Abstract

Modified atmosphere packaging and related technologies are increasingly used to extend shelf-life of fresh products. This paper covers the effect of such techniques on increasing shelf life. Salad-cut lettuce was washed in different solutions for a period of 1 min. Then, salad-cut lettuce was packed in modified atmosphere (3–5% CO2, 3–5% O2, 97–95% N2) and stored at 4 °C for 12 days. Quality indicators of packaged lettuce including color, texture, sensory properties, total phenol content and antioxidant activity were analyzed at 1, 3, 6, 9 and 12 days of storage. This study showed that combination of sodium hypochlorite and ascorbic acid was the best treatment to maintain most of the qualitative indicators of lettuce during storage at 4 °C (p < 0.05). Ascorbic acid and cysteine caused synergistic effect in preventing oxidation. Treatments containing calcium lactate and heat shock, caused better crispiness till the 9th day of storage. According to the results of current study, application of MAP alongside implementation of food grade chemicals showed to be remarkably effective in increasing the shelf life of lettuce.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fresh-cut product hint at fruit or vegetables having been catered and thereafter packaged to provide comfortable and protected ready-to-eat products for consumers, whereas keeping their fresh nature [1, 2]. There are a lot of consumers who are fan of leafy vegetables, especially lettuce; however, these products are very soft and susceptible to processing conditions [3, 4]. Innovative technologies should be followed to gain maximum results of fresh-cut processing conditions [5,6,7,8]. A fresh-cut product changes from its natural conditions during processing such as trimming or washing functions. Fresh-cut product keeps its overall pristine condition and is specified by living cells which stand or are sensitive to internal or external deterioration activities such as enzymatic rottenness or microbial spoilage [9,10,11,12,13]. In the fresh-cut industry, expiration date is determined by the loss of quality indicators like firmness, color or nutritional profile to an extent, which is not tolerable, by consumers anymore. Processing practices, packaging and storage temperature manipulation, do not terminate quality deterioration, they can only slow down the rate at which deterioration happens [14,15,16,17].Fresh fruit and vegetable postharvest losses have been evaluated to be between 2 and 20% in developed countries and between 24 and 40% in developing countries, respectively [18,19,20]. Most fruits and vegetables are cost effective foods having small fat level and high levels of nutritionally important ingredients such as vitamins or minerals, most of that could not be synthesized by the human body [20,21,22]. Alteration of eating habits, snacking, inclination towards year-round food access as well as increasing tendency to vegetarianism have led to an enhancing requirement for comfortable but healthy products matching the new-fashioned consumer lifestyle in sustainable food systems. It should be noted that the growth in quality preservation of fresh-cut food is of paramountcy for food plants because of its financial effect [23]. Keeping quality indicators such as color and texture is a prerequisite for every rinsing operation employed for fresh vegetable and fruit because consumers call for natural and comfortable food with extended shelf life [24]. Enzymatic browning of fresh-cut products emerging across the cutting side is well-established to be the result of oxidation by polyphenol oxidase (PPO) and peroxidase (POD) [25, 26]. It has been recognized that the catalysis of phenylalanine ammonia lyase produced phenolic compounds. To control aforementioned occurrence, some chemical compounds including chelating and reducing agents are applied in food plants [27, 28].

Besides, various treatments such as calcium lactate, heat shock, hypochlorite, ascorbic acid, cysteine and controlled atmospheres could potentially be effective in extending food shelf-life [29]. Calcium is known to interact with pectin and creates calcium pectate, thereby, holding the cell wall frame of plants. Besides, its interaction with middle lamella pectin causes more rigid texture for vegetables treated with calcium (compared with control samples) during their shelf life [30]. Calcium lactate has been found to be an appropriate substitution to calcium chloride since it prevents the bitterness or off-flavors brought about by this salt [31]. Incremental firmness impact is achieved when calcium treatment is combined by heating treatment. Heat causes calcium diffusion into the vegetable tissue, followed by demethylation of pectin methyl esterase and generation of carboxyl groups which cross link with calcium cations and, as a result, the above-mentioned firmness effect [32]. Among the compounds which prevent browning, there are sulphites, ascorbic acid and thiol compounds such as cysteine [33, 34].

Therefore, the main aim of the current study was to evaluate the physicochemical effects of different washing treatments on increasing shelf life of minimally processed lettuce packed under modified atmospheric packaging.

Materials and methods

Material

Iceberg lettuce (Lactuca sativa sp.) was obtained from Khuzestan (South of Iran). L-cysteine monohydrate, Ascorbic acid, Calcium lactate, Sodium hypochlorite, Folin-Ciocalteu, DPPH (2,2-diphenyl-1-picrylhydrazyl) were purchased from Titrachem, Germany.

Vegetable processing

Iceberg lettuce (Lactuca sativa sp.) grown in Khuzestan (South of Iran) and stored at 4 °C (2 h) was used. The most outside leaf was discarded, fresh-cut product was prepared and the core of the heads of lettuce was removed with a stainless steel knife. The lettuce was halved and each half was cut into four equal parts [35, 36]. The temperature in the processing plant was nearly 18–20 °C (room temperature).

Shelf-life tests

Salad-cut lettuce was washed in different solutions for 1 min. Treatments included: T1: sodium hypochlorite (100 mg/L) + cysteine (0.5%), T2: calcium lactate (1.5%) + heat shock (50 °C), T3: sodium hypochlorite (100 mg/L) + ascorbic acid (0.5%) and T4: sodium hypochlorite (100 mg/L) + calcium lactate (1.5%) + heat shock (50 °C), T5: calcium lactate (1.5%) + heat shock (50 °C) + hypochlorite (100 mg/L) + cysteine (0.5%) + ascorbic acid (0.5%) and tap water was used as the control treatment. Washing solution was removed using a spin dryer for 5 min; then salad-cut lettuce was packaged in modified atmosphere (3–5% CO2, 3–5% O2, 97–95% N2) and stored at 4 °C for 12 days (Allende and Artes, 2003). Each package contained 150 g of salad-cut lettuce.

Quality indicators

pH measurement

20 g sample of lettuce tissue was blended for 2 min in 40 mL of deionized water. The pH of the mixture was measured at room temperature using a pH meter) Metrohm, Switzerland)

Exudates

A weighed piece of lettuce tissue was placed between filter paper No. 595 (Albet, Germany) and a force of 10 kg applied for 2 s [37]. The sample was weighed and the percentage of weight loss was recorded as the exudate. The average of triplicate values was expressed as percentage of exudate/vegetable [37].

Texture analysis

Texture properties of iceberg lettuce were assessed by Instron texture analyzer (LFRA texture analyzer, USA) fitted with a puncture cell (6 mm, 10 m/s, Germany) The speed applied in the experiment was 10 mm/s [35, 38].

Sensory analysis

Sensory analysis was carried out for lettuce over 12 days of storage by twelve trained panelists from department with an age range of 25–40 years. Fresh appearance, brittleness, off-flavors and color were evaluated on a hedonic scale of 1–7, where 7 stands for the best quality and 1 stands for very poor quality [35].

Color measurement

The samples photos were taken inside the Panasonic camera model TH 5 box in 4 replications. Applying the RAL cards and Photoshop (Version CC), RGB images were determined for standards, and standard curves were plotted. Then, RGB of samples were obtained in Photoshop. Finally, using a linear equation, the color parameters of the standard sample and RGB values of the samples were reported. Hue values indicated product color, Chroma values indicated color saturation and variation of color (ΔE) was calculated by using the following formula:

where Li is the initial luminosity, Lf the final luminosity, af the a* value at final time, ai the a* value at initial time, bf the b* at final time and bi is the value b* at initial time. L* (lightness index scale) ranged from 0 for black to 100 for white. The a* scale assesses the degree of red (+ a) or green (− a*) colors and the b* scale evaluates the degree of yellow (+ b) or blue (− b*) color [35].

Extraction conditions

Dried lettuce powder (1 g) was extracted in 25 mL methanol/water (30%, v/v) at 60 °C for 10 min under stirring. This procedure was repeated three times and aluminum foil was used to hamper light degradation; after the process and reaching ambient temperature, filtering of the extract was carried out [39].

Antioxidant capacity by DPPH

One of the most popular techniques to evaluate the antioxidant capacity of food matrices is the method employing the stable 2,2-diphenyl-1-picrylhydrazyl (DPPH) [40]. The free radical scavenging activity was determined according to the method described by [39]. 0.3 mL of extract solution was added to 2,2-diphenyl-1-picrylhydrazyl (DPPH) solution (2.7 mL, 6 × 10−5 mol/L). After mixing, the solution was kept in the dark for 60 min. Measuring the absorbance was carried out at 517 nm and DPPH value was calculated accordingly: (Thermo Electro Corporation Genesys 10 UV–Vis Spectrophotometer).

Determination of total phenolic compounds

Total phenolic content of the extract was determined by the Folin-Ciocaltiue method [41]. 20 μL aliquot of extract solution was mixed with 1.16 mL distilled water and 100 μL of Folin-Ciocaltiue reagent, followed by the addition of 300 μL Na2CO3 solution (20% w/v) Subsequently, the mixture was incubated in a shaking incubator at 40 °C for 30 min and its absorbance was measured at 769 nm. Gallic acid was used as a standard for calibration curve. Total phenol content was expressed as mg of Gallic acid equivalents per g of lettuce dry matter.

Statistical analysis

The experiment was conducted in a factorial form, using a completely randomized design to study the effects of time and washing treatments on physicochemical characteristics of lettuce. Experiments were carried out in triplicate. Mean comparison was carried out using LSD test (P < 0.05). The results were expressed as mean ± SD (standard deviation).

Results and discussion

pH measurement

Data presented in Table 1 indicates that effect of washing treatment and storage time and their interaction on pH values were significant (P ≤ 0.05). As shown in Fig. 1, the pH of salad-cut lettuce in all treatments increased significantly with storage time. In all treatments, pH showed an increasing trend until third or 6th day, and then decreased. T2, T4 and T5 had significant differences with other treatments. This impact has been attributed to the preventive influence of temperature on microbial growth [42]. Warm water could cause a decrease in microbial population.T5 had significant differences with other treatment on the 9th day as well. The decreasing trend of pH for T3 was slow and, till 9th day, it was maintained at an appropriate level. T3 had the highest pH at the end of storage period (P ≤ 0.05).

Effect of washing treatments on pH in fresh-cut lettuce stored at 4 °C for 12 days.T1: sodium hypochlorite + cysteine; T2: calcium lactate + heat shock; T3: sodium hypochlorite + ascorbic acid; T4: sodium hypochlorite + calcium lactate + heat shock; T5: Calcium lactate + heat shock + hypochlorite + cysteine + ascorbic acid; Control: tap water

Exudate values

The effect of washing treatment and storage time and their interaction on exudates values were significant (Table 1). As obvious in Fig. 2, exudate values increased significantly in all treatments during storage (P ≤ 0.05). The level of exudate in T1, T4, and T5 were more than other treatments. The exudate in T2 and T3 was low till 9th day. Samples treated at 50 °C showed the lowest exudate values. This finding was in agreement with those reported by Martin-Diana et al. [33]. T3 had the lowest pH at the end of storage period (P ≤ 0.05).

Effect of washing treatments on exudate in fresh-cut lettuce stored at 4 °C for 12 days. T1: sodium hypochlorite + cysteine; T2: calcium lactate + heat shock; T3: sodium hypochlorite + ascorbic acid; T4: sodium hypochlorite + calcium lactate + heat shock; T5: Calcium lactate + heat shock + hypochlorite + cysteine + ascorbic acid; Control: tap water

Texture analysis

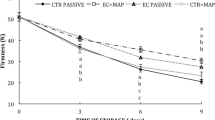

Firmness was evaluated by a puncture cell attachment. The maximum puncture load resembles crispiness index in salad-cut lettuce. The effect of washing treatment and storage time and their interaction on texture values were significant (Table 1). On the first day of storage the highest puncture force was observed in T1 following by T5 and T4 (Fig. 3). T1 and T5 contained cysteine, while T5 and T4 contained calcium lactate and heat shock which caused diffusion of calcium to the tissue. Calcium lactate (T2) concentration did not significantly affect the maximum load measurement on the first day of storage but calcium lactate in combination with other factors in T5 and T4 was more effective on the first day. Figure 3 shows a considerable increase in the maximum load was obtained in all of the treatments at day 12. The difference of load was not significant on the last day of storage. Increased load values during storage could be attributed to flexibility rise and crispness reduction [35]. In fact, loss of the cell moisture leads to tissue dehydration and elasticity promotion.

Effect of washing treatments on texture in fresh-cut lettuce stored at 4 °C for 12 days. T1: sodium hypochlorite + cysteine; T2: calcium lactate + heat shock; T3: sodium hypochlorite + ascorbic acid; T4: sodium hypochlorite + calcium lactate + heat shock; T5: Calcium lactate + heat shock + hypochlorite + cysteine + ascorbic acid; Control: tap water

Color measurement

Color parameters were estimated with digital image analysis on the surface of salad-cut lettuce during storage. The effects of washing treatments and storage time and their interaction on color were significant (Table 1). Color changes increased during storage in control samples. The highest color change was observed on the third day in T1, containing cysteine and sodium hypochlorite which increase L* intensively. As illustrated in Fig. 4, the processes at higher temperatures resulted in increased luminosity (P ≤ 0.05), attributed to the lack of polyphenol oxidase activity at higher temperature. Small luminosity values represent great browning indices as darkness is related to browning. This finding was in agreement with King et al. [43]. Also, a* value is relevant to browning index as it is associated with the breakdown of chlorophyll. The salad-cut lettuce treated at high temperatures (T4 and T5) showed a significantly lower variation of color (P ≤ 0.05) compared to the other treatments (Fig. 4) and their color variation was similar to T3.

Effect of washing treatments on color of fresh-cut lettuce stored at 4 °C for 12 days. T1: sodium hypochlorite + cysteine; T2: calcium lactate + heat shock; T3: sodium hypochlorite + ascorbic acid; T4: sodium hypochlorite + calcium lactate + heat shock; T5: Calcium lactate + heat shock + hypochlorite + cysteine + ascorbic acid; Control: tap water

Antioxidant activity

The antioxidant activity of lettuce is derived from its phenolic compounds. Ascorbic acid quenches free radicals by the growth in active ascorbyl radicals. The ene-diol compound exhibits an impressive effect in scavenging free radicals. Cysteine functions as a free radical scavenger due to the availability of a thiol group. In fact, cysteine contains three reactive groups: the carboxylic acid, the amino group and the Sulphur center. The only reactivity of physiological significance is at the Sulphur center. Reactions of cysteine with radicals demonstrated the ability of its thiol group to clear free radicals and revealed that a positive conjugation impact applied by Sulphur, attenuating the O–H links of the phenolics, is the main reason of an observed antioxidant activity [44]. Data showed that on the first day, antioxidant activity of T5 and T3 increased significantly compared to the control. This is because of the role of antioxidant activity of ascorbic acid (Fig. 5). On the third day, no significant difference among the treatments was found (except of T5). Antioxidant activity of T5 was remarkably higher than other treatments on each day of the study indicating the synergistic effect of ascorbic acid and cysteine in preventing oxidation. On the sixth day up to end of storage time, antioxidant activity reduced slowly in all of the treatments but this trend was slower (Fig. 5).

Effect of washing treatments on antioxidant activity of fresh-cut lettuce stored in 12 days of storage at 4 °C. T1: sodium hypochlorite + cysteine; T2: calcium lactate + heat shock; T3: sodium hypochlorite + ascorbic acid; T4: sodium hypochlorite + calcium lactate + heat shock; T5: Calcium lactate + heat shock + hypochlorite + cysteine + ascorbic acid; Control: tap water

Total phenolic compounds

Changes in total phenolic content were observed during storage, in all the treatments. Total phenol content showed a decreasing trend with time and this was in agreement with data reported by other researchers [44]. The decrease in antioxidant activity paralleled the decrease in total phenol content (Fig. 6). The results also showed that there was a substantial link between antioxidant activity and total phenol content of the T5. These results reveal suppressors could be applied to prevent damage of antioxidant activity and loss of antioxidants, such as polyphenols.

Effect of washing treatments on total phenolic compounds of fresh-cut lettuce stored at 4 °C for 12 days. T1: sodium hypochlorite + cysteine; T2: calcium lactate + heat shock; T3: sodium hypochlorite + ascorbic acid; T4: sodium hypochlorite + calcium lactate + heat shock; T5: Calcium lactate + heat shock + hypochlorite + cysteine + ascorbic acid; Control: tap water

Sensory analysis

As indicated Table 2 the sensory panel analysis showed significant differences over the storage time (P ≤ 0.05). Fresh vegetables lose their typical fresh appearance and texture following processing after a short storage time. Crispness, flavor and freshness in all treatments were acceptable up to day 6. T2 and T3 showed better result in case of maintaining flavor, crispness and freshness up to the 9th day of storage.

Conclusion

Commercially packaged lettuce loses its quality over time and during its shelf time; two significant reasons of this quality loss are intensified browning and the damage to crispy texture. In an attempt to maintain quality indicators, various washing treatments were investigated in this study. According to the results, application of Calcium lactate + heat shock (50 °C) + hypochlorite + cysteine + ascorbic acid showed the highest effects on preserving antioxidant activity and total phenolic compounds of modified atmospheric packed lettuce during 12 days of cold storage. Evaluation of current treatments and procedures revealed that application of ascorbic acid and sodium hypochlorite was useful in maintaining most of the quality indicators. Combination of this treatment with cysteine is suggested due to maintenance of more phenolic compounds and providing more satisfaction of consumers.

Change history

29 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s11694-021-01073-8

References

R. Siddiq, R. Auras, M. Siddiq, K.D. Dolan, B. Harte, Effect of modified atmosphere packaging (MAP) and NatureSeal® treatment on the physico-chemical, microbiological, and sensory quality of fresh-cut d’Anjou pears. Food Packag. Shelf Life (2020). https://doi.org/10.1080/15538362.2020.1858470

N. Zamindar, Z. Ghorbani, L. Mosafa, Changes in the physicochemical and microbial properties of fresh-cut cucumber during storage as affected by modified atmosphere packaging and films of polypropylene containing clay nanoparticles. Iran JNutr Sci Food Technol 15(1), 83–92 (2020)

R. Esteban, J. Buezo, J.M. Becerril, J.I. García-Plazaola, Modified atmosphere packaging and dark/light refrigerated storage in green leafy vegetables have an impact on nutritional value. Plant Foods Hum. Nutr. (2019). https://doi.org/10.1007/s11130-018-0705-y

S. Paidari, S.A. Ibrahim, Potential application of gold nanoparticles in food packaging: a mini review. Gold Bull 54, 31–36 (2021)

H. Peng, J. Sthapit Kandel, R.W. Michelmore, et al., Identification of Factors Affecting the Deterioration Rate of Fresh-Cut Lettuce in Modified Atmosphere Packaging. Food Bioprocess Technol. 13, 1997–2011 (2020). https://doi.org/10.1007/s11947-020-02538-2

A. Bahrami, R. Delshadi, E. Assadpour, S.M. Jafari, L. Williams, Antimicrobial-loaded nanocarriers for food packaging applications. Adv. Colloid Interface Sci. (2020). https://doi.org/10.1016/j.cis.2020.102140

M. Tajkarimi, S.A. Ibrahim, Antimicrobial activity of ascorbic acid alone or in combination with lactic acid on Escherichia coli O157: H7 in laboratory medium and carrot juice. Food Control (2011). https://doi.org/10.1016/j.foodcont.2010.11.030

Z. Ghorbani, N. Zamindar, S. Baghersad, S. Paidari, S.M. Jafari, L. Khazdooz, Evaluation of quality attributes of grated carrot packaged within polypropylene-clay nanocomposites. J. Food Measur. Character. (2021). https://doi.org/10.1007/s11694-021-00925-7

M. Islam, Y. Lee, M. Mele, I. Choi, D. Jang, Y. Ko, Y. Kim, H. Kang, Effect of modified atmosphere packaging on quality and shelf life of baby leaf lettuce. Qual Assur. Safety Crops Foods (2019). https://doi.org/10.3920/QAS2019.1626

M.S. Daneshzadeh, H. Abbaspour, L. Amjad, A.M. Nafchi, An investigation on phytochemical, antioxidant and antibacterial properties of extract from Eryngium billardieri F Delaroche. J. Food Measur. Character. 14, 708–715 (2019)

R. Gyawali, Zimmerman, T., S.O. Aljaloud, S.A. Ibrahim, Bactericidal activity of copper-ascorbic acid mixture against Staphylococcus aureus spp. Food Control 111, 107062 (2020)

M. Moradi, S.A. Kousheh, R. Razavi, Y. Rasouli, M. Ghorbani, E. Divsalar, H. Tajik, J.T. Guimarães, S.A. Ibrahim, Review of microbiological methods for testing protein and carbohydrate-based antimicrobial food packaging. Trends Food Sci. Technol. (2021). https://doi.org/10.1016/j.tifs.2021.03.007

S. Paidari, H. Ahari, The effects of nanosilver and nanoclay nanocomposites on shrimp (Penaeus semisulcatus) samples inoculated to food pathogens. J. Food Measur.Characteriz. (2021). https://doi.org/10.1007/s11694-021-00905-x

W.J. Florkowski, S.E Prussia, R.L. Shewfelt, B. Brueckner, Postharvest handling: a systems approach. Academic Press (2009)

R. Hosseini, H. Ahari, P. Mahasti, S. Paidari, Measuring the migration of silver from silver nanocomposite polyethylene packaging based on (TiO 2) into penaeus semisulcatus using titration comparison with migration methods. Fish. Sci. (2017). https://doi.org/10.1007/s12562-017-1090-4

H. Ahari, G. Karim, S.A Anvar, S. Paidari, S.A Mostaghim, A.S. Mazinani, Method for producing antimicrobial nanofilms packaging cover based on titanium nano-dioxide through extrusion for extension of food shelf-life. Google Patents (2020)

D. Mousavian, A.M. Nafchi, L. Nouri, A. Abedinia, Physicomechanical properties, release kinetics, and antimicrobial activity of activated low-density polyethylene and orientated polypropylene films by Thyme essential oil active component. J. Food Measur. Character. (2021). https://doi.org/10.1007/s11694-020-00690-z

A.A. Kader, Postharvest technology of horticultural crops, University of California Agriculture and Natural Resources 3311 (2002)

M.D. Wilson, R.A. Stanley, A. Eyles, T. Ross, Innovative processes and technologies for modified atmosphere packaging of fresh and fresh-cut fruits and vegetables. Crit Rev Food Sci Nutr (2019). https://doi.org/10.1080/10408398.2017.1375892

M. Jokar, K. Loeschner, A.M. Nafchi, Modeling of silver migration from polyethylene nanocomposite packaging into a food model system using response surface methodology. Int. J. Food Eng. 2(2), 96–102 (2016)

C. Ghidelli, M.B. Pérez-Gago, Recent advances in modified atmosphere packaging and edible coatings to maintain quality of fresh-cut fruits and vegetables. Crit. Rev. Food Sci. Nutr. (2018). https://doi.org/10.1080/10408398.2016.1211087

H. Ahari, B. Fahimi, N. Sheikhi, A. Anvar, S. Paidari, Use of real-time PCR and high-resolution melting analysis for detection and discrimination of salmonella typhimurium and salmonella enteritidis in contaminated raw-egg samples. J. Food Biosci. Technol. 11(1), 59–68 (2021)

P. Qu, M. Zhang, K. Fan, Z. Guo, Microporous modified atmosphere packaging to extend shelf life of fresh foods: a review. Crit. Rev. Food Sci. Nutr. (2020). https://doi.org/10.1080/10408398.2020.1811635

T. Ohlsson, Minimal processing-preservation methods of the future: an overview. Trends Food Sci. Technol. (1994). https://doi.org/10.1016/0924-2244(94)90210-0

Y. Xing, X. Li, Q. Xu, Y. Jiang, J. Yun, W. Li, Effects of chitosan-based coating and modified atmosphere packaging (MAP) on browning and shelf life of fresh-cut lotus root (Nelumbo nucifera Gaerth). Innov. Food Sci. Emerg. Technol. (2010). https://doi.org/10.1016/j.ifset.2010.07.006

V.M. Moo-Huchin, Ac-Chim, D.M., Chim-Chi, Y.A., Rios-Soberanis, C.R., Ramos, G., Yee-Madeira, H.T., Ortiz-Fernandez, A., Estrada-Leon, R.J., Perez-Pacheco, E. Huaya (Melicoccus bijugatus) seed flour as a new source of starch: physicochemical, morphological, thermal and functional characterization. J. Food Measur. Characteriz. 14(6) (2020)

M. Mashabela, P.V. Mahajan, D. Sivakumar, Influence of different types of modified atmosphere packaging films and storage time on quality and bioactive compounds in fresh-cut cauliflower. Food Packag. Shelf Life (2019). https://doi.org/10.1016/j.fpsl.2019.100374

K.K. Gaikwad, S.M. Lee, J.S. Lee, Y.S. Lee, Development of antimicrobial polyolefin films containing lauroyl arginate and their use in the packaging of strawberries. J. Food Measur. Characteriz. 11(4), 1706–1716 (2017)

F. Moradinezhad, E. Ansarifar, M.M. Moghaddam, Extending the shelf life and maintaining quality of minimally-processed pomegranate arils using ascorbic acid coating and modified atmosphere packaging. J. Food Measur. Characteriz. (2020). https://doi.org/10.1007/s11694-020-00591-1

D. Rico, A.B. Martin-Diana, J. Barat, C. Barry-Ryan, Extending and measuring the quality of fresh-cut fruit and vegetables: a review. Trends Food Sci. Technol. (2007). https://doi.org/10.1016/j.tifs.2007.03.011

I. Luna-Guzmán, D.M. Barrett, Comparison of calcium chloride and calcium lactate effectiveness in maintaining shelf stability and quality of fresh-cut cantaloupes. Postharvest Biol. Technol. (2000). https://doi.org/10.1016/S0925-5214(00)00079-X

A. López, G.-A. Javier, J. Fenoll, P. Hellín, P. Flores, Chemical composition and antioxidant capacity of lettuce: comparative study of regular-sized (Romaine) and baby-sized (Little Gem and Mini Romaine) types. J. Food Compos. Anal. (2014). https://doi.org/10.1016/j.jfca.2013.10.001

A.B. Martin-Diana, D. Rico, J. Frias, G. Henehan, J. Mulcahy, J. Barat, C. Barry-Ryan, Effect of calcium lactate and heat-shock on texture in fresh-cut lettuce during storage. J. Food Eng. (2006). https://doi.org/10.1016/j.jfoodeng.2005.08.037Get

S. Kumar, A. Shukla, P.P. Baul, A. Mitra, D. Halder, Biodegradable hybrid nanocomposites of chitosan/gelatin and silver nanoparticles for active food packaging applications. Food Package. Shelf Life (2018). https://doi.org/10.1016/j.fpsl.2018.03.008

A.B. Martin-Diana, D. Rico, C. Barry-Ryan, J.M. Frias, J. Mulcahy, G.T. Henehan, Calcium lactate washing treatments for salad-cut Iceberg lettuce: Effect of temperature and concentration on quality retention parameters. Food Res. In. 38(7) (2005)

S. Singh, M. ho Lee, I. Park, Y.J. Shin, Y.S. Lee, Antimicrobial properties of polypropylene films containing AgSiO 2, AgZn and AgZ for returnable packaging in seafood distribution. Journal of Food Measurement and Characterization 10(4) (2016)

C. Choma, M. Guinebretiere, F. Carlin, P. Schmitt, P. Velge, P. Granum, C. Nguyen-The, Prevalence, characterization and growth of Bacillus cereus in commercial cooked chilled foods containing vegetables. J. Appl. Microbiol. (2000). https://doi.org/10.1046/j.1365-2672.2000.00998.x

K.K. Gaikwad, Y.S. Lee, Effect of storage conditions on the absorption kinetics of non-metallic oxygen scavenger suitable for moist food packaging. J. Food Measur. Characteriz. 11(3) (2017)

T. Gomes, T. Delgado, A. Ferreira, J.A. Pereira, P. Baptista, S. Casal, E. Ramalhosa, Application of response surface methodology for obtaining lettuce (Lactuca sativa L.) by-products extracts with high antioxidative properties. Indus. Crops Products (2013). https://doi.org/10.1016/j.indcrop.2012.09.011

C.C. Denardin, G.E. Hirsch, R.F. da Rocha, M. Vizzotto, A.T. Henriques, J.C. Moreira, F.T. Guma, T. Emanuelli, Antioxidant capacity and bioactive compounds of four Brazilian native fruits. J. Food Drug Anal. (2015). https://doi.org/10.1016/j.jfda.2015.01.006

D.M. Ni Eidhin, E. Murphy, D. O’Beirne, Polyphenol oxidase from apple (Malus domestica Borkh cv. Bramley’s Seedling): purification strategies and characterization. J. Food Sci. (2006). https://doi.org/10.1111/j.1365-2621.2006.tb12388.x

P. Delaquis, S. Stewart, P. Toivonen, A. Moyls, Effect of warm, chlorinated water on the microbial flora of shredded iceberg lettuce. Food Res. Int. 32(1) (1999)

A. King, J. Magnuson, T. Török, N. Goodman, Microbial flora and storage quality of partially processed lettuce. J. Food Sci. (1991). https://doi.org/10.1111/j.1365-2621.1991.tb05303.x

A. Altunkaya, V. Gökmen, Effect of various inhibitors on enzymatic browning, antioxidant activity and total phenol content of fresh lettuce (Lactuca sativa). Food Chem. (2008). https://doi.org/10.1016/j.foodchem.2007.09.046

Acknowledgements

Professor Seid Mahdi Jafari is warmly acknowledged for his scientific supports.

Author information

Authors and Affiliations

Contributions

All the authors contributed in acquisition of data, analysis, interpretation of data, drafting, and revising the article.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they hacve no conflict no interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article unfortunately contained a typographical error in the article title, first author name and affiliation of Dr. Mohammad Goli.

Rights and permissions

About this article

Cite this article

Leila, A., Nafiseh, Z., Samira, N. et al. Evaluation of the shelf life of minimally processed lettuce packed in modified atmosphere packaging treated with calcium lactate and heat shock, cysteine and ascorbic acid and sodium hypochlorite. Food Measure 15, 4438–4445 (2021). https://doi.org/10.1007/s11694-021-00991-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-00991-x