (Kamal et al. 2015a).

Tribulus terrestris surfactant (TTS) was extracted from Tribulus terrestris, which is a plant growing in dry climate. Tribulus terrestris contains a steroidal Saponin called Protodioscin, two alkaloids and a phytosterol called hecogenin. Saponins are natural biodegradable non-ionic surfactants and composed of hydrophilic and hydrophobic parts that are attached by glycoside bonds. In aqueous solution, Saponin molecules align themselves vertically on the surface with their hydrophobic ends oriented away from the water, and consequently, the oil–water IFT will be reduced. Therefore, Saponins are surface-active agents with detergent, wetting, emulsifying and foaming properties. Moreover, it was observed that Saponins are capable to improve OR and reduce residual oil saturation (Daghlian et al. 2016; Moradi et al. 2019).

To synthesize Tribulus terrestris surfactant (TTS), a clear light brown-colored liquid was extracted by the Soxhlet extraction of Tribulus terrestris leaves with methanol for 48 h. Then, the solution was passed through filter paper and placed in an oven to evaporate methanol. After evaporation, the remaining yellow powder, which was soluble in the water, was used in the experiments (Moradi et al. 2019).

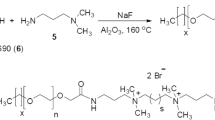

The second surfactant was introduced, for the first time, by Pal et al. (2019), which are from the Gemini surfactants (GS) family and synthesized from sunflower oil. Recently, GSs have been widely considered for their functionality, flexibility and economic effectiveness. GSs are composed of two polar heads and two nonpolar tails, which make them more hydrophilic and hydrophobic, compared to other known surfactants. GSs in lower critical micelle concentrations (CMC) can provide favorable IFT values. Therefore, GSs are surface-active agents with detergent, wetting, emulsifying and foaming properties. Therefore, they can improve OR more than known surfactants and produce additional oil from an oil reservoir (Menger and Littau 1993; Abo-Riya et al. 2016).

The procedure of synthesizing GS from sunflower oil and its characterization has been discussed by Pal et al. (2019). To prepare GS, 0.05 mol sunflower oil and 0.15 mol glycerol (C3H8O3) were mixed in the presence of 0.44 g CaO as the base catalyst at 80 °C for 45 min. The mixture was heated to 220–240 °C under nitrogen environment for 4 h. To separate excess glycerol, water was added to the mixture and distilled under vacuum to obtain glycerol ester. Then, 45 ml of 20% of potassium hydroxide (KOH) and 0.5 g tetrabutylammonium bromide (C16H36BrN) were added to 0.05 mol glycerol ester and stirred for half an hour. The mixture was stirred for 24 h at 100 °C, after the addition of 0.025 mol 1,4-dibromobutane(C4H8Br2)/1,6-dibromohexan (C6H12Br2). The organic phase was separated and dried over anhydrous sodium sulfate, and then, the solvent was removed under vacuum. The resulting products are non-ionic GSs including SF-4-SF and SF-6-SF with molecular weights 809 g/l and 834 g/l, respectively. Both surfactants are soluble in the aqueous phase. In this work, SF-6-SF surfactant was applied in the experiments for its better solubility in the aqueous solution than SF-4-SF (Pal et al. 2019).

Core Samples

Required core samples were taken from outcrops of a carbonate oil reservoir in the southwestern of Iran. Properties of the core samples are given in Table 4. A helium porosity test was performed to measure the porosity of the core samples. In addition, the permeability of the core samples and irreducible water saturation were calculated. (The measurement method is described in the core flooding test section.)

Methods

Contact Angle (CA) Measurement

Young’s equation (1) was used to calculate CAs in the water–oil–solid system. The Young’s equation is (Anderson 1986):

According to Figure 1, \(\sigma_{\text{ws}}\) is the water–solid IFT, \(\sigma_{\text{os}}\) is the oil–solid IFT, and \(\sigma_{\text{ow}}\) is the oil–water IFT. The angle θ is an important factor to determine rock wettability. When θ is 0°–75°, the rock is water wet, 75°–115° is mixed wet, and 115°–180° is oil wet.

Contact angle in oil–water–solid system (Manshad et al. 2017)

The captive drop method was used to measure the CAs. The schematic of a captive drop instrument is shown in Figure 2. To measure the CAs, 5-mm slices of core samples were prepared, then polished and smoothed. Afterward, these slices were washed with distilled water and dried at 120 °C for 24 h. All slices were placed in a vacuumed cell for 8 h until there was no air in the slices. Then, crude oil was injected into the cell and the slices were kept under 6.8947 MPa for 3 days. Subsequently, the slices were aged in crude oil for about 5 weeks at 75 °C. The slices were placed in a glass vessel, which was filled with prepared solutions. A crude oil drop was squeezed into the solution and attached to the lower surface of the slice. The CAs were recorded by a high-resolution camera. For each solution, CA was measured until it became constant. All CA measurements were taken at 25 °C and 101.3529 kPa.

Schematic of captive drop instrument (Manshad et al. 2017)

Interfacial Tension (IFT) Measurement

The IFT between oil and the solutions was measured by the pendant drop method, which has been used widely to measure IFT between fluids. This method is based on the shape of a liquid drop suspended in another liquid. A schematic of a pendant drop set is shown in Figure 3. In this method, the following relationship is used to obtain IFT based on drop shape (Manshad et al. 2017):

where γ is the IFT (mN/m), Δρ is the density (g/cm3) difference, D is the equatorial diameter of the drop, H is a correction factor, which is related to the shape factor of the pendant drop, and S is defined as:

where d is the drop diameter measured horizontally at a distance D away from the apes of the drop as shown in Figure 4. The amounts of 1/H based on S are given in different researches (e.g., Manshad et al. 2017).

General schematic of pendant drop set (Manshad et al. 2017)

Here, the pendant drop test was performed to find the optimum concentration of GS and TTS (in distilled water) based on oil–water IFT reduction. In addition, the effect of different concentrations of PHPA (in optimum concentration of GS and TTS) on oil–water IFT was investigated by the pendant drop method. All tests were done at 75 °C and 13.7895 MPa.

Core Flooding Tests

First, the core samples were washed by toluene and acetone. Then, the samples were kept at 120 °C for 24 h. Then, all core samples were put in a vacuumed vessel for 8 h until there was no air in the cores. For presaturation, FW was injected into the vessel and kept under 13.7895 MPa for 72 h. The core samples were then placed in a core holder, and five pore volumes (PVs) of FW were injected through the cores under a confining pressure of 15.8579 MPa, back pressure of 12.4105 MPa and flow rate of 0.1 cm3/min. In this step, the permeability of the core samples was calculated and the results are listed in Table 3. Three to four PVs of the crude oil were injected (at 0.1 cm3/min flow rate) for the displacement of mobile water to achieve irreducible water saturation (Table 3). The core samples were then aged in crude oil and kept at 75 °C for 40 days. Finally, the core samples were placed into a core holder and four PVs of the prepared solutions were injected into the core samples. Reservoir temperature of 75 °C, back pressure of 12.4105 MPa, confining pressure of 15.8579 MPa and flow rate of 0.5 cm3/min were applied to mimic the reservoir conditions. During the core flooding tests, the oil and water production rates were measured to calculate RF.

Pendant drop for IFT measurement (Manshad et al. 2017)

Results and Discussion

Effect of Low Salinity Water on Rock Wettability

The effect of different concentrations (0–7000 ppm) of the salts (CaCl2, MgCl2, Na2SO4 and MgSO4) on the rock wettability was investigated (Fig. 5). Each salt at its optimal concentration leads to a significant reduction in the CA (Fig. 5). The most reduction in CA (about 79.14°, 156.34°–77.2°) belongs to 1000 ppm of MgSO4. The salts’ optimum concentration (which led to minimum CA), their corresponding CAs and ionic strengths are listed in Table 5. Figure 6 shows the method of CA measurement at the optimum concentration of each salt and FW. It should be noted that the measured CA in FW was 150.63°, which shows that reservoir rock is strongly oil wet. The CA measurement results clarified that LSW can alter rock surface wettability from oil wet toward more water wet.

CaCl2 and MgCl2

Mg2+ and Ca2+ ions can react with carboxylic hydrocarbon groups (carboxylic hydrocarbons have a negative charge, which can attach to positively charged rock surface) and remove them from the carbonate rock surface. Therefore, Mg2+ and Ca2+ ions are capable to alter wettability (Moradi et al. 2019). Measured CAs for 2500 ppm CaCl2 and 1500 ppm MgCl2 were 90.22° and 84.09°, respectively, showing that in the presence of Cl− ions, Mg2+ ions are more effective on wettability alteration compared to Ca2+ ion. As it is seen in Table 5, the ionic strength of MgCl2 (0.0321) is more than that of CaCl2 (0.0289), which leads to expansion of the double layer and consequently more reduction in CA by MgCl2. Moreover, calcite (CaCO3) dissolution is effective on wettability alteration. The negative charge of organic components allows Mg2+ to come near to the rock surface and react with CO32− (in CaCO3). Then, MgCO3 is precipitated and Ca2+ ions are released. Therefore, close to the rock surface, Ca2+ ions concentration increases and Ca2+ ions react with negatively charged organic components on the rock surface and some of them are released (Zhang et al. 2007).

MgCl2 and MgSO4

Comparison between the effect of MgCl2 (1500 ppm) and MgSO4 (1000 ppm) on wettability alteration (84.09° for MgCl2 and 77.2° for MgSO4) shows that sulfate ion (SO42−) is more effective on CA reduction compared to Cl− ion. In addition, MgCl2 (0.0321) has less ionic strength compared to MgSO4 (0.0352). Moreover, sulfate ions adsorption (on carbonate rock surface) decreases the positive charge of the rock surface. This positive charge reduction desorbs the loosely absorbed organic components from the calcite. Moreover, the presence of sulfate ions on the calcite surface results in increase in Mg2+ and Ca2+ ions concentration close to the rock surface. In addition, at temperatures below 90 °C, the sulfate ions act as a catalyst and alter wettability (Karimi et al. 2016; Zhang et al. 2006, 2007).

Na2SO4 and MgSO4

As can be seen in Table 5, in the presence of SO42− ions, divalent cation Mg2+ was more effective on CA reduction than monovalent cation Na+. Na2SO4 has less ionic strength (0.0217) compared to MgSO4 (0.0352). Therefore, MgSO4 expands the double layer and consequently CA decreases considerably. As mentioned earlier, Mg2+ can react with CO32− (in calcite, CaCO3) and release Ca2+ ions near the rock surface, and finally, wettability alters.

Effect of Natural Surfactants on IFT

To find the optimum concentration of each surfactant (GS and TTS), several solutions at different concentrations (at the range of 500–9000 ppm) of each surfactant in distilled water were prepared, and then oil–water IFT was calculated using the pendant drop method. Measured IFTs are shown in Figure 7. The optimum concentrations of GS and TTS that led to the minimum IFT were 2000 and 3000 ppm, respectively. The minimum IFT for 2000 ppm GS was 4.06 mN/m, and for 3000 ppm, TTS was 6.21 mN/m. The mechanism of oil–water IFT reduction by surfactants is related to the fact that surfactant species attach to an oil–water interface, resulting in IFT reduction (Daghlian et al. 2016). As it is seen in Figure 7, GS is more effective on oil–water IFT reduction compared to TTS. GSs belong to a unique category of surface-active agents, which have two hydrophobic tails and two hydrophilic heads, but TTS (Saponin as a monomeric surfactant) has a nonpolar (hydrophobic) tail and a polar (hydrophilic) head. Therefore, GSs can reduce IFT to a favorable value in lower concentrations in comparison with known monomeric surfactants.

Effect of Combining LSW with Natural Surfactants on CA and IFT

The combined effect of optimum concentrations of the surfactants (GS and TTS) and optimum salt concentrations (LSWs) on CA and water–oil IFT was studied. As observed in Table 6, a combination of GS and TTS altered wettability toward more water wetness, but GS was more effective on rock wettability improvement than TTS. An LSS solution containing 1000 ppm MgSO4 and 2000 ppm GS can significantly reduce CA (156.34°–31.25°) and alter wettability from oil wet to strongly water wet. Non-ionic surfactant alters carbonate rock wettability in two ways, which occur simultaneously (Moradi et al. 2019): (1) The weak attraction between the positive-charged head of surfactant with negative adsorbed chemicals (e.g., asphaltenes) leads to desorption of these groups; and (2) the hydrophilic head of the surfactant attracts the surfactant molecules toward the brine at the rock surface, to replace with adsorbed organic molecules, and makes the surface more water wet. Based on the results, the minimum IFT (1.02 mN/m) belongs to a solution containing 1000 ppm MgSO4 and 2000 ppm GS. In addition, the presence of the salts reduces IFT because the cations cover the interaction of acid–base between oil and aqueous phase; therefore, oil becomes more soluble in brine. Moreover, the presence of the cations converts asphaltene and resin to soluble ions in the water, resulting in more IFT reduction. SO42− ions adsorb resin and asphaltene from the crude oil to the oil–water interface, and IFT reduces (Lashkarbolooki et al. 2014). Therefore, synergy of 1000 ppm MgSO4 and 2000 ppm GS (contains Mg2+ and SO42− ions) was the most effective on IFT reduction.

Combination Effect of Polymer and LSS on IFT

Different concentrations (500–2500 ppm) of PHPA were added to the optimum concentrations of GS and TTS (in LSWs) to investigate PHPA concentration impact on IFT. As observed in Figures 8 and 9, the increase in PHPA concentration leads to an increase in IFT. The reasons for the increase in IFT due to the polymer are (Austad et al. 1994; Kamal et al. 2015b): (1) Increase in polymer concentration elevates solution viscosity, which reduces the diffusion of surfactant from aqueous phase toward the oil–water interface, and (2) some chains of the polymer may be adsorbed on the interface and form a mixed-adsorption layer with surfactant molecules.

Core Flooding Tests

LSW Flooding Tests

To evaluate the LSW effect on OR, the LSW solutions (optimum concentration of each salt in distilled water) and FW were injected into core samples 1–5 (Table 4) and then RFs were calculated (Fig. 10). According to the figure, LSW injection considerably improves OR compared to FW injection. An LSW containing 1000 ppm MgSO4 (which had the most wettability alteration) can improve OR up to 69.7%, an increase of 23.8% compared to FW injection. The final OR factors for each LSW injection are listed in Table 7.

LSS Flooding

To evaluate the effect of the surfactants on OR, LSWs were combined with the optimum concentrations of the surfactants (GS 2000 ppm and TTS 3000 ppm) and were injected into core samples 6–13 (Table 4). Core flooding results for the solutions are shown in Figures 11 and 12. As seen in the figures, synergy of the LSWs and 2000 ppm GS is more effective on OR factor (up to 82.2% with 1000 ppm MgSO4) than injection of LSWs with 3000 ppm TTS (76.4% with 1000 ppm MgSO4). Optimal LSS (2000 ppm GS and 1000 ppm MgSO4) flooding can increase OR about 12.5% compared to optimal LSW flooding (1000 ppm MgSO4). As discussed earlier, simultaneous effects on wettability alteration and IFT reduction lead to a significant increase in OR by LSS flooding. Total OR factors for LSS flooding are listed in Table 8.

Low Salinity Surfactant-Polymer Flooding

An LSS solution (2000 ppm GS and 1000 ppm MgSO4) was chosen due to its better performance in OR based on the previous section. Core flooding tests were performed on core samples 14–18 (Table 4) by injecting the LSS solution with different concentrations of PHPA (500, 1000, 1500, 2000 and 2500 ppm). As observed in Figure 13, the increase in PHPA concentration leads to OR improvement. Final OR factors at different concentrations of PHPA are given in Table 9. Adding 2500 ppm of PHPA to an LSS solution (2000 ppm GS and 1000 ppm MgSO4) increased OR from 82.2 to 87.9%, an increase of 5.7%. The decrease in water relative permeability improves the oil–water mobility ratio and finally enhances OR.

Conclusions

This paper describes an experimental study to investigate the combined impact of low salinity water and two natural surfactants on wettability alteration, IFT reduction and OR. The experiments were performed on oil wet carbonate core samples. The optimum concentrations for CaCl2, MgCl2, Na2SO4 and MgSO4 were obtained separately in LSWs by CA tests. Then, the optimum concentrations of GS and TTS in distilled water were determined based on IFT reduction. After that, the effect of LSS on IFT and CA was evaluated. Finally, core flooding tests were done to obtain OR factors for injection of the LSW, LSS and low salinity surfactant-polymer solutions. Based on this study, the following conclusions were reached:

-

1.

LSWs with optimum concentration of each salt changed the rock wettability from oil wet to mixed wet. An LSW with 1000 ppm of MgSO4 had the most reduction in CA from 156.34° to 77.2° compared to other salts optimum concentration. Moreover, the most OR (about 69.7% of original oil in place) was for injection of 1000 ppm MgSO4 through core sample (an increase of 23.8% compared to FW injection).

Table 8 Oil recovery factors for LSS flooding -

2.

The presence of GS at different concentrations (as a new non-ionic oil-based natural surfactant) in distilled water was more effective on IFT reduction than TTS (non-ionic plant-based natural surfactant). The least IFT (about 4.06 mN/m) was for 2000 ppm of GS in distilled water.

-

3.

The combination of LSW and the non-ionic natural surfactants (as low salinity surfactant) led to more reduction in IFT and CA (oil wet to water wet) compared to any one of them alone. The presence of GS in LSW was more effective in increasing the OR factor compared to TTS.

Table 9 Recovery factor at different concentrations of PHPA -

4.

An increase in PHPA polymer concentration in LSS increased IFT. An increase in oil–water IFT in a solution with PHPA and low salinity TTS was greater than the same solution with GS.

-

5.

Increase in PHPA concentration up to 1500 ppm in LSS (2000 ppm GS and 1000 ppm MgSO4) improved OR up to 87.47% (an increase of 5.27% compared to the low salinity surfactant). After 1500 ppm of PHPA, the rate of increasing OR declined. The OR factors for 2000 ppm and 2500 ppm of PHPA were 87.69% (an increase of 0.22% compared to) and 87.9% (an increase of 0.43% compared to 87.47%), respectively.

References

Abo-Riya, M., Tantawy, A. H., & El-Doughoug, W. (2016). Synthesis and evaluation of novel cationic gemini surfactants based on Guava crude fat as petroleum-collecting and dispersing agents. Journal of Molecular Liquids, 221, 642–650.

Ahmadi, M. A., Arabsahebi, Y., Shadizadeh, S. S., & Shokrollahzadeh Behbahani, S. (2014). Preliminary evaluation of mulberry leaf-derived surfactant on interfacial tension in an oil-aqueous system: EOR application. Fuel, 117, 749–775.

Alagic, E., & Skauge, A. (2010). Combined low salinity brine injection and surfactant flooding in mixed-wet sandstone cores. Energy & Fuels, 24, 3551–3559.

Alagic, E., Spildo, K., Skauge, A., & Solbakken, J. (2011). Effect of crude oil ageing on low salinity and low salinity surfactant flooding. Journal of Petroleum Science and Engineering, 78, 220–227.

Al-Saedi, H. N., Brady, P. V., Flori, R. E., & Heidari, P. (2019a). Insights into the role of clays in low salinity water flooding in sand columns. Journal of Petroleum Science and Engineering, 174, 291–305.

Al-Saedi, H. N., & Flori, R. E. (2019). Effect of divalent cations in low salinity water flooding in sandstone reservoirs. Journal of Molecular Liquids, 275, 163–172.

Al-Saedi, H. N., Flori, R. E., & Brady, P. V. (2019b). Effect of divalent cations in formation water on wettability alteration during low salinity water flooding in sandstone reservoirs: Oil recovery analyses, surface reactivity tests, contact angle, and spontaneous imbibition experiments. Journal of Molecular Liquids, 283, 417–426.

Anderson, W. G. (1986). Wettability literature survey—Part 2: Wettability measurement. Journal of Petroleum Technology, 38, 1246–1262.

Austad, T., Fjelde, I., Veggeland, K., & Taugbol, K. (1994). Physicochemical principles of low tension polymer flood. Journal of Petroleum Science and Engineering, 10, 255–269.

Chang, H., Zhang, H., Jia, Z., Li, X., Gao, W., & Wei, W. L. (2016). Wettability of coal pitch surface by aqueous solutions of cationic Gemini surfactants. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 494, 59–64.

Chhetri, A. B., Watts, K. C., Rahman, M. S., & Islam, M. R. (2009). Soapnut extract as a natural surfactant for enhanced oil recovery. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 31, 1893–1903.

Daghlian, S. J., Sharifi, M., & Hemmati, A. (2016). Toward mechanistic understanding of surfactant flooding in enhanced oil recovery processes: The role of salinity, surfactant concentration and rock type. Journal of Molecular Liquids, 222, 632–639.

Deymeh, H., Shadizadeh, S. S., & Motafakkerfard, R. (2012). Experimental investigation of Seidlitzia rosmarinus effect on oil–water interfacial tension: Usable for chemical enhanced oil recovery. Scientia Iranica, 12, 1661–1664.

Jia, H., Leng, X., Hu, M., Song, Y., Wu, H., Lian, P., et al. (2017). Systematic investigation of the effects of mixed cationic/anionic surfactants on the interfacial tension of a water/model oil system and their application to enhance crude oil recovery. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 529, 621–627.

Jiang, P., Li, N., Ge, J., Zhang, G., Wang, Y., Chen, L., et al. (2014). Efficiency of a sulfobetaine-type surfactant on lowering IFT at crude oil–formation water interface. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 443, 141–148.

Johannessen, A. M., & Spildo, K. (2013). Enhanced oil recovery (EOR) by combining surfactant with low salinity injection. Energy & Fuels, 27, 5738–5749.

Kamal, M. S., Sultan, A. S., Al-Mubaiyedh, U. A., & Hussein, I. A. (2015a). Review on polymer flooding: Rheology, adsorption, stability, and field applications of various polymer systems. Polymer Reviews, 55, 491–530.

Kamal, M. S., Sultan, A. S., Al-Mubaiyedh, U. A., Hussein, I. A., & Feng, Y. (2015b). Rheological properties of thermoviscosifying polymers in high-temperature and high-salinity environments. The Canadian Journal of Chemical Engineering, 93, 1194–1200.

Karimi, M., Al-Maamari, R. S., Ayatollahi, S., & Mehranbod, N. (2016). Wettability alteration and oil recovery by spontaneous imbibition of low salinity brine into carbonates: Impact of Mg2+, SO42− and cationic surfactant. Journal of Petroleum Science and Engineering, 147, 560–569.

Khorsandi, S., Qiao, C., & Johns, R. T. (2017). Displacement efficiency for low-salinity polymer flooding including wettability alteration. SPE Journal, 22(2), 417–430.

Lashkarbolooki, M., Ayatollahi, S., & Riazi, M. (2014). The impacts of aqueous ions on interfacial tension and wettability of an asphaltenic-acidic crude oil reservoir during smart water injection. Journal of Chemical and Engineering Data, 11, 3624–3634.

Manshad, A. K., Rezaei, M., Moradi, S., Nowrouzi, I., & Mohammadi, A. H. (2017). Wettability alteration and interfacial tension (IFT) reduction in enhanced oil recovery (EOR) process by ionic liquid flooding. Journal of Molecular Liquids. https://doi.org/10.1016/j.molliq.2017.10.009.

Menger, F. M., & Littau, C. A. (1993). Gemini surfactants: A new class of self-assembling molecules. Journal of the American Chemical Society, 115, 10083–10090.

Moradi, S., Isari, A. A., Bachari, Z., & Mahmoodi, H. (2019). Combination of a new natural surfactant and smart water injection for enhanced oil recovery in carbonate rock: Synergic impacts of active ions and natural surfactant concentration. Journal of Petroleum Science and Engineering, 176, 1–10.

Pal, N., Samanta, K., & Mandal, A. (2019). A novel family of non-ionic Gemini surfactant from sunflower oil: Synthesis, characterization and physicochemical evaluation. Journal of Molecular Liquids, 275, 638–653.

Pooryousefy, E., Xie, Q., Chen, Y., Sari, A., & Saeedi, A. (2018). Drives of low salinity effect in sandstone reservoir. Journal of Molecular Liquids, 250, 396–403.

Puntervold, T., Strand, S., Ellouz, R., & Austad, T. (2015). Modified seawater as a smart EOR fluid in chalk. Journal of Petroleum Science and Engineering, 133, 440–443.

Saboorian-Jooybari, H., Dejam, M., & Chen, Z. (2016). Heavy oil polymer flooding from laboratory core floods to pilot tests and field applications: Half-century studies. Journal of Petroleum Science and Engineering, 142, 85–100.

Shadizadeh, S. S., & Kharrat, R. (2015). Experimental investigation of Matricaria chamomilla extract effect on oil-water interfacial tension: Usable for chemical enhanced oil recovery. Petroleum Science and Technology, 33, 901–907.

Shiran, B. S., & Skauge, A. (2013). Enhanced oil recovery (EOR) by combined low salinity water/polymer flooding. Energy & Fuels, 27(3), 1223–1235.

Spildo, K., Sun, L., Djurhuus, K., & Skauge, A. (2014). A strategy for low cost, effective surfactant injection. Journal of Petroleum Science and Engineering, 117, 8–14.

Strand, S., Hognesen, E. J., & Austad, T. (2006). Wettability alteration of carbonates—Effect of potential ions Ca2+ and SO42− and temperature. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 275, 1–10.

Xie, Q., Saeedi, A., Pooryousefy, E., & Liu, T. (2016). Extended DLVO-based estimates of surface force in low salinity water flooding. Journal of Molecular Liquids, 221, 658–665.

Yildiz, H. O., & Morrow, N. R. (1996). Effect of brine composition on recovery of Moutray crude oil by waterflooding. Journal of Petroleum Science and Engineering, 221, 658–665.

Zaitoun, A., Makakou, P., Blin, N., Al-Maamari, R. S., Al-Hashmi, A. R., Abdel-Goad, M., et al. (2012). Shear stability of EOR polymers. SPE Journal. https://doi.org/10.2118/141113-PA.

Zhang, P., Tweheyo, M. T., & Austad, T. (2006). Wettability alteration and improved oil recovery in chalk: The effect of calcium in the presence of sulfate. Energy & Fuels, 20, 2056–2062.

Zhang, P., Tweheyo, M. T., & Austad, T. (2007). Wettability alteration and improved oil recovery by spontaneous imbibition of seawater into chalk: Impact of the potential determining ions: Ca2+, Mg2+ and SO42−. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 310, 199–208.

Zhou, H., Liang, Y., Huang, P., Liang, T., Wu, H., Lian, P., et al. (2018). Systematic investigation of ionic liquid-type Gemini surfactants and their abnormal salt effects on the interfacial tension of a water/model oil system. Journal of Molecular Liquids, 249, 33–39.

Zhou, H., Luo, Q., Gong, Q. T., Liu, Z. Y., Zhang, L., & Zhao, S. (2017). Interfacial dilatational properties of di-substituted alkyl benzene sulfonates at kerosene/water and crude oil/water interface. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 520, 561–569.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dabiri, A., Honarvar, B. Synergic Impacts of Two Non-ionic Natural Surfactants and Low Salinity Water on Interfacial Tension Reduction, Wettability Alteration and Oil Recovery: Experimental Study on Oil Wet Carbonate Core Samples. Nat Resour Res 29, 4003–4016 (2020). https://doi.org/10.1007/s11053-020-09657-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-020-09657-9