Abstract

Mexican lime (Citrus aurantifolia Swingle) is a widely consumed citrus fruit, but its shelf life is limited. Edible coatings have gained significant interest due to their ability to prolong fruit storage time. The objective of this study is to assess the efficacy of edible coatings derived from wild sage seeds and pomegranate seed oil (PSO) in extending the shelf life of Mexican lime fruit stored at 20 ± 2 °C and 50–60% relative humidity. The study findings suggest that the treatments effectively prevented a decline in fruit weight and titratable acidity. The total phenolic, flavonoid, and total antioxidant activity of the fruit showed a decreasing trend over the 24-day shelf life. However, the coated fruits (excluding PSO) exhibited higher total phenolic content, antioxidant capacity, as well as peroxidase and catalase activity during storage. Except for PSO, the application of edible coatings had a beneficial impact on preserving the a* value, visual quality, and marketability of Mexican lime fruit by reducing the activity of the polyphenol oxidase enzyme. The results suggest that these treatments can be an effective strategy for improving the quality and extending the shelf life of Mexican lime fruit stored at ambient temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mexican lime (Citrus aurantifolia), a commonly known citrus cultivar, holds significant commercial importance and is cultivated worldwide [1]. Citrus fruits are esteemed for their exceptional nutritional content, especially their organic acids and sugars, which serve as primary metabolites and crucial elements contributing to the fruit’s flavor quality. Among citrus fruits, lime stands out as an excellent source of natural bioactive compounds renowned for their health-promoting properties [2]. Despite their remarkable nutritional value, lime fruits are susceptible to significant water loss after harvest, particularly in hot and humid tropical regions. This inherent vulnerability restricts their storage life to a mere 6–9 days [3]. Furthermore, the degradation of chlorophyll in the peel results in a loss of greenness, exacerbating the reduction in the fruit’s shelf life [4].

The application of edible coatings has emerged as a promising approach for extending the shelf life of fruits. Edible coatings are eco-friendly, non-toxic, readily available, cost-effective, user-friendly, and renewable, making them a reliable and trustworthy option for consumers [5]. Edible coatings are thin layers of edible materials that are applied to the surface of food products. One of the main purposes of edible coatings is to act as a barrier, regulating the migration of various substances such as oxygen (O2), carbon dioxide (CO2), flavorings, lipids, moisture, and other dissolved compounds [6]. Previous studies have demonstrated that employing renewable coating materials on fresh citrus fruits is an effective postharvest practice that enhances quality and extends shelf life. This is achieved by improving the fruit’s visual appearance and mitigating postharvest losses [7]. In a study, it was found that the application of Persian gum on oranges helped to maintain their quality and extend their storage life [8]. In the conducted research, edible coatings composed of pea starch and guar gum were utilized to evaluate their effects on the quality, storability, and shelf life of oranges. The study findings revealed that oranges coated with these edible coatings received superior ratings in terms of overall flavor and freshness when compared to uncoated oranges after being stored for a duration of four weeks at a temperature of 5 °C [9].

Wild sage (Salvia macrosiphon Boiss) gum contains a mucilage layer that can be utilized in edible coatings for fruits and vegetables. The seeds of the sage plant serve as the source of this gum, which has been proven effective in creating a semi-permeable barrier to CO2 and O2. As a result, the respiration rate of the fruit decreases, leading to an extension in its shelf life [10, 11].

Incorporating extracts from plants into coatings can enhance the mechanical, sensory and nutritional properties of the initial edible coating materials [12]. Pomegranate seed oil is a valuable nutritional ingredient known for its richness in phytochemicals, including punicic acid and antioxidants. The beneficial properties of extracts are attributed to the presence of phenolic compounds, particularly ortho-diphenols [13]. Studies have demonstrated that the nutritional and medicinal properties of pomegranate seed oil can be harnessed to facilitate the emulsification of edible and biodegradable coatings [14]. Recent studies have revealed that the utilization of pomegranate seed oil can enhance the production of edible biofilms with improved mechanical and barrier properties. These enhancements are attributed to the interactions between polysaccharides and proteins in the coating [15].

Considering recent advances in the application of edible coatings to enhance fruit shelf life, this study aimed to embark on an innovative approach by utilizing wild sage (Salvia macrosiphon Boiss) gum enriched with pomegranate seed oil (PSO) on Mexican lime (Citrus aurantifolia) fruits postharvest. The primary objective was to investigate the impact of these novel coatings on extending the shelf life of the fruits during storage at 20 ± 2 °C. Building on existing scientific discussions that highlight the potential benefits of edible coatings in preserving fruit quality and reducing postharvest losses, we sought to explore the unique combination of wild sage gum and PSO to further optimize the mechanical and barrier properties of the coatings. This research holds the promise of introducing an eco-friendly and effective strategy to revolutionize the postharvest management of Mexican lime fruits, benefiting both producers and consumers alike.

Materials and methods

The Mexican lime (Citrus aurantifolia) fruits were harvested from a commercial garden located in Rodan city, Hormozgan province, at a river section with geographical coordinates of 57° 29′ E and 27° 59′ N. Harvesting was carried out at the mature green stage, with careful attention to technical points to ensure optimal fruit quality. Subsequently, uniform-sized, healthy fruits without any mechanical damage were selected for testing. Prior to testing, the selected fruits underwent a thorough washing and disinfection process. The fruits were immersed in water and treated with 0.05% sodium hypochlorite solution for one minute to effectively disinfect and remove any surface contaminants. By following these stringent procedures during the harvesting and preparation stages, we aimed to obtain high-quality and uncontaminated Mexican lime fruits, ensuring the reliability and accuracy of our research results.

Preparation of coating

Edible coatings based on wild sage were prepared at two different concentrations: 0.1% and 0.2% (dissolve in water). Subsequently, pomegranate seed oil (PSO) was incorporated into each treatment at a concentration of 0.05% (weight/volume). The test treatments included the following groups: a control (distilled water), wild sage seed (WS) at 0.1%, WS at 0.2%, WS 0.1% + PSO, WS 0.2% + PSO, and PSO alone. To apply the coatings, the lime fruits were immersed in their respective treatments at room temperature for 5 min, ensuring even and complete coverage. After the fruit surface was completely dry, the coated fruits were carefully placed in disposable plastic containers and subsequently stored for 24 days at a constant temperature of 20 ± 2 °C and 50–60 relative humidity (RH). Throughout the storage period, we closely monitored and evaluated the desired factors to assess the effectiveness of the different coatings in preserving the quality and extending the shelf life of the Mexican lime fruits.

Physiological loss in weight (PLW)

To assess the physiological weight loss of both coated and uncoated lime fruits, the mass difference method was employed. Lime fruits were carefully weighed on the first and last day of the storage period, utilizing a digital scale (AXIS BTA 210D) with an accuracy of 0.01 g. The reduction in lime mass, expressed as a percentage, was then calculated using the following formula (1) [16]:

where w0 represents the initial mass and w1 represents the final mass.

By quantifying the physiological weight loss, we aimed to gain insights into the efficacy of the edible coatings in mitigating fruit dehydration and prolonging shelf life.

Determination of the total soluble solid (TSS) and titratable acidity (TA)

To determine the total soluble solids (TSS) concentration in the fruit juice, a digital refractometer (DBR 95) was employed, following the methodology proposed by Kumar et al. [17]. The TSS content was expressed as a percentage. For measuring the titratable acidity (TA) content, the samples were titrated with a 0.1 N NaOH solution at pH 8.2. The NaOH solution was slowly added drop by drop to the fruit juice while continuously stirring or swirling the container. The addition of NaOH causes the reaction between the acid present in the sample and the base (NaOH). The acid gradually gets neutralized, resulting in a decrease in acidity. The endpoint of the titration was reached when the pH of solution was 8.2. The results were subsequently expressed as a percentage of citric acid.

By understanding how these key parameters are affected, we aimed to further evaluate the potential of wild sage and pomegranate seed oil-based coatings in preserving the nutritional quality and sensory attributes of Mexican lime fruits.

Determination of the total phenolic content (TPC) and the total flavonoid content (TFC)

To extract the compounds, fruit pulp samples were homogenized with 80% methanol (96%, barad). The homogenized sample was then centrifuged at 4000×g for 10 min at room temperature, and the resulting supernatant was collected for the determination of total phenolic and total flavonoid content, as well as antioxidant activity. The total phenolic content of the methanolic solution was determined using the method developed by Ordonez et al. [18] with slight modifications. For the reaction mixture, 0.3 mL of the methanol extract was combined with 1.2 mL of 7% sodium carbonate solution and 1.5 mL of diluted Folin-Ciocalteu reagent. After 90 min of incubation at room temperature, the absorbance was measured at 750 nm using a spectrophotometer (CECIL-2501, England). A calibration curve was constructed using gallic acid as a standard. The content of phenolics in the extracts was expressed as mg of gallic acid equivalents per gram of fresh weight. For the measurement of total flavonoid content, a modified colorimetric method described by Chang et al. [19] was employed. The methanol extract was mixed with 10% AlCl3 and acetate potassium solution (1 mM). After 30 min of incubation, the absorbance was measured at 415 nm using a UV–vis spectrophotometer. A calibration curve was constructed using quercetin as a standard.

By quantifying the total phenolic and flavonoid content, this analysis provided valuable information about the presence of these bioactive compounds in the fruit pulp, supporting the scientific basis for implementing edible coatings enriched with wild sage and pomegranate seed oil for fruit preservation.

Determination of antioxidant activity

The DPPH (2,2-Diphenyl-1-picrylhydrazyl) radical scavenging activity was assayed using the method described by Bourtoom et al. [20] with some modifications. To conduct this technique, 30 μL of the methanol extract was mixed with 150 μL of a DPPH solution, prepared by dissolving 0.025 g of DPPH in 100 mL of 85% methanol. The resulting mixture was then kept in the dark at room temperature for 40 min. Subsequently, the absorbance of the solution was measured at 517 nm using a UV–VIS spectrophotometer. The percentage of inhibition (In) was calculated using the following equation:

where Ca and Sa represent the control absorbance and sample absorbance, respectively.

Determination of antioxidant enzyme activity

To assess the activity of antioxidant enzymes, we conducted the extraction and assay of polyphenol oxidase (PPO), peroxidase (POD), and catalase (CAT).

For PPO activity determination, a 2.0 mL sample was blended in 20 mL of phosphate buffer containing 1 mM PEG and 4% w/v PVPP while placed in an ice bath. After centrifugation at 6000 rpm for 10 min at 4 °C, the supernatant (crude extract) was collected for the assay. The reaction mixture consisted of 80 μL of 0.5 M catechol and 100 μL of 0.05 mM phosphate buffer at pH 6.5, which was incubated at 35 °C for 5 min. Subsequently, 20 μL of crude extract was added, and the changes in absorbance were monitored at 420 nm [21].

To evaluate POD activity, a modified spectrophotometric method based on Wang et al. [22] was employed. Similarly, a 2.0 g sample was homogenized in 20 mL of phosphate buffer containing 1 mM PEG and 4% w/v PVPP while placed in an ice bath. After centrifugation, the supernatant was collected for the assay. The POD activity assay was performed in a reaction cuvette, comprising 60 μL of 0.05 M guaiacol, 20 μL of the enzyme solution (with the blank group containing sodium phosphate buffer), and 20 μL of 0.05 mM hydrogen peroxide. The absorbance changes of the mixture were measured at 470 nm at 15-s intervals.

For CAT activity evaluation, we employed the method developed by Aebi (1983). The reaction mixture contained 0.2 mL of crude extract and 50 mM sodium phosphate buffer (650 μL) at pH 7.0, along with 150 μL of 20 mM H2O2. The activity of CAT on H2O2 resulted in a reduction in absorbance at 240 nm, which was determined using a spectrophotometer [23].

By examining the activities of these antioxidant enzymes, we aimed to gain insights into the potential impact of wild sage and pomegranate seed oil-based coatings on the fruit’s antioxidant defense system.

Determination of fruit color

The color of both the control and coated lime fruits was quantified using a Chroma meter CR-400 (Konica, Tokyo, Japan) in CIE Lab coordinates (L*, a*, b*). The luminosity (L*; 0 = black, 100 = white), chromaticity (C*), and Hue angle (H°) were assessed to provide a comprehensive evaluation of the fruit’s color characteristics. The L* values indicated the lightness of the fruit’s color, with positive values denoting greater lightness and negative values indicating darkness. The a* values represented the color’s position along the red-green axis, with positive values indicating redness and negative values indicating greenness. On the other hand, the b* values represented the color’s position along the yellow-blue axis, with higher positive readings indicating yellowness and negative readings indicating blueness [24].

By analyzing these color parameters, we aimed to discern any perceptible changes in the appearance of the lime fruits due to the application of wild sage and pomegranate seed oil-based coatings. Understanding the color variations provides valuable insights into the visual quality of the coated fruits during postharvest storage, contributing to our assessment of the overall effectiveness of these innovative coatings in preserving the marketability and consumer appeal of Mexican lime fruits.

Overall visual acceptability (OVA)

To conduct a subjective evaluation of fruit quality, we employed a four-point scoring system. The scoring system allowed us to assess the overall visual acceptability of the lime fruits based on various attributes. A score of four was assigned to fruits of excellent quality, characterized by their freshness, firmness, and glossy peel, without any signs of dehydration, skin shriveling, or discoloration. These fruits were deemed to be in the best condition and highly marketable. Fruits that received a score of three were of good quality, still acceptable for marketing, but exhibiting slight shriveling and softness. Despite these minor imperfections, they remained suitable for consumer purchase. A score of two was given to fruits that were not suitable for sale but still edible. These fruits displayed moderate symptoms of shriveling, loss of green color, dryness, and progression towards browning. Finally, a score of one was assigned to fruits of poor quality, showing severe symptoms of shriveling, darkening of the peel color, and decay. These fruits were deemed unfit for consumption [9].

Statistical analysis

For the factorial experiment in this investigation, a fully completely randomized design (CRD) was employed. The data obtained from the experiment were subjected to a comparative analysis using the LSD (Least Significant Difference) test at a statistical significance level of p < 0.05. This allowed us to determine whether there were any significant differences among the different treatments. The statistical analysis was conducted using SAS software version 9.4, a widely used tool for analyzing experimental data and drawing meaningful conclusions from the results.

Results

Weight loss

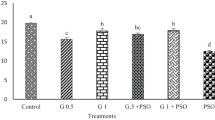

Shown in Fig. 1, the impact of the edible coatings on weight loss was evident. After 24 days of storage at room temperature, the fruits coated with the edible coatings exhibited significantly lower weight loss compared to the control (19.3%) group. Among the different treatments, the fruits treated with PSO demonstrated the lowest percentage (12.5%) of weight loss, and this result was statistically significant when compared to both the control and other coating treatments.

Effect of treatments (control, wild sage seed 0.1%, wild sage seed 0.2%, wild sage seed 0.1% with pomegranate seed oil, wild sage seed 0.2% with pomegranate seed oil, and pomegranate seed oil (0.05%)) on weight loss of Mexican lime fruit stored for 24 days at 20 ± 2 °C and 50–60% RH. The data represent the mean values of n = 3, and the error bars indicate standard errors (SE) of the means. Statistical analysis was performed using the LSD test at the P ≤ 0.05 level

Total soluble solids (TSS) and Titratable acidity (TA)

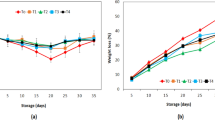

As represented in Fig. 2a, the total soluble solids (TSS) content of the samples demonstrated a progressive increase during the 24-day storage period. Except for the PSO treatment, which did not exhibit a notable distinction from the control group, the remaining treatments demonstrated lower TSS compared to the control. The treatments involving a 0.2% WS and 0.2% WS + PSO produced the minimum TSS values, measuring 6.8% and 6.9% respectively.

Effect of treatments (control, wild sage seed 0.1%, wild sage seed 0.2%, wild sage seed 0.1% with pomegranate seed oil, wild sage seed 0.2% with pomegranate seed oil, and pomegranate seed oil (0.05%)) on a Total Soluble Solids (TSS) and b Titratable Acidity (TA) of Mexican lime fruit stored for 24 days at 20 ± 2 °C and 50–60% RH. The data represent the mean values of n = 3, and the error bars indicate standard errors (SE) of the means. Statistical analysis was performed using the LSD test at the P ≤ 0.05 level

Regarding titratable acidity (TA), our results showed varying patterns among the different treatments. While the fruits treated with 0.1% and 0.2% WS coatings did not exhibit any significant change in TA after 24 days of storage, the other coated fruits demonstrated a significant decrease in acidity compared to the first day of storage. The control group and the PSO treatment displayed the minimum (8.9% and 9.8% respectively) TA levels after the storage period (Fig. 2b).

Total phenolic, flavonoids content and antioxidant capacity

Our investigation revealed significant changes in the total phenolic content of lime fruits during the 24-day storage period at 20 ± 2 °C. All treatments, except PSO, showed a higher phenolic content than the control. Maximum (3.73 mg/g) phenolic content was observed in 0.2% WS, WS (0.2%) + PSO treatments (Fig. 3a).

Effect of treatments (control, wild sage seed 0.1%, wild sage seed 0.2%, wild sage seed 0.1% with pomegranate seed oil, wild sage seed 0.2% with pomegranate seed oil, and pomegranate seed oil (0.05%)) on a Total phenolic, b Antioxidant capacity, and c Flavonoids of Mexican lime fruit stored for 24 days at 20 ± 2 °C and 50–60% RH. The data represent mean values of n = 3, and the error bars indicate standard errors (SE) of the means. Statistical analysis was performed using the LSD test at the P ≤ 0.05 level

Regarding antioxidant capacity, our study demonstrated a significant decrease in the antioxidant capacity of the coated fruits after 24 days of storage at 20 ± 2 °C when compared to the control group (Fig. 3b). The control treatment displayed the lowest level of antioxidants at 69%, and this result differed significantly from the other treatments. However, it is essential to note that despite the decrease, the fruits still retained a considerable level of antioxidant capacity, suggesting that the edible coatings offered some protective effect against oxidative stress during storage.

Furthermore, the flavonoid content of the fruits also exhibited changes during the storage period. At the end of the 24-day storage, the flavonoid levels decreased in all treated fruits (Fig. 3c). However, it is worth mentioning that despite the decrease, the coated fruits (With the exception of PSO) displayed significantly higher flavonoid levels than the control group.

The activity of antioxidant enzymes

The enzymatic activity of polyphenol oxidase (PPO) showed an increase after 24 days of storage at 20 ± 2 °C (Fig. 4a). However, it is noteworthy that the coated fruits, except for the PSO treatment, demonstrated significantly lower PPO enzyme activity compared to the fruits in the control group. The lowest activity of PPO enzyme activity, measuring 59.4 U/mgFW, was observed in the 0.1% WS treatment.

Effect of treatments (control, wild sage seed 0.1%, wild sage seed 0.2%, wild sage seed 0.1% with pomegranate seed oil, wild sage seed 0.2% with pomegranate seed oil, and pomegranate seed oil (0.05%)) on a Polyphenol Oxidase (PPO), b Peroxidase (POD), and c Catalase (CAT) of Mexican lime fruit stored for 24 days at 20 ± 2 °C and 50–60% RH. The data represent mean values of n = 3, and the error bars indicate standard errors (SE) of the means. Statistical analysis was performed using the LSD test at the P ≤ 0.05 level

Regarding peroxidase (POD) enzyme activity, treatments with 0.1% and 0.2% WS and 0.2% WS + PSO displayed a significant increase after 24 days of storage (Fig. 4b). However, treatments with 0.1% WS and PSO did not show any significant difference from the control group and remained relatively constant compared to the first day of storage.

After 24 days of fruit storage, the activities of CAT enzyme in the 0.2% WS, 0.1% WS + PSO, and 0.2% WS + PSO treatments exhibited a significant increase (Fig. 4c). In contrast, the control group displayed a significant decrease in catalase activity compared to the first day and compared to the other coating treatments. The 0.2% WS + PSO treatment (167.4 U/mgFW) exhibited the highest activity of CAT, followed by the 0.2% WS treatment (158 U/mgFW).

Color parameters

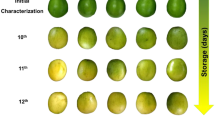

The color parameters of the coated fruits were analyzed to assess their visual quality and changes during the storage period (Fig. 5).

Effect of treatments (control, wild sage seed 0.1%, wild sage seed 0.2%, wild sage seed 0.1% with pomegranate seed oil, wild sage seed 0.2% with pomegranate seed oil, and pomegranate seed oil (0.05%)) on a L*, b a*, c b*, d chroma, e hue, and f CCI of Mexican lime fruit stored for 24 days at 20 ± 2 °C and 50–60% RH. The data represent mean values of n = 3, and the error bars indicate standard errors (SE) of the means. Statistical analysis was performed using the LSD test at the P ≤ 0.05 level

The L* index, representing lightness, displayed an increasing trend in most treatments during storage, indicating the lightening of the fruit’s peel color. Notably, the treatment with 0.1% wild sage seed + PSO showed the highest increase in L* index at 24 days of storage, followed by the treatment with 0.2% wild sage seed + PSO, both of which exhibited a significant difference compared to the control group (Fig. 5a).

The a* index, indicating greenness, gradually increased during storage, reflecting the breakdown of chlorophyll and the reduction of green color in the fruit’s peel. At the end of the storage period, the PSO treatment displayed the highest a* value (4.72), followed by the control group (2.2) (Fig. 5b).

Similarly, the b* index, representing yellowness, increased during the storage period, with the highest b* value observed at the end of storage. The treatments of 0.1% wild sage seed + PSO (29.84) on the 24th day of storage and 0.2% wild sage seed (11.23) on the 12th day of storage recorded the lowest and highest b* values, respectively (Fig. 5c).

The Chroma index (Fig. 5d) demonstrated an increasing trend during storage, with the highest value recorded at the 24th day of storage, particularly in the treatment of 0.1% wild sage seed + PSO, followed by 0.2% wild sage seed + PSO and 0.1% wild sage seed.

Furthermore, the Hue index (Fig. 5e) showed an increasing trend during storage, indicating changes in the dominant wavelength of the fruit’s color.

Lastly, the citrus colour index (CCI) (Fig. 5f) displayed a significant decrease at the end of the storage period compared to the 12th day of storage. The PSO treatment showed the highest CCI, suggesting that the edible coatings, particularly those enriched with PSO, contributed to maintaining the color stability of the fruits over time.

Overall visual acceptability (OVA)

Upon the completion of the 24-day storage period at 20 ± 2 °C, the evaluation of overall visual acceptability (OVA) revealed interesting results. The control group and the PSO treatment showed the lowest OVA scores compared to the other treatments (Fig. 6a). Conversely, the fruits coated with 0.1% and 0.2% WS exhibited the highest OVA scores, signifying superior visual appeal and acceptance among the various treatments. As shown in Fig. 6b, the treated fruits, except for PSO, showed less color changes (browning) than the control. The minimum color change was observed in the 0.1% and 0.2% WS treatment.

Effect of treatments (control, wild sage seed 0.1%, wild sage seed 0.2%, wild sage seed 0.1% with pomegranate seed oil, wild sage seed 0.2% with pomegranate seed oil, and pomegranate seed oil (0.05%)) on overall visual acceptability of Mexican lime fruit stored for 24 days (a). Color changes of Mexican lime fruit under different treatments after 24 days of storage (b) at 20 ± 2 ℃ and 50–60% RH

Discussion

The degree of weight loss is a critical factor in evaluating the quality of lime fruit and its acceptance by consumers [25]. During storage, weight loss occurs due to evapotranspiration caused by increased metabolic activity [26]. To address this issue, postharvest treatments, such as the application of specific coatings, have been explored to modify fruit physiology and reduce respiration and moisture loss. The observed reduction in weight loss in the coated fruits can be attributed to the formation of a protective film by the coatings on the fruit peel, acting as a semipermeable barrier to water transfer and effectively delaying water loss [27]. Several studies have highlighted the efficacy of edible coatings in reducing weight loss and extending the shelf life of fruits. For instance, the use of an edible oil emulsion coating, specifically coconut oil, had a significant impact on reducing the weight loss (reduced by 9.67%) and retaining a high percentage (70%) of marketable kagzi lime fruits [28].

The application of beeswax coatings has been shown to lower the respiration rate of sweet oranges, resulting in decreased weight loss and prolonged shelf life [29]. Additionally, the use of Persian gum in oranges has been reported to effectively prevent weight loss in the fruit [8]. Similarly, the application of cellulose in Kinnow mandarin fruit has demonstrated the ability to maintain fruit weight [30]. These findings corroborate our results, where the coated fruits, especially those treated with wild sage seed and pomegranate seed oil, showed significantly lower weight loss, highlighting the potential of such coatings in preserving the quality and marketability of Mexican lime fruits during storage.

Typically, the total soluble solids (TSS) content of fruits increases during storage, driven by processes such as water loss, changes in polysaccharides and pectin materials, and degradation of starch, leading to the formation of various sugars, mono- and disaccharides [30, 31]. However, the application of edible coatings can significantly delay senescence and starch breakdown, resulting in a slower and lower increase in TSS levels [32]. Studies have shown that the use of bio-wax treatment significantly decreased the levels of variation in total soluble solids, titratable acidity, and juice pH of lime fruit [4]. In line with our findings, a study on oranges (Citrus sinensis L., Osbeck) using an edible chitosan coating demonstrated a preservation of TSS levels during storage [33]. Similarly, previous research has shown that carnauba wax-based coatings can maintain TSS values in various fruits, such as Indian jujube fruits [34], Kinnow mandarin [30] and pomegranates [35]. The natural decrease in acidity observed in some fruits is attributed to the utilization of organic acids as substrates for respiration, leading to their conversion into sugars. In our study, we observed that the treated fruits displayed relatively stable titratable acidity (TA) levels during storage, while the TA in other treated fruits showed a significant decrease compared to the first day. These findings align with a study on guava fruits, where the application of Aloe vera gel as a postharvest treatment effectively retained titratable acidity up to the 8th day of storage [36]. This suggests that the edible coatings may have played a role in preserving the fruit’s acidity, contributing to its sensory attributes and overall quality during postharvest storage. Our study supports the notion that edible coatings can exert a positive influence on the physicochemical attributes of fruits during storage, contributing to the preservation of key parameters such as TSS and TA. By regulating the migration of substances and reducing moisture evaporation, these coatings help maintain the freshness and integrity of the fruit for a longer duration.

Phenolic compounds play a key role in the antioxidant activity of foods, and their significance lies in their ability to respond the effects of free radicals generated during the senescence process. These antioxidant compounds are essential because they effectively minimize the impact of free radicals, which are produced as a natural consequence of the senescence process [37]. Indeed, coatings play a crucial role in the metabolism of phenolic compounds by creating a tailored environment around the fruit. This modified environment acts as a protective shield, effectively limiting the respiration and oxidation rates of phenolic compounds. One of the key mechanisms behind this protective effect is the reduction in the activity of polyphenol oxidase, an enzyme responsible for catalyzing the oxidation of phenolic compounds [38]. The significance of flavonoids as antioxidant compounds has been extensively investigated through various studies, as they play a crucial role in protecting fruits against oxidative damage during the postharvest period [39]. Indeed, the application of coatings to fruits has been shown to effectively delay senescence and preserve a higher concentration of total phenolic compounds, as exemplified in the study on carboxymethyl cellulose + garlic essential oil coated strawberry fruits [40]. The observed enhancement in total phenolic content by edible coatings can be attributed to their unique semi-permeable barrier properties, which effectively regulate the exchange of gases such as CO2 and O2, reduce water loss, and modulate the ripening process by influencing the levels of endogenous gases and ethylene production [41]. The findings of [42] align closely with our results, as they also observed a decline in the total antioxidant activity of strawberries during storage. However, their study revealed that the application of edible coatings to the fruits resulted in the maintenance of higher levels of total antioxidant activity. This protective effect can be attributed to the formation of a thin film by the coatings around the fruit surface, which creates a controlled microenvironment that limits the availability of oxygen required for the enzymatic oxidation of phenolic compounds [43]. Indeed, the findings of Khorram et al. [8] align with our own research, indicating that the application of gelatin coating and shellac on oranges led to improved phenolic content and antioxidant capacity while preserving the fruit’s natural shine [8]. A study was conducted on guava fruit, revealing that coating it with 10% gum Arabic, either alone or in combination with moringa extract, effectively preserved the total antioxidant activity of the fruit [44]. A study was conducted on strawberries to investigate the effects of coating with chitosan nanoparticles and propolis on the antioxidant compounds and antioxidant capacity of the fruit during storage [45]. A study was conducted on Kinnow mandarin fruit to investigate the impact of carboxymethylcellulose (CMC) coating at a concentration of 2.0 g L−1 on various quality attributes during cold storage [46]. The study conducted on raspberries examined the impact of an edible coating made with chitosan nanoparticles on the storage life and phytochemical content of the fruit [47]. Collectively, these studies, along with our own research, emphasize the promising role of edible coatings in preserving phenolic compounds and antioxidant capacity in fruits, offering a sustainable approach to postharvest management, and enhancing the overall quality and nutritional value of fresh horticultural products.

Indeed, several studies have shown the positive effects of edible coatings on preserving the activity of antioxidant enzymes in fruits during storage. Coatings, such as gum Arabic and alginate, create a protective barrier around the fruit, limiting the exposure to external factors that could lead to enzyme degradation [41]. The findings from Li et al.’s study on strawberry fruit further support the positive impact of polysaccharide coatings on antioxidant enzyme activity and fruit preservation. The study focused on three polysaccharide coatings: alginate, chitosan, and pullulan. These coatings demonstrated the ability to enhance the functions of antioxidant enzymes in strawberries, contributing to the protection of the fruit’s cellular integrity [48]. Momin et al.’s research underscores the significant impact of edible coatings on the activity of essential antioxidant enzymes in fruits. Their study focused on enzymes such as catalase, peroxidase, superoxide dismutase, and ascorbate peroxidase, which play vital roles in counteracting oxidative stress and preserving the nutritional value of fruits [5]. The study conducted by Ali et al. [49]on apricot fruit provides further evidence of the positive impact of edible coatings on antioxidant enzyme activities and the nutritional quality of fruits during storage. Their findings revealed that fruit coated with gum Arabic exhibited significantly higher activities of key antioxidant enzymes, including ascorbate peroxidase, catalase, peroxidase, and superoxide dismutase, compared to the control group. Indeed, peroxidase (POD) is a heme-containing enzyme that plays a crucial role in various physiological processes within plants. It is widely distributed throughout plant tissues and is involved in several essential functions [50]. Preserving the function of peroxidase (POD) can help maintain the nutritional quality of the fruit by reducing the breakdown of phenolic compounds and extending the postharvest storage period [51]. Edible coatings have been shown to preserve antioxidative enzyme activity and protects fruit tissues from reactive oxygen species (ROS), thereby extending their postharvest storage potential [52]. A study investigating the use of CMC coating demonstrated that it effectively controlled free radicals and maintained elevated levels of antioxidant enzyme activity in coated fruits. Notably, the CMC coating sustained higher levels of catalase (CAT) and peroxidase (POD) activity, leading to reduced oxidative damage and preservation of overall Kinnow fruit quality [30].

The color of fruit plays a significant role in assessing its quality and marketability, and it can be influenced by various factors, including storage conditions and treatments. Consumers’ acceptance of fruit is often influenced by its color. In citrus fruit, color is determined by three primary classes of natural pigments: chlorophylls, carotenoids, and anthocyanins. Changes in citrus fruit color are attributed to the breakdown of chlorophyll and the accumulation of carotenoid pigments in the flavedo, the outer layer of the fruit’s peel [53]. After harvesting, lime undergoes rapid green color degradation during storage, which diminishes its market value. Various methods have been explored to prevent chlorophyll degradation, and one such method is surface coating [54]. According to color scores and CIE L*, a*, and b* values, the application of Aloe vera gel coating significantly reduced the rate of lime fruit yellowing and extended its shelf life by approximately four days more than the untreated fruit, which had a shelf life of 10 days [55].

In a study on apricot fruit, the application of a gum Arabic coating did not significantly affect the L* and b* values (representing lightness and yellowness, respectively), but it did lead to a significant increase in the a* value (representing redness) compared to the control [49]. Variations in the quantity and composition of carotenoids have been observed in Valencia orange (Citrus sinensis L. Osbeck) and Lisbon lime (Citrus limon Burm) [56]. [57] demonstrated that edible coatings can extend the shelf life and preserve the color of fruits, enhance their visual appeal, reduce shriveling and wilting, maintain their biochemical properties, stabilize texture and color, protect cell membranes, prolong storage life, and inhibit browning [58]. Similar findings to the results of this study indicate that the application of a gelatin coating enhanced the visual appeal of strawberries [59]. Wang et al. [60] reported similar outcomes in Ponkan mandarins, as well as in sweet orange fruit [61].

Overall visual acceptability (OVA) is a crucial measure of the visual appeal of a food product to consumers. It considers factors such as color, texture, and shape, making it a vital consideration for food manufacturers aiming to create products that will be well-received by consumers [62, 63]. In a study on the use of chitosan coatings on strawberries, the coatings were found to maintain the fruit’s color and texture, resulting in a higher OVA compared to uncoated strawberries [64]. Similarly, a study on persimmon fruits revealed that samples coated with tragacanth gum exhibited better taste, aroma, and firmness during storage compared to uncoated fruits [65]. These findings highlight the significant impact that edible coatings can have on the overall visual acceptability of fruits, thereby enhancing consumer satisfaction and marketability.

Conclusion

In summary, the use of edible coatings derived from wild sage seeds, either on their own or enriched with pomegranate seed oil, demonstrated significant effectiveness in preserving lime fruits. The results of this study demonstrate that treating fruits with pomegranate seed oil significantly reduces weight loss during storage. However, it is important to note that this treatment led to an increase in peel browning, which negatively impacted the overall visual acceptability (OVA) of the fruits. In contrast, the use of wild sage seed, either alone or in combination with pomegranate seed oil, resulted in a notable decrease in the activity of the polyphenol oxidase (PPO) enzyme. Moreover, these treatments effectively enhanced the activity of peroxidase (POD) and catalase enzymes in the lime fruits. These findings suggest that the incorporation of wild sage seed, either as a standalone coating or in conjunction with pomegranate seed oil, can be a promising approach to enhance the quality and extend the shelf life of lime fruits. Overall, this study highlights the potential of edible coatings, particularly those derived from wild sage seed and supplemented with pomegranate seed oil, as a valuable postharvest technique for lime fruits. The preservation of enzymatic activities and the reduction in weight loss contribute to the improved shelf life and overall visual acceptability of the fruits, offering promising prospects for the fruit industry. Further research in this area is warranted to explore additional coating combinations and optimize their application to maximize the preservation and quality enhancement of various fruits during storage.

Data Availability

Authors confirm that all data supporting the findings of the study are included in the manuscript. Raw data that support the findings of the current study are available from the corresponding author on reasonable request.

References

M. Ladaniya, R. Marathe, A. Das, C. Rao, A. Huchche, P. Shirgure, A. Murkute, High density planting studies in acid lime (Citrus aurantifolia Swingle). Sci. Hortic. 261, 108935 (2020)

S. Suri, A. Singh, P.K. Nema, Current applications of citrus fruit processing waste: a scientific outlook. Appl. Food Res. (2022). https://doi.org/10.1016/j.afres.2022.100050

S. Samaradiwakara, W. Champa, J. Eeswara, Harvest maturity affects postharvest quality of lime fruits (Citrus aurantifolia Swingle). Tropical Agricultural Research 30, 125–131 (2019)

W. Champa, N. Gunasekera, W.S. Wilson, I. Hewajulige, W. Weerasinghe, B. Kumara, Postharvest treatment of cinnamon (Cinnamomum zeylanicum) bark oil and hexanal incorporated bio-wax maintains quality and extends marketable life of lime (Citrus aurantifolia Swingle). Intern. J. Fruit Sci. 20, 76–88 (2020)

M.C. Momin, A.R. Jamir, N. Ankalagi, T. Henny, O.B. Devi, Edible coatings in fruits and vegetables: a brief review. Pharma Innov. J 10, 71–78 (2021)

A.E. Quirós-Sauceda, J.F. Ayala-Zavala, G.I. Olivas, G.A. González-Aguilar, Edible coatings as encapsulating matrices for bioactive compounds: a review. J. Food Sci. Technol. 51, 1674–1685 (2014)

M. Miranda, X. Sun, C. Ference, A. Plotto, J. Bai, D. Wood, O.B.G. Assis, M.D. Ferreira, E. Baldwin, Nano-and micro-carnauba wax emulsions versus shellac protective coatings on postharvest citrus quality. J. Am. Soc. Hortic. Sci. 146, 40–49 (2021)

F. Khorram, A. Ramezanian, S.M.H. Hosseini, Shellac, gelatin and Persian gum as alternative coating for orange fruit. Sci. Hortic. 225, 22–28 (2017)

B. Saberi, J.B. Golding, J.R. Marques, P. Pristijono, S. Chockchaisawasdee, C.J. Scarlett, C.E. Stathopoulos, Application of biocomposite edible coatings based on pea starch and guar gum on quality, storability and shelf life of ‘Valencia’oranges. Postharvest Biol. Technol. 137, 9–20 (2018)

F. Salehi, Rheological and physical properties and quality of the new formulation of apple cake with wild sage seed gum (Salvia macrosiphon). J. Food Meas. Charact. 11, 2006–2012 (2017)

S. Abdi, D. Bakhshi, A.M. Nikoo, E. Fallahi, Shelf life quality changes of´ Camarosa´ strawberry fruit in response to Persian and wild sage gums application. Agric. Conspec. Sci. 88, 115–125 (2023)

H. Arnon-Rips, E. Poverenov, Improving food products’ quality and storability by using Layer by Layer edible coatings. Trends Food Sci. Technol. 75, 81–92 (2018)

Y. Soleimanian, S.A.H. Goli, J. Varshosaz, F. Maestrelli, Propolis wax nanostructured lipid carrier for delivery of β sitosterol: effect of formulation variables on physicochemical properties. Food Chem. 260, 97–105 (2018)

E. Sogut, A.I. Balqis, Z.N. Hanani, A.C. Seydim, The properties of κ-carrageenan and whey protein isolate blended films containing pomegranate seed oil. Polym. Testing 77, 105886 (2019)

A.E.M. de Medeiros Teodosio, B.G.F.L. Santos, J.A. Linné, J.M.F. de Lima Cruz, E.A. Onias, J.F. de Lima, R.H.C.R. Araújo, Preservation of Spondias tuberosa fruit with edible coatings based on Chlorella sp. enriched with pomegranate seed oil during storage. Food Bioprocess Technol. 14, 2020–2031 (2021)

F. Dong, X. Wang, Guar gum and ginseng extract coatings maintain the quality of sweet cherry. LWT 89, 117–122 (2018)

N. Kumar, A. Ojha, A. Upadhyay, R. Singh, S. Kumar, Effect of active chitosan-pullulan composite edible coating enrich with pomegranate peel extract on the storage quality of green bell pepper. LWT 138, 110435 (2021)

A. Ordonez, J. Gomez, M. Vattuone, Antioxidant activities of Sechium edule (Jacq.) Swartz extracts. Food Chem. 97, 452–458 (2006)

C.-C. Chang, M.-H. Yang, H.-M. Wen, J.-C. Chern, Estimation of total flavonoid content in propolis by two complementary colorimetric methods. J. food Drug Analysis (2002). https://doi.org/10.38212/2224-6614.2748

T. Bourtoom, M.S. Chinnan, Preparation and properties of rice starch–chitosan blend biodegradable film. LWT-Food Sci. Technol. 41, 1633–1641 (2008)

MdlD. Serradell, P.A. Rozenfeld, G.A. Martínez, P.M. Civello, A.R. Chaves, M.C. Añón, Polyphenoloxidase activity from strawberry fruit (Fragaria ananassa, Duch., cv Selva): Characterisation and partial purification. J. Sci. Food Agric. 80, 1421–1427 (2000)

B. Wang, J. Zhou, T. Koschny, M. Kafesaki, C.M. Soukoulis, Chiral metamaterials: simulations and experiments. J. Opt. A: Pure Appl. Opt. 11, 114003 (2009)

U. Aebi, W.E. Fowler, P. Rew, T.-T. Sun, The fibrillar substructure of keratin filaments unraveled. J. Cell Biol. 97, 1131–1143 (1983)

O.A. Fawole, S.C. Riva, U.L. Opara, Efficacy of edible coatings in alleviating shrivel and maintaining quality of Japanese plum (Prunus salicina Lindl.) during export and shelf life conditions. Agronomy 10, 1023 (2020)

V. Serna-Escolano, D. Martínez-Romero, M.J. Giménez, M. Serrano, S. García-Martínez, D. Valero, J.M. Valverde, P.J. Zapata, Enhancing antioxidant systems by preharvest treatments with methyl jasmonate and salicylic acid leads to maintain lemon quality during cold storage. Food Chem. 338, 128044 (2021)

L. Liao, S. Li, Y. Li, Z. Huang, J. Li, B. Xiong, M. Zhang, G. Sun, Z. Wang, Pre-or post-harvest treatment with MeJA improves post-harvest storage of lemon fruit by stimulating the antioxidant system and alleviating chilling injury. Plants 11, 2840 (2022)

M. Rasouli, M.K. Saba, A. Ramezanian, Inhibitory effect of salicylic acid and Aloe vera gel edible coating on microbial load and chilling injury of orange fruit. Sci. Hortic. 247, 27–34 (2019)

A. Bisen, S.K. Pandey, N. Patel, Effect of skin coatings on prolonging shelf life of Kagzi lime fruits (Citrus aurantifolia Swingle). J. Food Sci. Technol. 49, 753–759 (2012)

M.N. Shahid, N. Abbasi, Effect of bee wax coatings on physiological changes in fruits of sweet orange CV.“blood red.” Sarhad J. Agric. 27, 385–394 (2011)

S. Ali, M.A. Anjum, S. Ejaz, S. Hussain, S. Ercisli, M.S. Saleem, H. Sardar, Carboxymethyl cellulose coating delays chilling injury development and maintains eating quality of ‘Kinnow’mandarin fruits during low temperature storage. Int. J. Biol. Macromol. 168, 77–85 (2021)

A. Hossain, M. Karim, S.A. Juthee, Postharvest physiological and biochemical alterations in fruits: a review. Fundam Appl. Agric. 5, 453–469 (2020)

G. Khaliq, M.T.M. Mohamed, A. Ali, P. Ding, H.M. Ghazali, Effect of gum arabic coating combined with calcium chloride on physico-chemical and qualitative properties of mango (Mangifera indica L.) fruit during low temperature storage. Scientia Horticulturae 190, 187–194 (2015)

D. Xu, H. Qin, D. Ren, Prolonged preservation of tangerine fruits using chitosan/montmorillonite composite coating. Postharvest Biol. Technol. 143, 50–57 (2018)

H. Chen, Z. Sun, H. Yang, Effect of carnauba wax-based coating containing glycerol monolaurate on the quality maintenance and shelf-life of Indian jujube (Zizyphus mauritiana Lamk.) fruit during storage. Scientia Horticulturae 244, 157–164 (2019)

H. Meighani, M. Ghasemnezhad, D. Bakhshi, Effect of different coatings on post-harvest quality and bioactive compounds of pomegranate (Punica granatum L.) fruits. J. Food Sci. Technol. 52, 4507–4514 (2015)

M.C. Momin, A.R. Jamir, N. Ankalagi, A comparative study of different edible coatings on physico-chemical properties of guava (Psidium guajava L.) cv. Khaza during storage. J. Pharmacogn. Phytochem. 8, 2023–2026 (2019)

A.D. Asencio, M. Serrano, S. García-Martínez, M.T. Pretel, Organic acids, sugars, antioxidant activity, sensorial and other fruit characteristics of nine traditional Spanish Citrus fruits. Eur. Food Res. Technol. 244, 1497–1508 (2018)

B. Hassan, S.A.S. Chatha, A.I. Hussain, K.M. Zia, N. Akhtar, Recent advances on polysaccharides, lipids and protein based edible films and coatings: a review. Int. J. Biol. Macromol. 109, 1095–1107 (2018)

A. Esteban-Muñoz, S. Sánchez-Hernández, C. Samaniego-Sánchez, R. Giménez-Martínez, M. Olalla-Herrera, Differences in the phenolic profile by uplc coupled to high resolution mass spectrometry and antioxidant capacity of two diospyros kaki varieties. Antioxidants 10, 31 (2020)

F. Dong, X. Wang, Effects of carboxymethyl cellulose incorporated with garlic essential oil composite coatings for improving quality of strawberries. Int. J. Biol. Macromol. 104, 821–826 (2017)

S.M. Wani, A. Gull, T. Ahad, A. Malik, T.A. Ganaie, F.A. Masoodi, A. Gani, Effect of gum Arabic, xanthan and carrageenan coatings containing antimicrobial agent on postharvest quality of strawberry: assessing the physicochemical, enzyme activity and bioactive properties. Int. J. Biol. Macromol. 183, 2100–2108 (2021)

M.S. Saleem, M.A. Anjum, S. Naz, S. Ali, S. Hussain, M. Azam, H. Sardar, G. Khaliq, İ Canan, S. Ejaz, Incorporation of ascorbic acid in chitosan-based edible coating improves postharvest quality and storability of strawberry fruits. Int. J. Biol. Macromol. 189, 160–169 (2021)

G. Khaliq, M.T.M. Mohamed, H.M. Ghazali, P. Ding, A. Ali, Influence of gum Arabic coating enriched with calcium chloride on physiological, biochemical and quality responses of mango (Mangifera indica L.) fruit stored under low temperature stress. Postharvest Biol. Technol. 111, 362–369 (2016)

S.F. El-Gioushy, M.F. Abdelkader, M.H. Mahmoud, H.M. Abou El Ghit, M. Fikry, A.M. Bahloul, A.R. Morsy, A.M. Abdelaziz, H.A. Alhaithloul, D.M. Hikal, The effects of a gum Arabic-based edible coating on guava fruit characteristics during storage. Coatings 12, 90 (2022)

Md.C. Martínez-González, S. Bautista-Baños, Z.N. Correa-Pacheco, M.L. Corona-Rangel, R.I. Ventura-Aguilar, J.C. Del Río-García, Md.L. Ramos-García, Effect of nanostructured chitosan/propolis coatings on the quality and antioxidant capacity of strawberries during storage. Coatings 10, 90 (2020)

A.K. Baswal, H.S. Dhaliwal, Z. Singh, B.V.C. Mahajan, A. Kalia, Edible coatings maintain the phytochemicals in cold-stored’Kinnow’mandarin (‘Citrus nobilis’ Lour x’C. deliciosa’Tenora) fruit. Aust. J. Crop Sci. 15, 1332–1338 (2021)

S.R. Ishkeh, H. Shirzad, M. Asghari, A. Alirezalu, M. Pateiro, J.M. Lorenzo, Effect of chitosan nanoemulsion on enhancing the phytochemical contents, health-promoting components, and shelf life of raspberry (Rubus sanctus Schreber). Appl. Sci. 11, 2224 (2021)

L. Li, J. Sun, H. Gao, Y. Shen, C. Li, P. Yi, X. He, D. Ling, J. Sheng, J. Li, Effects of polysaccharide-based edible coatings on quality and antioxidant enzyme system of strawberry during cold storage. Int. J. Polym. Sci. 2017, 1–8 (2017)

S. Ali, M. Akbar Anjum, A. Nawaz, S. Naz, S. Ejaz, M. ShahzadSaleem, S. Tul-AinHaider, M. Ul Hasan, Effect of gum Arabic coating on antioxidative enzyme activities and quality of apricot (Prunus armeniaca L.) fruit during ambient storage. J. Food Biochem. 45, e13656 (2021)

J.K. de Medeiros, J.R. Sarkis, D.P. Jaeschke, G.D. Mercali, Thermosonication for peroxidase inactivation in sugarcane juice. LWT 140, 110730 (2021)

H. Zheng, W. Liu, S. Liu, C. Liu, L. Zheng, Effects of melatonin treatment on the enzymatic browning and nutritional quality of fresh-cut pear fruit. Food Chem. 299, 125116 (2019)

M.S. Nair, A. Saxena, C. Kaur, Effect of chitosan and alginate based coatings enriched with pomegranate peel extract to extend the postharvest quality of guava (Psidium guajava L.). Food Chem. 240, 245–252 (2018)

J. Gross, Pigments in vegetables: chlorophylls and carotenoids (Springer Science & Business Media, Berlin, 2012)

A.S. Khan, Z.S. Zora Singh, Harvesting and post-harvest management, The lime: botany, production and uses (CABI, Wallingford, 2017), pp.186–204

O. Pimsorn, S. Kramchote, P. Suwor, Effects of Aloe vera gel coating on quality and shelf life of lime (Citrus aurantifolia) fruit during ambient storage. Hortic. J. 91, 416–423 (2022)

M. Kato, Y. Ikoma, H. Matsumoto, M. Sugiura, H. Hyodo, M. Yano, Accumulation of carotenoids and expression of carotenoid biosynthetic genes during maturation in citrus fruit. Plant Physiol. 134, 824–837 (2004)

D. Valero, H.M. Díaz-Mula, P.J. Zapata, F. Guillén, D. Martínez-Romero, S. Castillo, M. Serrano, Effects of alginate edible coating on preserving fruit quality in four plum cultivars during postharvest storage. Postharvest Biol. Technol. 77, 1–6 (2013)

Z. Deng, J. Jung, J. Simonsen, Y. Zhao, Cellulose nanomaterials emulsion coatings for controlling physiological activity, modifying surface morphology, and enhancing storability of postharvest bananas (Musa acuminate). Food Chem. 232, 359–368 (2017)

M. Aitboulahsen, S. Zantar, A. Laglaoui, H. Chairi, A. Arakrak, M. Bakkali, M. Hassani Zerrouk, Gelatin-based edible coating combined with Mentha pulegium essential oil as bioactive packaging for strawberries. J. Food Qual. (2018). https://doi.org/10.1155/2018/8408915

X. Wang, W. Yin, J. Wu, L. Chai, H. Yi, Effects of exogenous abscisic acid on the expression of citrus fruit ripening-related genes and fruit ripening. Sci. Hortic. 201, 175–183 (2016)

M. Rehman, Z. Singh, T. Khurshid, Methyl jasmonate alleviates chilling injury and regulates fruit quality in ‘Midknight’Valencia orange. Postharvest Biol. Technol. 141, 58–62 (2018)

D.V. Byrne, Consumer preference and acceptance of food products (MDPI-Multidisciplinary Digital Publishing Institute, Basel, 2020)

P.K. Raghav, N. Agarwal, M. Saini, Edible coating of fruits and vegetables: a review. Education 1, 188–204 (2016)

N.F.C.B. Melo, M.M.E. Pintado, J.A. da Costa Medeiros, A. Galembeck, M.A. da Silva Vasconcelos, V.L. Xavier, M.A.B. de Lima, T.L.M. Stamford, T.M. Stamford-Arnaud, M.A.P. Flores, Quality of postharvest strawberries: comparative effect of fungal chitosan gel, nanoparticles and gel enriched with edible nanoparticles coatings. Intern. J. Food Stud. (2020). https://doi.org/10.7455/ijfs/9.2.2020.a9

M.N. Mashabela, K.M. Selahle, P. Soundy, K.M. Crosby, D. Sivakumar, Bioactive compounds and fruit quality of green sweet pepper grown under different colored shade netting during postharvest storage. J. Food Sci. 80, H2612–H2618 (2015)

Acknowledgements

The authors express their gratitude for the financial and technical assistance provided by University of Hormozgan, Iran, in facilitating this research project.

Author information

Authors and Affiliations

Contributions

MM: Writing—original draft, Methodology, Investigation, Formal analysis, Data curation. SR: Review & editing, Validation, Methodology, Investigation, Project administration, Supervision. AR: Editing, Conceptualization, Validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammadi, M., Rastegar, S. & Rohani, A. Enhancing shelf-life and quality of Mexican lime (Citrus aurantifolia cv.) fruit: utilizing edible coating from wild sage seeds enriched with pomegranate seed oils. Food Measure 18, 331–344 (2024). https://doi.org/10.1007/s11694-023-02176-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-02176-0