Abstract

Previous study showed that deep eutectic solvent (DES)-extracted pectin exhibited undesirable structural and functional properties. It has to be noted that most of the researchers were seeking the parameters that could increase the extraction yield and neglected the importance of the pectin structures that could ultimately affect the functional properties. Hence, a comparison between the use of DES and less acidic medium (citric acid monohydrate, CAM) in extracting the pectin was conducted. This study demonstrated that the mediums used significantly influenced these aforementioned properties and the optimum extraction parameters. The maximum Averrhoa bilimbi pectin (ABP) yield (9.34%) was obtained at the optimal condition: CAM percentage = 3.71% (w/v), extraction temperature = 80 °C and extraction time = 3.0 h. The result showed that extraction using CAM required longer time (30 min more) than DES and the yield was lower (4.96% less). Apart from that, ABP-CAM was found lower in linearity with higher contribution of RG and branch size of the pectin compared to the ABP-DES which was found to be more linear pectin with a lower contribution of RG and less branch size. Besides that, it was also observed that using CAM as the extraction medium had improved the water holding capacity (6.22%), emulsifying activity (145.59%) and ferric reducing antioxidant power (38.26%) compared to ABP-DES. Overall, it suggested that the extraction medium plays an important role in the extraction of the pectin, structure of the pectin and, hence affects the properties of the extracted pectin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Acids are the most efficient pectin extracting agents as they help to extract the pectin that is strongly linked to the plant cell matrix and resulting in higher yields [1]. According to Hossein [2], acidic condition is not only capable of solubilizing water-soluble pectin, it is also capable of dissolving pectin by hydrolysis because insoluble pectin must be hydrolyzed from the cell wall before it can be isolated. Our previous study [3] was suggested citric acid monohydrate—choline chloride based deep eutectic solvents (DES) as an alternative medium for pectin extraction from Averrhoa bilimbi. A high pectin yield of 14.44% (w/w) was obtained at the %DES of 3.74%, a temperature of 80 °C, extraction time of 2.5 h and DES molar ratio of 1:1. However, there are some drawback of the pectin extracted using DES as an extraction medium such as the pectin exhibited lower emulsifying and antioxidant activity. It was hypothesized that due to high acidic condition that induced by the DES, extensive hydrolysis might occur and thus, increased the yield and yet significantly affect the structure integrity of the pectin. Therefore, the extraction of pectin using citric acid monohydrate, a conventional approach with lower acidity condition, was suggested in this research because the use of this acid also showed high extraction yield and gave better quality pectin compared to other acids as reported by other studies [1].

Previously, Yang et al. [4] used citric acid to extract the pectin from potato pulp. The citric acid gave higher yield (14.34%) of the potato pulp pectin than nitric acid (9.83%), hydrochloric acid (9.72%), sulphuric acid (8.38%), and acetic acid (4.08%). Other than that, the potato pulp pectin showed higher emulsifying activity (46.06%) and emulsion stability (36.54%) compared to commercial apple pectin with the value of 45.34% and 19.15% for emulsifying activity and emulsion stability, respectively. However, the extracted potato pulp pectin using citric acid had a lower degree of degrees of methylation with the value of 21.51%. A similar result was reported by Raji et al. [5], who extracted pectin from mango peel. The authors reported that the extraction using citric acid (14.30%) was the most effective medium for pectin extracted from melon peel than tartaric acid (13.30%), hydrochloric acid (9.50%), acetic acid (7.00%), lactic acid (4.70%), nitric acid (4.40%), phosphoric acid (3.40%) and sulfuric acid (1.40%). In term of pectin properties, the melon peel pectin was categorized as a low methoxyl pectin and exhibited 35.00% of emulsifying activity and 90.20% of emulsion stability. From these results, it was recommended that using citric acid as the extraction medium could enhance the extraction efficiency and the properties of the extracted pectin might be different due to the structure of the pectin obtained could be different. Hence, the main objective of this study was to optimize the citric acid monohydrate (CAM) extraction condition (i.e. percentage of CAM, temperature and extraction time) of pectin from A. bilimbi fruit. The physico-chemical properties, functional properties as well as antioxidant activities of the pectin (ABP-CAM) produced from the optimal condition were also examined, followed by comparison the results obtained with the pectin produced under optimal condition using DES as the extraction medium (ABP-DES) in our previous study [3].

Materials and methods

Materials and chemicals

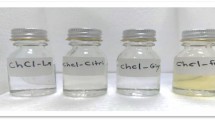

Averrhoa bilimbi fruit powder was prepared according to the same process as our previous study [3] and stored at 4 °C prior to extraction. Citric acid monohydrate (CAM) was purchased from Fluka (Malaysia). All other chemicals and reagents used in this study were analytical grade.

Extraction of A. bilimbi pectin (ABP-CAM)

The optimization of ABP-CAM extraction was carried out as stated by our previous study [3]. The response effects of selected variables (i.e. percentage of CAM (X1: 2–4%), extraction temperature (X2: 60–80 °C) and extraction time (X3: 1–3 h)) were optimized using Box-Behnken design (BBD). Table 1 summarized the levels of the three independent variables and the variables were coded according to the equation below:

where \(x\) was the coded value, Xi was the corresponding actual value, X0 was the actual value in the center of the domain, and ∆X was the increment of Xi corresponding to a variation of 1 unit of \(x\). The codes of − 1, 0 and + 1 referred to the low, middle and high levels of variables, respectively.

The mathematical model for the composite design was as follows:

where \(Y\) was the pectin yield, \({\beta }_{0}\) was the model constant, \({\beta }_{i}\), \({\beta }_{ii}\) and \({\beta }_{ij}\) were the model coefficients, and \(\varepsilon \) was an error. Design Expert Software (version 6.0, USA) was used to analyze the data and calculate the predicted response. Subsequently, five confirmation experiments were carried out to verify the validity of the optimized condition, followed by evaluate the statistical significant (p < 0.05) difference between the predicted and experimental values using t-test.

Characterization of ABP-CAM

Physico-chemical properties of ABP-CAM

The pH of ABP-CAM (1%, w/v) was examined using a digital pH meter (Mettler Toledo, USA). Then, the total carbohydrate, protein and total phenolic contents (TPC) were determined using the phenol sulphuric acid method, Bradford method and TPC method, as described by Masuko et al. [6], Bradford [7] and María et al. [8], respectively. The solubility of ABP-CAM (0.5%, w/v) in water (cold or hot) and alkaline solution (cold or hot) was examined using a method as described by Fishman et al. [9] with the addition of solubility percentage calculation. The blank was prepared without the ABP-CAM. The solubility was calculated according to Liew et al. [10] using the following equation:

where W1 was the initial weight (g) of the sample, W2 was the supernatant weight (g) and Wb was the blank weight (g) after drying.

Structural properties of ABP-CAM

The monomeric analysis of ABP-CAM based on neutral sugar was analyzed using a high-performance liquid chromatography (HPLC) system at the Analytical Biochemistry Research Centre (ABrC), Universiti Sains Malaysia, fitted with UV detector as mentioned by Lv et al. [11]. A functional groups and the degree of esterification were determined using Fourier transform infrared (FTIR) spectrometer (Nicolet, USA) at the School of Technology Industry, Universiti Sains Malaysia. The degree of esterification is used as a pectin categorization criteria and determine the proportion of esterified galacturonic acid groups to total galacturonic acid groups in the pectin molecule, which might contribute to the functional properties of pectin such as gelation of pectin [12]. The degree of esterification (DE) value was calculated according to Singthong et al. [13] using the following equation:

where A1 was the area between 1730 and 1760 cm−1 whereas A2 was the area between 1600 and 1650 cm−1.

Functional properties of ABP-CAM

The water and oil holding capacity as well as emulsifying capacity and stability were then determined according to the methods mentioned by Du et al. [14], followed by foaming capacity and stability by Akhtar et al. [15]. ABP-CAM solution (1%, w/v) was prepared using deionized water or palm oil in these tests and blended with the aid of homogenizer TH-02 homogenizer (OMNI International, USA) at 26,000 rpm for 3 min.

Antioxidant properties of ABP-CAM

The DPPH free radical scavenging and ferric reducing power (FRAP) were used to determine the antioxidant activity of ABP-CAM as stated by Blois [16] and Benzie and Strain [17], respectively. ABP-CAM (10 mg/mL) prepared in deionized water was used as sample.

Statistical analysis

ABP-CAM extraction was performed in 3 replicates and each replicate was tested in the aforementioned analyzes. The one-way analysis of variance (ANOVA) was used to analyze 3 replicates value in the single factor experiment whereas the paired sample t-test was carried out in order to compare the results obtained with ABP-DES. The statistical analysis of the data was performed using the SPSS statistical 24.0 software (IBM, USA). The significant difference at a 95% confidence interval among the treatment means was analyzed using Duncan’s multiple range test.

Results and discussion

Optimization extraction of ABP-CAMs

Figure 1 shows the effects of %CAM, temperature and time on the extraction yield. The extraction yield was significantly increased when the percentage of CAM was increased from 1% (pH 2.33) to 4% (pH 1.96) and reached the maximum yield (7.31%) at 4% of CAM. Due to acidification effect of citric acids, these results can be attributed to acid hydrolysis of the bond linkages between pectin and cell wall constituents and subsequently, released the pectin into the extraction medium, thus increasing the extraction yield [1]. This result is consistent with the investigation made by Pereira et al. [18] who reported that the yield of pomegranate peels pectin increased when the pH of citric acid decreased from pH 4 (4.39%) to pH 2 (11.18%). However, no further yield increment was found for 5% of CAM. Besides that, the yield significantly increased from 5.39 to 12.34% (Fig. 1b) by increasing the temperature from 40 to 80 °C. As reported by Lu et al. [19], the temperature was responsible for swelling and loosening effects in the matrix during the extraction process. These two effects enhanced medium extraction penetration as well as pectin solubility and thus, improved pectin extraction yield. A similar result was reported by Nguyen and Pirak [20] which the yield of white dragon fruit peel pectin increased with increasing the temperature of extraction from 45 °C (6.51%) to 75 °C (12.35%). Pereira et al. [18] also reported that the yield of pectin from pomegranate peels increased when the temperature increased from 74 °C (7.02%) to 86 °C (9.93%). Besides that, the result showed the pectin yield significantly increased with increasing the extraction time from 0.5 to 3.0 h and reached the maximum yield (7.03%) at 3.0 h (Fig. 1c). This phenomenon was due to the time is needed (3.0 h) to release the pectin into the extraction medium completely. The CAM solution penetrates into the A. bilimbi matrices throughout the process, hydrolyzing the bonds between the cell wall and pectin, dissolving pectin and then diffusing it out from the cell wall. A similar result was reported by Guo et al. [21] that the yield of sugar beet pectin increased with increasing time of extraction from 2.0 h (12.90%) to 3.0 h (15.00%). Based on the results of the single-factor experiment, the ranges of response surface methodology (RSM) factors were selected as follows: DES percentage (2–4%), extraction temperature (60–80 °C) and extraction time (1.0–3.0 h).

Effects of each factor on the extraction yield of pectin (%): a percentage of CAM (%); b extraction temperature (°C); c extraction time (h). Data reported are average values with error bars indicating the standard deviation of 3 replicates (n = 3). Values with different letters are significantly different (p < 0.05) according Duncan’s multiple range test

A modelling polynomial regression was performed with a total of 17 runs (Appendix 1) between the response variables and the corresponding coded value (x1, x2, and x3) of the three different process variables. The quadratic model was selected with the p value of 0.0161 and the p value for the lack of fit was 0.2023 (Table 2). The regression model (R2 = 0.8972, adjusted R2 = 0.7650) and coefficient of variation (CV) of 9.46% were observed. This model had a low CV, suggesting that the experiment was carried out with good precision and high reliability [22]. The main effect on pectin yield was a linear term of extraction time (\({X}_{3}\)), followed by a linear term of extraction temperature (\({X}_{2}\)), a quadratic term of extraction temperature (\({X}_{2}^{2}\)) and a quadratic term of extraction time (\({X}_{3}^{2})\). On the other hand, the linear term and quadratic term for a percentage of CAM (\({X}_{1}\) and \({X}_{1}^{2}\)), as well as the other interaction terms were not significant (p > 0.05). The influence of the extraction temperature and reaction time was thus suggested to play the dominant roles in pectin extraction, whereas the percentage of CAM within the experimental range was insignificant (p > 0.05). The non-significant terms were eliminated using a backward elimination process to better fit the quadratic model for pectin yield. The final response equations for ABP-CAM yield are obtained in terms of coded factors after elimination of the non-significant terms and are shown as follow:

Figure 2 illustrates the three-dimensional (3-D) response surface for yield as a function of extraction temperature and time. It can be found that the extraction temperature and time showed a quadratic effect (exponential increase) on the ABP-CAM yield. The rising trend on yield with temperature was related to the solubility of pectin due to physical adsorption and chemical interactions between the pectin and the cell wall material tend to decrease at high temperatures. Therefore, increasing pectin leaching out in the extraction medium. As mentioned by Zhang and Wang [23], high temperatures during extraction process can significantly reduce the viscosity of extraction solvents, increase the distribution of extraction solvents and improve the mass transportation of target compounds. It is therefore reasonable to predict that the higher temperature would increase pectin release. Similar results were reported by Muthusamy et al. [24] and Lu et al. [19], the pectin yield from Helianthus annuus (sunflower) heads and Premna microphylla Turcz leaves were increased with increasing the temperature from 30 to 45 °C and 90 to 100 °C, respectively. In addition, the extraction time significantly influenced the ABP-CAM yield and reached a maximum yield at 3.0 h. This phenomenon was due to the time needed for CAM to penetrate into the A. bilimbi, followed by dissolving the pectin before extracting the pectin from the A. bilimbi fruit [25]. This explanation was in agreement with Jafari et al. [26] and Yang et al. [4], who extracted carrot pomace pectin and potato pulp pectin, respectively. As reported by Pasandide et al. [27], the Citrus medica peel pectin yield significantly (p < 0.05) increased when the extraction time increased from 1.0 h (~ 6.00%) to 3.0 h (~ 17.00%).

Based on the verification of predictive models and desirability value of 0.908, the optimal condition for obtaining a maximum pectin yield of 9.74% corresponded to 3.71% (w/v) of CAM, an extraction temperature of 80 °C, and extraction time of 3.0 h. Referring to an independent samples t-test analysis, it was indicated that there was no significant difference (p = 0.142) between the experimental value (9.34%) and the predicted value. As a comparison to our previous study [3], the maximum pectin yield (14.70%) using citric acid monohydrate—choline chloride based DES as the extraction medium were obtained at optimal condition of 3.74% (w/v) of DES, an extraction temperature of 80 °C, and extraction time of 2.5 h. These results validated that DES as the extraction medium gave a higher ABP yield with short periods of extraction time than CAM. However, the properties of ABP-CAM produced might be different as compared to the ABP-DES.

Physico-chemical properties of ABP-CAM

Table 3 summarized the pH, total carbohydrate content, protein content, and TPC of ABP-CAM extracted under optimum condition of extraction. Results showed that the pH value of ABP-CAM solution was pH 2.60, while the total carbohydrate content, protein content, and TPC were 23.72% glucose equivalent, 0.34% BSA equivalent and 0.67% gallic acid equivalent, respectively. As a comparison to our previous study, the ABP-DES expressed the total carbohydrate content, protein content and TPC of 25.72% glucose equivalent, 0.30% BSA equivalent and 1.39% gallic acid equivalent, respectively. The higher value of ABP-DES carbohydrate content could be due to the properties of DES that improved the ability of the extraction medium in dissolving the acid soluble and partially soluble carbohydrates. This result suggested that extracted ABP-CAM has less sugar branch and comparable protein content compared to the ABP-DES. Other than that, the ABP-DES exhibited higher TPC value due to the efficiency of DES for extraction phenolic compounds. As reported by Vieira et al. [28], the different extraction solvent or media could affect the total phenolic compounds of the sample. The authors also reported that, the mixture of choline chloride and phenylpropionic acid based DES presented higher extraction of phenolic compounds (34.3 mg/g) compared to water (8.8 mg/g) and ethanol (10.3 mg/g). This result indicated that the ABP-CAM could be have lower antioxidant property due to a relative lower TPC.

Moreover, the solubility of ABP-CAM was shown in Table 3. Based on our previous study, the ABP-CAM has similar behavior with ABP-DES. Nevertheless, ABP-CAM showed higher solubility in all solution tested compared to the ABP-DES. This result could be elucidated by contribution of different polar effect backbone and the linearity of pectin [29].

Structural analysis of ABP-CAM

The sugar composition analysis was useful for understanding the monomer units and primary structure of ABP-CAM. As shown in Table 3, the main compositions of ABP-CAM were galacturonic acids (1.000), xyloses (0.641), arabinoses (0.293), glucoses (0.277), galactoses (0.156) and rhamnoses (0.104). The other monosaccharides which could be found in ABP-CAM were glucuronic acids (0.096), mannoses (0.058), fucoses (0.013) and riboses (0.010). The higher molar ratio of galacturonic acids was suggested that ABP-CAM composes mainly of d-galacturonic acids as the backbone with α-1,4 glycosidic bonds. It could also be seen that the predominant neutral sugars in ABP-CAM were xyloses, arabinoses, glucose, galactose and rhamnose, suggested that contribution of rhamnogalacturonan I (RG-I) branching. The linearity (R1), the contribution of RG (R2) and branching size (R3) of the ABP-CAM was therefore calculated based on molar content of natural sugar content in ABP, as mentioned by Houben et al. [30]. As a comparison to our previous study, the ABP-DES was found to be more linear pectin (R1 = 2.34) with a lower contribution of RG (R2 = 0.07) and less branch size (R3 = 2.97) than ABP-CAM (i.e. R1 = 0.78, R2 = 0.11 and R3 = 4.30). Hence, it was indicated that the extraction medium could cause differences in the structure of the extracted pectin in terms of its linearity and branch size.

Apart from that, the infrared (IR) spectrum of ABP-CAM extracted under optimal extraction conditions was demonstrated in Fig. 3. The result showed that the IR spectra of ABP-CAM was comparable with ABP-DES, as reported by our previous study [3]. The major group orientation exists in ABP-CAM were hydroxyl group (O–H), C–H absorption (i.e. CH, CH2, and CH3 stretching/bending vibrations), ester carbonyl group (C = O), unesterified carboxylate ion (COO−), CH3 bend, C–O stretching (i.e. C–O–C and C–O–H), and pyranose ring in the region of 3418 cm−1, 2930 cm−1, 1742 cm−1, 1626–1653 cm−1, 1437 cm−1, 1300–1000 cm−1, and 1020–1103 cm−1, respectively. In terms of O–H stretching and C–H absorption, it could be observed that the wavenumbers were shifted to higher values for ABP-CAM compared to the ABP-DES (3400 and 2926 cm−1 for O–H stretching and C–H absorption, respectively) [3]. This can be explained by the contributions of the bond length and electronegativity of atoms [31]. The higher in electronegativity in the pectin had resulted in a decrease in bond length (higher wavenumber based on Hooke’s law) due to the formation of stronger inter-molecular interaction (i.e. hydrogen bonding) with neighboring atom. This phenomenon indicated that the oxygen ion (in alcohol group) and carbon ion (in C–H absorption) of ABP-CAM had higher electronegativity, thus, resulted wavenumber shifted to be higher due to short bond length. It was expected that these inter-molecular interactions could contribute to the properties of the pectin. However, it could also be observed that the wavenumbers for the ester carbonyl group, unesterified carboxylate ion and CH3 bend of ABP-CAM were shifted to be lower than ABP-DES (1743 cm−1, 1629 to 1651 cm−1 and 1450 cm−1, respectively) because the variations of bond length due to inter-molecular interaction as aforementioned. Furthermore, the degree of esterification (DE) of ABP-CAM was calculated based on the proportion of esterified galacturonic acid groups to total galacturonic acid groups in the pectin molecule. The DE value for ABP-CAM was 58.0% and categorized to be a high esterified pectin as its DE is (> 50%) [12]. As a comparison to the ABP-DES that was produced in our previous study, the ABP-CAM has a comparable DE value with ABP-DES (54.0%).

Water and oil holding capacity, emulsifying and foaming properties

As seen in Table 4, the ABP-CAM exhibited 3.93 g water/g sample, 1.18 g oil/g sample, 65.50% and 125.56% for water holding capacity (WHC), oil holding capacity (OHC), emulsifying activity (EA) and foaming capacity (FC), respectively. As a comparison to the ABP-DES [3], the ABP-DES exhibited slightly (p < 0.05) lower WHC (3.70 g water/g sample) and EA (26.67%) than ABP-CAM. The ABP-CAM gave higher WHC and EA due to more contribution of RG to pectin population and larger branch size could consist steric interest that contribute in absorption of water and stabilizing of the emulsion [32]. However, the ABP-DES had a significantly (p < 0.05) higher value of OHC (2.40 g oil/ g sample) and foaming capacity (133.33%) due to higher in linearity, lower contribution of RG to pectin population and less average size of sample branching that allows more oil to bind with the backbone of the sample. This occurrence resulted the colloidal system with a gaseous phase stabilized in a continuous matrix to give a product an aerated structure. The emulsion stability (ES) of ABP-CAM was 100% (Table 4). This phenomenon could be explained by pectin molecules formed a gel-like film covering oil droplets and prevented the droplets from coalescing by imparting a charged surface to the coated/covered particles which would repel each other and maintain a stable, dispersed state at higher temperature [33]. The foaming stability (FS) value for ABP-CAM was also 100%. The similar result was reported by our previous study for both ES and FS value of ABP-DES.

As a comparison to other pectins extracted using citric acid as extraction medium, Kazemi et al. [34] reported that the pistachio green hull pectin (PGH) had higher WHC (4.11 g water/g sample) and OHC (2.02 g oil/g sample) than ABP-CAM. However, ABP-CAM gave higher EA and ES value than PGH with the EA and ES value of 58.30% and 92.5%, respectively. The ABP-CAM also possessed better FC and FS values compared to the FC (17.33%) and FS (4.61%) value obtained from eggplant peel pectin [35]. These results validated that ABP-CAM could be a potential candidate as emulsifier and stabilizer in high fat food products.

DPPH free radical scavenging activity and ferric ion reducing power

ABP-CAM showed 28.88% (Table 4) DPPH free radical scavenging activity and found to be a lower DPPH scavenging activity than ABP-DES (41.64%) at 10 mg/mL [3]. This different antioxidant activity could be explained by the contribution of TPC in the sample. It could be seen that the TPC value of ABP-CAM (0.67% gallic acid equivalent) was lower than the TPC value of ABP-DES (1.39% gallic acid equivalent). Apart from that, ABP-CAM showed ferric reducing antioxidant power (FRAP) of 1.59 mM (Table 4) and comparatively higher than ABP-DES (1.15 mM) at 10 mg/mL as found in our previous study [3]. As mentioned by Benzie and Strain [17], the reduction of Fe3+ to Fe2+ is higher at a lower pH and it could be seen that, the ABP-CAM had a lower pH value (Table 3) when comparing with ABP-DES (pH 2.81) [3]. This can be explained by the antioxidant can act as a reducing agent to reduce [Fe3+-TPTZ] to [Fe2+-TPTZ] at a lower pH, resulting in an intense blue color and the ferric ion reducing power was measured at 593 nm.

As a comparison, the ABP-CAM has comparable DPPH radical scavenging activity with Mormordica charantia polysaccharide (31.90%) [36]. On the other hand, the Suaeda fruticosa leaves pectin (SFP) (60.00%) and Spinacia oleracea polysaccharide (69.00%) at 10 mg/mL exhibited higher value of DPPH scavenging activity than ABP-CAM as reported by Mzoughi et al. [37] and Mzoughi et al. [38], respectively. Moreover, Mzoughi et al. [37] reported that SFP has a similar value of ferric ion reducing power (1.50 mM) compared to the ABP-CAM. However, ABP-CAM had relatively higher reducing power than Ganoderma lucidum polysaccharide (0.55 mM) and sweet potato pectin (0.43 mM) as mentioned by Zeng et al. [39] and Ogutu and Mu [40], respectively. In short, this finding suggested that the ABP-CAM exhibited low DPPH radical scavenging activity. However, higher FRAP was observed in this sample. Therefore, it was suggested that these activities could be affected by TPC and pH of the pectin.

Conclusions

The extraction medium had significantly affected the efficiency of extraction and the properties of the pectin. Results indicated that CAM had less efficiency as the extraction medium for extraction of ABP and the ABP-CAM produced was found to be less linear, higher contribution of RG and more branching size. However, using CAM as the extraction medium showed significant improvement in the solubility, WHC and EA due to steric effect of the ABP-CAM chains. Furthermore, lower in pH value of ABP-CAM gave higher values ferric reducing antioxidant power. The results obtained indicated that the use of CAM and DES as the extraction medium significantly affects the extraction yield as well as the properties of ABP. These properties are mainly contributed by the structure of pectin. It is advisable that the purpose of extraction is not merely to increase the yield, the importance of the pectin structure and functional properties have to be taken into consideration. It is advisable that the purpose of extraction is not merely to increase the yield, the importance of the pectin structure and functional properties have to be taken into consideration. Hence, the researchers should not just explore the potential of extraction medium that could increase the yield, but also have to investigate the properties of the pectin that could be used in the food applications.

References

M. Sandarani, J. Pharmacognosy Nat. Prod. 3, 1 (2017)

A.A. Hossein, Pectin and Galacturonic Acid from Citrus Wastes (M.Sc. diss), University of Boras, Sweden (2009).

M.H. Shafie, R. Yusof, C.Y. Gan, Carbohydr. Polym. 216, 303 (2019)

J.S. Yang, T.H. Mu, M.M. Ma, Food Chem. 244, 197 (2018)

Z. Raji, F. Khodaiyan, K. Rezaei, H. Kiani, S.S. Hosseini, Int. J. Biol. Macromol. 98, 709 (2017)

T. Masuko, A. Minami, N. Iwasaki, T. Majima, S.I. Nishimura, Y.C. Lee, Anal. Biochem. 339, 69 (2005)

M.M. Bradford, Anal. Biochem. 72, 248 (1976)

R. María, M. Shirley, C. Xavier, S. Jaime, V. David, S. Rosa, D. Jodie, J. King Saud Univ. Sci. 30, 500 (2018)

M.L. Fishman, P.E. Pfeffer, R.A. Barford, L.W. Doner, J. Agric. Food Chem. 32, 372 (1984)

S.Q. Liew, G.C. Ngoh, R. Yusoff, W.H. Teoh, Biocatal. Agric. Biotechnol. 13, 1 (2018)

Y. Lv, X. Yang, Y. Zhao, Y. Ruan, Y. Yang, Z. Wang, Food Chem. 112, 742 (2009)

D.P. Leao, B.G. Botelho, L.S. Oliveira, A.S. Franca, LWT-Food Sci. Technol. 87, 575 (2018)

J. Singthong, S.W. Cui, S. Ningsanond, H.D. Goff, Carbohydr. Polym. 58, 391 (2004)

S.K. Du, H. Jiang, X. Yu, J.L. Jane, LWT-Food Sci. Technol. 55, 308 (2014)

H.M.S. Akhtar, M. Abdin, Y.S. Hamed, W. Wang, G. Chen, D. Chen, X. Zeng, LWT, Article ID: 108265 (2019).

M.S. Blois, Nature 181, 1199 (1958)

I. F. Benzie, J. Strain, Method Enzymol. 29915 (1999).

P.H.F. Pereira, T.Í.S. Oliveira, M.F. Rosa, F.L. Cavalcante, G.K. Moates, N. Wellner, H.M.C. Azeredo, Int. J. Biol. Macromol. 88, 373 (2016)

J. Lu, J. Li, R. Jin, S. Li, J. Yi, J. Huang, Int. J. Biol. Macromol. 131, 323 (2019)

B. M. N., Nguyen, T., Pirak, Cogent Food Agric. 5, Article ID: 1633076 (2019).

X. Guo, X. Guo, H. Meng, B. Zhang, S. Yu, Food Hydrocoll. 70, 105 (2017)

M. Yolmeh, S.M. Jafari, Food Bioprocess Tech. 10, 413 (2017)

L. Zhang, M. Wang, Int. J. Biol. Macromol. 95, 675 (2017)

S. Muthusamy, L.P. Manickam, V. Murugan, M. Chendrasekar, A. Pugazhendhi, Int. J. Biol. Macromol. 124, 750 (2018)

W. Wang, X. Li, X. Bao, L. Gao, Y. Tao, Int. J. Biol. Macromol. 120, 1420 (2018)

F. Jafari, F. Khodaiyan, H. Kiani, S.S. Hosseini, Carbohydr. Polym. 157, 1315 (2017)

B. Pasandide, F. Khodaiyan, Z.E. Mousavi, S.S. Hosseini, Carbohydr. Polym. 178, 27 (2017)

V. Vieira, M.A. Prieto, L. Barros, J.A.P. Coutinho, I.C.F.R. Ferreira, O. Ferreira, Ind. Crops Prod. 115, 261 (2018)

F. Rubio-Senent, G. Rodríguez-Gutiérrez, A. Lama-Muñoz, J. Fernández-Bolaños, Food Hydrocoll. 43, 311 (2015)

K. Houben, R.P. Jolie, I. Fraeye, A.M. Van Loey, M.E. Hendrickx, Carbohydr. Res. 346, 1105 (2011)

X. Landreau, B. Lanfant, T. Merle, C. Dublanche-Tixier, P. Tristant, Eur. Phys. J. D 66, 1 (2012)

E. Dickinson, Food Hydrocoll. 17, 25 (2003)

Y. Wu, W. Cui, N.A.M. Eskin, H.D. Goff, Food Res. Int. 42, 1141 (2009)

M. Kazemi, F. Khodaiyan, M. Labbafi, S. SaeidHosseini, M. Hojjati, Food Chem. 271, 663 (2019)

M. Kazemi, F. Khodaiyan, S.S. Hosseini, Food Chem. 294, 339 (2019)

H.-F. Tan, C.-Y. Gan, Int. J. Biol. Macromol. 85, 487 (2016)

Z. Mzoughi, A. Abdelhamid, C. Rihouey, D. Le Cerf, A. Bouraoui, H. Majdoub, Carbohydr. Polym. 185, 127 (2018)

Z. Mzoughi, G. Souid, R. Timoumi, D. LeCerf, H. Majdoub, Int. J. Biol. Macromol. 136, 332 (2019)

X. Zeng, P. Li, X. Chen, Y. Kang, Y. Xie, X. Li, Y. Zhang, Int. J. Biol. Macromol. 126, 867 (2019)

F.O. Ogutu, T.H. Mu, Ultrason. Sonochem. 38, 726 (2017)

Acknowledgements

This research was financially supported by Universiti Sains Malaysia RUI Grant (Grant Number: 1001/CABR/8011045). The authors acknowledged Analytical Biochemistry Research Centre (ABrC), Universiti Sains Malaysia and School of Technology Industry, Universiti Sains Malaysia for its testing facilities. The authors would also like to acknowledge the financial support from USM Fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are none conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

BBD with the observed responses and predicted values for the yield of ABP-CAM.

Run | Variable levels | Yield (%) | |||

|---|---|---|---|---|---|

x1 (% CAM) | x2 (temperature) | x3 (time) | Observed (y1) | Predicted (y0) | |

1 | 0 | + 1 | − 1 | 8.65 | 7.67 |

2 | + 1 | 0 | − 1 | 6.42 | 6.13 |

3 | 0 | 0 | 0 | 7.29 | 6.38 |

4 | + 1 | + 1 | + 1 | 10.23 | 9.74 |

5 | 0 | 0 | 0 | 5.99 | 6.38 |

6 | − 1 | 0 | + 1 | 8.56 | 8.20 |

7 | 0 | − 1 | − 1 | 6.19 | 6.29 |

8 | 0 | 0 | 0 | 6.59 | 6.38 |

9 | + 1 | − 1 | 0 | 6.42 | 6.13 |

10 | − 1 | − 1 | 0 | 6.78 | 6.54 |

11 | 0 | 0 | 0 | 6.35 | 6.38 |

12 | − 1 | + 1 | 0 | 8.06 | 7.93 |

13 | + 1 | + 1 | 0 | 6.33 | 7.93 |

14 | 0 | 0 | 0 | 7.05 | 6.38 |

15 | + 1 | 0 | + 1 | 7.37 | 8.20 |

16 | 0 | − 1 | + 1 | 8.34 | 8.36 |

17 | − 1 | 0 | − 1 | 4.96 | 6.13 |

Rights and permissions

About this article

Cite this article

Shafie, M.H., Gan, CY. A comparison of properties between the citric acid monohydrate and deep eutectic solvent extracted Averrhoa bilimbi pectins. Food Measure 14, 2889–2897 (2020). https://doi.org/10.1007/s11694-020-00533-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00533-x