Abstract

A simple, cost-effective, instrumental-free prototyping process has been developed for fabricating flexible, multilayer colorimetric microfluidic sensor. A hand-hold punch was used to make microfluidic sensor pattern with no use of any expensive instruments (laser cutter, cutting plotter, screen printer, wax printer, etc.). Colorimetric analysis was carried out using a smartphone camera as a reader. Sensitive quantitation of copper has been demonstrated on the developed sensor under the optimal parameters. In the presence of copper ion, the Blue channel color values decreased with increasing the Cu2+ concentration. The Blue channel color intensity was linear with the concentration of Cu2+ in the range from 0 to 30 mg/L with a detection limit of 0.096 mg/L (3σ). The developed microfluidic sensor possesses good selectivity, satisfying reproducibility and high recoveries in tap water. Furthermore, through changing hole punch with different hole shape and hole numbers, it is extremely easy to produce microfluidic sensors with different design in quantity at low cost. What’s more, the developed sensor could be easily extended to detect other single analyte or multiple analytes, showing promising practical applications in environmental analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Copper ion [Cu(II)], as the third most abundant transition metal ion after iron and zinc in the human body, has been proven to play important roles in a variety of physiological processes (O’Dell and Sunde 1997; Uriu-Adams and Keen 2005). When human is exposed to low levels of copper, it is likely to be beneficial for human health as copper is an essential micronutrient for all living organisms (Besold et al. 2018; Chetri et al. 2017). However, copper ions at elevated concentrations are highly toxic and can result in severe health effects such as gastrointestinal disturbance, jaundice, hemoglobinuria, kidney failure, liver damage, Wilson diseases, Alzheimer’s diseases, and potentially death (Zeng et al. 2006; Yun et al. 2017). Therefore, it is of great importance to monitor the levels of copper in drinking water, food, soil and other environmental samples. The safe thresholds of Cu2+ in drinking water are 1.3 mg/L and 2.0 mg/L according to the US Environmental Protection Agency and World Health Organization, respectively (Bandara et al. 2018a, b; Fitzgerald 1998).

Till now, there are many analytical methods which has been reported for copper detection, such as flame atomic absorption spectroscopy (FAAS) (Antunes et al. 2017), atomic emission spectroscopy (AES) (Yu et al. 2016), inductively coupled plasma-mass spectroscopy (ICP-MS) (Song et al. 2004), inductively coupled plasma-optical emission spectroscopy (ICP-OES) (Ferreira et al. 2002), electrochemistry (Wu et al. 2017) and fluorimetry (Fan et al. 2018). Although they are fast, reliable, and accurate for the quantitative detection of Cu(II) in environmental samples, they often suffer generalized disadvantages in terms of expensive instruments, tedious analysis time, the need for skilled operators, lack of instrument portability and in-filed capability (Peng et al. 2017; Chen et al. 2017). Thus, it is highly desirable to develop a sensitive, rapid, simple, and cost-effective analytical method for precise monitoring of Cu2+.

Microfluidic devices have gained significant popularity due to their low assay cost, reduced time consumption and low sample volume (Ko et al. 2017; Mukhitov et al. 2016). The recent technological improvements have increased the applicability of microfluidic devices in the real-world problems (Almeida et al. 2018; Cunningham et al. 2016). Till now, a great number of assay methods has been combined with microfluidic devices such as colorimetry (Sayad et al. 2017), electrochemistry (Li et al. 2017), chemiluminescence (Hu et al. 2017), electrochemiluminescence (Bist et al. 2017), fluorometry (Weng and Neethirajan 2017), surface plasmon resonance (SPR) (Nguyen et al. 2017), electrophoresis (Fu et al. 2017), chromatography (Ianovska et al. 2017) and mass spectrometry (Pedde et al. 2017). Colorimetry combined with microfluidic devices is particularly attractive since some facile electronic platforms (e.g., desktop scanner, digital camera and smart phone) can be used for image collection or data analysis, which greatly reduces the diagnostic cost and the usage of instrumentation (Bandara et al. 2018a, 2018b; Pena-Pereira et al. 2016; Zheng et al. 2019). Among the electronic platforms, the smartphone, thanks to its multifunctional capabilities, imaging, and computing power, is increasingly playing a pivotal role in colorimetric microfluidic analysis (Kim et al. 2017a, b; Roda et al. 2014; Wu et al. 2015; Xu et al. 2015). The quantitative detection can be easily carried out using the smart phone and the color intensity can be measured by an open-source image processing program (Jalal et al. 2017). The assay does not require expensive instruments and could be easily performed by anyone.

Until now, some colorimetric microfluidic devices have been fabricated for copper detection. Chaiyo et al. developed a microfluidic paper-based analytical device for copper detection with the help of wax printing (Chaiyo et al. 2015). Ratnarathorn et al. fabricated a colorimetric paper-based device for copper sensing using a computer-controlled X–Y knife plotter and cutting printer (Ratnarathorn et al. 2012). Rattanarat developed a multilayer paper-based device for colorimetric detection of copper using a CO2 laser cutter and wax printing technique (Rattanarat et al. 2014). Koesdjojo et al. developed a colorimetric microfluidic device for copper assay using cutting plotter and laminator (Koesdjojo et al. 2015). All these works need the use of expensive instruments for cutting or printing, which increases the cost of microfluidic sensor fabrication.

In this paper, a home-made microfluidic sensor for copper detection has been fabricated with the advantages of simplicity, low cost and rapid response. The sensor was manufactured by a simple prototyping process without using any expensive instruments (laser cutter, screen printer, wax printer, etc.). The sensor was composed of multiple layers by stacking 6-mm filter punches with sensing solution, electrical tape with circular holes, punched PVC film with circular holes, double-sided adhesive tape and PVC film from top to bottom. Sodium diethyldithiocarbamate (DDTC) is a classical complexing agent, which is most commonly used in spectrophotometric analysis (Atanassova et al. 1998; Marczenko and Balcerzak 2000). Therefore, DDTC was selected as the chelating agent to react with copper ions. Interaction of Cu2+ ions with DDTC in the microfluidic assay resulted in the formation of a yellow-colored complex (Lou et al. 2009; Noll and Betz 1952). Several important parameters such as pH of the buffer solution, the concentration of DDTC and the reaction time between DDTC and copper ion were optimized. Under the optimized parameter, the sensor showed good assay performance, satisfying selectivity, good reproducibility and high recoveries in tap water.

Experimental

Chemicals and instruments

Copper dinitrate, potassium nitrate, zinc nitrate, calcium nitrate, lead nitrate, nickel nitrate, magnesium nitrate, sodium nitrate, ferrous nitrate, ferric nitrate, cobaltous nitrate, dibasic sodium phosphate, citric acid, nitric acid, ethylenediaminetetraacetic acid disodium salt (EDTA), sodium diethyldithiocarbamate (DDTC) were of analytical grade and bought from Sinopharm Chemical Reagent Co., Ltd. (China). Ultrapure water was used for solution preparation. The standards with differing concentrations of Cu2+ were prepared by diluting the standard stock solutions with 0.5% HNO3. The sensing solution was prepared by dissolving EDTA and DDTC in the buffer solution [disodium acid phosphate (0.2 M) and citric acid (0.1 M), pH 7.6]. Whatman filter paper no. 1 was purchased from Whatman International Ltd. (Maidstone, England). A 6-mm diameter single-round hole punch was bought from local store for cutting patterned layer. Transparent PVC film with A4 size, black electrical tape and double-sided adhesive tape were also purchased from local store. A cell phone (oppo A53 M) made in china was used to take the digital pictures of the colored products in the detection zones. The sensor area was strictly controlled by the 6-mm diameter single-round hole punch. RGB values for each of the detection zones were measured using ImageJ software (version 1.50b, National Institutes of Health, USA) by analyzing the color intensities of the entire detection zone (“Analyze”/“Histogram”/“RGB”). The control experiment for the developed sensor was studied in the presence of other commonly occurring inorganic cations (K+, Zn2+, Ca2+, Pb2+, Ni2+, Mg2+, Na+, Fe2+, Fe3+, and Co2+). The tap water in the lab was used as real water sample for the recovery test.

The fabrication of colorimetric microfluidic sensor

A simple, inexpensive and fast process of sensor fabrication was carried out in this paper without using any expensive instruments such as wax printer and screen printer. The sensing zone was at first fabricated. Through punching circular holes into Whatman paper No. 1, filter punches with a diameter of 6 mm were generated. Then the filter punches were spotted with 6 μL of the sensing solution (50,000 mg/L EDTA and 900 mg/L DDTC, pH 7.6) and allowed to dry in a vacuum oven at 40 °C for 15 min. The patterned layers were cut by hand hole puncher into black electrical tape and transparent PVC film. The layer of black electrical tape was used to make the colorimetric reactions to be observed easily. The sensor was assembled by stacking filter punches with sensing solution, electrical tape with circular holes, punched PVC film with circular holes, double-sided adhesive tape and PVC film according to the finished layout provided in Fig. 1.

Copper detection

Different concentration of copper standard solution with a volume of 6 μL was added to the microfluidic sensor to investigate the assay performance. The copper ions reacted with the assay reagents for 10 min and yellow-colored complex was formed in the sensing zones. A cell phone was used to record the images of the sensors and ImageJ software was utilized to analyze the color intensity values in Red, Green and Blue channels. To study the selectivity of the developed microfluidic sensor, several commonly occurring inorganic cations (K+, Zn2+, Ca2+, Pb2+, Ni2+, Mg2+, Na+, Fe2+, Fe3+, and Co2+) have been checked. The spiked tap water was used as real sample to investigate the recovery of the sensor.

Results and discussion

The feasibility of the developed microfluidic sensor

The feasibility of the developed microfluidic sensor was demonstrated by measuring the color intensity in RGB channels. According the reported work (Sadollahkhani et al. 2014), the linear range for colorimetric detection of copper using paper-based sensor was 0.95–95.32 mg/L. Therefore, the intermediate level of concentration (50 mg/L) was selected for the feasibility experiment. Figure 2a showed the RGB profile plot for the blank sample and the mean color intensities for Red, Green and Blue channels were 180, 190 and 187, respectively. It is noted that the RGB profile plot for copper standard solution (50 mg/L) is shown in Fig. 2b and the mean color intensities for Red, Green and Blue channels were 171, 173 and 116, respectively. So, the absolute value of the color intensity changes for Red, Green and Blue channels for copper standard solution (50 mg/L) were 9, 17 and 71, respectively. These results indicate that Blue channel intensity for copper detection showed the highest sensitivity. Thus, Blue channel intensity was chosen for analysis throughout the rest of the experiments.

RGB profile plots for sensor after reacting with copper ion with the concentration of 0 mg/L (a) and 50 mg/L (b). The solid lines with Red, Green and Blue color in RGB profile plots represented the color intensities for Red, Green and Blue channels, respectively. Inserts: actual device used to measure 0 mg/L (a) and 50 mg/L (b) (n = 10) of copper ion standards

The optimization of several experimental parameters

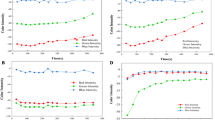

Several experimental parameters such as the pH of the buffer solution, the concentration of DDTC and the reaction time were optimized by comparing the results of the Blue channel intensity of sensors after the addition of Cu2+. For optimization of experimental parameters, 100 mg/L copper standard solution was selected as the analyte because the linear range for colorimetric detection of copper using paper-based sensor was up to nearly 100 mg/L as shown in the reference (Sadollahkhani et al. 2014). It is noted from Fig. 3a that the pH of the buffer solution was optimized over the range of 5.4–7.8. The Blue channel intensity greatly decreased when the pH of the buffer solution increased from 5.4 to 7.6 but plateaued with further increase. Therefore, 7.6 is chosen as the optimum pH value for the buffer solution. DDTC was used to react with copper ion to produce yellow color because of the formation of the Cu-DDTC complex. More importantly, Cu-DDTC complex is ideal for copper detection because of its sensitivity, simplicity (no prereduction is required) and, especially, tolerance to interferences (Chen et al. 1997). So it is of great importance to optimize the concentration of DDTC (CDDTC) to react with low concentration of copper ion and generate a measurable analytical signal. Figure 3b shows that the Blue channel intensity greatly decreased when CDDTC changed from 0 to 900 mg/L but plateaued with further increase from 900 to 1700 mg/L. Therefore, 900 mg/L was selected as the optimum CDDTC. The reaction time for the interaction between Cu2+ and DDTC was also optimized. It is noted from Fig. 3c that the color value greatly decreased when the reaction time changed from 5 to 10 min but slightly increased from 10 to 15 min. So, 10 min was selected the optimum reaction time.

Effect of various parameters on the Blue channel intensity: a pH of the buffer solution, b the concentration of DDTC (CDDTC), c the reaction time between copper ion and DDTC. The concentration of Cu2+ used for the optimization experiments is 100 mg/L. Error bars represent the standard deviation of three parallel experiments

Copper assay

Under the optimal parameters, the assay performance of the microfluidic sensor was investigated. After adding a series of Cu2+ standards on the sensor, a digital photo of the sensor was taken by a cell phone and the Blue channel intensity of the detection zone was measured under the help of ImageJ software. The color intensity values at the assay zone on paper-based devices were examined at room temperature in the presence of Cu2+ in the range of 0 – 70 mg/L. It is noted from Fig. 4a that the Blue channel color values decreased with increasing of Cu2+ concentration. Figure 4b indicates that the sensing system exhibited a linear relationship between the Blue channel color value and the copper concentration in the range 0 – 30 mg/L (Blue channel intensity = − 1.7918CCu + 186.2584, R2 = 0.9968). Thus, the detection limit is 0.096 mg/L (3σ), which was calculated according to the linear equation of Cu2+. Table 1 provides a performance comparison of different colorimetric sensors for detection of Cu(II). As shown in the table, the LOD value obtained in this paper is lower than those reported in the literature, indicating a high sensitivity of the developed sensor towards the copper assay. Furthermore, compared to the commercial pack test for copper detection manufactured by Kyoritsu Chemical-Check Lab., Corp. (https://kyoritsu-lab.co.jp/english/seihin/list/packtest/cum.html), the sensor developed in this work enables not only qualitative analysis but also quantitative analysis for copper detection and exhibits a broader linear range.

a Dependence of Blue channel intensity on Cu2+ concentration. The concentrations are 0 mg/L, 1 mg/L, 3 mg/L, 5 mg/L, 10 mg/L, 20 mg/L, 30 mg/L, 50 mg/L, and 70 mg/L. b The linear fit plots of Blue channel intensity as a function of the concentration of Cu2+. Error bars represent the standard deviation of ten parallel experiments

Selectivity, reproducibility and stability

The selectivity of the microfluidic sensor was evaluated by performing control experiments. The co-existing metal ions (K+, Zn2+, Ca2+, Pb2+, Ni2+, Mg2+, Na+, Fe2+, Fe3+, Co2+, Mn2+, and Bi3+) were chosen as the interferents for copper detection, most of which could interact with DDTC to form the DDTC-Mn+ complexes (Atanassova et al. 1998; Sato and Ueda 2001). From Fig. 5, the interferents induced a small color value change compared with the response signal of blank sample, while copper ion gave an obvious change of the Blue channel intensity. More importantly, the mixture containing Cu2+ and interferents produced almost the same signal as that of Cu2+. The reason is that the interference from Zn2+, Ni2+, Fe3+, Co2+, and Mn2+ was largely eliminated as they form less stable DDTC-Mn+ complex than Cu2+ (Wu et al. 2008; Yan et al. 2003). Furthermore, the interference from Pb2+, Ni2+, Co2+, Mn2+ and Bi3+ can be eliminated using EDTA as masking agent. EDTA does not mask Cu(II) as DDTC ligand forms stronger complex (Uddin et al. 2013). These results suggest that the developed microfluidic sensor performed satisfactory selectivity for copper detection. The reproducibility of the sensor was also investigated by determining five concentration levels (1, 5, 10, 20, 30 mg/L) with ten replicate measurements using fresh microfluidic chip for each measurement. The relative standard deviations (RSD) of the measurements were 5.2, 5.6, 3.7, 2.8, and 4.0%, respectively, for the five concentrations studied, indicating that the reproducibility of the sensor for copper detection was acceptable. The stability of the developed microfluidic sensor in which DDTC was immobilized on the paper layer was investigated. It is noted from Fig. 6 that the sensor remains stable after a 3-h storage at − 15 °C, and the Blue channel intensities have no significant changes compared to the freshly fabricated sensor (0 h). However, the Blue channel intensity increased obviously after the developed sensor was stored at − 15 °C for longer than for 4 h. The possible reason is that DDTC could be spontaneously broken down to form carbon disulfide, diethylamine, and other metabolites (Jin et al. 1994; Yourick and Faiman 1987).

The applicability of the developed microfluidic sensor

To investigate the applicability and reliability of the proposed microfluidic sensor, the spiked-recovery experiment was studied with diluted tap water. Ten independent measurements were performed for each concentration. 5 ml of water sample was spiked with different concentrations of Cu2+, and then diluted to 10 mL with 1% HNO3. It is noted from Table 2 that the recoveries for the added Cu2+ with 10, 20, and 30 mg/L are 94, 106, and 105%. Then, the developed microfluidic sensor toward analyzing real samples was investigated by testing two different compound-premix-containing copper elements. Multiple samples (n = 6) were tested with the approach developed in this work and analyzed with a standard FAAS method. The two different compound-premixes were microwave-digested with nitric acid to dissolve all the copper. Then, the digested solution was heated to near dryness using an electric furnace to remove the excess acid. The results are summarized in Table 3. The microfluidic analysis results are comparable to the results obtained by FAAS, proving the practical applicability of the microfluidic assay.

Conclusions

A simple, low-cost prototyping technology for home-made microfluidic devices has been developed. A one-hole circle punch was utilized to make patterned layers and there was no use of any expensive instruments (laser cutter, screen printer, wax printer, etc.) during the entire process for sensor manufacture. The flexible, multi-layer microfluidic sensor we developed is very inexpensive to produce, requires only simple tools for its fabrication. The sensor design is readily changed and optimized using hole punch with different hole shape. More importantly, the microfluidic sensor could be easily produced in quantity at low cost, especially when you use a six or more hole punches, resulting in the greatly improved working efficiency. We applied this device for the colorimetric detection of copper in tap water in a field-portable device format. Using cell phone as photo collector, a competitive limit of detection (0.096 mg/L) was established. In addition, the device had satisfactory selectivity, good reproducibility and high recovery in tap water. The simplicity, speed and stability of our fabrication and analytical approaches, coupled with the field portability, and low cost of our device, provides a highly useful and practical platform for frequent monitoring of Cu2+ in environmental/drinking waters.

References

Almeida MIG, Jayawardane BM, Kolev SD, McKelvie ID (2018) Developments of microfluidic paper-based analytical devices (μPADs) for water analysis: a review. Talanta 177:176–190. https://doi.org/10.1016/j.talanta.2017.08.072

Antunes GA, Santos HSD, Silva YPD, Silva MM, Piatnicki CM, Samios D (2017) Determination of iron, copper, zinc, aluminum, and chromium in biodiesel by flame atomic absorption spectrometry using a microemulsion preparation method. Energy Fuel 31:2944–2950. https://doi.org/10.1021/acs.energyfuels.6b03360

Atanassova D, Stefanova V, Russeva E (1998) Co-precipitative pre-concentration with sodium diethyldithiocarbamate and ICP-AES determination of Se, Cu, Pb, Zn, Fe Co, Ni, Mn, Cr and Cd in water. Talanta 47:1237–1243. https://doi.org/10.1016/S0039-9140(98)00211-2

Bandara GC, Heist C, Remcho VT (2018a) Chromatographic separation and visual detection on wicking microfluidic devices: quantitation of Cu2+ in surface, ground, and drinking water. Anal Chem 90:2594–2600. https://doi.org/10.1021/acs.analchem.7b04087

Bandara GC, Heist CA, Remcho VT (2018b) Patterned polycaprolactone-filled glass microfiber microfluidic devices for total protein content analysis. Talanta 176:589–594. https://doi.org/10.1016/j.talanta.2017.08.031

Besold AN, Gilston BA, Radin JN, Ramsoomair C, Culbertson EM, Li CX, Cormack BP, Chazin WJ, Kehl-Fie TE, Culotta VC (2018) Role of calprotectin in withholding zinc and copper from Candida albicans. Infect Immun 86:e00779-17. https://doi.org/10.1128/IAI.00779-17

Bist I, Bano K, Rusling JF (2017) Screening genotoxicity chemistry with microfluidic electrochemiluminescent arrays. Sensors 17:1008. https://doi.org/10.3390/s17051008

Chaiyo S, Siangproh W, Apilux A, Chailapakul O (2015) Highly selective and sensitive paper-based colorimetric sensor using thiosulfate catalytic etching of silver nanoplates for trace determination of copper ions. Anal Chim Acta 866:75–83. https://doi.org/10.1016/j.aca.2015.01.042

Chen H, Jin J, Wang Y (1997) Flow injection on-line coprecipitation-preconcentration system using copper(II) diethyldithiocarbamate as carrier for flame atomic absorption spectrometric determination of cadmium, lead and nickel in environmental samples. Anal Chim Acta 353:181–188. https://doi.org/10.1016/S0003-2670(97)87776-8

Chen H, Li Z, Liu X, Zhong J, Lin T, Guo L, Fu F (2017) Colorimetric assay of copper ions based on the inhibition of peroxidase-like activity of MoS2 nanosheets. Spectrochim Acta A 185:271–275. https://doi.org/10.1016/j.saa.2017.05.071

Chetri M, Choudhury SR, Sen A (2017) Response of pheretima posthuma and some soil fertility enhancing bacteria to the copper stress. Int J Biomed Sci Eng 5:14–17. https://doi.org/10.11648/j.ijbse.20170502.11

Cunningham JC, DeGregory PR, Crooks RM (2016) New functionalities for paper-based sensors lead to simplified user operation, lower limits of detection, and new applications. Annu Rev Anal Chem 9:183–202. https://doi.org/10.1146/annurev-anchem-071015-041605

Fan C, Lv X, Liu F, Feng L, Liu M, Cai Y, Liu H, Wang J, Yang Y, Wang H (2018) Silver nanoclusters encapsulated into metal-organic frameworks with enhanced fluorescence and specific ion accumulation toward the microdot array-based fluorimetric analysis of copper in blood. ACS Sens 3:441–450. https://doi.org/10.1021/acssensors.7b00874

Ferreira SL, Queiroz AS, Fernandes MS, Santos HCD (2002) Application of factorial designs and Doehlert matrix in optimization of experimental variables associated with the preconcentration and determination of vanadium and copper in seawater by inductively coupled plasma optical emission spectrometry. Spectrochim Acta B 57:1939–1950. https://doi.org/10.1016/S0584-8547(02)00160-X

Fitzgerald DJ (1998) Safety guidelines for copper in water. Am J Clin Nutr 67:1098S–1102S. https://doi.org/10.1093/ajcn/67.5.1098S

Fu X, Mavrogiannis N, Ibo M, Crivellari F, Gagnon ZR (2017) Microfluidic free-flow zone electrophoresis and isotachophoresis using carbon black nano-composite PDMS sidewall membranes. Electrophoresis 38:327–334. https://doi.org/10.1002/elps.201600104

Hu B, Li J, Mou L, Liu Y, Deng J, Qian W, Sun J, Cha R, Jiang X (2017) An automated and portable microfluidic chemiluminescence immunoassay for quantitative detection of biomarkers. Lab Chip 17:2225–2234. https://doi.org/10.1039/C7LC00249A

Ianovska MA, Mulder PPM, Verpoorte E (2017) Development of small-volume, microfluidic chaotic mixers for future application in two-dimensional liquid chromatography. RSC Adv 7:9090–9099. https://doi.org/10.1039/C6RA28626G

Idros N, Chu D (2018) Triple-indicator-based multidimensional colorimetric sensing platform for heavy metal ion detections. ACS Sens 3:1756–1764. https://doi.org/10.1021/acssensors.8b00490

Jalal UM, Jin GJ, Shim JS (2017) Paper-plastic hybrid microfluidic device for smartphone-based colorimetric analysis of urine. Anal Chem 89:13160–13166. https://doi.org/10.1021/acs.analchem.7b02612

Jin L, Davis MR, Hu P, Baillie TA (1994) Identification of novel glutathione conjugates of disulfiram and diethyldithiocarbamate in rat bile by liquid chromatography-tandem mass spectrometry. Evidence for metabolic activation of disulfiram in vivo. Chem Res Toxicol 7:526–533. https://doi.org/10.1021/tx00040a008

Jo HY, Park GJ, Na YJ, Choi YW, You GR, Kim C (2014) Sequential colorimetric recognition of Cu2+ and CN− by asymmetric coumarin-conjugated naphthol groups in aqueous solution. Dyes Pigment 109:127–134. https://doi.org/10.1016/j.dyepig.2014.05.014

Kim DB, Hong JM, Chang SK (2017a) Colorimetric determination of Cu2+ ions with a desktop scanner using silica nanoparticles via formation of a quinonediimine dye. Sens Actuators B Chem 252:537–543. https://doi.org/10.1016/j.snb.2017.06.033

Kim SC, Jalal UM, Im SB, Ko S, Shim JS (2017b) A smartphone-based optical platform for colorimetric analysis of microfluidic device. Sens Actuators B Chem 239:52–59. https://doi.org/10.1016/j.snb.2016.07.159

Ko E, Tran VK, Geng Y, Chung WS, Park CH, Kim MK, Jin GH, Seong GH (2017) Continuous electrochemical detection of hydrogen peroxide by Au-Ag bimetallic nanoparticles in microfluidic devices. J Electroanal Chem 792:72–78. https://doi.org/10.1016/j.jelechem.2017.03.027

Koesdjojo MT, Pengpumkiat S, Wu Y, Boonloed A, Huynh D, Remcho TP, Remcho VT (2015) Cost effective paper-based colorimetric microfluidic devices and mobile phone camera readers for the classroom. J Chem Educ 92:737–741. https://doi.org/10.1021/ed500401d

Li Y, Roy WV, Lagae L, Vereecken PM (2017) Analysis of fully on-chip microfluidic electrochemical systems under laminar flow. Electrochim Acta 231:200–208. https://doi.org/10.1016/j.electacta.2017.02.054

Liu Y, Yu J, Chen W, Liu D, Wang Z, Jiang X (2012) Cu2+ detection with gold nanoparticles by patterning colorimetric strips on a filter membrane assembled in a microfluidic chip. Chin J Chem 30:2047–2051. https://doi.org/10.1002/cjoc.201200655

Liu L, Xie MR, Fang F, Wu ZY (2018) Sensitive colorimetric detection of Cu2+ by simultaneous reaction and electrokinetic stacking on a paper-based analytical device. Microchem J 139:357–362. https://doi.org/10.1016/j.microc.2018.03.021

Lou XD, Li Z, Qin JG (2009) DDTC-Na-based colorimetric chemosensor for the sensing of cyanide in water. Sci China Ser B Chem 52:802–808. https://doi.org/10.1007/s11426-009-0111-2

Marczenko Z, Balcerzak M (2000) Separation, preconcentration and spectrophotometry in inorganic analysis. Elsevier, New York

Mehta VN, Kumar MA, Kailasa SK (2013) Colorimetric detection of copper in water samples using dopamine dithiocarbamate-functionalized Au nanoparticles. Ind Eng Chem Res 52:4414–4420. https://doi.org/10.1021/ie302651f

Mukhitov N, Spear JM, Stagg SM, Roper MG (2016) Interfacing microfluidics with negative stain transmission electron microscopy. Anal Chem 88:629–634. https://doi.org/10.1021/acs.analchem.5b03884

Nguyen TT, Yoon WJ, Lee NY, Ju H (2017) Integration of a microfluidic polymerase chain reaction device and surface plasmon resonance fiber sensor into an inline all-in-one platform for pathogenic bacteria detection. Sens Actuator B Chem 242:1–8. https://doi.org/10.1016/j.snb.2016.10.137

Noll CA, Betz LD (1952) Determination of copper ion by modified sodium diethyldithiocarbamate procedure. Anal Chem 24:1894–1895. https://doi.org/10.1021/ac60072a008

O’Dell BL, Sunde RA (1997) Handbook of nutritionally essential mineral elements. CRC Press, Boca Raton

Pedde RD, Li H, Borchers CH, Akbari M (2017) Microfluidic-Mass spectrometry interfaces for translational proteomics. Trends Biotechnol 35:954–970. https://doi.org/10.1016/j.tibtech.2017.06.006

Pena-Pereira F, Lavilla I, Bendicho C (2016) Paper-based analytical device for instrumental-free detection of thiocyanate in saliva as a biomarker of tobacco smoke exposure. Talanta 147:390–396. https://doi.org/10.1016/j.talanta.2015.10.013

Peng J, Liu G, Yuan D, Feng S, Zhou T (2017) A flow-batch manipulated Ag NPs based SPR sensor for colorimetric detection of copper ions (Cu2+) in water samples. Talanta 167:310–316. https://doi.org/10.1016/j.talanta.2017.02.015

Pratiwi R, Nguyen MP, Ibrahim S, Yoshioka N, Henry CS, Tjahjono DH (2017) A selective distance-based paper analytical device for copper (II) determination using a porphyrin derivative. Talanta 174:493–499. https://doi.org/10.1016/j.talanta.2017.06.041

Qiao J, Ding H, Liu Q, Zhang R, Qi L (2017) Preparation of polymer@AuNPs with droplets approach for sensing serum copper ions. Anal Chem 89:2080–2085. https://doi.org/10.1021/acs.analchem.6b04722

Ratnarathorn N, Chailapakul O, Henry CS, Dungchai W (2012) Simple silver nanoparticle colorimetric sensing for copper by paper-based devices. Talanta 99:552–557. https://doi.org/10.1016/j.talanta.2012.06.033

Rattanarat P, Dungchai W, Cate D, Volckens J, Chailapakul O, Henry CS (2014) Multilayer paper-based device for colorimetric and electrochemical quantification of metals. Anal Chem 86:3555–3562. https://doi.org/10.1021/ac5000224

Roda A, Michelini E, Cevenini L, Calabria D, Calabretta MM, Simoni P (2014) Integrating biochemiluminescence detection on smartphones: mobile chemistry platform for point-of-need analysis. Anal Chem 86:7299–7304. https://doi.org/10.1021/ac502137s

Sadollahkhani A, Hatamie A, Nur O, Willander M, Zargar B, Kazeminezhad I (2014) Colorimetric disposable paper coated with ZnO@ZnS core-shell nanoparticles for detection of copper ions in aqueous solutions. ACS Appl Mater Interfaces 6:17694–17701. https://doi.org/10.1021/am505480y

Sato H, Ueda J (2001) Coprecipitation of trace metal ions in water with bismuth (III) diethyldithiocarbamate for an electrothermal atomic absorption spectrometric determination. Anal Sci 17:461–463. https://doi.org/10.2116/analsci.17.461

Sayad A, Ibrahim F, Uddin SM, Cho J, Madou M, Thong KL (2017) A microdevice for rapid, monoplex and colorimetric detection of foodborne pathogens using a centrifugal microfluidic platform. Biosens Bioelectron 100:96–104. https://doi.org/10.1016/j.bios.2017.08.060

Song QJ, Greenway GM, McCreedy T (2004) Interfacing a microfluidic electrophoresis chip with inductively coupled plasma mass spectrometry for rapid elemental speciation. J Anal Atom Spectrom 19:883–887. https://doi.org/10.1039/B401657B

Uddin MN, Salam MA, Hossain MA (2013) Spectrophotometric measurement of Cu(DDTC)2 for the simultaneous determination of zinc and copper. Chemosphere 90:366–373. https://doi.org/10.1016/j.chemosphere.2012.07.029

Uriu-Adams JY, Keen CL (2005) Copper, oxidative stress, and human health. Mol Aspects Med 26:268–298. https://doi.org/10.1016/j.mam.2005.07.015

Wang H, Li YJ, Wei JF, Xu JR, Wang YH, Zheng GX (2014) Paper-based three-dimensional microfluidic device for monitoring of heavy metals with a camera cell phone. Anal Bioanal Chem 406:2799–2807. https://doi.org/10.1007/s00216-014-7715-x

Weng X, Neethirajan S (2017) Aptamer-based fluorometric determination of norovirus using a paper-based microfluidic device. Microchim Acta 184:4545–4552. https://doi.org/10.1007/s00604-017-2467-x

Wu P, Gao Y, Cheng G, Yang W, Lv Y, Hou X (2008) Selective determination of trace amounts of silver in complicated matrices by displacement-cloud point extraction coupled with thermospray flame furnace atomic absorption spectrometry. J Anal Atom Spectrom 23:752–757. https://doi.org/10.1039/B719579F

Wu YY, Boonloed A, Sleszynski N, Koesdjojo M, Armstrong C, Bracha S, Remcho VT (2015) Clinical chemistry measurements with commercially available test slides on a smartphone platform: colorimetric determination of glucose and urea. Clin Chim Acta 448:133–138. https://doi.org/10.1016/j.cca.2015.05.020

Wu KH, Lo HM, Wang JC, Yu SY, Yan BD (2017) Electrochemical detection of heavy metal pollutant using crosslinked chitosan/carbon nanotubes thin film electrodes. Mater Express 7:15–24. https://doi.org/10.1166/mex.2017.1351

Xu XY, Akay A, Wei HL, Wang SQ, Pingguan-Murphy B, Erlandsson BE, Li XJ, Lee WG, Hu J, Wang L, Xu F (2015) Advances in smartphone-based point-of-care diagnostics. Proc IEEE 103:236–247. https://doi.org/10.1109/JPROC.2014.2378776

Yan XP, Li Y, Jiang Y (2003) Selective measurement of ultratrace methylmercury in fish by flow injection on-line microcolumn displacement sorption preconcentration and separation coupled with electrothermal atomic absorption spectrometry. Anal Chem 75:2251–2255. https://doi.org/10.1021/ac026415f

Yourick JJ, Faiman MD (1987) Diethyldithiocarbamic acid-methyl ester: a metabolite of disulfiram and its alcohol sensitizing properties in the disulfiram-ethanol reaction. Alcohol 4:463–467. https://doi.org/10.1016/0741-8329(87)90086-3

Yu J, Yang S, Lu Q, Sun D, Zheng J, Zhang X, Wang X, Yang W (2016) Evaluation of liquid cathode glow discharge-atomic emission spectrometry for determination of copper and lead in ores samples. Talanta 164:216–221. https://doi.org/10.1016/j.talanta.2016.11.015

Yun SH, Xia L, Edison TNJI, Pandurangan M, Kim DH, Kim SH, Lee YR (2017) Highly selective fluorescence turn-on sensor for Cu2+ ions and its application in confocal imaging of living cells. Sens Actuator B Chem 240:988–995. https://doi.org/10.1016/j.snb.2016.09.070

Zeng L, Miller EW, Pralle A, Isacoff EY, Chang CJ (2006) A selective turn-on fluorescent sensor for imaging copper in living cells. J Am Chem Soc 128:10–11. https://doi.org/10.1021/ja055064u

Zheng L, Cai G, Wang S, Liao M, Li Y, Lin J (2019) A microfluidic colorimetric biosensor for rapid detection of Escherichia coli O157: H7 using gold nanoparticle aggregation and smart phone imaging. Biosens Bioelectron 124:143–149. https://doi.org/10.1016/j.bios.2018.10.006

Acknowledgements

This work was financially supported by Natural Science Foundation of Hunan Province (Grant No. 2018JJ3500), Research Foundation for PhD of Xiangtan University (Grant No. KZ08042) and National Science and Technology Major Project (Grant No. 2016ZX05040-002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, GL., Yu, H., Deng, MH. et al. A colorimetric microfluidic sensor made by a simple instrumental-free prototyping process for sensitive quantitation of copper. Chem. Pap. 73, 1509–1517 (2019). https://doi.org/10.1007/s11696-019-00702-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00702-3