Abstract

The investigation aimed at optimizing the process conditions for the enzymatic extraction of apricot juice from Halman variety with pectinase enzyme. The study was conducted at different enzyme concentrations (0.2–1%), temperature (25–50 °C) and time duration (5–375 min). The effects of the enzymatic treatments on selected responses (juice yield, juice clarity, juice turbidity, total soluble solids (TSS), titratable acidity, ascorbic acid content, color index and pectin content) were determined employing a single factor experiment and response surface methodology (RSM) based on central composite rotatable statistical design (CCRD). The treatment effectively hydrolyzed polysaccharides, resulting in increased juice yield, total dissolved solids and juice lightness. The maximum juice recovery (73.06%), total soluble solids (12.9°Brix), clarity (94.76%) and lightness (L*) value (42.85) while minimum turbidity (3.95 NTU) and pectin content (0.59%), were obtained when enzyme treatment was set up with 0.9% w/w enzyme concentration at 44 °C and 300 min. The derived optimum conditions were used for the production of apricot juice of desirable quality in terms of physicochemical and antioxidant properties. Moreover, enzymatic process offers a number of advantages over mechanical-thermal comminution and thus, finds tremendous applications in modern fruit processing industries involving treatment of fruit masses. The process not only facilitates easy pressing and increase in juice recovery but also ensures the highest possible quality of end products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Apricot (Prunus armeniaca) is a temperate fruit that belongs to plant family Rosaceae. It is cultivated world-wide and consumed either fresh or after processing. It is a rich source of carbohydrates, minerals and vitamins. Carbohydrate concentration in fresh apricots ranges from 11–13% and provides 50 Kcals of energy per 100 g on fresh weight basis [1]. It is also rich in bioactive phytochemicals i.e. polyphenols and carotenoids that have certain roles in the biological system and effective in preventing oxidative stresses [2]. These compounds also confer colors to plant tissues and thus largely contribute to the visual quality of fruits. Apricot also carries a reasonable amount of dietary fiber in the range of 1.5–2.4 g/100 g on fresh weight basis [3]. Apricots contain varied amounts of essential minerals such as potassium, phosphorus, calcium, magnesium, iron and selenium [3], while sodium, manganese, zinc and copper are present in trace amounts [1]. Similarly, the vitamins found in apricot are pro- vitamin A, vitamins C, K, E, thiamine (B1), riboflavin (B2), niacin (B3), pyridoxine (B6), folic acid (B9) and pantothenic acid [4]. Apricot contains organic acids i.e. malic acid (500–900 mg/100 g) and citric acid (30–50 mg/100 g) as the major acids [5]. The average range of protein and fat content in apricot fruit is 1.4–2.0% and 0.4–0.6%, respectively [1].

Owing to its bioactive components of pharmacological importance, it has been found effective against chronic gastritis, oxidative intestinal damage, hepatic steatosis, atherosclerosis, coronary heart disease and tumor formation [6]. India ranks 35th in the world apricot production with Ladakh (Leh and Kargil districts) being the major apricot producing region, followed by Himachal Pradesh [7]. Since large varieties of apricot are grown around the world but Halman variety is usually preferred because of its large fruit size and pulp yield besides having better organoleptic properties [8].

Apricot is a highly perishable fruit with moisture content ranging from 80–86% and a shelf life of only 2–5 days under ambient conditions [9]. The high perishability of apricot reduces its physical and organoleptic attributes and thus limits its end use. Thus, it is imperative to reduce post-harvest losses of the crop and facilitate its value addition [10]. The utilizable lifespan of the crop can be prolonged by converting it into value added product. Extraction of fresh fruit juice from apricot pulp (Halman var.) thus seems to be a beneficial approach that could be an innovative value addition to the crop. However, the higher concentration of structural components like pectin, pectin–protein complexes in its pulp hampers the juice extraction process. As such, there is a need for extraction of juice with high degree of clarification that will result in elevated juice quality. Juice extraction can be done by various mechanical means [11] however, these methods of fruit juice extraction are less efficient and such techniques involve excessive amounts of energy and result in lower juice yields [12]. Enzymatic treatment, prior to mechanical extraction, not only facilitates pressing and juice recovery, but also ensures the highest possible quality of the end product [11]. The use of pectinolytic enzymes like pectinases aid in the liquefaction of fruit pulp and juice extraction [13]. These enzymes hydrolyze pectic substances and aid in the flocculation of suspended particles and clarification of juices. This results in the production of fruit juices with higher total soluble solids (TSS), total sugars, acidity and color. Moreover, enzyme assisted juice extraction process is critical for maximizing the juice yield and retaining the organoleptic characteristics of the prepared fruit juices. The time required for pectinolytic liquefaction of fruit pulps depends on the type of fruits, type of enzyme, enzyme concentration and incubation temperature [14]. The determination of the optimum levels of enzyme extraction process parameters (enzyme concentration, incubation temperature and incubation time) is an important aspect in this regard. Moreover, no such study has been carried out wherein the pectinases have been used for the enzymatic extraction of apricot juices.

Keeping all these things into consideration, investigation was undertaken to optimize the conditions for the pectinolytic liquefaction of apricot pulp for juice extraction using response surface methodology (RSM). This methodology is an affective statistical technique for optimizing complex processes as it reduces the number of experimental trials needed to evaluate multiple parameters and their interactions. It is less laborious and time-consuming than other approaches and can be successfully used for optimizing operational parameters [15].

Materials and methods

Procurement of fruit pulp

The fresh apricot pulp (Halman Var.) was procured from Kargil region of Ladakh, India.

Apricot juice extraction and clarification process

Fresh sample of apricot pulp was treated with different concentrations of pectinase for extraction and clarification of juice at varied incubation temperature and time as per the experimental combinations (Table 1). The process flowsheet for the extraction of apricot juice from pulp is given in Fig. 1. Apricot juice, to which pectinase enzyme was not added, was taken as control.

Experimental design and process optimization

Central composite rotatable design (CCRD) was used to investigate the effects of three independent variables: enzyme concentration (A), incubation temperature (B) and incubation time (C) on various dependent variables (juice yield, juice clarity, turbidity, total soluble solids, titratable acidity, ascorbic acid, instrumental color and pectin content). The experimental ranges of the independent variables along with their respective coded levels are presented in Table 1. To fit the experimental data for each response of the dependent variables, second order polynomial models were developed using Statistical Software Design Expert 12 (Stat Ease Inc., Minneapolis, MN, USA). For analysis of the data, multiple regression models were used and the statistical significance of each response was tested using analysis of variance (ANOVA). Response surface of desirability function was applied for the optimization of apricot juice clarification process and the optimum condition criteria were used to maximize juice yield, clarity, TSS, acidity, ascorbic acid and color and to minimize the turbidity and pectin content.

Determination of product responses

Juice yield (JY)

The juice yield was calculated using Eq. (1) as reported by Akesowanand and Choonhahirun [16],

Juice clarity (JC)

The clarity of the juice was determined by transmittance (%T) at 660 nm [17].

Juice turbidity (JT)

Turbidity was determined using portable Turbidimeter (2100 AN – HACH Company). The results were reported as Nephelometric Turbidity Units (NTU).

Total soluble solids (TSS)

Total soluble solids (TSS) were determined using an Abbe Refractometer (RSRT-1) following the procedures as described by AOAC [18].

Titratable acidity (TA), ascorbic acid (AA) and pectin content (PC)

Titratable acidity was determined by the procedure as described by Barret et al. [19], and was expressed as percentage citric acid. Ascorbic acid was determined by titration with a 2, 6-dichlorophenolindophenol sodium salt solution as described by AOAC [20]. Total pectin was evaluated according to the method described by Kulkarni and Vijayanand [21].

Instrumental color (L*, a*and b*)

The Hunter Colorimeter (SN3001476, Accuracy Micro-sensors, New York) was used for measurements of color values- lightness (L*), redness (a*) and blueness (b*) of juice following the procedures followed by Rai et al. [17].

Proximate analysis of pectinase enzyme extracted apricot juice

The apricot juice produced using optimization process conditions was evaluated for the following parameters:

Proximate composition

Moisture, crude protein, crude fat, crude fiber and ash content of control and enzymatically extracted apricot juice (EEAJ) were performed following the standard procedures of AOAC [22].

Carbohydrate content was calculated using an Eq. (2),

Energy value was determined by multiplying the percentages of protein, fat and carbohydrate by 4, 9 and 4, respectively.

Total, reducing and non-reducing sugars

Total and reducing sugars in the samples were determined using Lane and Eynon method [23]. Non-reducing sugars were determined by subtracting reducing sugars from total sugars.

pH, TSS, titratable acidity, TSS/acid ratio and ascorbic acid content

pH values were measured using pH-meter (Inolab WTW Series, Germany) according to the protocols of AOAC [23]. TSS was determined by Abbe Refractometer (RSRT-1). TSS/acid ratio was determined as the ratio of oBrix (TSS) and the acid content of juice. Titratable acidity (as citric acid) and ascorbic acid content were determined following the procedures of AOAC [23].

Total carotenoids

Total carotenoids were determined by following the procedures of Kimura, Rodriguez and Amaya [24].

Water activity

Water activity (aw) was estimated using water activity meter (Pre-Aqua Lab, Water Activity Analyzer, Decagon Devices Inc., Pullman, Wash., USA).

Mineral content

Mineral content of apricot juice was determined according to AOAC procedures [25].

Antioxidant activity

DPPH assay

DPPH assay of apricot juice was determined spectrophotometrically according to the protocols of Amin et al. [26] which involved the use of free radical, 1.1-diphenyl-2-picrylhydrazy (DPPH). Briefly, 80 μL of the sample extract was mixed with 200 μL of 0.05%DPPH· in a total volume of 4-mL methanol and allowed to react in the dark for 30 min. Then, the absorbance was read at 515 nm using a spectrophotometer (Hitachi U-2900) and the results were expressed as percent inhibition.

Ferric reducing antioxidant power assay

The ferric-reducing antioxidant power (FRAP) was estimated following the method outlined by Yang, Guo, and Yuan [27]. 1 mL of antioxidant solution (0.5 mL of fruit extract mixed in 0.5 mL of water) was mixed with phosphate buffer (2.5 mL, 0.2 M, pH 6.6) and K3Fe(CN)6 (2.5 mL, 30 mM). The mixture was incubated at 50 °C for 20 min, after which trichloroacetic acid (2.5 mL, 0.6 M) was added to terminate the reaction followed by centrifugation step (10 min, 5000 rpm). From the upper layer, 2.50 mL of solution was then removed and mixed with FeCl3 (0.5 mL) and left to incubate for another 10 min. Formation of ferrous ions (Fe2+) was measured spectrophotometrically at 700 nm, with higher absorbance values indicative of greater reducing capacity of ferric (Fe3+) to ferrous (Fe2+) ions. All the samples were run in triplicate. Moreover, blanks (control) were also run in parallel with their absorbance values subtracted from those of the samples.

Total phenolic content

Total phenolic contents (TPC) of the samples were estimated according to the method of Amin et al. [26].

Besides the above parameters, pectin and juice yield were determined, the procedures of which are already explained in previous section.

Statistical analysis

For each experimental condition, all of the readings were taken three times and the mean values were reported. General linear model (GLM) procedure of SPSS Statistics (V. 16, Inc., Chicago, IL) was used to analyze the data. The difference between the means was determined using Duncan’s multiple range test (p < 0.05).

Results and discussion

Fit of models

Analysis of variance (ANOVA) given in Table 2 indicates that the models developed for all the product responses (juice yield, clarity, turbidity, TSS, titratable acidity, ascorbic acid, instrumental color and pectin) were significantly (p < 0.05) affected by independent variables viz. enzyme concentration (A), incubation temperature (B) and incubation time (C). The coefficient of determination computed for all the selected parameters were highly desirable (R2 ranged between 0.7797 and 0.9760), which indicates the reasonable fit of empirical models with actual data. The predicted and adjusted R2 values for all the product responses were in sound agreement with each other. In addition, the lower coefficient of variation (% CV) obtained for all the models confirms accuracy, reliability and reproducibility of results. Models for all the parameters (juice yield, clarity, turbidity, TSS, titratable acidity, ascorbic acid, instrumental color and pectin) showed non-significant lack of fit which indicates that the second order polynomial models correlated well with the measured data. Adequate precision computed for the models of all parameters were much higher than 4, which indicates highly desirable validation of models.

Effect of process parameters on product responses

Effect of enzyme extraction on juice yield (JY)

From economic point of view, juice yield is an important aspect in extraction process. The juice yield (JY) ranged between 52 and 74.55% as shown in Table 3.The regression equation obtained for JY is given below as Eq. (3),

where, A is the enzyme concentration, B is the incubation temperature, and C is the incubation time.

From the regression Eq. (3), it was evident that all of the independent variables significantly (p < 0.05) affected JY (Fig. 2a). The positive coefficients of linear terms of enzyme concentration (A), incubation temperature (B) and incubation time (C) implied the increase in JY with increase in enzyme concentration (A), incubation temperature (B) and incubation time (C). The increase in JY with increase in enzyme concentration is due to the enzyme hydrolysis of protopectin and formation of water soluble pectin [28]. Similar results were also obtained by Diwan and Shukla [29] in guava juice. The significant (p < 0.05) positive effect of incubation temperature (B) and incubation time (C) on JY could be due to an increased enzyme activity at optimum temperature and time. High temperature enhances the molecular motion, which results in faster reaction rate [30]. The interactive effect of all the independent variables was significant (p < 0.05) and a significant (p < 0.05) positive interactive effect was shown by enzyme concentration and incubation temperature (Eq. 3). This might be due to the action of enzyme on pectic substances of pulp, resulting in hydrolysis of these substances thus, releasing dissolved material within an optimum temperature range.

The positive interactive effect of enzyme concentration (A) and incubation time (C) can be ascribed to the prolonged exposure of enzymes to substrate, resulting in an increased juice recovery. Incubation temperature (B) and incubation time (C) also increased enzyme activity possibly by increasing the kinetic energy within molecules. However, at extreme temperature and time, the enzyme denatures, resulting in decreased JY. The findings of Zhang et al. [31] corroborate well with results of the present study wherein a curvilinear increase in juice recovery with increase in α-amylase dosage and hydrolysis time has been reported.

From the regression Eq. (3), it was further evident that the linear effect of incubation period (C) was dominant amongst all the three independent variables viz. enzyme concentration (A), incubation temperature (B) and incubation time (C).

Effect of enzyme extraction on juice clarity (JC)

The enzyme assisted juice extraction process resulted in the production of juice with better clarity, concentrated flavor and color, thereby increasing its overall acceptability. Enzymatic extraction of juice reduces viscosity and cluster formation, which enhances the separation during centrifugation or filtration processes [32]. The juice clarity (JC) of EEAJ ranged between 55 and 95% T as shown in Table 3. The regression Eq. (4) obtained for juice clarity is given below,

where, A is the enzyme concentration and C is the incubation time.

From the regression Eq. (4), it is observed that increase in enzyme concentration (A) and incubation time (C) enhanced JC (Fig. 2b). The increase in enzyme concentration causes degradation of pectin and protein molecules thereby increasing the rate of clarification by exposing part of the positively charged protein beneath. This reduces electrostatic repulsion between cloud particles thus causing them to aggregate into larger particles and eventually settle out thereby, enhancing JC [33]. The incubation time (C) greatly affected the JC. Sin et al. [33] also observed the significant influence of incubation time (B) and enzyme concentration (A) on juice clarity while studying the liquefaction of sapodilla and mango pulp.

Effect of enzyme application on juice turbidity (JT)

Turbidity is one of the major problems in fruit juices due to the presence of pectins and the fibrous molecular structures associated with it that lead to haziness in fruit juices [34]. For high quality juices, turbidity values must be as low as possible. Turbidity may decrease due to the action of pectinase on pectin layers encapsulating the protein core of proteinaceous pectin particles in suspension. The turbidity values of EEAJ ranged between 2 and 9 NTU as shown in Table (3). The regression Eq. (5) obtained for JT is given below,

where, A is enzyme concentration and C is the incubation time.

From the regression Eq. (5), it was observed that the negative coefficients of interactive terms of incubation temperature (B), and incubation time (C) implied an inverse relation with turbidity (Fig. 2c). The negative quadratic effects of enzyme concentration (A2) and incubation time (C2) on turbidity explains that the excessive enzyme concentration with prolonged time reduces the turbidity of juice by exposure of positive nucleus sites to surrounding negative charges where large protein-pectin clusters are formed [35]. Further, long exposition of pectin to high enzyme concentrations are likely to break down pectic substances, exposing positive nucleus sites to surrounding negative charges, settling out the so formed large protein-pectin particles [35] thus decreasing turbidity. Similar results were also obtained by Marcelo et al. [36] and Saxena et al. [37] for caja-mango pulp and watermelon juice, respectively.

Effect of enzyme treatment on total soluble solids (TSS)

TSS in fruit juice reflects the amount of soluble constituents like sugars, carbohydrates and proteins [37]. TSS of EEAJ ranged between 11.39 and 13.4 B as shown in Table 3. The regression equation obtained for TSS is given below as Eq. (6),

where, A is enzyme concentration, B is incubation temperature and C is incubation time.

From the regression Eq. (6), it was observed that the enzyme concentration (A), incubation temperature (B) and incubation time (C) showed a significant (p < 0.05) positive effect on TSS (Fig. 2d). A significant (p < 0.05) positive linear effect exhibited by enzyme concentration (A), incubation temperature (B) and incubation time (C) and significant (p < 0.05) positive quadratic effect of incubation time (C2) might be due to the action of enzyme on pectic substances of juice pulp, causing hydrolysis of these substances and release of dissolved material [37]. The results of this study were in close agreement with the observations of Shah [38] wherein the enzyme-assisted process for extraction and clarification of juice from litchis has significantly led to higher TSS.

Effect of enzyme treatment on total titratable acidity (TTA)

TTA (as citric acid) of EEAJ ranged between 0.59 to 0.73% (Table 3). The regression Eq. (7) obtained for TTA is given below,

where, A is enzyme concentration and B is incubation temperature.

From the regression Eq. (7), it was concluded that there was a positive significant linear effect of enzyme concentration (A) and incubation time (C) on TTA (Fig. 2e). Pectinases act on protenacious pectin matrix, resulting in the release of carboxylic and galactouronic acid monomers, leading to the development of higher acidity in juice [39]. Similar results were also observed by Akesowan and Choonhahirun [16] for enzymatically extracted guava juice.

Effect of enzyme application on ascorbic acid (AA)

Ascorbic acid (vitamin C) has a high bioavailability and is consequently one of the most important water-soluble antioxidants capable of scavenging reactive oxygen species such as hydroxyl and peroxyl radicals and singlet oxygen [40]. AA of EEAJ ranged between 6.04 to 6.8 mg/100 g (Table 3). The regression equation obtained for AA is given as Eq. (8),

where, B is the incubation temperature. From regression Eq. (8), a significant negative linear effect of incubation temperature (B) on ascorbic acid could be observed (Fig. 2f). Ascorbic acid undergoes oxidative degradation during thermal treatment [41], thereby leading to a decrease in ascorbic acid with increase in incubation temperature.

Effect of enzyme application on color (L*, a* and b*)

Color is an important quality attribute in food as it influences the consumer’s choice and preferences [42]. From consumer’s point of view, high values of lightness (L*) is desirable for clarified juice. L* values of EEAJ ranged between 34.85 and 44.72, and redness (a*) and blueness (b*) ranged between -0.21 and- 2.98 and 24.05 and 42.09, respectively as shown in table (3). The regression Eqs. (9), (10) and (11) obtained for L*, a* and b* values are given below,

where, A is enzyme concentration, B is incubation temperature and C is incubation time.

From regression Eq. (9), it can be concluded that the increase in enzyme concentration (A) and incubation time (C) increased L* value (Fig. 2g). Enzymes breakdown the structural tissues, releasing those components which possess color thereby resulting in increase in lightness (L*) [32]. Similar results were also reported by Ghosh et al. [28] for jamun juice. Furthermore, with the increase in enzyme concentrations (A), incubation temperature (B) and incubation time (C), a* decreased (Fig. 2h). Additionally, all the three independent variables (enzyme concentration, incubation temperature and incubation time) had a positive linear effect on b* value (Fig. 2i). The more the positive value, more is the original color of apricot juice. The inverse results for a* and b* values were obtained by Ghosh et al. [28] for jamun juice.

Effect of enzyme treatment on pectin content (PC)

Pectolytic enzymes hydrolyze pectic substances that are present in the fruit, so the resulting juice has a much lower amount of pectin [43]. The enzymes not only help in softening the tissue but also lead to the release of cell contents as well. Pectin content of EEAJ ranged between 0.59 and 0.80% as shown in Table 3. The regression Eq. (12) obtained for PC is given below

From regression Eq. (12), it was evident that the enzyme concentration (A) and incubation temperature (B) showed a negative significant linear effect on pectin content (Fig. 2j). Enzymatic treatment resulted in a decrease in pectin content and consequently, the decrease in the viscosity [44]. Pectinases degrade the pectin chain at an optimal incubation time and temperature, thus exposing positively charged proteins. The electrostatic interaction between pectin and the protein components results in the aggregation of these particles and hence settle down thereby reducing the pectin content in the obtained juice [45]. The enzymatic treatment led to the degradation and solublization of insoluble materials (pectin, hemicelluloses and some cellulosic materials) from fruit cell wall, resulting in increased juice yield [46]. With increase in enzyme concentration (A) and incubation temperature (B), hydrolysis of complex polysaccharides increased due to the formation of simpler substances, thus reducing pectin content.

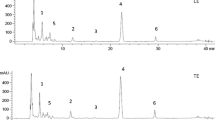

Optimization and model validation

For the optimum formulation, the final condition would be considered optimum if the juice yield, TSS, titratable acidity, clarity, ascorbic acid and L* value were as high as possible while turbidity, and pectin content were as low as possible. According to the optimized-dependent parameters, concentration of enzyme will be 0.9% (w/v), the incubation temperature (B) should be 44 °C with 300 min as the incubation time. The predicted response values and the actual obtained response values were within 4% of the predicted values (Fig. 3) (Table 4). At the optimized condition, product responses were juice yield: 73.06%; clarity: 94.76% T; turbidity: 3.95 NTU; TSS:12.9°B; titratable acidity: 0.71%; ascorbic acid: 6.08 mg/100 g; L* value: 42.85; a* value: -2.95; b* value: 38.32; and pectin content: 0.59%.

Physicochemical properties of enzymatically extracted apricot juice (EEAJ)

Proximate composition

The proximate composition of control and enzymatically extracted apricot juice (EEAJ) are presented in Table 5. A significant (p < 0.05) decrease in carbohydrate, protein, energy value, pH and phenolic content was observed in EEAJ while as there was no significant (p < 0.05) change in fat and ash contents. The percentage moisture content of EEAJ (85.07 ± 0.20%) was significantly (p < 0.05) higher than control (83.01 ± 0.01%) due to the breakage of glycosidic bond in pectin by two different mechanisms viz. hydrolysis, with the introduction of water across the oxygen bridge and the transelimination lysis [43]. The crude protein content of control was 1.06 ± 0.02%, which decreased significantly (p < 0.05) in enzymatically extracted juice (0.98 ± 0.01%). The reduction in protein content is attributed to the breakdown of pectin–protein interactions by pectinase enzyme [47]. A significant (p < 0.05) decrease in crude fiber (1.08 ± 0.05%) was observed after enzymatic extraction which is due to solubilization and degradation of insoluble materials like cellulosic and hemicellulosic components [41]. The carbohydrate content of control was 13.69 ± 0.02% and it reduced significantly (p < 0.05) to 12.61 ± 0.03% after an enzymatic clarification process. The polysaccharides and colloidal materials present as solid materials in juices form gels thus, accumulate on the filter surface during filtration thereby, reducing their respective contents [48]. The energy values of control and the EEAJ were found to be 63.14 ± 0.02 Kcals/100 g and 58.50 ± 0.03 Kcals/100 g, respectively. A significant (p < 0.05) decrease in energy value of juice after enzymatic treatment may be due to the lower values of carbohydrate and protein contents in the clarified juice.

Water activity (aw) of control (0.96 ± 0.02) was significantly (p < 0.05) lesser than that of EEAJ (0.98 ± 0.01). This increase in water activity in EEAJ is attributed to pectin degradation that led to the reduction in water holding capacity of pectin and release of unbound free water in the system after enzyme extraction [41].

Juice yield and pectin content

The percentage juice yield of control and EEAJ samples was 66.38 ± 0.02% and 71.45 ± 0.03%, respectively (Table 5). The significant (p < 0.05) increase in juice yield after enzyme treatment may be due to hydrolysis of the protopectin by pectinase and formation of water soluble pectin thereby releasing more juice from the structural network [43].

There was a significant (p < 0.05) decrease in pectin content in EEAJ (0.57 ± 0.025%) in comparison to control (0.75 ± 0.02%). This is due to pectinase aided hydrolysis of polygalacturonic acid chain via break down of α-1,4 glycosidic bond and hydrolysis of methoxy group of pectin chain [49].

Few parameters like juice yield, pectin, TSS, titratable acidity and ascorbic acid have been explained two times just to indicate that these parameters were kept as dependent variables in optimization process and were also characterized for final product i.e. pectinase enzyme assisted apricot juice.

Reducing, non-reducing and total sugar

The amount of natural sugars like glucose and fructose in EEAJ (11.13 ± 0.01%) were significantly (p < 0.05) higher than the control (10.59 ± 0.01%) (Table 5). A significantly (p < 0.05) higher amount of reducing sugar in EEAJ (9.09 ± 0.05%) than control is attributed to the action of pectinase (polygalacturonases and pectin lyases) enzymes on the polygalacturonic chains as well as hydrolysis and inversion of the non-reducing sugars. Similar results were reported by Fang et al. [50] in passion fruit, where the concentration of reducing sugars (fructose and glucose) increased over time while that of non reducing sugars like sucrose decreased.

TSS, titratable acidity and pH

TSS of control and EEAJ were 11.73 ± 0.3% and 12.20 ± 0.02%, respectively (Table 5). A significant (p < 0.05) increase in TSS after enzymatic extraction is related to greater degree of tissue breakdown, releasing more compounds such as sugars and soluble components and the conversion of insoluble pectin by pectinolytic enzymes to produce soluble sugars [41].

The titratable acidity of control and EEAJ was 0.72 ± 0.01% and 0.74 ± 0.02%, respectively. A significant (p < 0.05) increase in titratable acidity is due to the hydrolysis of proteinacious pectin matrix with the release of carboxylic and galactouronic acid monomers [51].

pH value of control was 3.78 ± 0.03 and it decreased significantly (p < 0.05) after the enzymatic extraction (3.67 ± 0.02%), which is due to de-esertification of highly methylated pectin molecules [51]. Similar results have also been reported in case of date syrup by Abbes et al. [52].

Carotenoid and ascorbic acid

A significant (p < 0.05) increase in carotenoid content was observed in enzymatically treated juice (Table 5), which is due to the release of pigments by pectinase thereby, releasing carotenoids from the cell wall [53]. Similar findings were also reported in apple pomace by Joshi et al. [54]. The concentration of ascorbic acid in control and EEAJ was found to be 6.32 ± 0.01 mg/100 g and 5.89 ± 0.02 mg/100 g, respectively. The amount of ascorbic acid was significantly (p < 0.05) lower in EEAJ possibly due to the less thermal stability of ascorbic acid structure that makes it more prone to oxidative reactions [55].

°Brix/acid ratio

EEAJ had a significantly (p < 0.05) higher °Brix/acid ratio (16.48 ± 0.02) than control (16.29 ± 0.05), which might be due to more increase in TSS than titratable acidity of EEAJ [54]. Similar findings were also reported in grape juice by Aponso et al. [56].

Mineral content

Amongst the minerals, a significantly (p < 0.05) higher amount of sodium was found in EEAJ (Table 5), possibly due to an increase in the movement of sodium from the cells [57].

Antioxidant activity

The antioxidant activity (DPPH and FRAP) increased significantly (p < 0.05) after the enzyme treatment, which may be ascribed to the enhanced extraction of the antioxidants (phenols and carotenoids) from the cellular cytoplasm. Pectinase facilitated the degradation of the middle lamella of cell wall and primary wall, thereby releasing polyphenolic compounds and carotenoids located in cells. Since these bioactive components possess antioxidant activity, therefore, their increase in EEAJ may have improved the antioxidant potential [58]. Similar findings were reported by Zuniga-Hansen and Laroze [59] in raspberry.

Conclusion

From the systematic study of the variation in the operating variables and measurement of the dependent properties, response functions were established employing an appropriate statistical analysis. Using response surface methodology and contour plots, the optimum set of the operating variables are obtained graphically in order to obtain the desired levels of the properties of the apricot juice. The methodology of the experimental design was shown to be very useful for the evaluation of enzyme (pectinase) hydrolysis for apricot juice clarification. The different conditions (enzyme concentration, incubation temperature and time) for enzyme treatment revealed that all these variables markedly affected the different physical parameters (juice recovery, clarity, turbidity, TSS, acidity, ascorbic acid, color and pectin). The optimum processing conditions for pectinase assisted extraction of quality juice were 0.90% enzyme concentration, 44 °C incubation temperature and 300 min incubation time. Moreover, pectinase assisted juice extraction process had a positive impact on the nutritional profile and yield of apricot juice compared to control. Production of pectinase assisted high quality apricot juice, both in terms of yield and nutritional value, is believed to increase its consumption very promptly in future which endeavors to promote and improve its production to make it competitive for both domestic demand and export markets.

References

USDA, United States Department of Agriculture.Database for Flavonoid Content of Selected Foods. (2007).

R.V. Leccese, S. , Bartolini. Central Eu. J. Bio. 6(2), 199–204 (2011)

S. Ali, T.Masud, K.S.Abbasi K (2011) Scientia Horti. 130(2): 386–392.

H. Haciseferogullari, I. Gezer, M.M.Ozcan, B. Murat Asma, J. Food Eng., 79(1), 364–373 (2007).

F. Gurrieri, J.M. Audergon, G. Albagnac, M. Reich, Euphytica 117, 183–189 (2001)

T. Fatima, O. Bashir, G. Gani, T. Bhat, N. Jan, Int. J. Unani and Int. Med 2(2), 05–09 (2018)

FAO Food and Agriculture Organization, United Nations (Apricot. FAO STAT, Agriculture Statistics, 2019).

L. Stanzin, S. Lobzang, L. Padma, D. Stanzin, Int. J. Current Microbio App. Sci. 7(3), 1001–1005 (2018)

F. Akinci, A. Ozdemir, O. Topuz, M. Kabas, Kanakc. J Food Eng. 65, 325–331 (2004)

M. Ratikant,K.T. Ashok, G.Anil, M.Debasish, Res. Trends in Biores. Mang. and Technol., 137–166 (2018).

H.P. Sharma, H. Patel, S. Sharma, Trends in Post-Harvest Technology 2, 1–14 (2014)

V.K. Joshi, S.K. Chauhan, B.B. Lal, J. Food Sci. and Technol. 28(1), 64–65 (1991)

S.K. Chauhan, S.M. Tyagi, D. Singh, Int. J. Food Prop. 4(1), 103–109 (2001)

R. Rajanala, S.M. Tyagi, G.S. Chauhan, Beverage Food World 23(4), 28–29 (1996)

GCMO. Eimear, AGM Berain, EKA Scannell (2003) J. Food Eng 56(2–3): 269–271

A.Akesowanand, A.Choonhahirun, J. Animal and Plant Sci., 23(1), 114–120. (2013)

P. Rai, C. Rai, G.C. Majumdar, S. Dasgupta, S. De, J Membrane Sci 283, 116–122 (2006)

AOAC,. Official Method of Analysis. 16th ed. Association of Official Analytical Chemists, Washington D.C (1995)

D.M. Barrett, C. Weakley, J.V. Diaz, M. Watnik, J. Food Sci. and Technol. 72, C441–C451 (2007)

AOAC, Official Method of Analysis. 18th ed. Association of Official Analytical Chemists, Washington D.C, USA, (2005).

Kulkarni.S.G,Vijayanand.P, LWT Food Sci. andTechnol.,43(7),1026–31(2010)

AOAC, Official Method of Analysis, 18th edn. (Association of Official Analytical Chemists, Maryland, USA, 2006).

AOAC, Association of Official and Analytical Chemists (Official methods of analysis Washington, DC, 2012).

D.B. Rodriguez-Amaya, A Guide to Carotenoid Analysis in Foods (ILSI Press, Washington, 1999).

AOAC. Official Methods of Analysis, 17th Ed Association of Official Analytical Chemists, Arlington, USA, (2000)

T. Amin, H.R. Naik, S.Z. Hussain, A. Jabeen, M. Thakur, Food Meas. charact. 12, 182–190 (2018)

J. Yang, J. Guo, J. Yuan, LWT Food Sci. and Technol. 41, 1060–1066 (2008)

P. Ghosh, R.C. Pradhan, S. Mishra, J. Food Process Eng. 40(2), 12414 (2016)

S. S.Diwan and Shukla (2006) J. Food Sci. and Technol.,42(3): 245–249

S. Deepali, S. Latha, K.C. Subir, S. Dheer, J Food Sci. and Technol. 51(10), 2490–2498 (2013)

H. Zhang, Z. Wang, S.Y. Xu, 80(4), 1226–1232 (2007).

G.L. Abdullah, N.M. Sulaiman, M.K. Aroua, M.N.M.J. Megat, J. Food Eng 81, 65–71 (2007)

H.N. Sin, S. Yusof, S.A. Hamid, R. Rahman. J. Food Eng. 73, 313–319 (2006)

S. Sevda, A. Singh, C. Joshi, L. Rodrigues, Am. J Food Technol. 7(6), 326–339 (2012)

D.R. Kashyap, Biores. Technol 77, 215–227 (2001)

M. Andres, R. Rebeca, S. Ellen, M. Natalia, S. Roberto, G.Eleni, C.JoãoCláudio, Food Sci. and Technol., 31(2) ( 2011)

D. Saxena, L. Sabikhi, S.K. Chakraborty, D. Singh, Journal of Food Science and Technology 49, (2012)

N. Shah, Int. J. Food Eng. 3(3), 1–17 (2007)

S. Tadakittisarn, V. Haruthaithanasan, P. Chompreeda, T. Swonsichon, kasetsart. J. Nat. Sci. 41(4), 740–750 (2007)

R.Sumati, Mudambi,M.V. RajagopalFundamentals of foods and nutrition, Fourth Edition,135. ,(2003).

P. Arsad, R. Sukor, W. Z. Wan Ibadullah, N.A.Mustapha, A.S.Meor Hussin, Int. J. Adv. Sci.Eng, 5(5). (2015).

P. Nisha, R.S. Singhal, A.B. Pandit, Food and Bioprocess Technol. 4, 781–787 (2011)

W.C. Lee, S. Yusof, N.S.A. Hamid, B.S. Baharin, J Food Eng. 73, 55–63 (2006)

D. Vaidya, M.J. Vaidya, S. Sharma, Nat. Pdt. Rad. 8(4), 380–385 (2009)

V. Sorrivas, D.B. Genovese, J.E. Lozano, J. Food process. and presv. 30, 118–133 (2006)

M.F. Ramadan, J.T. Moersel, J. Sci. of Food and Agric. 87, 452–460 (2007)

E.F.Torres, C. Aguilar, J.C.C. Esquivel, G.V. Gonzalez, Enzyme Technol. 273–29 (2005).

K.S. Youn, J.H. Hong, D.H. Bae, S.J. Kim, S.D. Kim, J. Membrane Sci. 228, 179–186 (2004)

P. Rai, S. De, Current Sci. 96(10), 1361–1371 (2009)

Y.Z.Fang, S.Yang, G.Y Wu,. Nutr 18, 872–879. ,(2002)

L.Chi, Nguyen, & Ha, V. H. Nguyen (2018) Beverages, 4(2): 41.

F.Abbes, M.A.Bouaziz, C. Blecker, M.Masmoudi, , H.Attia, ,S. Besbes,S, LWT - Food Sci and Technol, 44, 1827–1834. (2011)

J. Oszmianski, A. Wojdylo, J. Kolniak, Food Chem. 127, 623–631 (2011)

V.K. Joshi, M. Parmar, N. Rana, Ind. J. Nat. Prod. and Res. 2(2), 189–197 (2011)

N.C.Igwemmar,S.A. Kolawole, I.AImran, Int. J.Sci. & Technol., 2277–8616 (2013).

M. Aponso, U. Marapana, R. Manawaduge, Eu. J. Acad. Essays 4(4), 165–174 (2017)

J. Carcel, J. Benedito, N. San-Juan, E. Sanchez, Alimentacion. Equipos Tecnology 17, 135–141 (1998)

G. Durmaz, M. Alpaslan, Food Chem. 100, 1177–1181 (2007)

M.E. Zuniga-Hansen, L. Laroze, New Biotechnol. 25, S170 (2009)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bashir, O., Hussain, S.Z., Gani, G. et al. Evaluating the physicochemical and antioxidant characteristics of apricot juice prepared through pectinase enzyme-assisted extraction from Halman variety. Food Measure 15, 2645–2658 (2021). https://doi.org/10.1007/s11694-021-00833-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-00833-w