Abstract

The present study fills a gap in a continuous research of formulation and characterization of zero-trans cake (ZTC) shortening and investigation of the impacts on sensory properties, texture of high ratio cake and rheological behavior of batter. The results revealed that the batter produced from formulated ZTC shortening had the highest linear viscoelastic range (LVE = 0.384%) as a measure of batter uniformity, the lowest G′ at the end of the LVE (552 Pa), the lowest “a” value (415.88 Pa) in power law model fitted on frequency sweep data as a measure of hardness and strength, and the lowest “m” value (49.11 Pa sn) in power law model fitted on apparent viscosity data as a consistency coefficient of batter. In addition, the final cake made from ZTC shortening had the second softest texture after CM101 cake sample and the highest overall acceptance score (6.88) in sensory evaluation. Through this research, it was proven that the softest texture does not necessarily result in highest consumer acceptance and cake textural characteristics are not solely dependent on batter rheology, meaning that firmer batter does not always result in increasing cake hardness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fats as the main source of energy, essential fatty acids, fat soluble vitamins and cell membrane building blocks are necessary in human diet [1]. In food industry, specifically bakery, fats impart palatability, desirable flavor, taste, lubricity, texture, appearance and overall quality in final products [2]. In term of shortening as fat base constituent, formulation, production procedure, functionality and cost efficiency along with nutritional specifications should be considered to meet consumer demands on public health [3, 4].

Despite the desirable functional characteristics of partially hydrogenated shortenings, a high proportion of trans fatty acids (TFAs), has raised public health concerns about the intake of TFAs [5]. Evidence linking TFAs intake with non-communicable diseases (NCDs) such as coronary heart diseases, shortening of pregnancy period, cancers and risks of preeclampsia has noticeably forced the food industry toward reducing or eliminating TFAs in food products [6, 7]. Consequently, the Food and Drug Administration of the United States (US FDA) announced that there is no safe level of TFAs intake, while considering ten times as harmful as saturated fatty acids (SFAs). Following this agenda, in 2006, nutritional fact labels on food packaging were required to mention whether the product contain 0.5% TFAs per serving or more. Ultimately, the FDA has finalized the decision on removing partially hydrogenated fats from Generally Recognized as Safe “GRAS” list of food products in 2018 [8,9,10]. Based on preventive policies in the field of NCDs, some countries like Iran has forced food manufacturers to mention the amount of TFAs by nutritional traffic light labeling since year 2016 [11].

According to the FDA report, major sources of TFAs in the US population diet are margarines, animal products and baked goods (cakes, cookies and crackers) with the share of 17, 21 and 40%, respectively [12]. Nowadays, redesigning zero-trans shortenings without any negative impacts on sensory and structural properties of high ratio cakes challenges bakery industry to meet consumer satisfaction on public health and product quality [13].

Solid–liquid ratio, melting profile, rheological behavior and firmness of shortening have great impacts on quality, texture, volume, palatability and sensory characteristics of cakes. Therefore, shortening is probably the most important ingredient in formulation of high ratio cakes [13, 14]. Based on shortening formulation, the cake batter, as an oil-in-water emulsion, exhibits various physicochemical properties including elasticity reduction and batter shrinking during molding, while also inhibits starch molecules re-association in retrogradation of cake [15].

Many recent studies have shown that complete eliminating or partial replacing of fats in bakery products can result in adverse effects on textural and sensory properties of finished products. For instance, numerous studies have dealt with the application of non-lipid base fat replacers in bakery products through increasing trend toward reduction of TFAs and SFAs consumption. Grigelmo-Miguel et al. reported that by substituting dietary fiber with oil in muffins, the final products became darker, while hardness and chewiness values rose, however, springiness and cohesiveness did not alter significantly [16]. Kim et al. also studied the impacts of shortening replacement with maltodextrin, amylodextrin and octenyl succinylated amylodextrin in yellow layer cake formulation and found that maltodextrin caused significant decrease in cake batter viscosity while the firmness and springiness of the final product increased noticeably [17]. In another study, Khoriyeh et al. studied the functionality of xanthan gum, maltodextrin and sucralose to produce no sugar, low fat muffin and resulted that the reduction of fat caused an increase in hardness and chewiness of the final product [18]. Based on previous researches, it can be concluded that, the use of trans-free non lipid base substitutes for partially hydrogenated shortenings has technological issues due to processing performance limitations [2].

Modified fat systems such as chemically interesterified shortenings have offered special functionalities such as a wide range of melting and solid fat profile in bakery industry [19]. Different types of vegetable oils such as sunflower, corn, soybean, canola and palm oil can be recruited in shortening formulation, however, based on crystallization form (β′) and oxidative stability, palm oil and its derivatives are more sufficient to be used as hard stocks [20].

Major characteristics of shortenings have been explored in previous studies [21,22,23,24,25], while the recent developments in trans free cake shortening formulation and production have heightened the need for the investigation of textural properties and sensory evaluation of final bakery products.

The main aim of the present study was to investigate the effect of three cake shortening types on rheological behavior of the batter, textural and sensory properties of high ratio cake. Zero trans cake (ZTC) shortening was made of palm stearin and canola oil, using chemical interesterification process along with two commercial shortenings were recruited to compare their impacts on batter and high ratio cake. It should be mentioned that formulation of ZTC shortening and the investigation of rheological and physicochemical properties of the utilized shortenings were described in our previous research [26].

Materials and methods

Materials

Commercial wheat flour (protein content 9.9 ± 0.2%, ash 0.59 ± 0.04%, moisture 14.2 ± 0.1% wet basis and pH 5.8 ± 0.05, Setareh Co., Tehran, Iran), baking powder (Hermin Co., Tehran, Iran), pasteurized egg (total solid = 23.5 ± 0.6%, pH 6.7 ± 0.7 and negative α-amylase activity) and skim milk powder (lactose 51.65 ± 0.06%, protein 36.42 ± 0.4%, fat 0.92 ± 0.03% Binavarzan Co., Tehran, Iran) and salt (Sadaf Co., Tehran, Iran) were provided.

Two commercial shortenings were purchased from local markets, in order to keep the confidentiality of shortenings, they were being labeled as CM101 and CM102. ZTC shortening was formulated and optimized from chemically interesterified blend of 66.416% palm stearin and 33.584% canola oil with 2% glycerol monopalmitate, and compared with CM101 and CM102 in terms of fatty acid composition triglyceride composition, slip melting point, solid fat content (SFC), physicochemical, rheological, and textural properties in our previous research which is briefed in Table 1 [26]. Palm stearin and canola oil were generously provided by Kourosh Food Industry Company (Tehran, Iran).

Methods

Batter preparation and cake baking

Standard cake formulation, the procedure of batter preparation, and baking of high ratio cake were provided by Flour, Milling and Research Association (Chorleywood, UK). Cake recipe including: flour (300 g), sugar (345 g), shortening (195 g), whole egg (255 g), water (105 g), baking powder (10.5 g), skim milk powder (15 g), salt (3 g) were provided and tempered to the ambient temperature. All ingredients were mixed together at low speed for 1 min and bitten at top speed for three more min by a mixer (heavy duty stand mixer 5KPM5 kitchen AID, UK). Cake batter (40 g) was placed in cake pans and baked at 170 ± 1 °C preheated convectional oven (Miwe, Germany) for 20 min. Baked cakes were allowed to cool at ambient temperature for 1 h, then wrapped in plastic bags and stored at 25 ± 0.1 °C for 1 day to perform further tests.

Batter viscosity and viscoelasticity measurements

Dynamic oscillatory tests of cake batter samples were carried out with a Physica MCR 301 rheometer (Anton-Paar, GmbH, Graz, Austria) using a Peltier system, equipped with a fluid circulator as a temperature control system. Serrated plate geometry, 40 mm in diameter, with constant gap of 1 mm at 25 ± 0.1 °C was used to conduct strain sweep, frequency sweep and apparent viscosity measurements. All of the rheological experiments data was analyzed using Rheoplus software (version 3.21, Anton-Paar).

Strain sweep test was conducted to determine linear viscoelastic (LVE) and G′ at the end of the LVE range [27]. After calculating the LVE range, a frequency sweep test was performed at 0.862–126 rad/s and constant strain of 0.1% to investigate batter strength and microstructural properties. Power law model was also used to describe frequency dependency and viscosity of batter structure (Eqs. 1 and 2) [28]. The investigation of flow behavior and apparent viscosity of cake batters, were performed in shear rate from 0.1 to 100 s−1 in 5 min at 25 ± 0.1 °C [29]. Power law models fitted on frequency sweep and Eq. 1.

Moisture content

Determination of moisture content of cake samples (wet basis) was performed by the single-stage air-oven (Gallenhamp oven Model No. OV-165) according to AACC 44-15A (1984) method number.

Cake volume

Specific volume of cake samples was determined using rapeseed displacement, AACC 10–05 (2000) method [30].

Texture profile analysis of high ratio cakes

Texture profile analysis of cake samples was performed one day after baking, by double compression test with a PC-controlled TA-XT2i texture analyzer (Stable Microsystems, Godalming, England). Cylindrical probe, 25 mm in diameter, test speed of 1 mm/s, 40% strain and 5 kg load cell were utilized to determine cake texture profile including: hardness, adhesiveness, springiness, cohesiveness, chewiness and resilience, in five replicates using Exponent software provided by Stable Microsystems Ltd.[29].

Sensory evaluation

A total of 60 untrained panelists from Iran National Nutrition and Food Technology Research Institute students and staff were asked to evaluate sensory characteristics of cake samples 1 day after baking. Cake samples with three-digit random codes were given to the panelist with 5 min interval and the panelists were asked to wash their mouth before each evaluation. Questionnaire based on 9-point hedonic scale (1 refers to extreme disliking and 9 refers to extreme liking) was used to evaluate different aspects such as overall acceptance, taste, color, fat congelation, odor and texture [31]. Although textural attributes were determined through instrumental measurements, we included cake texture item in sensory evaluation questionnaire so as to investigate the impact of this parameter on consumer acceptance.

Statistical analysis

In order to brief the samples name, they were given codes: samples produced with commercial shortenings known as CM101, CM102 and the one produced with zero trans shortening as ZTC which are the same as their shortening names in our previous research [26]. Analysis of variances with one-way ANOVA and the significance determination with Duncan test were performed by SPSS software (IBM SPSS Statistics Ver. 21, New York) at the significance level of P < 0.05.

Result and discussion

Rheological behavior of cake batter

We recently published work on formulation of ZTC shortening, made from palm stearin and canola oil, characterized its rheological, textural and physicochemical properties along with two commercial shortenings (CM101 and CM102). Determination of rheological behavior of batter is important due to its correlation with micro and macro properties of cakes [29, 32]. Strain sweep test was conducted to determine LVE range, G′ at the end of the LVE, and the crossover point.

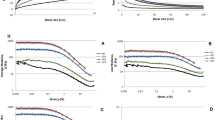

As Fig. 1 shows, all samples had higher G′ than G″ value and both moduli decreased by increasing the strain before the cross over point, meaning that elastic nature outweighed viscose behavior before tan δ = 1. The cross over point is the location in which both G′ and G″ values become equal. The strain in which tan δ = 1 occurs, was significantly higher in CM102 batter, showing that it was more resistant to higher strain in comparison with other batters (P < 0.05).

ZTC batter had the highest (0.384%) and CM101 batter had the lowest (0.165%) LVE range indicated that ZTC batter was more uniform and flexible in comparison with two other samples (P < 0.05). The G′ at the end of the LVE range as a measurement of strength was higher in CM101 batter being in relation with higher apparent viscosity of the batter and firmness of its shortening (Table 1). However, the G′ and G″ of CM101 and CM102 batter were almost close to each other with a significant gap from ZTC batter.

As described by Patel et al., cake sample with oleogel base emulsion as alternative of cake margarine resulted in a reduction in G′ and cross over point of batters, due to the lack of fat crystal network in oleogel base emulsion, therefore, it can be concluded that fat crystals in shortening system can cause an increase in the LVE range of batter which is accordance with our findings [33].

Figure 2 represents storage modulus and loss modulus of cake batters in frequency sweep test. All samples had more elastic behaviour due to higher G′ than G″ value over the given frequency range. Three shortenings with various charachteristics affected the cake batters accordingly; CM101 shortening caused an increase in both G′ and G″ moduli of the batter due to higher firmness of its shortening (25 °C) and SFC (20 °C) while ZTC shortening decreased them dramatically (P < 0.05).

“Tan δ” is a rheological index used in defining elastic and viscose characteristics of food products caused by their components [2]. As Fig. 3 represents, the lowest value of tan δ was observed in the CM101 batter while CM102 and ZTC batters had higher tan δ, thus the use of CM102 and ZTC shortenings imparted more viscose behavior in the cake batters (P < 0.05).

According to the result of Hesso et al. study, shortening replacement with rapeseed oil led to reduction of both moduli in cake batter and more fluid behavior due to less air incorporation liquid oil [29]. It can be assumed that SFC had direct impacts on viscoelastic properties of batter as a function of frequency. An other interesting point is that shortenings should have enough liquid oil in order to envelope gas cells while large amount of gas could not retain in finished bakery products made from solely liquid oils [34].

High coefficient of determination (R2 > 0.98) obtained from power law model fitted on frequency sweep (Eq. 1) showed that it can perfectly characterize frequency dependency of cake batters (Table 2). “a” value as an indicator of structural strength in power law model was significantly higher in CM101 batter (2197.3 Pa) which is related to higher content of SFAs and stronger structure of CM101 shortening, followed by CM102 (846.27 Pa) and ZTC batter (415.88 Pa) (P < 0.05). According to the result of the Lim et al. study, the replacement of shortenings by oleogel with lower content of SFAs in aerated bakery products can cause an increase in “a” value of power law model (Eq. 1) and both moduli in the frequency test [2, 35].

Effect of shortening type on apparent viscosity of high ratio cake batter was investigated as a function of shear rate in Fig. 4. The viscosity decreased by increasing shear rate which exhibited almost similar pattern in all three batters. Batter viscosity dependency on shear rate is known as pseudoplastic (shear thinning) behavior and non-Newtonian flow, which could be related to the influence of shear on batter particles and their interaction [36].

It was noticed that CM101 batter had the highest apparent viscosity in all over the shear rate range, due to the highest firmness and SFC at 20 °C of CM101 shortening while ZTC batter had the lowest apparent viscosity. These findings were in accordance with Leelawat et al. research about the impact of trans free shortening on pie crust dough and quality of pie crust, reported that the consistency coefficient of batter containing commercial shortening was noticeably higher than trans free shortening in five various temperatures (5, 10, 15, 20, 25 °C) due to higher biaxial consistency coefficient of commercial shortening as the result of its higher melting point [13].

It should be noted that the role of fat in a cake batter system, as air entrapment and lubrication, resulted in decreasing viscosity [37, 38]. In addition, it was discussed that batter with higher SFC has lower density [15].

Replacing semisolid fats with liquid oils in previous researches resulted in decreasing the batter viscosity due to the effects on bubble incorporation [39, 40]. For instance, replacing shortening in pound cake with sunflower oil in Kumari et al. research resulted in lower viscosity and higher specific gravity which caused lower cake volume. While addition of 0.5% sodium stearoyl-2-lactylate and polysorbate-60 increased the batter viscosity [41].

Power law model (Eq. 2) was fitted on the data of apparent viscosity test, where (m) (n) and (η) values represented consistency coefficient (Pa sn), flow behavior index and apparent viscosity (Pa s), respectively (Table 2).

CM101 batter had the highest and ZTC batter had the lowest consistency coefficient; while, the difference between values of flow behavior index of samples (0.33–0.35) was not statistically significant (P > 0.05).

The flow behavior index represented the shear thinning nature of samples. Flow behavior index which was near to zero showed high shear thinning, while values near 1 represented a Newtonian nature [42]. Thus, it can be concluded that all of the samples showed a similar trend in shear thinning behavior which showed that constituents of batters align with flow.

Cake volume and moisture content

Effect of shortening type on specific volume and moisture content of high ratio cake samples are represented in Table 3. It is generally accepted that cake shortening can influence both tenderness and moisture of the final products, while cake size and the amount of trapped air inside can influence the cake volume [38, 43]. In ZTC batter the amount of trapped carbon dioxide and water vapor was lower than other samples as a consequence of low viscosity of batter sample [43]. However, based on “m” value in the power law model fitted on batters’ apparent viscosity data, CM101 and CM102 cakes should have much higher volume than ZTC cake while it can be seen that the CM102 cake volume was not much higher than ZTC cake volume (P > 0.05), therefore, it can be assumed that cake volume is affected by more than one factor like batter viscosity. Lower volume and moisture content of samples may be as a result of content and type of emulsifier used in shortening formulation since the emulsifier presence can lead to production of lipid and amylase complex with the ability to prevent water evaporation during baking process [44].

Texture profile analysis and sensory evaluation of cake samples

In bakery industry, texture of baked products is considered as one of the most important determinative quality indexes affected by microscopic and macroscopic properties, while, determining the sensory attributes; small changes in cake formulation or process directly influence the final structure [45]. The changes in textural properties of cake samples as a function of shortening type are reported in Table 4. CM102 cake had the highest (505.50 g) and the CM101 cake had the lowest (376.88 g) hardness among the samples (P < 0.05). One possible explanation about the hardness values can be related to the type and content of emulsifier in commercial shortenings and the formulated ZTC shortening [10].

Based on the previous reports, total replacement of commercial hydrogenated shortening with sesame oil increased firmness and caused oily mouthfeel in cake. In fact the decrease of SFC in formulation led to more hardness in the texture of cake (P < 0.05) [40].

The springiness of cake samples as the ability in recovering the cake texture between the first and second bite in double compression tests were not significantly different in cake samples (P > 0.05). Overall, the most significant difference between samples was seen in hardness factor while other parameters were almost close to each other.

According to the previous research conducted by Jacob et al. on the effect of fat type on cookie dough, batter hardness did not necessarily control the texture of the final product, meaning harder dough can result in softer cake or cookie texture. This finding was in accordance with our result showing that CM101 batter with higher G′ moduli as a strength and hardness characteristic of batter in strain and frequency sweep test, did not result in higher firmness of the final cake [46].

Information about the effect of shortening type on sensory characteristics of high ratio cakes was provided in Table 5. It was observed that ZTC cake had higher overall acceptance mean score (6.88) than CM101 sample (5.75), while ZTC cake did not have a significant difference with CM102 cake in term of overall acceptance score (P > 0.05). Similarly, in another research, chemically interesterified blend of palm and cottonseed oil in layer cakes achieved higher overall score than hydrogenated shortening [19].

CM101 and ZTC shortenings with 37.20% and 10.51% SFC at 37 °C caused the lowest and highest scores in term of fat congelation of final cakes, respectively. Obviously high SFC at 37 °C resulted in fat congelation and waxy mouthfeel in cakes. Due to the fact that, in 9-point hedonic scale questionnaire, 9 refers to extreme liking and 1 refers to extreme disliking, higher score in term of fat congelation refers to the panelist more satisfaction [13]. Although fat congelation of shortening is a negative parameter, complete replacement of shortening with vegetable oils is not a desired approach due to the mentioned functional properties. According to the result of shortening replacement with sesame oil by Sowmya et al. the scores of the sensory evaluation in terms of crust color and shape decreased by increasing the proportion of sesame oil because of darker color and flat tendency of crust. It was concluded that, complete replacement of shortening with sesame oil made the sensory score totally unacceptable. In another study, the results revealed that in half replacement of bakery margarine with sunflower oil, the scores in the terms of crust and crumb properties of cakes decreased significantly. However, in this study, addition of sodium stearoyl-2-lactylate noticeably increased the scores of cake texture and mouthfeel while polysorbate-60 improved the mentioned characteristics marginally; control sample containing bakery margarine showed the highest sensory evaluation scores among all the samples [40, 41].

The sensory evaluation data in term of cake texture showed that higher firmness did not necessarily result in lower acceptance, as CM101 cake with softer texture did not achieve higher sensory score in term of texture and overall acceptance. This can be as the result of oily and waxy mouthfeel of CM101 cake which led to more fat congelation and decreased sensory scores. Patel et al. research showed that replacement of cake margarine with shellac oleogels resulted in significant lower softness in texture while the sensory properties of cake samples were not significantly different in term of texture (P > 0.05) [33].

The results of the study on the investigation of shortening replacement with flaxseed oil on cookie quality showed that the replacement of shortening with flaxseed oil up to 30% did not significantly alter the scores in texture, taste and overall acceptability parameters; however, with increasing the flaxseed oil proportion, texture score started to decrease, showed that there was an optimum content for replacing solid shortenings with liquid oil [47].

Conclusion

In conclusion, formulated ZTC shortening along with two commercial shortenings were studied to evaluate their impacts on high ratio cake and batter properties. Measurements of rheological properties of cake batters indicated that cake containing ZTC shortening had a more uniform batter due to higher LVE range (P < 0.05). Although the softness of cake containing ZTC shortening was lower than CM101, the sensory evaluation in term of texture was significantly higher. Moreover, it was found that the textural properties and sensory evaluation of high ratio cake containing ZTC shortening was almost comparable with, and even better than cakes containing commercial shortenings (CM101 and CM102) (P < 0.05). In formulation of fat products like bakery shortenings as an important ingredient of bakery goods, their application in finished product should be considered along with its own physicochemical and quality parameters. Through this research, it was proven that the softest texture does not necessarily result in highest consumer acceptance and cake textural characteristics are not solely dependent on batter rheology, meaning that firmer batter does not always result in an increase in the cake hardness.

References

S. Damodaran, K.L. Parkin, O.R. Fennema, Fennema’s Food Chemistry (CRC Press, Taylor and Francis Group, Boca Raton, 2007)

J. Lim, S. Jeong, J. Lee, S. Park, J. Lee, S. Lee, Effect of shortening replacement with oleogels on the rheological and tomographic characteristics of aerated baked goods. J. Sci. Food Agric. 97(11), 3727–3732 (2017)

G.M. de Oliveira, M.A. Stahl, A.P.B. Ribeiro, R. Grimaldi, L.P. Cardoso, T.G. Kieckbusch, Development of zero trans/low sat fat systems structured with sorbitan monostearate and fully hydrogenated canola oil. Eur. J. Lipid Sci. Technol. 117(11), 1762–1771 (2015)

Z. Saghafi, B. Nikooyeh, A. Jamali, M. Mehdizadeh, A. Zargaraan, Influence of time and temperature on stability of added vitamin D3 during cooking procedure of fortified vegetable oils. Nutr. Food Sci. Res. 5(4), 43–48 (2018)

E. Zoulias, V. Oreopoulou, C. Tzia, Effect of fat mimetics on physical, textural and sensory properties of cookies. Int. J. Food Prop. 3(3), 385–397 (2000)

L.L. Darweesh, R. Toma, H.C. Lee, T. Weiss, Chemical and sensory evaluation of lipid blends used in pie crusts. Food Chem. 39(1), 87–98 (1991)

V. Dhaka, N. Gulia, K.S. Ahlawat, B.S. Khatkar, Trans fats—sources, health risks and alternative approach—a review. J. Food Sci. Technol. 48(5), 534–541 (2011)

F.C. Wang, A.J. Gravelle, A.I. Blake, A.G. Marangoni, Novel trans fat replacement strategies. Curr. Opin. Food Sci. 7, 27–34 (2016)

H. Zhong, K. Allen, S. Martini, Effect of lipid physical characteristics on the quality of baked products. Food Res. Int. 55, 239–246 (2014)

J. Zhou, J.M. Faubion, C.E. Walker, Evaluation of different types of fats for use in high-ratio layer cakes. LWT Food Sci. Technol. 44(8), 1802–1808 (2011)

A. Zargaraan, R. Dinarvand, H. Hosseini, Nutritional traffic light labeling and taxation on unhealthy food products in Iran: health policies to prevent non-communicable diseases. Iran. Red Crescent Med. J. (2017). https://doi.org/10.5812/ircmj.57874

G.R. List, T. Pelloso, Zero/low trans margarine, spreads, and shortening, in Trans Fats in Foods, eds. by G.R. List, D. Kritchevsky, N. Ratnayake (AOCS Press, Urbana, 2007)

B. Leelawat, P. Mundee, Effect of trans-fat free shortening and temperature on the rheological characteristics of pie crust dough and quality of pie crust. Food Process. Eng. (2014). https://doi.org/10.14456/fabj.2014.9

O. Daglioglu, M. Tasan, U. Gesgel, F. Daglioglu, Changes in oxidative stability of selected bakery products during shelf life. Food Sci. Technol. Res. 10(4), 464–468 (2007)

S. Rønholt, J.J.K. Kirkensgaard, K.F. Høyer, K. Mortensen, J.C. Knudsen, The effect of capacity, rotational speed and storage on crystallization and rheological properties of puff pastry butter. J. Am. Oil Chem. Soc. 91(1), 29–38 (2014)

N. Grigelmo-Miguel, E. Carreras-Boladeras, O. Martín-Belloso, Influence of the addition of peach dietary fiber in composition, physical properties and acceptability of reduced-fat muffins. Food Sci. Technol. Int. 7(5), 425–431 (2001)

H.Y.L. Kim, H.W. Yeom, H.S. Lim, S.-T. Lim, Replacement of shortening in yellow layer cakes by corn dextrins. Cereal Chem. 78, 267–271 (2001)

H.A. Khouryieh, F.M. Aramouni, T.J. Herald, Physical and sensory characteristics of no-sugar-added/low-fat muffin. J. Food Qual. 28(5–6), 439–451 (2005)

I.S. Dogan, I. Javidipour, T. Akan, Effects of interesterified palm and cottonseed oil blends on cake quality. Int. J. Food Sci. Technol. 42(2), 157–164 (2007)

J. deMan, L. deMan, Palm oil as a component for high quality margarine and shortening formulations. Malays. Oil Sci. Technol. 4, 56–60 (1995)

R.A. Latip, Y.-Y. Lee, T.-K. Tang, E.-T. Phuah, C.-P. Tan, O.-M. Lai, Physicochemical properties and crystallisation behaviour of bakery shortening produced from stearin fraction of palm-based diacyglycerol blended with various vegetable oils. Food Chem. 141(4), 3938–3946 (2013)

T. Jeyarani, M.I. Khan, S. Khatoon, Trans-free plastic shortenings from coconut stearin and palm stearin blends. Food Chem. 114(1), 270–275 (2009)

W. Jirasubkunakorn, A. Bell, M. Gordon, K. Smith, Effects of variation in the palm stearin:palm olein ratio on the crystallisation of a low-trans shortening. Food Chem. 103(2), 477–485 (2007)

S.Y. Reddy, T. Jeyarani, Trans-free bakery shortenings from mango kernel and mahua fats by fractionation and blending. J. Am. Oil Chem. Soc. 78(6), 635–640 (2001)

A.P.B. Ribeiro, R. Grimaldi, L.A. Gioielli, L.A. Gonçalves, Zero trans fats from soybean oil and fully hydrogenated soybean oil: physico-chemical properties and food applications. Food Res. Int. 42(3), 401–410 (2009)

Z. Saghafi, M.H. Naeli, M. Tabibiazar, A. Zargaraan, Zero-trans cake shortening: formulation and characterization of physicochemical, rheological, and textural properties. J. Am. Oil Chem. Soc. 95(2), 171–183 (2018)

A. Zargaraan, Z. Saghafi, M. Hasandokht Firouz, G. Fadavi, S. Ghorbani Gorji, M.A. Mohammadifar, Effect of rheological properties on sensory acceptance of two-model dysphagia-oriented food products. J. Texture Stud. 46(3), 219–226 (2015)

M. Jekle, T. Becker, Dough microstructure: novel analysis by quantification using confocal laser scanning microscopy. Food Res. Int. 44(4), 984–991 (2011)

N. Hesso, C. Garnier, C. Loisel, S. Chevallier, B. Bouchet, A. Le-Bail, Formulation effect study on batter and cake microstructure: correlation with rheology and texture. Food Struct. 5, 31–41 (2015)

A. Aydogdu, G. Sumnu, S. Sahin, Effects of addition of different fibers on rheological characteristics of cake batter and quality of cakes. J. Food Sci. Technol. 55(2), 667–677 (2018)

M. Gómez, F. Ronda, P.A. Caballero, C.A. Blanco, C.M. Rosell, Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 21(2), 167–173 (2007)

A.M. Frye, C.S. Setser, Optimizing texture of reduced-calorie yellow layer cakes. Cereal Chem. 69, 338–343 (1992)

A.R. Patel, P.S. Rajarethinem, A. Gredowska, O. Turhan, A. Lesaffer, W.H. De Vos, D. Van de Walle, K. Dewettinck, Edible applications of shellac oleogels: spreads, chocolate paste and cakes. Food Funct. 5(4), 645–652 (2014)

E. Wilderjans, A. Luyts, K. Brijs, J.A. Delcour, Ingredient functionality in batter type cake making. Trends Food Sci. Technol. 30(1), 6–15 (2013)

A. Zargaraan, Y. Omaraee, R. Rastmanesh, N. Taheri, G. Fadavi, F. Zaeri, M.A. Mohammadifar, Rheological and clustering approach to classify Iranian soft/liquid food products to meet dysphagia diet requirements. Ital. J. Food Sci. 26(3), 243 (2014)

S.M. Lee, J. Yoo, G.E. Inglett, S. Lee, Particle size fractionation of high-amylose rice (Goami 2) flour as an oil barrier in a batter-coated fried system. Food Bioprocess. Technol. 6, 1–8 (2013)

J. Rodríguez-García, A. Salvador, I. Hernando, Replacing fat and sugar with inulin in cakes: bubble size distribution, physical and sensory properties. Food Bioprocess. Technol. 7(4), 964–974 (2014)

O. Sakiyan, G. Sumnu, S. Sahin, G. Bayram, Influence of fat content and emulsifier type on the rheological properties of cake batter. Eur. Food Res. Technol. 219(6), 635–638 (2004)

S.S. Sahi, J.M. Alava, Functionality of emulsifiers in sponge cake production. J. Sci. Food Agric. 83(14), 1419–1492 (2003)

M. Sowmya, T. Jeyarani, R. Jyotsna, D. Indrani, Effect of replacement of fat with sesame oil and additives on rheological, microstructural, quality characteristics and fatty acid profile of cakes. Food Hydrocoll. 23(7), 1827–1836 (2009)

R. Kumari, T. Jeyarani, C. Soumya, D. Indrani, Use of vegetable oils, emulsifiers and hydrocolloids on rheological, fatty acid profile and quality characteristics of pound cake. J. Texture Stud. 42(5), 377–386 (2011)

V. Psimouli, V. Oreopoulou, The effect of alternative sweeteners on batter rheology and cake properties. J. Sci. Food Agric. 92(1), 99–105 (2012)

K. Shelke, J. Faubion, R. Hoseney, The dynamics of cake baking as studied by a combination of viscometry and electrical resistance oven heating. Cereal Chem. 67(6), 575–580 (1990)

K. Ghiasi, R. Hoseney, E. Varriano-Marston, Effects of flour components and dough ingredients on starch gelatinization. Cereal Chem. 60(1), 58–61 (1983)

S. Dinç, I. Javidipour, Ö.Ö. Özbas, A. Tekin, Utilization of zero-trans non-interesterified and interesterified shortenings in cookie production. J. Food Sci. Technol. 51(2), 365–370 (2014)

J. Jacob, K. Leelavathi, Effect of fat-type on cookie dough and cookie quality. J. Food Eng. 79(1), 299–305 (2007)

V. Rangrej, V. Shah, J. Patel, P. Ganorkar, Effect of shortening replacement with flaxseed oil on physical, sensory, fatty acid and storage characteristics of cookies. J. Food Sci. Technol. 52(6), 3694–3700 (2015)

Acknowledgements

The Research Vice-Chancellor of Tabriz University of Medical Sciences financially supported this study.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have not any conflict of interest to declare.

Ethical approval

This study is approved by Ethical Board of Tabriz University of Medical Sciences.

Informed consent

Written informed consent was obtained from all sensory evaluation participants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saghafi, Z., Naeli, M.H., Bahmaei, M. et al. Zero-trans cake shortening: effects on batter, texture and sensory characteristics of high ratio cake. Food Measure 13, 3040–3048 (2019). https://doi.org/10.1007/s11694-019-00226-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00226-0