Abstract

Pomegranate is a berry fruit that has attracted a lot of attention since, besides its appetizing taste, it confers important health benefits when consumed. Pomegranate derivatives such as seeds are also an excellent nutritional source of bioactive components and functional lipids. The present study aimed to evaluate the influence of microwave-assisted and ultrasound-assisted extractions, under different extraction parameters (temperature, extraction time, solvent to sample ratio) for the recovery of the highest amount of pomegranate seed oil. There were not significant differences between the obtained oil yields for microwave-assisted and ultrasound-assisted extractions (18.38 and 17.64%, respectively). For both methods, temperature and solvent to sample ratio exerted the main influence on pomegranate seed oil extraction yield, whereas extraction time only affected microwave-assisted extraction. Based on the obtained results and considering economic issues, the best treatment was using ultrasound-assisted extraction at 45 °C, 10 min and a solvent to sample ratio of 1:5 (g/mL), with an oil yield of 17.64%. Six fatty acids were identified by GC/MS, with punicic acid (> 75%) as the major residue in pomegranate seed oil. The extracted oil showed antioxidant values of 9.81 and 3.93 mg TE/g of seed, with 91.29 and 98.28% scavenging activity against DPPH and ABTS radicals, respectively. The oil also exhibited a 95.99% of lipid oxidation inhibition. Pomegranate seed is a potential source of health-promoting compounds, such as punicic acid, and natural antioxidants with a high radical scavenging activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pomegranate (Punica granatum L.) is a native fruit from the Middle East that belongs to the berry’s group. During the last decade, it has gained a lot of attention due to its important health benefits and appetizing taste [1, 2]. Pomegranate consists of arils (55–60%, w/w) [3], peel (40–50%, w/w) [4], and seeds (3%, w/w) [5]. In general, the fruit and its derivatives are an excellent nutritional source of bioactive components, such as phenolic compounds (anthocyanins, vitamin C, tannins, punicalagin, punicalin, among others), organic acids, sterols, terpenoids, alkaloids, and enzymes [1, 6, 7]. Many of these bioactive compounds, as well as bioactive lipids (conjugated linoleic acids), are found in the pomegranate seed oil (PSO) [8,9,10,11,12]. Hence, the oil contained in seeds (12–20%, w/w [13]) has been reported to exert nutraceutical and bioactive properties (antioxidant activity), as well as medical applications since it can be used for women therapy during menopause [14, 15]. The fatty acid profile of PSO mainly includes punicic acid (PuA) (up to 80% of total fatty acids), an isomer of α-linolenic acid [13, 16, 17] with considerable health benefits; namely, antioxidant, antitumor, immunomodulatory, anti-atherosclerotic and serum lipid-lowering activities [11, 18]. Other fatty acid residues are linoleic (0.4–17.7%), oleic (0.4–17.7%), stearic (2.8–16.7%), and palmitic (0.3–9.9%). For this reason, PSO is of high industrial value and its extraction methodologies have become quite relevant [19]. Different extraction methods have been employed to recover the maximal amount of PSO by comparison of different solvent systems and techniques, such as Soxhlet [20], supercritical CO2 [21], superheated solvent [22], ultrasound [23], cold solvent, and microwave extraction [14]. Ultrasound-assisted and microwave-assisted extraction (UAE and MAE, respectively) are environmentally-friendly methods, and they do not pose any danger to human health. These methods offer some advantages in comparison to Soxhlet, for instance, lower temperatures, less amount of solvent, shorter extraction times, and higher yields. These operational parameters reduce energy consumption and preserve heat-sensitive and unstable compounds [24, 25]. Besides, it is known that both techniques can extract chemicals of interest faster and efficiently from solid plant matrixes [26].

At the moment, there have not been found studies related to the extraction of PSO from Punica granatum L. var. Apaseo. Therefore, the present work aimed to evaluate two extraction methods, UAE and MAE, comparing the effects of extraction time, temperature and solvent to sample ratio (s:s ratio), on the extraction oil yield. The obtained oil was used to characterize its fatty acid profile by selective derivatization and GC-MS, as well as its antioxidant capacity.

Materials and methods

Materials

Pomegranate (Punica granatum L. var. Apaseo) seed was provided by a fruit juice company Mashei® (Hidalgo, MX). All chemicals and solvents were of analytical grade. Ethanol, n-hexane, chloroform, methanol, sulfuric acid, chlorhydric acid, sodium hydroxide, ferrous chloride, iso-Amyl alcohol, petroleum ether, methyl red, methylene blue, acetate buffer, and boric acid were obtained from J.T. Baker (New Jersey, US). The selenium reagent mixture was purchased from Merck (Darmstadt, Germany). Trolox [(±)-6-hydroxy2,5,7,8- tetramethylchromane-2-carboxylic acid], DPPH (2,2-diphenyl-1-picrylhydrazyl), ABTS (2,2’-azino-bis[3-ethylbenzothiazoline-6-sulphonic acid]), Folin-Ciocalteu reagent, gallic acid (GA), and linoleic acid were purchased from Sigma-Aldrich (Missouri, US). Tween-20 was acquired from Hycel (CDMX, MX). Certified 37 FAME mix standard reference was acquired from Supelco (Pennsylvania, US) and Sigma-Aldrich (Missouri, US).

Sample conditioning

Seeds were dried in an oven (Shel Lab model 1380FX; Sheldon Manufacturing, Inc., Oregon, US) at 60 °C for 48 h. Dried seeds were crushed and grounded in a coffee grinder (Hamilton Beach model 80350R) until the powder was obtained (≤ 500 µm). The powder was stored at room temperature in dark-coloured bags until its use.

Seed oil extraction

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) methods were conducted under different values of temperature, extraction time, and solvent to sample ratio (s:s ratio), as given in the oil extraction design (Table 1). MAE was conducted in a Milestone Microwave Digestion system (START D; Milestone Srl, Bérgamo, IT). Seed samples were set into microwave pressure vessels with <<vent-and-reseal>> technology. Power value remained constant at 800 watts. UAE was carried out in a water bath VWR sonicator (150 D; VWR International., West Chester, PA) at 50–60 Hz. Erlenmeyer flasks (250 mL) hermetically sealed were used as sample containers for the extraction process. Hexane was employed as organic solvent in both extraction systems.

Once the extraction times concluded (in both UAE and MAE), the extract was centrifuged (Eppendorf Centrifuge model 5804R) at 4300 ⋅g for 10 min. The supernatant was separated by decantation. Hexane was evaporated using a hotplate (LMS-1003; Dahan Labtech, LTD, Kyungki-Do, KR) at 63 °C. Subsequently, oil extracted was filtered through a filter paper #1 (125 mm Ø; Whatman, Maidston, UK) and stored in amber vials (− 20 °C) until the fatty acid profile and antioxidant capacity analysis were performed. Oil yield value was calculated according to the following Eq. (1):

Oil extraction design

For each extraction method, a three-factor Box Behnken design was applied to evaluate the effects of temperature, s:s ratio, and extraction time on oil extraction yield. Table 1 shows the levels used for each factor for MAE and UAE, respectively. Both designs consisted of 15 randomized experimental runs, with three central points (Table 2).

Antioxidant capacity

The DPPH free radical scavenging activity was determined using the method of Meléndez et al. [31], adapted to microplate. For that purpose, 7 µL of sample were mixed with 193 µL of a 60 µM DPPH solution. The resulting mixture was allowed to react for 30 min in the darkness at room temperature. After that, the absorbance was measured at 517 nm, using methanol as blank in a microplate reader (Multiskan GO, Thermo Fisher Scientific, Finland).

The capture of the ABTS free radical (ABTS•+) was used to determine the in vitro antioxidant activity of PSO, as described by Re et al. [32] using a 96-well plate. Briefly, ABTS•+ was first obtained by mixing a solution of 7 mM ABTS with 2 mM K2S2O8. The latter solution was then incubated in the dark at room temperature for 12 h. Finally, the ABTS•+ was diluted with ethanol to obtain an absorbance value of 0.70 at 734 nm. For the assay, 190 µL of the ABTS•+ were mixed with 10 µL of the sample. One minute later, absorbance was measured at 734 nm using a microplate reader. Ethanol was used as a blank.

Each assay was performed by triplicate. The antioxidant activity in DPPH and ABTS assays were obtained by linear regression, using a calibration curve of Trolox (0–200 mg/L) and expressed as µmol of Trolox Equivalents/100 g (µmol TE/100 g).

Lipid oxidation inhibition capacity

The lipid oxidation inhibition capacity was performed according to Martínez-Ávila et al. [33]. A linoleic acid solution (0.56 g of linoleic acid and 1.5 g of Tween-20 in 8 mL of 96% ethanol) was used as a lipid source. In amber vials, 5 µL of sample was mixed with 10 µL of a linoleic acid solution and 150 µL of 0.02 M acetate buffer at pH 4. 5 µL of distilled water were used as control. Samples were homogenized in a Maxi Mix II vortex (M37615; Thermolyne, Iowa, US) and sonicated for 3 min in an ultrasonic bath (150 D; VWR International., West Chester, PA), before incubated at 37 °C for 1 min. After that, 75 µL of 0.7 µM FeCl2 solution (0.0994 g FeCl2 and 0.168 g EDTA appraised to 1 L in distilled water) were added to induce oxidation of linoleic acid. It was incubated for 24 h at 37 °C. Three aliquots of 14 µL were taken at 1 and 24 h of reaction and placed in a 96 well-plate. 53 µL of a 0.1 M NaOH solution in 10% ethanol was added to each sample to stop the oxidation process. Finally, samples were diluted with 133 µL of 10% ethanol and the absorbance was recorded at 232 nm against a 10% ethanol blank. The percentage of antioxidant activity was estimated according to Eq. (2):

where A is the difference between the absorbance of the control sample after 24 h and 1 h of incubation; B is the difference between the absorbance of extract sample after 24 h and 1 h of incubation.

Fatty acid profile

For the determination of fatty acid composition, fatty acids methyl esters were obtained via total selective derivatization with a 0.2 N solution of HCl-MeOH [34]. Samples were analysed by gas chromatography with a Varian® (CP3800; Varian Inc, California, US) chromatograph coupled to a Saturn 200 mass spectrometer (Varian Inc, California, US) and a SP-2560 column (L × I.D. 100 m × 0.25 mm, df 0.20 µm) was used. The analysis conditions were as follows: the injector and detector temperature were both set at 260 °C. The oven temperature was held at 140 °C for 5 min, which subsequently was increased to 240 °C at a rate of 4 °C/min and maintained for 15 min. The carrier gas was helium at a flow of 1 mL/min. Fatty acids were identified by comparing their retention times with those observed in Supelco 37 FAME Mix standard.

Statistical analysis

A Box–Behnken design was built using the Statistica 7.0 software (Stat Soft, Tulsa, OK, USA) to evaluate the effect of temperature, extraction time, and s:s ratio on the PSO extraction. All experiments were carried out in triplicate and expressed as mean (n = 3) ± standard deviation. Data were submitted to an analysis of variance (ANOVA) and differences between treatments were evaluated by a Tukey test (p < 0.05) using the SAS 9.0 software (SAS Institute Inc., US).

Results and discussion

Proximate analysis

Pomegranate proximate analysis is shown in Table 3. The main proximate components were carbohydrates and crude fibre, followed by fat and protein. Therefore, pomegranate seed is a rich source of important nutritional components and oil. In contrast, ash presented the lowest value. Ash content was lower than the value reported by Robledo et al. [35] (3.62%) but higher than those reported by Dadashi et al. [36]. In the latter, sample values ranged from 1.59 to 1.88% in ash content from four Iranian commercial pomegranate varieties. Lipid content is within the reported values by Kýralan et al. [37], who extracted the lipid content from fifteen pomegranate varieties and obtained values from 13.95 to 24.13%. On the other hand, Van Nieuwenhove et al. [38] obtained a lower lipid content of 12.91% from their pomegranate seeds acquired from markets. As for crude fibre content, it was within the range values of 36.5 to 42.4% cited by Dadashi et al. [36] and higher than the reported by Saeidi et al. [39] (20%). Protein content is comparable to Saeidi et al. [39] data (18.8%). The carbohydrate content of our sample is lower than the 73.1% reported by Bourekoua et al. [40] but similar to the 65.60% obtained by Van Nieuwenhove et al. [38]. Moisture content is approached to the value of 5.73% referred by Aruna et al. [41], however, it is lower compared with those of Van Nieuwenhove et al. [38] (9.4%) and Robledo et al. [35] (25.66%). Chemical composition of pomegranate seeds is strongly affected by the fruit variety, harvesting conditions, geographical location, and dehydrated conditions [42, 43].

Extraction of PSO

In this study, the effects of extraction conditions (time, temperature and s:s ratio) and methods used (MAE and UAE) on the PSO yield were evaluated. According to ANOVA, both extraction techniques showed significant differences between treatments (Table 4), indicating that at least one of them significantly enhanced the efficiency of the extraction.

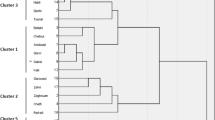

For MAE, all factors evaluated had a significant influence on PSO yield (p < 0.05) (Fig. 1). An increase in extraction time from 10 to 15 min affects the oil yield (Fig. 1a), while an increase in s:s ratio and temperature levels increase the oil yield (Fig. 1b and c). The PSO extraction yields obtained by MAE are shown in Table 2. The highest oil yield was attained with treatment 12 (18.38%), whereas treatments 2 and 6 showed the lowest value (without significant differences between them). Treatment 12 (0.05 g/mL or 20:1 s:s ratio, 90 °C, 10 min) allows to obtain 1.73-fold more oil in comparison to treatments 2 and 6.

Increasing the s:s ratio not only significantly increased oil yield, but it was also the parameter that affected the most. These results are similar to those reported by Çavdar et al. [14], who found that increasing s:s ratio from 2:1 to 10:1 (by mass), the extraction yield of PSO increased 5%. The findings of Zhong et al. [44], also support the results of our work, since they stated that increasing from 4:1 to 10:1 ratio (solvent:sample), statistically enhanced Moringa oleifera oil yield extractions. The obtaining of higher oil yields by increasing the s:s ratio is due to an increase in s:s ratio, the mass transfer between both phases is intensified due to a greater concentration gradient. Hence, more oil is transferred from the sample matrix into the organic solvent. Conversely, extraction time exerted a negative effect on the oil yield. This result disagrees Wang et al. [45] and Çavdar et al. [14] studies since they concluded that the extraction time did not significantly affect their extraction yields. On the other hand, Nde et al. [46] obtained similar results. They optimized the extraction of neem oil by MAE, and reported a significant decrease in oil yield when extraction time was increased from 0 to 20 min. They discussed that it was possible that by prolonging the extraction time, the solvent used for the oil extraction vaporized and remained in the headspace of the pressurized vessels, unable to interact with the sample. Thus, lower oil yields were obtained. Temperature, as expected, also had a significant effect in the oil yields, leading to higher oil yield values when the oil extraction was carried out at 90 °C. It is known that increasing temperature values leads to higher oil solubility and less viscosity. The highest extraction yield of 18.38% obtained in the present work, was below to the one by Çavdar et al. [14], who achieved 35.1% in 5 min, and 34.7% in 8 h via MAE and Soxhlet, respectively. Nevertheless, Çavdar et al. [14] design experiment considered particle size, the parameter which affected the most the extraction yield in their study. On the other hand, our result is within the typical oil content of pomegranate seeds reported: 7–20% in seed weight [47]. Therefore, variations can be attribute to the difference between extraction times, temperatures and s:s ratios, as well as the factors described previously in the proximate analysis section that determine the chemical composition of the fruit.

In the case of UAE, different effects of the evaluated factors were observed (Fig. 1d–f), with temperature and s:s ratio of a significant influence on PSO yield (p < 0.05). However, the increase in the levels used in temperature decreased the oil yield, while s:s ratio increased it (Fig. 1e and f, respectively).

Table 2 shows the oil yield results obtained for UAE. Treatments 11 and 12 reached the maximum oil yields (17.64 and 17.08%, respectively) without significance difference between them. Conversely, the lowest oil yields were observed in treatments 5 and 6, with values 1.84–1.94-fold lower than the obtained with treatment 11. To determine the best treatment in UAE, time and temperature were considered, since they imply an energy and time consumption. In that matter, the main difference between treatments 11 and 12 was temperature (45 and 75 °C, respectively), since statistically, they achieved the same oil yield. For treatment 11, a temperature of 45 °C was employed, while in treatment 12 a higher temperature (75 °C) was required. Also, longer extraction times may induce a higher degradation of the biological components, or the oil could be embedded by other components present in the matrix, such as pectin and gums [48]. For this reason, treatment 11 (10 min, 45 °C, 0.2 mg/mL or 5:1 s:s ratio) was considered to present the best for UAE of pomegranate seeds. Time surprisingly did not exhibit any statistical effect. In contrast, Goula [49] mentioned that in all their experiment runs, oil yield was time dependant and significantly improved as extraction time increased. Possibly, in the present study, less time was required to extract most of the oil from the sample, since Goula [49] achieved up to 40.2% of extraction yield, whereas in the present work the highest value reached was 17.64%. These variations can be attributed to the fact that they carried out their experiments evaluating more extraction parameters (seed particle size, amplitude level, and pulse interval/duration) and the chemical composition of their pomegranate seeds. The extraction temperature effect was also contrary to our expectations. Increasing temperature from 45 to 60 °C, significantly decrease the extraction yield of oil and increasing from 60 to 75 °C significantly promoted the extraction. However, oil yields obtained at 45 °C and 75 °C were not statistically different. The obtained results partially agree with those reported by Zhang et al. [50], who observed that flaxseed oil extraction by ultrasound significantly decreased (6%) when temperature increased from 30 to 50 °C. One possible explanation could be that the vapor pressure of solvent increased as the temperature increased as well, affecting the occurrence and the intensity of the bubbles produced by acoustic cavitation. In this context, as temperature and vapor pressure were higher, more bubbles were produced. In consequence, a smaller pressure difference between the internal and external medium of the bubbles is obtained, collapsing with less intensity. This limits the cell tissue disruption of the sample during the extraction process, decreasing oil yields. Another reason may be attributed to the surface tension. Surface tension could decrease as temperature increases, also affecting the bubble formation and exploding force. Bubbles then weakly collapse reducing mass transfer between phases [51].

Once again, increasing the s:s ratio enhanced the oil extraction, thus better yields were achieved. However, oil yield significantly improved only when the s:s ratio increased from 1:20 (g/mL) to 1:10 (g/mL); exceeding the 1:10 ratio (g/mL) did not significantly increase the oil yield. Similar results had also been reported by other studies [23, 50, 52]. The same principle explained before occurs. The driving force of mass transfer intensifies proportionally to the concentration gradient, which increases by using a higher s:s ratios. However, based on the results, the use of excessive solvent volumes did not significantly improve the oil yield.

In general, ANOVA did not show any significant difference between the extraction methods used. Therefore, both applied methods showed the same oil extraction efficiency. However, the maximum yield obtained in treatment 12 with MAE (18.38%) is slightly higher than the obtained with treatment 11 with UAE (17.64%). Before selecting some extraction method, it is necessary to take into account economic aspects. Compared to treatment 11 in UAE, the use of treatment 12 in MAE requires an increase in temperature (from 45 to 90 °C) and m/v ratio (from 0.2 to 0.05 g/mL or 5:1 to 20:1 s:s ratio), which means higher energy and solvent consumptions. In that matter, UAE was selected as the best extraction method since it demonstrated to be as efficiently as MAE, but possibly with a notably lower production cost at long term or industrial scale. Moreover, UAE can be adapted to small or large scales, with less instrumental investment [24]. For the abovementioned, PSO extracted under treatment 11 conditions and UAE, was selected for the evaluation of antioxidant activity and determining its fatty acid profile.

Antioxidant activity analysis

Antioxidant activity results can be observed in Table 5. The oil obtained in the present study presented a value of 9.81 mgTE/g of seed, with a 91.29% scavenging activity against DPPH radical, similarly to that reported by He et al. [53] for pomegranate seed (92.75%). For ABTS radical, the scavenging activity value obtained (98.26% of inhibition; 3.83 mgTE/g of seed) were equivalent to 15.32 µmol TE/g of seed and 102.11 µmol TE/g of oil. Đurđević et al. [8] reported 4.10 µmol TE/g of seed, which is 3.73 times lower than the value obtained in the present work. On the other hand, ABTS activity obtained in this work was slightly lower to the value of 19.8 µmol TE/g of seed reported by Durante et al. [54]. Nevertheless, authors also reported an activity value of 19.1 µmol TE/g oleoresin, which is 5.35 times lower in comparison to the obtained with oil in the present work. Although DPPH and ABTS techniques are widely used to measure in vitro the elimination of free radicals from extracts of various vegetable samples, they provide limited information of their antioxidant properties in real biological systems. Therefore, an additional assay should be performed to simulate oxidation conditions in food systems. A 95.99 ± 6.90% antioxidant capacity was presented by lipid oxidation inhibition of the oil, which supports the antioxidant properties of PSO, which is granted by all the compounds present in it, such as phenolic compounds and fatty acids. Bihamta et al. [55] also reported a reduction in the peroxidation of lipids and formation of free radicals. They could reduce the production of malondialdehyde (235.7 ± 7.9%) almost by half (129 ± 5%) in H9c2 cardiomyocyte cells exposed to H2O2, by using a dose of 200 µg of cells/mL of PSO.

Fatty acid composition

A total of six fatty acids were identified by GC/MS (Fig. 2). Table 6 shows the fatty acid composition expressed as a percentage of the total fatty acids present in PSO. Unsaturated fatty acids (UFA) mainly constituted (86.06%) the fatty acid profile of PSO, resulting in an UFA/saturated fatty acid ratio (UFA/SFA) of 0.16. The low UFA/SFA ratio indicates that the PSO could be an important source of high nutritional value polyunsaturated fatty acids such as omega-3, -5, and -6, known for their health benefits [56,57,58]. As expected, PuA (an omega-5 fatty acid) was the main residue with a 75.56% content. This is in accordance with Kýralan et al. [37], Dadashi et al. [36], and Van Nieuwenhove et al. [38] studies; however, the latter despite identified PuA as the major fatty acid as well, only at lower content (57.65%). The high content of PuA observed in this study, confirms the commercial value of PSO, since it is known that PuA is a conjugated linoleic acid isomer that brings health benefits [59], and could be used as a potential feedstock for functional foods.

Palmitic acid showed the highest value of the SFA, and the second in general composition followed by oleic acid. This contrasts with other studies since palmitic content exceeds the published ranged values of 0.3–9.9% and oleic acid content, which is commonly found in greater amounts than palmitic acid. Moreover, even though linoleic acid is one of the most common fatty acids founded in PSO, it was not identified in our current work. These discrepancies could be explained by the fact that the geographical location, maturity stage, and oil extraction method are crucial factors that significantly affect the fatty acid composition of PSO [13].

Conclusions

This study examined the efficiency of oil extraction from pomegranate seed assisted by microwave and ultrasound under different extraction parameters, which is a rich source of bioactive compounds of interest. There were not statistically differences between the extraction yields by microwave-assisted (18.38%) and ultrasound-assisted (17.64%) extractions. However, ultrasonic-assisted extraction was considered more effective when economic factors were considered since it requires a lower temperature and solvent amounts. Our results also demonstrated the potential role of pomegranate seed oil as a source of health-promoting components such as the punicic acid, and natural antioxidants due to its high radical scavenging activity.

References

J.A. Ascacio-Valdés, J.J. Buenrostro-Figueroa, A. Aguilera-Carbo, A. Prado-Barragán, R. Rodríguez-Herrera, C.N. Aguilar, J. Med. Plants Res. 5(19), 4696–4703 (2011)

S. Smaoui, H.B. Hlima, A.C. Mtibaa, M. Fourati, I. Sellem, K. Elhadef, K. Ennouri, L. Mellouli, Meat Sci. 158, 107914 (2019)

M. Erkan, A.A. Kader, 14-Pomegranate (Punica granatum L.), in Postharvest Biology and Technology of Tropical and Subtropical Fruits. ed. by E.M. Yahia (Woodhead Publishing, Cambridge, 2011), pp. 287–313

A. Ali, Y. Chen, H. Liu, L. Yu, Z. Baloch, S. Khalid, J. Zhu, L. Chen, Int. J. Biol. Macromol. 129, 1120–1126 (2019)

E.P. Lansky, R.A. Newman, J. Ethnopharmacol. 109(2), 177–206 (2007)

Z. Amri, F. Zaouay, H. Lazreg-Aref, H. Soltana, A. Mneri, M. Mars, M. Hammami, Int. J. Biol. Macromol. 104, 274–280 (2017)

N. Kumar, S. Neerajand, Kumar, J. Pharm. Innov. 7(10), 71–81 (2018)

S. Đurđević, K. Šavikin, J. Živković, V. Böhm, T. Stanojković, A. Damjanović, S. Petrović, J. Supercrit. Fluids 133, 225–232 (2018)

M. Karimi, R. Sadeghi, J. Kokini, Trends Food Sci. Technol. 69, 59–73 (2017)

M. Kaufman, Z. Wiesman, J. Agric. Food Chem. 55(25), 10405–10413 (2007)

H.H. Orak, H. Yagar, S.S. Isbilir, Food Sci. Biotechnol. 21(2), 373–387 (2012)

S. Özgül-Yücel, J. Am. Oil Chem. Soc. 82(12), 893–897 (2005)

R. Holic, Y. Xu, K.M.P. Caldo, S.D. Singer, C.J. Field, R.J. Weselake, G. Chen, Appl. Microbiol. Biotechnol. 102(8), 3537–3549 (2018)

H.K. Çavdar, D.K. Yanık, U. Gök, F. Göğüş, Food Technol. Biotechnol. 55(1), 86–94 (2017)

A. Khoddami, T.H. Roberts, Lipid Technol. 27(2), 40–42 (2015)

A.-C. Schneider, P. Beguin, S. Bourez, J.W. Perfield II., E. Mignolet, C. Debier, Y.-J. Schneider, Y. Larondelle, PLoS ONE 7(3), e32824 (2012)

N.Z. Shaban, M.A.L. El-Kersh, F.H. El-Rashidy, N.H. Habashy, Food Chem. 141(3), 1587–1596 (2013)

V. Verardo, P. Garcia-Salas, E. Baldi, A. Segura-Carretero, A. Fernandez-Gutierrez, M.F. Caboni, Food Res. Int. 65, 445–452 (2014)

I. Pereira de Melo, E. Carvalho, J. Filho, J. Hum. Nutr. Food Sci. 2, 1024 (2014)

H. Abbasi, K. Rezaei, L. Rashidi, J. Am. Oil Chem. Soc. 85(1), 83–89 (2008)

G. Liu, X. Xu, Y. Gong, L. He, Y. Gao, Food Bioprod. Process. 90(3), 573–578 (2012)

M.H. Eikani, F. Golmohammad, S.S. Homami, Food Bioprod. Process. 90(1), 32–36 (2012)

Y. Tian, Z. Xu, B. Zheng, Y. Martin Lo, Ultrason. Sonochem. 20(1), 202–208 (2013)

D.B. Muñiz-Márquez, G.C. Martínez-Ávila, J.E. Wong-Paz, R. Belmares-Cerda, R. Rodríguez-Herrera, C.N. Aguilar, Ultrason. Sonochem. 20(5), 1149–1154 (2013)

E. Yabalak, B. Külekçi, A.M. Gizir, J. Environ. Sci. Heal. B 54(14), 1412–1422 (2019)

C. Castro-López, J.M. Ventura-Sobrevilla, M.D. González-Hernández, R. Rojas, J.A. Ascacio-Valdés, C.N. Aguilar, G.C.G. Martínez-Ávila, Food Chem. 237, 1139–1148 (2017)

Normas Mexicanas, NMX-F-607-NORMEX, México (2013). https://produccionindustrialdealimentos2.jimdofree.com/1-1-2-nmx-f-607-normex-2013/ (accessed 21 July 2019)

Normas Mexicanas, NMX-F-089-S, México (1978). https://www.colpos.mx/bancodenormas/nmexicanas/NMX-F-089-S-1978.PDF (accessed 18 July 2019)

Normas Mexicanas, NMX-F-090-S, México (1978). https://www.colpos.mx/bancodenormas/nmexicanas/NMX-F-090-S-1978.PDF (accessed 24 July 2019)

Normas Mexicanas, NMX-F-068-S, México (1980). https://sci-hub.tw/https://springerlink.bibliotecabuap.elogim.com/article/10.1007/s11694-020-00452-x (accessed 20 July 2019)

N.P. Meléndez, V. Nevárez-Moorillón, R. Rodríguez-Herrera, J.C. Espinoza, C.N. Aguilar, Afr. J. Biochem. Res. 8(1), 14–18 (2014)

R. Re, N. Pellegrini, A. Proteggente, A. Pannala, M. Yang, C. Rice-Evans, Free Radic. Biol. Med. 26(9), 1231–1237 (1999)

G.C. Martínez-Ávila, A.F. Aguilera-Carbó, R. Rodríguez-Herrera, C.N. Aguilar, Ann. Microbiol. 62(3), 923–930 (2012)

G. López-García, L. López-Martínez, O. Dublán-García, R. Baeza-Jiménez, Rev. Mex. Ing. Quím. 16(3), 835–844 (2017)

A. Robledo, A. Aguilera-Carbó, R. Rodriguez, J.L. Martinez, Y. Garza, C.N. Aguilar, J. Ind. Microbiol. Biotechnol. 35(6), 507–513 (2008)

S. Dadashi, M. Mousazadeh, Z. Emam-Djomeh, S.M. Mousavi, Int. J. Adv. Biol. Biomed. Res. 4(4), 334–342 (2016)

M. Kýralan, M. Gölükcü, H. Tokgöz, J. Am. Oil Chem. Soc. 86(10), 985–990 (2009)

C.P. Van Nieuwenhove, A. Moyano, P. Castro-Gómez, J. Fontecha, G. Sáez, G. Zárate, P.L. Pizarro, LWT - Food Sci. Technol. 111, 401–407 (2019)

Z. Saeidi, B. Nasehi, H. Jooyandeh, J Food Sci Technol. 55(8), 3110–3118 (2018)

H. Bourekoua, R. Różyło, U. Gawlik-Dziki, L. Benatallah, M.N. Zidoune, D. Dziki, Int. J. Food Sci. Tech. 53(8), 1906–1913 (2018)

P. Aruna, B. Manohar, R.P. Singh, J. Food Process. Preserv. 42(5), e13609 (2018)

U.A. Fischer, A.V. Jaksch, R. Carle, D.R. Kammerer, Eur. Food Res. Technol. 237(2), 209–221 (2013)

J.M. Tirado-Gallegos, R. Baeza-Jiménez, J.A. Ascacio-Valdés, J.C. Bustillos-Rodriguez, J. Buenrostro-Figueroa, Pomegranate seeds as a potential source of punicic acid: extraction and nutraceutical benefits, in Practical Applications of Physical Chemistry in Food Science and Technology. ed. by C.N. Aguilar, J. Sandoval-Cortés, J.A. Ascacio-Valdés, A.K. Haghi (Apple Academic Press, Boca Raton, 2021), pp. 129–153

J. Zhong, Y. Wang, R. Yang, X. Liu, Q. Yang, X. Qin, Ind Crops Prod. 120, 1–10 (2018)

Y. Wang, J. You, Y. Yu, C. Qu, H. Zhang, L. Ding, H. Zhang, X. Li, Food Chem. 110(1), 161–167 (2008)

D.B. Nde, D. Boldor, C. Astete, Ind. Crops Prod. 65, 233–240 (2015)

R.P. Singh, K.N. Chidambara Murthy, G.K. Jayaprakasha, J. Agric. Food Chem. 50(1), 81–86 (2002)

M.L. Chávez-González, L.I. López-López, R. Rodríguez-Herrera, J.C. Contreras-Esquivel, C.N. Aguilar, Chem. Pap. 70(4), 412–417 (2016)

A.M. Goula, J. Food Eng. 117(4), 492–498 (2013)

Q.-A. Zhang, Z.-Q. Zhang, X.-F. Yue, X.-H. Fan, T. Li, S.-F. Chen, Food Chem. 116(2), 513–518 (2009)

Z. Hromádková, J. Kováčiková, A. Ebringerová, Ind. Crops Prod. 9(2), 101–109 (1999)

Z. Lou, H. Wang, M. Zhang, Z. Wang, J. Food Eng. 98(1), 13–18 (2010)

L. He, H. Xu, X. Liu, W. He, F. Yuan, Z. Hou, Y. Gao, Food Res. Int. 44(5), 1161–1167 (2011)

M. Durante, A. Montefusco, P.P. Marrese, M. Soccio, D. Pastore, G. Piro, G. Mita, M.S. Lenucci, J. Food Compos. Anal. 63, 65–72 (2017)

M. Bihamta, A. Hosseini, A. Ghorbani, M.T. Boroushaki, Avicenna J. Phytomed. 7(1), 46–53 (2017)

P. Aruna, D. Venkataramanamma, A.K. Singh, R.P. Singh, Compr. Rev. Food. Sci. Food Saf. 15(1), 16–27 (2016)

L. Hooper, L. Al-Khudairy, A.S. Abdelhamid, K. Rees, J.S. Brainard, T.J. Brown, S.M. Ajabnoor, A.T. O’Brien, L.E. Winstanley, D.H. Donaldson, F. Song, K.H. Deane, Cochrane Database Syst. Rev. 7(7), CD011094–CD011094 (2018)

F. Shahidi, P. Ambigaipalan, Annu. Rev. Food Sci. Technol. 9(1), 345–381 (2018)

J. Miranda, L. Aguirre, A. Fernández-Quintela, M.T. Macarulla, M.G. Martínez-Castaño, J. Ayo, E. Bilbao, M.P. Portillo, J. Agric. Food Chem. 61(21), 5089–5096 (2013)

Acknowledgements

Authors thank to National Council of Science and Technology (CONACYT), for the financial support received through the project CONACYT-PEI-252365. This project was performed out in the frame of the innovation stimulus program with ANTARES NETWORK S.A. DE C.V. Authors also thank CONACYT for the scholarship assigned to ERG in the PhD program in Food Science and Technology at the Research Center in Food and Development, A.C., Delicias, Chihuahua, México.

Funding

This research was supported by the CONACyT PEI Project 252365.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation and data collection were performed by C-.M. and R-G. GC/MS analyses were performed by C-G. The first draft of the manuscript was written by R-G. Writing, review & editing were supported by all authors. B-F: conceptualization, formal analysis, funding acquisition, project administration, resources, writing-review and editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rojo-Gutiérrez, E., Carrasco-Molinar, O., Tirado-Gallegos, J.M. et al. Evaluation of green extraction processes, lipid composition and antioxidant activity of pomegranate seed oil. Food Measure 15, 2098–2107 (2021). https://doi.org/10.1007/s11694-020-00804-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00804-7