Abstract

Although cereal brans are gripping the functional food market due to their health promoting components, minor millet brans obtained as a prime by-product of millet processing remain underutilized and understudied. Bran has a short shelf life and requires stabilization before its industrial application. Hence, the present study was conducted to stabilize selected minor millet brans viz. kodo, proso, barnyard and foxtail coupled with estimation of their functional, nutritional, antioxidant and phytonutrient profile. It was evident that stabilization significantly controlled the rise in FFA (free fatty acid) and moisture during 15 days storage, with microwave heating (900 W at 2.5 min) effectively maintaining FFA within permissible limits. Stabilized bran exhibited good water (197.76–265.47 ml/100 g) and oil (162.62–258.18 g/100 g) absorption capacity. Protein, fat, ash, and dietary fibre (DF) content of selected brans ranged from 5.68 to 13.04%, 5.28 to 9.87%, 6.90 to 12.15% and 34.39 to 61.52%, respectively. Amongst all, kodo bran had significantly higher DF (61.52%), total phenols (449.27 mg GAE/100 g), flavonoids (22.37 µg RE/g) and phytic acid (630 mg/100 g), accounting for its highest antioxidant capacity. Mineral composition of brans suggested that foxtail millet was high in iron (65.58 mg/100 g) and calcium (94.63 mg/100 g), while proso millet in zinc (5.59 mg/100 g) and potassium (630.83 mg/100 g). However, sodium (18.08 mg/100 g) content was highest in barnyard bran. Thus, the present study highlights potent application of selected brans as a promising functional ingredient in food formulations and processing industry, especially where fiber rich nutri-dense products are desired and the isolated compounds can be used in nutraceutical industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Debranning, dehulling, decortication, polishing and milling of cereal grains is primarily carried out to improve edibility, sensory parameters and shelf life. However, it also generates by-product viz. bran—a hard outer layer usually discarded as processing waste or used as animal feed [1, 2]. Several authors have reported a reduction in nutrients, fiber, phytonutrients and antioxidant capacity of whole grains after bran removal, suggesting that bran, bran rich fractions (aleurone layer, testa and pericarp) are concentrated source of nutrients [1, 3, 4]. Moreover, studies have established that health benefits upon consumption of whole-grain are also associated with its bran component, playing a protective role and assisting in risk reduction of various physiological, non-communicable disorders such as obesity, hypercholesterolemia, hypertension, hyperglycaemia etc. [5, 6]. A sedentary lifestyle coupled with changed dietary habits, snacking patterns and increased consumption of processed foods has escalated the incidences of these non-communicable disorders [7]. Owing to this, consumers have become more vigilant about nutrition and are demanding nutrient rich food products. Understanding these demands, scientists and food industries are developing designer products with functional and nutraceutical properties. Several researchers are trying to harness brans as functional ingredients and have worked on value addition of rice, wheat and oat bran in bakery items, breakfast cereals, chapati, extruded snacks, pasta, etc. [6, 8]. Therefore, consumption of cereal bran enriched products has witnessed a drastic increase in the past few decades globally, especially as bran oil, high fiber bakery products, breakfast cereals, cereal bars, etc. Rice bran oil (RBO) is the most popular product from rice bran, and its global market has reached 1.58 million tonnes in 2020 [9]. One of the main producers of rice bran oil is India, with a larger section of Indian population consuming it as ‘healthy oil’ [10]. Wheat bran utilization across the globe has also increased in the past decade, with incorporations under section ‘bakery and cereals’ (including breakfast cereals, bread, buns and muesli bars) contributing approximately 60% of market share [5]. Thus, much attention and abundant research is available on the utilization and nutritional profiling of these major cereal brans while minor millet brans remain under-explored, and underutilized, with limited studies available [11].

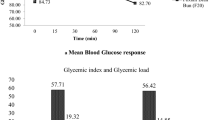

Millets are recently gaining importance due to their nutritional composition, ability to survive even under harsh conditions and are labelled as climate resilient crops. Millets’ nutraceutical benefits are due to their mineral, antioxidant, phytonutrients, phenolic compounds [4, 12] and higher dietary fiber content, which may contribute to their hypoglycaemic effect. For the same reason, millets are designated as ‘nutri-cereals’. Despite these benefits, presently, millets are underutilized, especially minor millets viz., Kodo millet (Paspalum scrobiculatum), Proso millet (Panicum miliaceum), Barnyard millet (Echinochloa esculenta) and Foxtail millet (Setaria italica). One main reason for underutilization of millets is primary processing being cumbersome owing to their small size and limited availability of high-end efficient dehullers. This also accounts to the abundant production of bran and bran rich fractions as a considerable portion of seeds is lost during processing [3]. However, now-a-days millet production and consumption are increasing in view of their nutrient potential. Thus, paving way in generation of ample amount of millet bran during their processing. Presently millet brans are discarded or used as animal feed, however, due to their nutritional and phytochemical profile, they can be used as a promising functional ingredient to improve the nutrient content of empty calorie products [13,14,15,16]. Also, millet bran extracts, as therapeutic agents can be availed in nutraceutical industries manufacturing products bearing hypoglycaemic, hypocholesterolaemia and anti-cancer properties [12, 17,18,19,20,21].

Although brans are nutritious, their short shelf life is an important constraint towards their application in food industries. They cannot be stored for a longer duration without stabilization because of their fat content, lipase activity, hydrolysis of triglycerides and release of free fatty acids (FFA), developing rancid off-flavour, making them unfit for human consumption. Stabilization, immediately after obtaining bran, helps to prevent deterioration, improve shelf life, ensure quality and feasibility for its further use [10, 22]. Many researchers have reported using various treatments to stabilize cereal bran such as hot air oven heating, microwave heating, ohmic heating, autoclaving, parboiling, and enzymatic treatments [23,24,25]. However, limited studies are available to stabilize minor millet brans and its application in the food processing industry. Knowing the phytochemical constituents and pharmacological profile of bran is expected to give insight to their potential application in promotion of health. Thus, against this background, the present investigation aimed at stabilizing minor millet brans, assessing their chemical composition and probing their usage as functional ingredients in the commercial market.

Material and methods

Market samples of minor millets were dehulled and studied for their dehulling parameters to obtain necessary information and estimate the amount of bran (%) generated during such primary processes. Following bran collection, stabilization studies were carried out immediately to select the best suitable treatment based on stability. The stabilized brans were analyzed for functional properties, nutrients, antioxidant activity and phytonutrients.

Sample procurement

Commercially available market samples of four minor millets viz, Kodo (Paspalum scrobiculatum), Proso (Panicum miliaceum), Foxtail (Setaria italica) and Barnyard (Echinochloa esculenta) millets were purchased from a local vendor, cleaned and stored properly in a dry place until further use at Millet Processing and Incubation Centre (MPIC), Professor Jayashankar Telangana State Agricultural University, Rajendranagar, Hyderabad.

Dehulling characteristics, bran extraction and grain dimensions

Millets were dehulled using a stone abrasive mini dehuller (Gurunanak Engineering, Hyderabad) for 30 min (foxtail, proso and barnyard) and 35 min (kodo). After dehulling, the grain and bran fractions (true bran + broken grain + husk) were separated using an air separator. Bran samples were finely ground, sieved using 60 mesh sieve and stored in an airtight container at − 20 °C until further use. Average values of 10 readings were reported for per cent bran recovery, dehulling percentage and degree of dehulling as per the methods described by Gautam et al. [26] and Sreerama et al. [27] with modifications.

The percentage of recovered bran was calculated using the following formula:

Dehulling % was calculated as follows:

Degree of dehulling was calculated using the following formula:

Grain dimensions such as length, width and perimeter were measured for both whole (before dehulling) and dehulled grain (after dehulling) using a digital image capture method with slight modifications [28]. Grain samples were observed under a stereo zoom microscope (Make: Lawrence and Mayo, attached to the computer with the TC capture software) at 1 × magnification and high-resolution images were captured. Further, they were measured using a set scale for 1 × magnification from the calibration table. Average of 10-grain measurement was reported for grain dimensions.

Stabilization of bran

Millet brans were stabilized using microwave and hot air oven heating at different levels. The treatments were HT1: hot air oven heating at 100 ºC for 3 h [8], HT2: hot air oven heating at 130 ºC for 20 min, microwave oven heating at 900 W for 1.5 min (MW1) and 2.5 min (MW2) [23]. Millet bran without any stabilization treatment served as a control (CT). The treated brans were placed in polythene bags, sealed and stored under ambient condition at room temperature for 15 days. The samples were analyzed at 0, 7th and 15th day intervals for free fatty acid (FFA) [29] and moisture [30] content using standard protocols to select the best stabilization treatment for further study.

Functional properties of bran

Best stabilized bran from each grain was analyzed for water absorption and oil absorption properties as described by Sairam et al. [31]. Foaming capacity of the bran was estimated as described by Chandra et al. [32] with slight modification. Briefly, the sample was weighed accurately (1 g) and transferred into a graduated cylinder, to which 50 ml distilled water (V1) was added. This mixture was shaken and then homogenized for 5 min to foam. The volume of foam at 30 s was noted (V2), and foaming capacity was calculated using the following formula:

where V1 = volume before whipping and V2 = volume after whipping.

Proximate and mineral analysis

Proximate content of best stabilized brans was analyzed using standard protocols. Moisture was estimated by drying 5 g of bran sample 130 ± 3 °C for 2 h in a hot air oven, cooled, weighed and expressed in g/100 g of sample [30]. Kjeldahl method [29] was followed to estimate crude protein and the final value was calculated by multiplying with a factor N × 6.25 and expressed as g/100 g. Soxhlet method [33] was employed to estimate fat content. Total dietary fiber (TDF) was determined using standard protocol [29] based on enzymatic and gravimetric methods. The samples (moisture and fat free) were weighed accurately, subjected to gelatinization with heat stable α-amylase and then digested with protease followed by amyloglucosidase to remove starch and protein content in the samples. Further, the samples were treated with ethanol for precipitation of soluble dietary fiber; residue was then filtered, washed with ethanol and acetone, followed by drying. Half of the samples were then analyzed for protein and other half for ash. TDF was calculated as weight of residue minus the weight of protein and ash. Total ash was estimated using standard protocol [30]. Total and available carbohydrate content was calculated ‘by difference’ method. Energy was calculated using the following formula:

For mineral estimation, moisture-free bran samples were wet digested in a microwave digester using nitric acid. Iron, calcium and zinc contents were determined using Atomic Absorption Spectrophotometry, while sodium and potassium were estimated using Flame Photometry [34].

Antioxidant activity and phytonutrients

Phytonutrients (Total phenol, Flavonoids and Phytic acid) and antioxidant activity (DPPH, FRAP and TBARS) were estimated for the stabilized bran samples.

Sample extraction

Millet bran samples were accurately weighed (0.5 g) in a conical flask, to which 15 ml of 80% acidified methanol (pH 2.0) was added. The mixture was extracted by continuous shaking (155 rpm) at room temperature for 30 min, and the supernatant was collected. The residue was re-extracted twice, and all three collected supernatants were centrifuged at 6000 rpm for 15 min and filtered using Whatman No. 1 filter paper. Volume of the extract was noted and made to 50 ml using solvent. The extracts were transferred to centrifuge tubes and stored at − 20 °C until further use. This extract was used to determine total phenol (TP), flavonoids, 1,1-diphenyl-2-picrylhydrazyl (DPPH) and Ferric reducing antioxidant power (FRAP) activity.

Estimation of total phenol (TP)

The Folin–Ciocalteu (FC) method [35] was used with slight modification for the estimation of total phenol content. Briefly; 0.1 ml aliquot was taken in a test tube, and 0.5 ml of FC reagent, diluted with distilled water (1:1, v/v) was added, followed by 10 ml of (7.5%) sodium carbonate. This solution was incubated at 37 °C for 60 min, and absorbance was measured at 765 nm using UV spectrophotometer (Model: UV-1800, Shimadzu, Japan). Gallic acid standard curve (5 µg–35 µg) was prepared and TP content was determined from standard curve (y = 0.0113x + 0.0148; R2 = 0.992). Further it was expressed as mg gallic acid equivalent (GAE)/100 g of the millet bran.

Estimation of flavonoids

The protocol described by Zhishen et al. [36] was used to determine flavonoid content with slight modification. In a 10 ml volumetric flask a known amount of sample extract was taken (0.2 ml) and distilled water was added (4.8 ml) to make 5 ml. Further, 0.3 ml 5% NaNO2 was added, and 5 min later 0.6 ml of AlCl3 was added. The samples were mixed thoroughly using vortex mixture and after 10 min, 2 ml of 1 N NaOH was added followed by addition of distilled water (2.1 ml) to make final volume 10 ml. The solution was mixed properly and read at 510 nm using UV spectrophotometer (Model: UV-1800, Shimadzu, Japan). Rutin was used to prepare the standard curve. Flavonoid content was calculated from the standard curve (y = 0.0045x − 0.0226, R2 = 0.995) and expressed as µg Ruitn equivalent (RE) /g of the millet bran where ‘y’ is absorbance and ‘x’ is flavonoid content. Distilled water was treated the same as sample and used as a blank.

Estimation of phytic acid

Estimation of phytic acid for all brans was conducted as described by Sadashivam and Manickam [35].

DPPH radical scavenging activity

Standard procedure as described by Blois [37] was followed with slight modification. Briefly; 0.1 ml aliquot of methanolic extract (as described in 2.6.1) was pipetted in a test tube, to which 3 ml of 1 Mm methanolic solution of DPPH was added and incubated in the dark at 37 °C for 20 min. Absorbance was measured at 517 nm by using a spectrophotometer (Model: UV-1800, Shimadzu, Japan) and expressed as percentage DPPH scavenging activity relative to control. Methanol (1 ml) as control and Trolox to obtain standard curve (Conc. 1 µg-5 µg, y = -0.1297x + 0.6667; R2 = 0.9941) were treated the same as sample.

Ferric reducing antioxidant power (FRAP)

Protocol described by Benzie and Strain [38] was followed with slight modification. Sample extract/standards were mixed with 3 ml distilled water and 1.8 ml FRAP reagent prepared by mixing acetate buffer, 2,4,6-tripyridyl-S-triaizine (TPTZ) and FeCl3 in 10:1:1 proportion. This mixture was incubated for 4 min at 37 °C and samples were read at 593 nm (Model: UV-1800, Shimadzu Japan). FRAP reagent (1.8 ml) and distilled water (3 ml) was used as blank. Standard curve (y = 0.8493x + 0.0079; R2 = 0.986) was obtained using Trolox. The final value was calculated using the following formula and expressed as µM/g.

Estimation of thiobarbituric acid reactive substances (TBARS)

TBARS was estimated using standard protocol as described by Zeb and Ullah [39] with slight modification. Sample was weighed accurately (1 g), to which 5 ml of 100% glacial acetic acid was added and the mixture was agitated continuously for 1 h followed by filtration with Whatman No1 filter paper. An aliquot (2 ml) of the extracted sample was mixed with 2 ml TBA (thiobarbituric acid) reagent. This was then incubated in a boiling water bath (95 °C) for 60 min. Working standards (0.1, 0.2, 0.4, 0.6, 0.8 and 1.0 mM) from 1 mM Malondialdehyde (MDA) stock solution were prepared same as sample to obtain standard curve (y = 0.3204x—0.1118; R2 = 0.997) and read at 532 nm (Model: UV-1800, Shimadzu Japan). TBARS was calculated using following formula and represented as µM/g:

where Ac: amount determined from the calibration curve, W: weight of sample taken, and V: volume (ml) of the total extract prepared.

Estimation of phytate/minerals molar ratios

Bioavailability of minerals gets affected by the presence of many anti-nutrients; one such anti-nutrient is phytate. It binds with minerals and decreases their absorption, therefore reducing bioavailability. Thus, knowledge of both the amount and bioavailability of elements present in food or diet is essential. There are many procedures to determine the bioavailability of minerals. One such approach is calculation of phytate/minerals molar ratios that help to estimate the adverse effect of phytate on minerals bioavailability. Molar ratio was calculated for phytate/iron and phytate/zinc as described by FAO/IZiNCG [40]. Molar ratio for phytate/calcium and phytate × calcium/zinc was calculated using the formula described by Ma et al. [41].

Statistical analysis

The data was analyzed statistically using INDOSTAT (version 9.1) and Stat Graphics software (version 18). All the experiments were conducted at least in triplicates and mean scores were recorded. MANOVA (multifactor analysis of variance) was performed for selecting best stabilization treatment based on the main and interaction effect of different factors viz., treatments, grain, storage on FFA and moisture. One-way analysis of variance (ANOVA) was performed for functional properties, nutritional, antioxidant and phytonutrient composition. Significant differences among the treatments were noted based on CD values.

Results and discussion

Dehulling characteristics, bran extraction and grain dimensions

Various processes like milling and dehulling are employed to obtain bran. The percentage of bran recovery, percentage dehulling, and degree of dehulling depends on the size, type and moisture content of the grain, including time taken and equipment used for dehulling [42]. In the present study, a stone abrasive dehuller was used to dehull selected minor millets. It was observed that per cent bran recovery varied among all grains ranging from 12.36 to 17.93% (Table 1). Kodo exhibited the highest bran recovery but lowest dehulling per cent (72.22%) and degree of dehulling (62.95%) compared to other grains. Reduced dehulling per cent and degree of dehulling indicated that complete dehulling did not occur, resulting in more unhulled grains. One of the main reasons being, firm attachment of pericarp to the seed coat as kodo millet is a caryopsis-type. Thus, making it difficult to remove the seed coat, compared with other grains such as proso, foxtail and barnyard, which fall the under-utricle type, where the seed coat is loosely attached only at a point facilitating easy removal [43]. Despite, lowest dehulling per cent and degree of dehulling, bran recovery was highest in kodo millet which corresponds to its structure, with bran and husk contributing almost 37% of total grain weight [43]. While, husk and bran in foxtail, proso and barnyard contribute 13.5–23% of the total grain weight [43, 44].

Grain dimensions observed before and after dehulling revealed that the degree of dehulling and efficiency of dehuller directly affected grain size. The highest reduction in grain length, width and perimeter was found in kodo millet, followed by barnyard millet, foxtail millet and proso millet (Table 1, Fig. 1). These reductions account for removal of husk and bran during dehulling. Studying these parameters revealed that a large amount of bran as a by-product is generated during processing to find utilization in the food industry.

Effect of bran, storage and treatment on FFA and moisture content

Results on FFA (Table 2) and moisture (Table 3) content revealed that stabilization significantly (p < 0.05) reduced the upsurge in FFA and moisture for all treated brans compared to control during storage periods (0, 7, 15 days).

It was observed that FFA (% oleic acid) content in control brans increased rapidly, whereas it was much slower in treated brans (HT1, HT2, MW1, MW2), suggesting that stabilization by both hot air and microwave oven heating inhibited the lipase activity during storage (Table 2). Amongst all the treatments, irrespective of brans, MW2 was most effective with the lowest FFA values, followed by HT1, HT2 and MW1. Statistically, no significant difference was observed between both hot air oven treatments (HT1, HT2). Similar was the case with HT1 and MW2, while HT2 and MW1 were on par with each other. In MW2, the initial FFA content (% oleic acid) for barnyard, foxtail, kodo and proso bran was 3.86, 2.99, 2.63 and 3.07, which increased to 3.98, 3.83, 4.78, 4.34 on the 15th day of storage, respectively. While control (CT) showed significant increase in FFA (% oleic acid) levels up to 10.33, 10.48, 21.40 and 26.89 for foxtail, barnyard, kodo, and proso millet brans respectively, after 15th day storage, leaving it unfit for consumption. As per the reports, FFA during storage below 10% in rice bran oil and below 5% in rice bran are acceptable for human consumption [24]. This suggested that microwave treated minor millet brans can be stored safely for 15 days without any signs of spoilage like rancidity or off flavor. The increase in FFA during storage could be attributed to the hygroscopic nature of bran and higher lipase activity, resulting in hydrolysis and oxidation of millet bran oil [25, 45]. Based on results in the present study, it could be inferred that the microwave exposure at high power for a longer time inhibited rapid formation of FFA and hydrolysis of oil by evaporating moisture molecules. These results were concurrent with previous studies that reported microwave stabilized rice bran had better storage stability than untreated bran [25, 46]. Although, some researchers also suggested hot air treatments to be suitable for stabilization of rice and wheat brans [8, 47]. However, the present study confirmed that both hot air treatments (HT1, HT2) were found suitable for stabilization of selected millet brans only next to microwave treatments. During storage, the increase in FFA content was highest in proso followed by kodo bran; however, there was no significant difference between foxtail and barnyard bran. All the stabilization treatments worked best for foxtail and barnyard bran during the storage period in controlling FFA between 3 and 4%, but kodo and proso bran relatively developed slightly higher FFA (4–7%).

Moisture content in all brans subjected to various treatments were recorded up to 15 days, and it increased with increasing storage period (Table 3). Reduction in moisture was higher on the 0th day due to higher temperature and exposure time in hot air oven heating (HT1, HT2) than microwave treatments (MW1, MW2). But irrespective of bran type, treatment and storage interaction effect indicated that per cent rise in moisture over the period was higher for hot air oven heating than microwave treatments. Overall, percentage moisture increase for all treatments from 0 to 15 days was highest in CT (13.55%), followed by HT1 (8.69%), HT2 (5.67%), MW1 (4.46%) and MW2 (4.28%), implying that MW2 was most effective. Several authors have reported similar findings suggesting the suitability of microwave treatment for controlling moisture increase and stabilization [23, 24].

The present study demonstrated that stabilization of minor millet brans using both hot air oven and microwave oven treatments resulted in consumable bran with permissible FFA (< 5–7%) levels. These results are in agreement with several studies that reported microwave treatment was effective for stabilization of rice bran and other cereal brans as it is less cumbersome and controls increase in FFA content [23,24,25, 46, 48]. In addition, microwave stabilization may also result in better nutrient stability and retention because of its less exposure time and quick, uniform internal heating than external heating in hot air oven treatments, requiring bran exposure for a longer time to stabilize [49].

Thus, in the present study control brans (without stabilization), which developed higher FFA amounts (than suggested permissible levels), making it unfit for human consumption, were not used for further analysis. Only brans stabilized with MW2 were considered for analyzing functional properties, nutrients, antioxidants and phytonutrients.

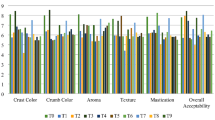

Functional properties of stabilized millet brans

Functional properties like water, oil absorption and foaming capacity are essential attributes in food formulation or bakery industry. Functional properties of stabilized minor millet bran viz. Foxtail (FSM), Kodo (KSM), Proso (PSM) and Barnyard (BSM) established that water absorption of the brans ranged from 197.76 to 265.47 ml/100 g (Table 4). KSM had the least water absorption (197.76 ml/100 g) however, there was no significant difference (p > 0.05) between PSM, FSM and BSM. The ability of bran to hold water can be attributed to the presence of polysaccharides and size of bran particles [50, 51]. These results were in agreement with the reported values for stabilized rice bran [31]. The water absorption ability of bran evinced that it could be utilized in food processing, where moisture retention is desired in the final product [31]. Oil absorption helps to retain flavor and enhances mouth feel of the products [32]. Oil absorption capacity of all brans differed significantly (p < 0.05) from each other. The oil absorption capacity of bran ranged from 162.62–258.19 g/100 g, with BSM having the highest while PSM having the lowest values, respectively. Altogether, brans showed good water and oil absorption capacity; this could be due to dietary fiber (DF) and protein [31, 50] content of the bran. Foaming capacity mainly depends on protein, its flexibility, elasticity, cohesiveness and denaturation [32]. All brans exhibited negligible foaming capacity suggesting that the proteins in the bran did not unfold quickly. This result correlated with the study where extruded full fat rice bran showed no foaming capacity [52]; however contradictory results with higher foaming capacity were observed for rice brans in another study [53]. These variations could be associated with flexibility, elasticity, cohesiveness, denaturation of protein, varietal differences and pH changes. However, treatments like extrusion can help obtain desired foaming as per requirement of final product [53].

Proximate and mineral composition

All bran samples (FSM, PSM, BSM, KSM) were analyzed for proximate content (Table 5); the moisture content was lower in KSM and PSM than FSM and BSM. A previous study also reported kodo millet bran had low moisture content than barnyard and proso millet bran as it had higher dry matter [18]. There was no significant difference in moisture content between FSM (2.385 g/100 g) and BSM (2.405 g/100 g) and between KSM (1.759 g/100 g) and PSM (1.876 g/100 g). Previous studies have reported a higher moisture content for unstabilised foxtail, proso, kodo and barnyard millet brans [18, 54] in contrast to a lower moisture content of stabilised brans exhibited in the present study. This might be due to evaporation of moisture during stabilization. Similar reports were available for cereal brans suggesting a reduction in moisture due to microwave stabilization [23, 24, 47].

Protein analysis showed that PSM (13.037 g/100 g) had the highest content, followed by FSM (10.491 g/100 g), BSM (7.696 g/100 g) and KSM (5.678 g/100 g). These values ranged as in previous reports [16,17,18, 55]. These proteins might be of high significance and can be employed in treatment of certain cancers. A novel peroxidase- homolog protein of 35 kDa protein extracted from foxtail millet bran reduced proliferation of colon cancer cells in nude mice, with minimum adversity on host cells [56]. The fat content of all brans in present study ranged from 5.283–9.870 g/100 g, wherein KSM and FSM had the lowest and highest levels, respectively. Similarly, some researchers stated that the amount of fat content ranged between 2.80 to 9.63%, with foxtail containing the highest amount (5.65–9.63%) followed by barnyard (4.04%), kodo (2.83- 3.36%) and proso (2.80%) brans [13, 14, 17, 18, 55]. Ash content in bran showed the following trend FSM > BSM > PSM > KSM. All these differences in proximate composition of bran in the present and previous studies could be due to various factors like genetic variation, environmental and storage conditions, processing of grain, i.e., degree of dehulling, milling and polishing [22].

Total dietary fiber (TDF) was highest in KSM (61.52%), followed by BSM (37.26%) whereas, no significant difference was observed between PSM and FSM. As the TDF content was higher in KSM, there was a reduction in the available CHO and energy. The values of TDF suggest that all brans are good sources of fiber. As per recommended dietary allowances (RDA) for Indians, an adult should consume 40 g of dietary fiber (based on 2000 kcal diet) per day [57]. Since, the intake of fibre is less than RDA, consumption of whole grains is promoted. Brans contributing high dietary fibre in whole grains, provide benefits such as hypoglycaemic, hypocholesterolaemic and laxative effects [6]. Some recent studies have shown that dietary fiber and extracts of kodo, proso and barnyard bran were able to bind glucose molecules delaying its absorption, enhancing glucose tolerance and exhibiting hypoglycaemic properties [17, 18]. Cholesterol regulating effect was also seen in kodo bran and hull extracts [12, 17]. Additionally, it is found that dietary fibre (DF) binds the phenolic compounds (PC) in grains forming a beneficial DF-PC complex in cereal bran. This helps in slow and continuous release of PC in intestine [58]. Furthermore, DF escapes digestion in the stomach and gets fermented in the colon, contributing to healthy gut microflora. Health benefits of DF are associated with its water holding and bulking capacity. Due to the same functional properties, brans can also be used in product formulations improving their water absorption, oil retention and swelling capacities. From the current study results, it can be recommended that proso and foxtail bran can be used to design protein-rich products, while kodo bran is for fibre-rich nutraceutical products.

The mineral content of minor millet bran (Table 5) indicated that iron content ranged from 8.87 to 65.58 mg/100 g, zinc 2.13–5.59 mg/100 g, calcium 37.87–94.63 mg/100 g, sodium 2.23–18.08 mg/100 g and potassium 343.84–630.83 mg/100 g. The mineral profile of minor millet bran in the present study revealed that they were equivalent or superior to rice and wheat bran [5, 31, 48]. One of the important micronutrients, iron, is necessary for cellular growth and differentiation, immune functions, mental and physical growth. It helps in binding, transportation and storage of oxygen. But deficiency of iron has led to a common global problem of anaemia [59]. The RDA for Indians suggests an intake of 17 and 21 mg/day for adult men and women respectively. The iron content of KSM (20.45 mg/100 g), PSM (60.74 mg/100 g) and FSM (65.58 mg/100 g) was much higher than RDA and thus, these brans could be used as fortificant in the food industry for developing iron rich supplements.

Zinc, another essential micronutrient is a part of more than 300 metalloenzymes, essential in synthesis, metabolism, degradation of macro, micronutrients and nucleic acids [57]. The present study revealed that minor millet brans were good sources of zinc with PSM (5.59 mg/100 g) and KSM (2.13 mg/100 g) having highest and lowest content, respectively. Calcium, a vital mineral in the human body, not only helps in the maintenance of bones and teeth but current studies also associate adequate intake of calcium with reduced risk of obesity, fractures, osteoporosis and diabetes in some populations [60]. In the present study, brans exhibited to be a fair source of calcium; FSM (94.63 mg/100 g) > KSM (76.09 mg/100 g) > BSM (62.28 mg/100 g) > PSM (37.87 mg/100 g). It was found that all brans had higher potassium content and lower sodium content; thus, it can be useful for cardiovascular patients, where the intake of sodium is associated with increased risk of stroke and consumption of potassium reduces the risk of stroke [61]. Thus, due to their rich mineral profile, selected brans find potent use in management of micronutrient deficiencies by probing them into menu planning and therapeutic diets via fortification into suitable recipes such as breads, buns, idli, dosa, chapatis etc.

Antioxidant capacity and phytonutrients

Cereals and millets are good sources of natural antioxidants as they contain phenolic compounds that are concentrated in the bran. Thus, bran and bran fractions obtained from processing tend to have antioxidant capacity [11, 12]. The present study, therefore, evaluated antioxidant potential of all bran samples, and the results were presented in Table 6. Extracting antioxidants is a tedious task, due to the presence of a wide range of active components differing in polarity. Some studies have shown methanol as suitable solvent for extraction of antioxidants as it is cheap, readily available and highly efficient [1]. Thus, sample extraction was done with methanol for estimating Total phenols (TP), flavonoids, 1,1-diphenyl-2-picrylhydrazyl (DPPH) and Ferric reducing antioxidant power (FRAP).

Total phenols (TP), phytic acid and flavonoid content revealed that among all the samples, KSM had significantly highest content (p ≤ 0.05) of 449.27 mg GAE /100 g, 630.00 mg /100 g, 22.37 µg RE/g respectively. KSM has exhibited the highest antioxidant capacity in terms of DPPH scavenging potential, FRAP and TBARS. There was no significant difference in TP and flavonoid content among BSM, FSM and PSM. Both TP and flavonoids followed the same trend; KSM > BSM > FSM > PSM. Concurrent results were reported by Chandrasekara and Shahidi [12], where kodo hulls showed 3 times more TP content than that of pearl millet hulls. Phytic acid content was highest in KSM (630 mg /100 g) than other brans studied. No significant difference was noticed between FSM–PSM (540.00, 516.25 mg /100 g), while BSM had (246.25 mg /100 g) lowest values. Similar presence of phytic acid in millet brans was reported by several authors [1, 14, 62]. Phytic acid is a chelating agent known to bind minerals, thereby reducing their bioavailability, however, it also contributes to antioxidant capacity [1, 14, 63]. It has been established through various research studies that phytates, phenols, flavonoids and tannins present in cereals are concentrated in the bran, bound with its dietary fiber. They act as a source of natural antioxidants promoting health and preventing various degenerative diseases caused by oxidative stress [1, 6]. The present study also confirmed the same, wherein all brans exhibited good antioxidant capacity due to the presence of TP, flavonoids and phytic acid. The antioxidant capacity increased with increase in TP, flavonoids and phytic acid. This trend was evident from the current results wherein, KSM with highest TP, flavonoids and phytic acid, had the highest antioxidant potential (31.13%, 1108.67 µM/g) followed by BSM (15.26%, 325.00 µM/g) in terms of DPPH and FRAP respectively. While lowest values compared to other brans were recorded in FSM (14.06%, 268.33 µM/g) and PSM (12.94%, 259.67 µM/g) that did not differ significantly.

TBARS is a standard marker for lipid peroxidation induced- oxidative stress that was lowest in KSM (0.117 µM/g) and highest in PSM (0.868 µM/g). In TBARS assay, thiobarbituric acid (TBA) reacts with malondialdehyde (MDA) formed during lipid peroxidation. The results indicated less MDA was formed in KSM compared to other bran samples, indicating a higher antioxidant potential [39]. The lower MDA could also be attributed to higher phytic acid content, resulting in a decreased lipid peroxidation rate [63].

The results indicated that high TP, flavonoid, phytic acid content contributed to the antioxidant activity of bran samples. Due to the presence of these phytonutrients in abundance, brans and their extracts might also contribute in strengthening immunity, if formulated in the form of nutraceuticals. They can also play a protective role against diseases caused due to free radical formation, especially cancer. Some polyphenols bound to the inner shell in foxtail millet bran were found to have anti-cancer properties against colon and colorectal cancer cell lines [19,20,21]. Similarly, kodo millet hulls extracts also showed anti-cancer activity [12].

Molar ratio of phytate/minerals

Though the mineral content of bran showed a higher amount, all of it may not be available due to the presence of phytate. Phytate binds with iron, zinc and calcium, hindering their absorption and bioavailability. One simple measure to understand hindering effects of phytate on mineral bioavailability is calculating their molar ratios. Critical values for phytate/iron > 1, phytate/zinc > 15, phytate/calcium > 0.24 and phytate × calcium/zinc > 200 have been suggested to exhibit inhibitory effect of phytate on minerals [41]. In the present study, it was observed that (Table 7) KSM (2.61) and BSM (2.35) had phytate/iron molar ratio above 1; however, PSM (0.72) and FSM (0.70) had ratios below 1; indicating that phytate had a less hindering effect on PSM and FSM, in contrast to KSM and BSM. As observed in mineral profile, this can also be due to higher iron content in FSM and PSM as compared to KSM and BSM. Phytate/zinc molar ratio was below 15 for all the bran except KSM, indicating that bioavailability of zinc was affected by phytate only in KSM. Phytate/calcium molar ratio for BSM was 0.24; rest all brans had a higher ratio than the critical limits. The effect of phytate on calcium is still uncertain and unknown [40]; high dietary calcium is also known to hinder zinc absorption. Thus phytate × calcium/zinc is calculated when there are higher calcium and phytate levels; the critical value denoted is above 200 [41]. In the present study, none of the brans had a value above 200, but ranged from 8.65–55.69. Considering the molar ratio results from the present study, it can be said that FSM and PSM can be preferred where products rich in iron and zinc are needed. Similarly, BSM can be selected where zinc and calcium rich products are desired.

Phytate being relatively heat stable, is not readily degraded in normal boiling water. However, food processing methods such as extrusion cooking or processes where the temperature is high, fermentation, soaking, and phytase can be employed to reduce the phytate content and improve the bioavailability of minerals [40, 41]. Specifically, particle size reduction of DF showed a decreased tendency of in vitro binding effect on selected minerals [64] which may open a potential way of processing fibre through micronisation before using it as an ingredient in food formulations. These molar ratios only help to predict the inhibitory effect of phytate. Hence, in vitro and in vivo methods need to be utilized to determine its effect on the bioavailability of minerals.

Conclusion

In most countries worldwide, the fast-growing food processing industry generates huge quantities of by-products, including minor millet bran. Moreover, with growing interest in health promoting functional foods, the demand of natural bioactive compounds has increased, and exploration for new sources is on the way. Thus, utilization of bran as health promoting ingredient will assist in developing economical and low-cost designer product. This current research provides primary data on minor millet bran stabilization along with nutritional profiling. Stabilization with microwave or hot air oven heating significantly lowered the FFA of selected brans. Both treatments can be used at household and industrial levels to enhance bran shelf life. Among the brans studied, kodo was rich in dietary fiber and antioxidant capacity compared to all other brans. On the other hand, proso millet bran had the least antioxidant property, but showed the highest protein, iron, zinc and potassium contents. Barnyard and foxtail millet bran also exhibited good antioxidant capacity next to kodo bran, with a superior nutritional profile. Overall, results of the present study indicated that minor millet brans had good proximate, mineral content and antioxidant capacity proving that they have prospects of being utilized as a fortificant for value addition of empty calorie foods. Their antioxidant profile encourages the potential of brans, bran rich fractions and extracts in formulating nutraceuticals. Emerging health issues associated with a sedentary lifestyle and increased consumption of processed foods have increased awareness of health and nutrition among consumers. Thus, the millet brans either directly or after modification can be used to manufacture various foods, i.e., bread, buns, cake, pasta, noodles, biscuit, vermicelli, extruded snacks, beverages to name a few. Hence, minor millet brans or their extracts can be explored as promising source of natural nutraceuticals and functional food ingredients in the food industry.

Data availability

Not applicable.

Code availability

Not applicable.

References

P.F. Suma, A. Urooj, Antioxidants. 3, 55–66 (2014)

Y. Luithui, B.R. Nisha, M.S. Meera, J. Food Sci. Technol. 56(1), 1–11 (2019)

R. Devisetti, S.N. Yadahally, S. Bhattacharya, LWT - Food Sci. Technol. 59, 889–895 (2014)

D.D. Shejawale, T.V. Hymavathi, K. Manorama, Z. Farzana, Food Meas Char. 10, 16–23 (2016)

O.O. Onipe, A.I.O. Jideani, D. Beswa, Int. J. Food Sci. Technol. 50, 2509–2518 (2015)

S. Patel, J Funct Foods. 14, 255–269 (2015)

R. Safdar, EC Nutrition. 14(10), 829–851 (2019)

M.L. Sudha, P.R. Ramasarma, G. Venkateswara Rao, Food Sci Technol Int. 17(1), 47–53 (2011)

Expert Market Research 2020. https://www.expertmarketresearch.com/reports/rice-bran-oil-market. Accessed 20 May 2021.

F.S. Garofalo, T. Tommasi, D.A. Fino, Biomass Conv. Bioref. 11, 569–587 (2021). https://doi.org/10.1007/s13399-020-00846-3

P.F. Suma, A. Urooj, J. Food Sci. Technol. 49, 500–504 (2012)

A. Chandrasekara, F. Shahidi, J. Agric. Food. Chem. 59, 9563–9571 (2011)

I.T. Amadou, Y.-H. Shi Amza, G.-W. Le, Warasan. Songkhla. Nakharin. 33(5), 509–515 (2011)

P. Nazni, T.D. Karuna, J. Food Indian Microbiol. 2(2), 1–6 (2016)

Y. Zhu, J. Chu, Z. Lu, F. Lv, X. Bie, C. Zhang, H. Zhao, J. Cereal Sci. 79, 456–461 (2018)

N.C. Mustač, D. Novotni, M. Habuš, S. Drakula, L. Nanjara, B. Voučko, M. Benković, D. Ćurić, J Cereal Sci. 91(1–7), 102864 (2020)

S.M. Sarma, P. Khare, S. Jagtap, D.P. Singh, R.K. Baboota, K. Podili, R.K. Boparai, J. Kaur, K.K. Bhutani, M. Bishnoi, K.K. Kondepudi, Food Funct. 8(3), 1174–1183 (2017)

P.C. Bisoi, G. Sahoo, S.K. Mishra, C. Das, K.L. Das, J. Food. Process. Technol. 3(7), 1–11 (2012)

J. Shi, S. Shan, Z. Li, H. Li, X. Li, Z. Li, J. Funct. Food. 17, 958–968 (2015)

S. Shan, Y. Lu, X. Zhang, J. Shi, H. Li, Z. Li, Mol. Cell. Biochem. 476(2), 513–523 (2020). https://doi.org/10.1007/s11010-020-03906-4

R. Yang, S. Shan, C. Zhang, J. Shi, H. Li, Z. Li, J. Agric. Food Chem. 68(11), 3506–3517 (2020)

A. Abdul-Hamid, R.R.R. Sulaiman, A. Osman, N. Saari, J. Food Compos. Anal. 20, 627–637 (2007)

T.B. Bagchi, T. Adak, K. Chattopadhyay, J. Crop Weed. 10(2), 303–307 (2014)

S.S. Patil, A. Kara, D. Mohapatra, Food Bioprod. Process. 99, 204–211 (2016)

N.S.M. Daud, D.N.A. Zaidel, L.K. Song, Y.M.M. Jusoh, I.I. Muhamad, H. Yaakob, Chem. Eng. Trans. 56, 1285–1290 (2017)

A.K. Gautam, D. Kumar, Y.S. Shivay, B.N. Mishra, Arch. Agron. Soil Sci. 54(5), 515–532 (2008)

Y.N. Sreerama, V.B. Sasikala, V.M. Pratape, J. Food Eng. 92, 389–395 (2009)

R.E. Espinosa-Mendoza, J. Solorza-Feria, M.L. Arenas-Ocampo, B.H. Camacho-Diaz, A.A.D. Villar-Martinez, P.E. Vanegas-Espinoza, A.R. Jimenez-Aparicio, Sci. World J. 1, 1–9 (2012)

AOAC. Official method 954.01, 985.29, 940.28. Association of Official Analytical Chemists International. 18th ed, 4th Revision (Horwitz, W., ed.) Gaithersburg, MD (2010).

IS: 1155–1968 Specification for Wheat Atta/IS I Hand book of Food Analysis (part IV), p. 114.

S. Sairam, A.G.G. Krishna, A. Urooj, J. Food Sci. Technol. 48(4), 478–483 (2011)

S. Chandra, S. Singh, D. Kumari, J. Food Sci. Technol. 52(6), 3681–3688 (2015)

AOAC. Official method 922.06. In Horwitz, W. (Eds.), Association of Official Analytical Chemists International. Gaithersburg, MD (2007)

AOAC. Official method 975.03, 956.01. Association of Official Analytical Chemists International (1990)

S. Sadashivam, A. Manickam, Biochemical Methods, 3rd edn. (New Age International Publishers, Coimbatore, 2007), pp. 203–204

J. Zhishen, T. Mengcheng, W. Jianming, Food Chem. 64(4), 555–559 (1999)

M.S. Blois, Nature 26, 1199–1200 (1958)

I.F.F. Benzie, J.J. Strain, Methods Enzymol. 299, 15–27 (1999)

A. Zeb, F. Ullah, Foods J. Anal. Methods Chem. 2016, 5 (2016)

FAO/IZiNCG, FAO/INFOODS/IZiNCG Global Food Composition Database for Phytate Version 1.0-PhyFoodComp 1.0. Rome, Italy (2018)

G. Ma, Y. Jin, J. Piao, F. Kok, B. Guusje, E. Jacobsen, J. Agric. Food Chem. 53(26), 10285–10290 (2005)

U.C. Lohani, J.P. Pandey, N.C. Shahi, Food Bioprocess. Technol. 5, 1113–1119 (2012)

S.O. Serna-Saldivar, J. Espinosa-Ramırez, in Sorghum and Millets, 2nd edn., ed. by J.R.N. Taylor, K.G. Duodu (Elsevier, Amsterdam, 2019), pp. 85–129

N. Sharma, K. Niranjan, Food Rev. Int. 34(4), 329–363 (2018)

L.E. Bultum, S.A. Emire, Y.T. Wolde, Food Measure 14, 2253–2261 (2020)

M.N. Lavanya, K. Saikiran, N. Venkatachalapathy, J. Food Sci. Technol. 56(2), 889–895 (2019)

A. Thanonkaew, S. Wongyai, D.J. McClements, E.A. Decker, LWT - Food Sci. Technol. 48(2), 231–236 (2012)

S. Bhosale, D. Vijayalakshmi, Curr. Res. Nutr. Food Sci. 3(1), 74–80 (2015)

Tao, J. LSU Historical Dissertations and Theses. 4812 (1989)

M.F. Chaplin, Fiber and water binding. Proc. Nutr. Soc. 62, 223–227 (2003)

P.J. Jacobs, S. Hemdane, E. Dornez, J.A. Delcour, C.M. Courtin, Food Chem. 179, 296–304 (2015)

C. James, S. Sloan, J Food Sci. 29, 310–311 (1984)

A. Rafe, A. Sadeghian, S.Z. Hoseini-Yazdi, Food Sci. Nutri. 5, 407–414 (2017)

J. Liu, X. Tang, Y. Zhang, W. Zhao, Molecules 17, 2271–2282 (2012)

S. Liang, G. Yang, Y. Ma, J. Am. Oil Chem. Soc. 87, 63–67 (2010)

S. Shan, Z. Li, I.P. Newton, C. Zhao, Z. Li, M. Guo, Toxicol. Lett. 227(2), 129–138 (2014)

ICMR, Nutrient requirements and recommended dietary allowances for Indians. a report of the expert group of the Indian Council of Medical Research, National Institute of Nutrition, Hyderabad (2010)

P. Vitaglione, A. Napolitano, V. Fogliano, Trends Food Sci. Technol. 19, 451–463 (2008)

R. Kumari, R.K. Bharti, K. Singh, A. Sinha, S. Kumar, S. Saran, U. Kumar, J. Clin. Diagnostic Res. 11(8), 4–06 (2017)

J.A. Beto, Clin. Nutr. Res. 4, 1–8 (2015)

K.J. Aaron, P.W. Sanders, Mayo Clin. Proc. 88(9), 987–995 (2013)

B. Sridevi, B.Y. Nirmala, R.R. Hanchinal, P.W. Basarkar, J Dairying Foods Home Sci. 30(3), 191–196 (2011)

I. Abdulwaliyu, S.O. Arekemase, J.A. Adudu, M.L. Batari, M.N. Egbule, S.I. Reuben Okoduwa, Clin. Nutr. Exp. 28, 42–61 (2019)

O.L. Yao, A.R. Komarek, Food Qual. Safety 1(1), 47–59 (2017)

Acknowledgement

The authors thank Millet Processing and Incubation Centre, PJTSAU and Central Instrumentation Cell, PJTSAU for their logistical support. The authors also acknowledge the fellowship support received from University Grant Commission for Junior Research Fellowship during the research work.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors contributed to study and are aware of its submission to Journal of Food Measurement and Characterization. BMD: Contribution in conceptualization, designing flow of work, conducted the actual study, analyzed the data, interpretation of results, drafted the paper and revised it critically. TVH: Conceptualization, decision making, suggestions for designing workflow, analyzed the data, critical suggestions to revise paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Ethical approval

Not applicable.

Consent for participation

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barbhai, M.D., Hymavathi, T.V. Nutrient, phytonutrient and antioxidant potential of selected underutilized nutri-cereal brans. Food Measure 16, 1952–1966 (2022). https://doi.org/10.1007/s11694-022-01301-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01301-9