Abstract

Talipot palm (Corypha umbraculifera L.) is a non-conventional source of starch with a higher yield (76%). In this work, the physicochemical, functional, morphological, thermal, pasting and rheological properties of flour and starch obtained from the trunk of Talipot palm were investigated. Talipot palm starch contains high amount of amylose (28.05%) and the starch is found to have a mixture of round, elongated and elliptical shaped granules. Talipot palm starch and flour exhibited A-type crystallinity. The functional properties like water absorption and oil absorption capacities do not show any significant difference (P ≤ 0.05) among Talipot palm flour and starch. Talipot palm starch exhibited higher value in pasting parameters. Talipot palm starch showed higher enthalpy of gelatinization when compared to the flour.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the entire flora, palm species ranks third in economic importance [1]. Palm starches are considered to be a genuine starch source belonging to the oldest plant families [2]. Corypha umbraculifera L., is a tropical monocarpic palm, commonly known as Talipot palm belonging to the family Arecaceae which inhabits in moist climate and is native to semi-wild coastal plains of south western India, Sri Lanka, Malaysia, and Myanmar [1]. It is one of the three sago palms, which is considered as the promising palm for future [3]. It is a multipurpose palm with a great utility which produces commercial and subsistence products from its stem, leaf, and seed.

The sap and stem from the Talipot palm are the two major portions which are widely utilized. A Talipot palm yields two liters of sap per day for 3–4 months, which is used to produce products like alcohol, wine, vinegar, and sugar. The pith of the mature Talipot palm is a storage house of abundant amount of light brownish colored starch. About 100–250 kg of edible starch can be procured from the stem of a fully matured palm before its fruiting and flowering. The yield of starch thus found to be 76% which is similar to starch from other non-conventional sources such as babassu, breadfruit and turmeric [4]. The Talipot palm flour and starch have a low amount of protein and lipid content. In India, the Talipot palm starch once served as a genuine source of carbohydrate to the tribes in the tropical region in famine-prone areas and was locally eaten as their staple food in the form of gruel and bread and performed as their source of supplement nutrition [5].

Starch is one of the most important but flexible food ingredient mainly governing the texture, viscosity, binding, moisture retention, film formation, and product homogeneity. It is mostly used in soups, sauces, gravies, bakery products, dairy products, confectionery, snacks, batters, meat products and as a coating material. Non-food applications of starch cover a wide spectrum of areas like adhesives, textiles, paper manufacturing, alcohol-based fuels and pharmaceuticals [6]. The use of new starches obtained from non-conventional sources such as legume, grass, seed, and palm for the commercial application provides a novel insight and cost reduction in industries [4].

The starch from Talipot palm can be considered as a non-conventional source of starch and can be used as an alternative to commercially exploited starches. The Talipot palm yields starch which equals the conventional starch obtained from tubers and cereals. Exploration and identification of desirable functionality of new and underexploited starch sources like Talipot palm is a necessity due to a number of food and non-food applications [4]. The objective of the work was, therefore, to analyse the chemical composition, physico-chemical and functional features of flour and native starch obtained from Talipot palm.

Materials and methods

Flour

The flour was collected from the pith of a fully matured Talipot palm (Corypha umbraculifera L.) in Malappuram district, Kerala, South India. The flour was obtained by the method proposed by Sudheesh et al. [7]. The extracted Talipot palm flour was stored in 100 gauge LDPE film under refrigerated condition (4 ± 2 °C) until further analysis.

Isolation of starch

The starch isolation from Talipot palm flour was done by the alkali method pursued by Sudheesh et al. [7]. The yield of starch isolated was 76%. The isolated starch was stored in poly ethylene bags (100 gauge) at refrigeration temperature (4 ± 2 °C) until further analysis.

Chemical composition

Moisture, ash, and protein

The amount of moisture (925.10) and ash (923.03) present in Talipot palm flour and starch are estimated by using AOAC, 1999 method [8]. The protein content was estimated by semi-micro Kjeldahl method followed by AOAC method 991.22.

Amylose content

The amount of amylose content in Talipot palm flour and starch were estimated by calorimetric method proposed by Williams et al. [9]. To 100 ml standard flask 0.1 g sample was taken, 99% ethanol (1 ml) and 1 M NaOH (9 ml) solution was poured into it and mixed well. The suspension was then placed in a water bath at boiling temperature for 10 min. After cooing the suspension was diluted to 100 ml with distilled water. Prepared sample (5 ml) was pipette out into standard flask, 1 M acetic acid (1 ml) and iodine solution (2 ml) were poured into it and then diluted to 100 ml with distilled water. The absorbance was taken by using spectrophotometer at 620 nm (Shimadzu, UV-1800, Japan). The blank solution was prepared accordingly and the amylose content was obtained by using the equation:

X-ray fluorescence spectroscopy (XRF)

The mineral content of Talipot palm flour and starch were found by using an X-ray fluorescence spectrophotometer (Bruker AXS, D 76,181, Karlsruhe, S4 PIONEER, Germany). The samples were blended with laboratory-grade crystalline boric acid (4:1) and made into pellets for analysis.

Morphological analysis

Polarized light microscopy (PLM)

The birefringence of Talipot palm flour and starch was studied using polarized light microscope (Nikon ECLIPSE LV 100POL, Japan). A starch suspension (2 mg/ml) in glycerol was made into a thin smear in a glass slide and observed under normal light and polarized light by using a polarized light microscope equipped with a digital camera (Nikon Coolpix 8400) at a magnification of ×4.

Scanning electron microscopy (SEM)

The morphological study of Talipot palm flour and starch was carried out by using a Scanning electron microscope. The samples were spread over the stubs with two-sided adhesive tape and covered with a slim layer of carbon using an automated sputter (HITACHI, E-1010, Japan) coater for 30 min and observed by using a scanning electron microscope (HITACHI, S-3400 N, Japan) with an acceleration voltage of 15 kV at ×500 magnification.

Fourier transform infrared spectroscopy (FTIR)

The functional groups present in Talipot palm flour and starch were identified by using FTIR spectrophotometer (Thermo Nicolet Model: 6700, UK). The range of wave number is 400–4000 cm−1 and resolution is 4 cm−1. The samples were prepared by mixing the powdered sample with optical grade KBr (1:100) and pellets were prepared by using a pelletizer (Shimadzu, MPH-1, Japan).

X-ray diffractometry (XRD) and relative crystallinity (RC)

The crystalline nature of Talipot palm flour and starch was examined using X-ray diffractometer (BRUKER AXS, D2 PHASER, Karlsruhe, Germany) operated by a power of 40 kV and 40 mA and Cu K − α used as an X-ray source. The samples were filled in the depression of test holder and scanning was done at 2θ = 4°–80°. The percentage crystallinity of the samples was determined by the formula:

Color

The color of Talipot palm flour and starch was analyzed and read in a Hunter colour lab digital colorimeter (Color Flex CX2748, Hunter Lab, USA), observation angle of 10° and calibrated by Hunter colour lab standard plates. The parameters L*, a* and b* were measured. Hue and chroma can be determined by the equations:

Bulk density, tapped density and true density

Bulk density (BD), tapped density (DT) and true density (Td) were done by the procedure described by Deepika et al. [10]. 1 g starch was weighed into a 10 ml measuring cylinder and the volume was marked. Tapped density is estimated by 100 taps of measuring cylinder with 1 g sample in one minute. The bulk and tapped densities are the ratio of the weight of the sample to the volume occupied. True density (Td) was determined by the following method. 1 g of flour or starch was weighed into a 10 ml measuring cylinder and 5 ml of petroleum ether was poured to it and slightly mixed to suspend the particles. Then, 1 ml of petroleum ether was poured through the walls of the measuring cylinder. The true density was determined by using the equation:

Powder flowability

The flowability of Talipot palm flour and starch was determined by Hausner’s ratio (HR) and Carr’s Index (CI) according to the procedure followed by Deepika et al. [10]. HR is the ratio of the tapped density (DT) to bulk density (BD) and CI was estimated by using the equation:

Porosity

Porosity (Pf) of Talipot palm flour and starch was obtained by the method followed by Deepika et al. [10] by the equation:

Angle of repose

The static angle of repose (θ) of the flour and the starch was analyzed by the method described by Deepika et al. [10] using a fixed funnel and free-standing cone method. A funnel was kept 2 cm high from a graph paper placed on a flat surface. The flour and starch were made to flow inside the funnel until the apex of the cone thus formed reaches the bottom of the funnel. The height of the heap (h) formed and the diameter (d) of the base was determined to calculate the tangent of the angle of repose with the equation:

pH and acidity

The pH and acidity of Talipot palm flour and starch were found by the method followed by Polesi et al. [11] with modest modification. The pH was analyzed in digital pH meter (EUTECH Instruments, Singapore, P/N:54X002605) by preparing a slurry 1gm/25 ml distilled water. The acidity was determined by titrating the suspension against 0.01 N NaOH solution to the pH 8.3.

Water and oil absorption capacity

The procedure suggested by Bashir et al. [12] was used to find out the water and oil absorption capacity. 0.5 g of flour and starch was added to 10 ml of distilled water in a centrifuge tube. The contents were blended well and then centrifuged (REMI Centrifuge, R8 C, Remi Instruments Ltd., Vasai India) at 3000 rpm for 15 min. The supernatant was drained off and reweighed the tube. The increase in weight was articulated as grams of water absorbed per gram of starch. Oil absorption capacity was performed by measuring 0.5 g of the sample, which was blended with 6 ml of mustard oil in a centrifuge tube. The content was vortexed for 1 min and kept for 30 min and then subjected to centrifugation at 3000 rpm for 15 min. The oil layer was decanted by draining and reweighing was done. The weight gain was communicated as grams of oil absorbed per gram of flour/starch.

Emulsifying properties

The emulsifying activity (EA) and emulsion stability (ES) was investigated by the method suggested by Sridaran et al. [13]. 0.5 g of the sample was mixed thoroughly with 5 ml of distilled water and mustard oil. The emulsions were then centrifuged at 1100 rpm for 5 min. The EA was calculated by the accompanying equation.

ES was found out by warming the obtained emulsion for 30 min at 80 °C and then centrifuged for 5 min at 1100 rpm.

Swelling index and solubility

Swelling index of starch was analyzed by the method followed by Dar et al. [14] with slight modification. 0.5 g of starch was mixed with to 10 ml of distilled water in pre-weighed centrifuge tubes. The mixture was heated in a water bath at various temperatures like 60, 70, 80 and 90 ºC for 30 min with continuous mixing. The contents were cooled and centrifugation was done at 4500 rpm for 15 min and the supernatant was removed to preweighed petri plate and the weight of sediment was taken. The petri plates were then placed in a hot air oven at 110 ºC for 12 h and the final weight was taken. Swelling index and solubility was determined by using the equations.

Syneresis

Syneresis was estimated by the procedure followed by Wani et al. [15]. 6% (db) of the sample was weighed into a pre-weighed centrifuge tube and then heated at 90 ºC to gelatinize. The supernatant was discarded and the samples were kept in refrigerated conditions for 7 days. The sample was taken in alternate days and centrifuged at 4500 rpm for 10 min and the amount of water expelled out indicated the percent syneresis.

Light transmittance

Light transmittance was done according to the procedure proposed by Bashir et al. [16] with a slight alteration. 1% (db) of the sample mixture was gelatinized at 90 ºC bath for 30 min with study mixing. The suspension was allowed to cool to room temperature then kept in refrigerated conditions for seven days and the transmittance was determined in an interval of 48 h at 640 nm, distilled water used as blank using UV- spectrophotometer (Shimadzu, UV-1800, Japan).

Pasting properties

The pasting characteristics of Talipot palm flour and starch were found by using Rapid Visco-Analyser (RVA starch master 2, Newport Scientific, Warriewood, NSW, Australia), by the procedure followed by Sudheesh et al. [7]. 12% starch suspension was set up in a canister and thoroughly mixed. The slurry was equilibrated for 1 min at 50 °C and then heated to 95 °C for 3.5 min and retained at 95 °C for 2.5 min, then cooled to 50 °C for 4 min and held at 50 °C for 1 min.

Rheology

The rheological characteristics were determined by using rotational rheometer (Anton Paar instrument, Graz, Austria). The starch paste was prepared by boiling 6% starch suspension and cooled to room temperature for 10 min. The paste was then exposed to rotational rheometer having titanium cone CP75-1 with a cone angle of 1° plate geometry with 40 mm measurement and 0.07 mm slit at 25 °C. Pre-shearing was done before each measurement at a rate of 0.01/s for 10 s and equilibrated for 10 s.

Thermal properties

Thermal properties of starch and flour were investigated by the technique pursued by Colussi et al. [17], using differential scanning calorimetry (TA instruments,Q20, Newcastle, DE, USA). 6 mg of sample was gauged and added to an aluminium pan and the suspension was made in the proportion of 1:3 (starch: water) with distilled water. The hermetically sealed pan was put for 1 h to bring equilibration. The pans were heated from 20 ºC to 100 ºC (10 ºC/min), a vacant pan was kept as a standard. Thermal characteristics like onset (To), peak (Tp), conclusion temperatures (Tc) and the enthalpy of gelatinization (\(\Delta \mathrm{H}\mathrm{g}\mathrm{e}\mathrm{l}\)) were measured.

Starch digestibility

Rapidly digestible starch ( RDS), slowly digestible starch (SDS) and resistant starch (RS), were estimated by the method proposed by Englyst et al. [18]. The starch digested within 20 min considered as RDS, starch digested between 20 to 120 min considered as SDS and starch digested after 120 min considered as RS.

Statistical analysis

Data expressed as mean ± SD. The data was subjected to analysis of variance (one-way ANOVA) and Duncan’s test was done by using SPSS software (IBM SPSS Statistics 23). Standard deviation is noted at a significant difference P ≤ 0.05.

Result and discussion

Chemical composition

The chemical composition of Talipot palm flour and starch are summarized in Table 1. Moisture is a major constituent which affects the shelf life of a food product, the product with higher moisture content is highly susceptible to deterioration. Moisture and ash content of flour was significantly (P ≤ 0.05) higher than that of starch. The protein content of flour and starch were significantly (P ≤ 0.05) different. The ash and protein content of Talipot palm flour and starch were less than that of other flours such as black gram [19] and rice starch [20, 21]. The Talipot palm flour has a small amount of fat and fiber. The amylose content of starch (28.05%) is found to be higher than that of flour (23.41%). The Talipot palm starch contains a higher amount of amylose when compared to commercially available starches such as cassava, wheat and potato [19]. The iron, sulphur and potassium content of starch were found to be less than that in flour, whereas there was no significant change (P ≤ 0.05) in phosphorous and magnesium content.

Morphology

The morphological characteristics of Talipot palm flour and starch are studied using a light microscope (Fig. 1a, b), polarized light microscope (Fig. 1c, d) and scanning electron microscope (Fig. 1c, f). Talipot palm flour contains fiber bodies and protein between the starch granules, which are of different shape and size. Birefringence is the property of optically anisotropic compounds to doubly refract polarized light. Talipot palm starch granules possess birefringence with off-centered hilum at the ends. The birefringence sequence in the granule points out that the amylo pectin crystals are orderly put inside the granule at 90° angle to the surface with the reducing ends aligned towards the hilum [22]. Birefringence patterns are indicative of starch crystallinity, and the weak crystalline properties of starch granules are the results of weak birefringence patterns [23]. Birefringence pattern and hilum position of the granules are influenced by the plant physiology and biochemistry of amyloplast [22].

The SEM monograph of Talipot palm flour and starch showed that the granules are embedded in the protein and fibre matrices which led to the development of large granular bundles (Fig. 1e). Talipot palm starch granules are elongated, round, elliptical and irregular in shape with a smooth surface. Most of the starch granules showed depression and deep furrows, more over a few of them showed pores on their surface. Length and breadth of Talipot palm starch granules ranged from 13.69 µm to 61.64 µm and 12.32 µm to 31.50 µm respectively. Starch with pores and furrows on the granule surface were reported in acorn starch [24]. The morphological features vary with their genetic makeup and origin. The functional properties such as swelling power, water absorption capacity and digestibility are greatly affected by the granule shape and size. The smaller sized granules exhibit better digestibility and higher surface area, which provides a great facility for enzyme action.

FTIR analysis

The FTIR spectra of Talipot palm flour and starch are presented in Fig. 2. The spectra of Talipot palm flour and starch are following a similar pattern and it indicates that the functional groups present on both flour and starch are similar. The broad peak at 3427 cm−1 in both Talipot palm and starch characterizes the stretching vibration of the OH group. The peak observed in 2925 cm−1 indicates the presence of CH2 stretching vibration. The peak at 1640 cm-1 is indicating the H–O–H bending vibrations presented in water molecules in the amorphous region [25]. The peaks observed at 989 cm−1 and 1444 cm−1 represents C–O–H bending and CH3 bending vibrations respectively. The peak at 892 cm−1 belongs to the CH groups from pyranose ring skeletal vibrations.

X-ray diffraction pattern and relative crystallinity of Talipot palm flour and starch

Talipot palm flour and starch have shown major peaks at diffraction angles (2θ) 15.1°, 17.2°, 18.1° and 23.2°, and minor peaks at a diffraction angle of 11.2° (Fig. 3). Talipot palm flour and starch exhibited type-A crystallinity and have comparable results with kithul palm flour and starch [7]. The double helix structure of type-A crystalline starches has an exceedingly monoclinic lattice having the maltotriose as the continuation unit and four water molecules per building block [26]. A-type crystal has greater thermodynamic stability [27]. Talipot palm flour have significantly (P ≤ 0.05) higher relative crystallinity than starch. The relative crystallinity of Talipot palm flour and starch are 18.46% and 16.35% respectively. The crystallinity of starch depends on the structure of starch and the ratio of small and large amylopectin side chain to amylose [28].

Physicochemical and functional properties of Talipot palm flour and starch

Color parameters

Talipot palm starch showed higher lightness value (L*) than flour (90.8 and 89.9) and are given in Table 2. Talipot palm flour and starch showed a significant difference in a* and b* values. Talipot palm flour exhibited higher a*-value which indicated redness and starch exhibited higher b*- value, indicated yellowness. The L*, a* and b* values of Talipot palm starch is comparable to the color values of native chestnut starch [29]. Hue angle is the measure of discoloration and chroma is the intensity of the color, and both are found to be higher for starch.

Bulk density and tapped density

Higher bulk and tapped density were observed in Talipot palm starch than flour (Table 2). The bulk and tapped density of flour and starch are 0.58 g/ml & 0.73 g/ml, 0.66 g/ml & 0.79 g/ml respectively. This result is in an agreement with the bulk density of legume flour [30] and Nigerian rice cultivars which are ranged between 0.65 g/ml and 0.79 g/ml [31]. Higher tapped density of Talipot palm flour and starch is due to the reduction of number of voids in tapped volume by the action of an external force. The higher bulk and tapped density of Talipot palm starch indicates higher expandability and blending property. Higher tapped density of Talipot palm starch when compared with Talipot palm flour indicates better packaging and storage behaviour of the substance during different unit operations.

True density and porosity

True density is the density which eliminates all the pores and is determined by the mass of the material and its true volume [11]. Talipot palm flour and starch did not show any significant difference (P ≤ 0.05) in their true density and are reported in Table 2. True density of Talipot palm flour and starch was 1.12 g/ml and 1.14 g/ml respectively, and comparable results were reported in wheat flour and starch [32]. The porosity indicates the exposed structure of the material and is the portion of the unoccupied space. Talipot palm flour and starch showed a significant difference (P ≤ 0.05) in porosity. The study found that the porosity of Talipot palm flour and starch are 48.0% and 42.3% respectively. A higher porosity was reported in Colocasia esculenta starch [10]. Higher porosity of Talipot palm flour than starch can be due to lower density of flour. Higher porosity of flour indicates that Talipot palm flour can have application in drug and pharmaceuticals.

Hausner's ratio, Carr's index and Angle of repose

The Hausner's ratio, Carr's index and Angle of repose of Talipot palm flour and starch are reported in Table 2. There is no significant difference (P ≤ 0.05) observed in Hausner’s ratio of flour and starch, and the values are 1.25 and 1.20 respectively. It indicates the cohesion between the particles and lower the Hausner’s ratio, higher the flowability [33]. Carr’s index is indicates the compressibility of material and it indirectly assess the material flowability. Carr’s index is directly proportional to the cohesiveness of the particle [10]. In the present study, Carr’s index of flour and starch are significantly different and is found that the flour showed a higher value of Carr’s index. The Angle of repose of flour and starch are 30.3° and 31.4° respectively. The powders with the angle of repose between 30- 35o indicate good flow property [33].

pH and acidity

Talipot palm starch showed a higher pH value than that of flour, and the values of starch and flour were 6.38 and 5.44 respectively (Table 2). The starch isolation by using alkali treatment causes an increase in the pH value of starch. This is similar to the value of Nigerian rice variety [21], brown rice [34] and chickpea flour [16]. The percent acidity of Talipot palm flour (1.63%) was found to be higher than starch (0.96%). It is observed that the Talipot palm flour has higher acidity than jackfruit seed flour (1.12%) [35] and the acidity of Talipot palm starch is similar to rice starch [11].

Water and oil absorption capacity

Water absorption capacity (WAC) is the measure of the ability to bind with water molecule [34]. Intake of the water molecule is an important trait in the textural and functional properties. The flour and starch do not show any change in water absorption capacity (Table 2) and the value was 1.70 g/g. This result is in comparable with the water absorption capacity of chickpea flour [16], and Citrullus lanatus and Limonia acidssima seed flour [36]. The presence of hydrophilic groups in the structure of carbohydrate and protein will increase the water absorption capacity of flour [34].

Oil absorption capacity (OAC) is an important trait, particularly in the enhancement of palatability, flavour retention and shelf life extension [12]. The OAC of Talipot palm flour and starch, given in Table 2 did not show any significant difference (P ≤ 0.05) and is found to be 1.41 and 1.42 (g/g) respectively. Similar studies were done in chickpea flour [16] and Bambara groundnut starch and flour [27]. The low OAC is due to the presence of less number of non-polar groups which lead to the formation of hydrophobic interaction with carbohydrates and lipids [34].

Emulsion capacity (EC) and emulsion stability (ES)

EC is the capability of protein to form an emulsion [30]. Talipot palm flour and starch showed EC and ES (Table 2). EC and ES of flour and starch are 19.1% and 28.3%, 10.8% and 25.3%, respectively, a higher values of EC and EV have been observed in legume flours [30], taro and rice flours [37]. The lower EC and ES of Talipot palm flour than legumes, taro and rice starch can be due to its lower protein content. Jitngarmkusol stated that [34], certain polysaccharides will aid in stabilizing the emulsion by augmenting the viscosity. The emulsion stability of Talipot palm flour is due to its higher starch content.

Swelling power and solubility

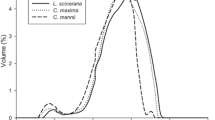

Swelling power is the capacity of starch to absorb water at a specific temperature. The swelling power of Talipot palm flour and starch at various temperatures (60–90 °C) are shown in Fig. 4a. In the presence of high amount water and temperature, disruption of crystalline structure and hydrogen bond formation with water molecules will occur which facilitates the swelling of granules. Swelling power of flour and starch increased with increase in temperature, except that the flour showed decrement at 90 °C. The increase was gradual at a temperature range of 70–80 °C. The higher swelling power of flour is due to the presence of the low amount of amylose in flour compared to the starch, and it indicates the weak interactive force between molecules. The decrease in swelling power of flour at 90 °C is due to the gelatinization of starch [16]. The amount of amylose and amylopectin and their molecular weight has an impact on the swelling power of starch. The solubility index of Talipot palm flour and starch are shown in Fig. 4b. Starch have higher solubility index and it increased with increase temperature. Flour showed a decrease at 90 °C and it may be due to lower swelling of flour at 90 ºC. The similar studies were done in Nigerian rice varieties [21]. The higher solubility index of starch is due to its higher amylose content, the solubility of flour is influenced by the presence of soluble substances presented in it [38].

Syneresis

Syneresis is the process of release of water during retrogradation of gels. Syneresis values of Talipot palm flour and starch are represented in Fig. 5. The syneresis values of flour and starch exhibited an increasing trend with the storage period (24–168 h). The syneresis value of flour and starch varied from 14.7 to 19.61% and 11.72–19.75% respectively during 24–168 h of storage. During storage, the interaction between amylose and amylopectin results in expelling the water molecules [38]. The strong interactive force of amylose and amylopectin with water molecule results in lower value of syneresis in gels [39]. It is observed that Talipot palm flour has higher syneresis value than starch. Higher syneresis value of Talipot palm flour gel is due to its higher retrogradation properties.

Light transmittance

Light transmittance is an important parameter which determines the application of flour and starch in the food industry [40]. The light transmittance of a gel indicates the paste clarity. The light transmittance value of Talipot palm flour and starch was decreased during a storage period of seven days and are presented in Fig. 6. During storage period the paste clarity was decreased due to increased turbidity. Light transmittance value of flour and starch ranged from 35.89% to 11.96% and 30.47% to 7.87% respectively. The light transmittance depends on the presence of swollen granules in the paste. Lower refraction of light by swollen granules results in increased light transmittance. Granule swelling, leached amylose and amylopectin and the molecular weight of leached substances also influence the paste clarity [41]. Higher paste clarity observed in Talipot palm flour than starch is due to the higher swelling index of flour, thus showing the property to be used as a thickening agent in fruit pie filling.

Pasting properties

The transformation of starch suspension to paste in the presence of heat increases viscosity parameters [27]. Pasting temperature is the temperature at which initial swelling of starch start. The Talipot palm flour and starch did not show any significant difference in gelatinization temperature (Fig. 7) and are 86.3 °C and 86.6 °C respectively. The higher pasting temperature indicates higher resistance of the flour and starch towards swelling [42]. The peak viscosity is the extreme viscosity attained by flour and starch and it occurs when most of the granules swell. Starch granule with the higher swelling index has high peak viscosity [41]. The peak viscosity of Talipot palm flour and starch are significantly different and are found to be 2868 cP and 3646 cp respectively and is higher than that of the peak viscosity of wheat, barley and sorghum [41]. Break down viscosity denotes the capacity of starch paste to withstand higher temperature and shear force [43]. 1218 cP and 1881 cP are the breakdown viscosity of Talipot palm flour and starch respectively. The higher breakdown viscosity of starch shows lower stability during heating [44]. Talipot palm flour has higher stability than that of starch. Trough viscosity, setback viscosity and final viscosity of Talipot palm starch was found to be higher than that of Talipot palm flour and is 1765 cP, 779 cP, 2562 cP, and 1647 cP, 789 cp, 2436 cP for starch and flour respectively. Set back viscosity reflects the gelling and retrogradation susceptibility of starch [45] and final viscosity is the viscosity attained on cooling the starch gel up to 50 °C and shows the capacity of starch to form a gel after cooling [44]. The pasting properties of starch may be varied with starch and it is influenced by crystalline structure, granular morphology, amylose content and the purity of starch. Starch with high peak and breakdown viscosity and low setback viscosity are generally used as a thickening or gelling agent, however, starch with low peak viscosity is used as an ingredient in the preparation of weaning food [43].

Rheological properties

Storage modulus (G′), loss modulus (Gʺ) and damping factor (tan δ) of Talipot palm flour and starch over an angular frequency (ω) of 1–100 rad sec−1 are presented in Fig. 8. The amount of recuperated or accrued energy in each cycle is known as storage modulus and indicates the elastic nature of paste, viscous nature of paste is indicated by loss modulus and it is the loss of energy in each cycle [23]. From the graph, it is demonstrated that both storage and loss modulus was increasing with ω. G′ and Gʺ of flour were noticed higher than that of starch, it might be due to the higher swelling power of flour [46]. Visco-elastic nature of the paste was studied by calculating the damping factor (tanδ). A value of tanδ > 1 indicates viscous nature of paste, whereas tanδ value < 1 indicates elastic nature [46]. Talipot palm flour and starch showed a significant difference (P ≤ 0.05) in tanδ value, and the starch showed a higher value of tanδ.

Thermal analysis

The gelatinization properties of Talipot palm flour and starch are studied by using differential scanning calorimeter and are given in Table 3 and Fig. 9. The onset and peak temperature of Talipot palm starch and flour did not show any significant difference (P ≤ 0.05) whereas conclusion temperature showed a significant difference (P ≤ 0.05). The gelatinization temperature range of flour and starch are 79.66–88.33 °C and 79.71–87.62 °C respectively. Onset, peak and conclusion temperature of Talipot palm flour and starch are higher than that of wheat [47], and most of the roots and tubers [48]. The thermal characteristics of flour and starch are affected by various factors such as the molecular arrangement of the crystalline region, amylose to amylopectin ratio, double helix order and chain distribution [49].

The enthalpy of gelatinization disclose the overall crystallinity of amylopectin and was found from the area under the endotherm curve [50]. The enthalpy of Talipot palm flour and starch are 8.30 J/g and 11.19 J/g respectively and it is higher than that of kithul palm flour and starch [7]. The starch crystallinity increased with increase in amylopectin content and the double-helical structure of starch has a strong relation to the amylopectin content of starch. The starch with higher enthalpy indicates higher crystalline strength and it depends on the sequential arrangement of A chain between amylopectin.

Starch digestibility

Starch digestibility of Talipot palm flour and starch are summarised in Table 4. Talipot palm flour and starch showed significant difference (P ≤ 0.05) in RDS, SDS and RS. Talipot palm flour have higher amount of SDS and RS, whereas Talipot palm starch have higher amount of RDS. Similar results were reported in wheat flour and starch [51], whereas rice starch contains higher amount SDS and RS than that of rice flour [52]. The higher SDS and RS value of Talipot palm flour maybe due to the presence of higher amount of protein and fibre in flour compare to the starch. In flour starch granules are bounded by proteins and fibre matrices which make hindrance to enzyme attack to the starch granules results in increased amount of SDS and RS.

Conclusion

In this research the physicochemical, functional, morphological, pasting, thermal and rheological properties of Talipot palm flour and starch were studied. The Talipot palm flour contains the higher value of iron, sulphur, and potassium. Talipot palm starch is a high amylose starch and the protein content is found to be very less and it does not show any significant difference (P ≤ 0.05) with Talipot palm flour. Talipot palm flour and starch exhibited higher lightness. The functional properties like WAC and OAC did not show a significant difference (P ≤ 0.05), whereas flour showed higher emulsion capacity and stability. Talipot palm flour and starch have type-A crystallinity and is comparable to cereal starches. Talipot palm flour and starch showed higher pasting temperature. Peak viscosity, breakdown viscosity, and setback viscosity are higher for Talipot palm starch as compare to flour. From the study, it is noticed that Talipot palm flour is having higher storage and loss modulus due to its higher swelling power. Talipot palm flour and starch showed a broad range of gelatinization temperature, and the starch exhibited a higher value of enthalpy of gelatinization. The high amylose content and pasting properties of Talipot palm starch has potential application in food and non-food industries [53, 54].

References

T.D. Umesh Madar, Sci. Pap. Ser. A. Agron. LX, 307 (2017)

K. Saranandha, J.A.A.C. Wijesinghe, I. Wicramasinghe, Int. J. Sci. Res. 4, 2189 (2015)

P. Rajyalakshmi, Nat. Prod. Radiance 3, 144 (2004)

Á.L. Santana, M. Angela, A. Meireles, Food. Public Health. 4, 229 (2014)

M.D.S. Chandran, Resonance 1, 69 (1996)

B. Kaur, F. Ariffin, R. Bhat, A.A. Karim, Food Hydrocoll. 26, 398 (2012)

C. Sudheesh, K. Valiyapeediyekkal, S. Johnsy, G. Sunny, J. Food Meas. Charact. 0, 0 (2019).

AOAC, Official Methods of Analysis AOAC 1990, 15th edn. (AOAC, Washington DC, 1990)

P.C. Williams, F.D. Kuzina, I. Hlynka, Cereal Chem. 47, 411 (1970)

V. Deepika, K. Jayaram Kumar, P. Anima, Carbohydr. Polym. 96, 253 (2013)

L.F. Polesi, S.B.S. Sarmento, J. De Moraes, C.M.L. Franco, S.G. Canniatti-Brazaca, Food Chem. 191, 59 (2016)

K. Bashir, T.L. Swer, K.S. Prakash, M. Aggarwal, LWT Food Sci. Technol. 76, 131 (2017)

A. Sridaran, A.A. Karim, R. Bhat, Food Chem. 130, 528 (2012)

M.Z. Dar, K. Deepika, K. Jan, T.L. Swer, P. Kumar, R. Verma, K. Verma, K.S. Prakash, S. Jan, K. Bashir, Int. J. Biol. Macromol. 108, 1348 (2018)

I.A. Wani, M. Jabeen, H. Geelani, F.A. Masoodi, I. Saba, S. Muzaffar, Food Hydrocoll. 35, 253 (2014)

K. Bashir, M. Aggarwal, LWT Food Sci. Technol. 69, 614 (2016)

R. Colussi, L. Kaur, E.R. Zavareze da, A.R.G. Dias, R.B. Stewart, J. Singh, Food Hydrocoll. 75, 131 (2018)

H.N. Englyst, S.M. Kingman, J.H. Cummings, Eur. J. Clin. Nutr. 46, S33 (1992)

H.Y.T. Nuda, I.S.M. Zaidul, N.A. Nik Norulaini, A.K. Mohd Omar, Carbohydr. Polym. 69, 784 (2007)

V. Singh, H. Okadome, H. Toyoshima, S. Isobe, K. Ohtsubo, J. Agric. Food Chem. 48, 2639 (2000)

O.J. Odejobi, M.M. Ige, K.A. Adeniyi, J. Food Meas. Charact. 9, 61 (2014)

J. Cai, C. Cai, J. Man, W. Zhou, C. Wei, Carbohydr. Polym. Jo 101, 289 (2014)

S.C. Alcázar-Alay, M.A.A. Meireles, Food Sci. Technol. 35, 215 (2015)

H. Molavi, S.M.A. Razavi, Starch/Starke 70, 1 (2018)

C. Sudheesh, K. Valiyapeediyekkal, J. George, S. Kumar, V. Appukuttan, J. Phys. Lett. 62, 54 (2019)

S. Pérez, E. Bertoft, Starch/Staerke 62, 389 (2010)

P. Sirivongpaisal, Songklanakarin J. Sci. Technol. 30, 51 (2008)

E. Bertoft, Agronomy 7, 56 (2017)

B.R. Cruz, A.S. Abraão, A.M. Lemos, F.M. Nunes, Carbohydr. Polym. 94, 594 (2013)

S. Du, H. Jiang, X. Yu, J. Jane, LWT Food Sci. Technol. 55, 308 (2014)

K.O. Falade, A.S. Christopher, Food Hydrocoll. 44, 478 (2015)

L. Wang, R.A. Flores, Cereal Chem. 76, 496 (1999)

R.B. Shah, M.A. Tawakkul, M.A. Khan, AAPS PharmSciTech 9, 250 (2008)

S. Jitngarmkusol, J. Hongsuwankul, K. Tananuwong, Food Chem. 110, 23 (2008)

F.C.K. Ocloo, D. Bansa, R. Boatin, T. Adom, W.S. Agbemavor, P.O.B. Lg, Agric. Biol. J. North Am. 5, 903 (2010)

S.K. Sonawane, M.B. Bagul, J.G. LeBlanc, S.S. Arya, J. Food Meas. Charact. 10, 72 (2016)

P. Kaushal, V. Kumar, H.K. Sharma, LWT Food Sci. Technol. 48, 59 (2012)

I.A. Wani, D.S. Sogi, B.S. Gill, Int. J. Food Sci. Technol. 48, 771 (2013)

S. Wang, C. Li, L. Copeland, Q. Niu, S. Wang, Compr. Rev. Food Sci. Food Saf. 14, 568 (2015)

A. Aprianita, U. Purwandari, B. Watson, T. Vasiljevic, Int. Food Res. J. 16, 507 (2009)

S. Ragaee, E.S.M. Abdel-Aal, Food Chem. 95, 9 (2006)

Q. Sun, Y. Xing, C. Qiu, L. Xiong, PLoS ONE 9, e95862 (2014)

O.K. Abegunde, T.H. Mu, J.W. Chen, F.M. Deng, Food Hydrocoll. 33, 169 (2013)

K. Guo, T. Liu, A. Xu, L. Zhang, X. Bian, C. Wei, Food Hydrocoll. 89, 829 (2019)

C.K. Simi, T.E. Abraham, J. Agric. Food Chem. 56, 12105 (2008)

M.K.P. Sneh, A.K. Siroha, K.J.S. Sandhu, Int. J. Biol. Macromol. 130, 595 (2019)

I.S.M. Zaidul, N. Absar, S.J. Kim, T. Suzuki, A.A. Karim, H. Yamauchi, T. Noda, J. Food Eng. 86, 68 (2008)

C. Lerdluksamee, K. Srikaeo, J.A.M. Tutusaus, J.G. Diéguez, Carbohydr. Polym. 97, 482 (2013)

P. Van Hung, N. Morita, Carbohydr. Polym. 61, 314 (2005)

R.V. Mota da, F.M. Lajolo, B.R. Cordenunsi, C. Ciacco, Starch Stärke 52, 63 (2000)

X. Chen, X. He, X. Fu, Q. Huang, J. Cereal Sci. 63, 109 (2015)

Q.H.X. Chan, X. He, X. Fu, B. Zhang, Int. J. Biol. Macromol. 98, 557 (2017)

P. Kumar, K.S. Prakash, K. Jan, T.L. Swer, S. Jan, R. Verma, K. Deepika, M.Z. Dar, K. Verma, K. Bashir, J. Cereal Sci. 77, 194 (2017)

A. Kaur, N. Singh, R. Ezekiel, H.S. Guraya, Food Chem. 101, 643 (2007)

Acknowledgement

The authors are thankful to the Dr. Shijin A, Department of Food Science and Technology and Central Instrumentation Facility, Pondicherry University for providing laboratory and instrumental facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Navaf, M., Sunooj, K.V., Aaliya, B. et al. Physico-chemical, functional, morphological, thermal properties and digestibility of Talipot palm (Corypha umbraculifera L.) flour and starch grown in Malabar region of South India. Food Measure 14, 1601–1613 (2020). https://doi.org/10.1007/s11694-020-00408-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00408-1