Abstract

Protein extracts from edible insects have not been exploited fully in product development due to limited information on extraction and functionality of the protein extracts. Therefore there was a need to evaluate the effect of selected protein extraction methods on the physico-chemical characteristics and functional properties of extracted proteins. Farmed edible crickets were obtained from JKUAT farm in Kenya, freeze dried and ground to powder. The proteins were extracted using two methods namely; hexane and aqueous extraction. Yield was determined gravimetrically and colour by colourimetric method. The crude protein, crude fibre, crude fat, crude ash and available carbohydrates were determined using standard analytical methods. Protein digestibility was determined using enzymatic digestion methods while protein fractions were extracted and quantified gravimetrically. The water holding capacity was determined using standard AACC procedure. Emulsion capacity and stability, foaming capacity and foam stability were also investigated. HE recorded the highest yield. Lightness and hue angle were significantly affected by the extraction method with hexane extraction recording higher values compared to aqueous extraction (P < 0.0001, P = 0.0003). The proximate components except crude fiber were affected by the extraction method. Aqueous extraction recorded significantly higher values for globulin (19.42%), prolamin (6.26%) and glutelin (10.10%) (P < 0.0001). There was no significance difference in water holding capacity and oil adsorption capacity. However AE precipitate recorded higher values for emulsion capacity (41.70%), emulsion stability (33.61%), foaming capacity (11.11%) and foam stability (10.15%). Extraction methods had an effect on physio- chemical and functional characteristics of the protein concentrates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The outburst of world population has led to a high demand for proteins and this poses a big challenge of ensuring food and nutrition security. Edible insects are being promoted as a sustainable source of proteins and is a viable solution in protein deficiency [1]. Globally there are more than one million insect species being consumed by different communities and for a long time, edible insects have been collected from the wild [2] hence not available all year round and posing a challenge to their sustainable utilization. Therefore to meet the world demand there is necessity for insect rearing technology. Cultivation of edible insects for human consumption has benefits which include high feed conversion efficiency and reduced environmental impact [3].

Insects fall under the class of arthropods which is further divided into orders for instance hemiptera (bugs), isoptera (termites), orthoptera (grasshoppers, crickets and locusts) among others [4]. Edible insects have been documented to be highly nutritious, specifically they are rich in proteins, fat and provide considerable amounts of minerals and vitamins [5, 6], thus a potential solution to food and nutrition security. Proteins have been recorded to be the dominant nutrient in edible insects with a range of 58.90–77.13% [7]. Crickets have been shown to have protein content ranging between 55 and 70.75% [8]. Proteins from the crickets (Acheta domesticus) have been shown to have high quality compared to soy protein in terms of weight gain and maximum nitrogen retention when used as feed [7]. Generally all the insect orders are able to meet the amino acid requirements for humans set by the WHO [9].

Edible insects can be consumed as whole or concealed in other products [3], culture has highly influenced the consumption [1]. The consumption of edible insects has been considered a primitive practice and as a result there has been little attention by governments and organizations involved in food and nutrition security [10]. However studies have revealed that people may consume insects more when they are in a concealed form such as protein extracts and concentrates incorporated in other foods [1, 11].

Researchers have used different methods to extract proteins for instance Yi et al. [3] used aqueous extraction to extracted protein fractions while Babiker et al. [12] used hexane extraction. Defatting has been a common practice in concentrating proteins. Hexane has been the commonly used solvent in defatting of plant materials such as soy bean [13]. However defatting by use of hexane has become unpopular due to effects on functionality and safety issues [14]. Therefore the focus has shifted to studying solvents such as ethanol which has similar defatting potential as hexane and also aqueous extraction of proteins. The aim of this study was to evaluate the influence of the extraction methods on the efficiency and protein characteristics of farmed insects with a view to advising on the most appropriate method for industrial application.

Materials and methods

Sample preparation

The crickets were farmed at Jomo Kenyatta University of Agriculture and Technology (JKUAT). They were fed on a diet consisting of 21% protein content feed for the first 14 days after eggs hatching followed by a 14% protein diet afterwards. Four weeks after hatching, the diet was supplemented with leafy vegetables such as pumpkins, cassava and morning glory depending on their availability. On the 10th week, 10 kg of crickets were harvested freeze dried and ground using a stainless steel blender.

For laboratory analysis, samples were coded (Table 1).

Protein extraction and yield

The cricket meal used for protein extraction consisted of 59.84 ± 1.64% protein, 4.61 ± 0.21% moisture, 18 ± 0.07% crude fat, 4 ± 0.06% crude ash, 7.16 ± 1.26% crude fiber and 6.39 ± 1.67% available carbohydrate.

Hexane extraction

The extraction was based on a modified method by Babiker et al. [12]. Cricket meal was mixed with hexane in the ratio of 1:5. The mixture was stirred using a mechanical shaker for 16 h and filtered. The residue was washed with hexane to remove any traces of oil. The mixture was filtered again and the defatted powder dried in open air at 25 °C. The dried powder was sieved through 500 µm screen the sieved residue was stored at 4 °C after determination of yield.

Aqueous extraction

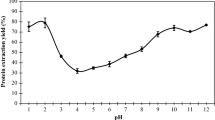

The extraction was based on the method by Yi et al. [3]. A 400 g sample of cricket meal was mixed with 1200 mL of distilled water and 2 g ascorbic acid and then blended using a blender (Signature SG-201) at speed 2 with for 1 min. The obtained insect suspension was sieved through a stainless steel filter sieve with a pore size of 500 μm resulting to a filtrate and residue. The residue was then freeze dried, weighed to determined yield and stored at 4 °C. Centrifugation of the filtrate was then done at 10,000 rpm for 30 min at 4 °C, after centrifugation the supernatant was decanted and the precipitate was freeze dried. The precipitate was then weighed (Figs. 1, 2, 3).

Determination of colour

The colour of the samples was determined using a hunter lab colour difference meter (Minolta, Tokyo, Japan) according to [15]. The colour was measured on the surface of the samples. Reflected colour L*, a* and b* values were determined directly. Results were tabulated and the L*, chroma and hue angle values were used to determine the colour components of the samples.

Where L = black to white, a = green to red, b = blue to yellow.

Proximate analysis

The moisture content, crude ash, crude fat, crude protein and crude fiber of the concentrated cricket proteins was determined according to the standard method of AOAC, (2005). The moisture content was determined by oven drying method at 105 °C where 2 g of the sample were used. Crude ash content was analysed by incineration where 5 g of the sample were dry ashed in an electric muffle furnace (Shimadzu KL- 420, Japan) at 550 °C for 16 h to a constant weight. The crude fat was extracted from 5 g of the concentrated cricket proteins using Soxhlet apparatus with petroleum ether as the solvent and quantified gravimetrically. The crude protein content of the concentrated cricket proteins was determined according to the Kjeldahl method and conversion factor of 6.25 was used to calculate the crude protein content from the nitrogen content. The crude fibre was determined by sequential digestion of samples with 1.25% H2SO4 and 1.25% NaOH using a fibre glass container drying in an oven for 5 h at 105 °C and ashing in the muffle furnace at 550 °C for 16 h. The fibre content was then determined gravimetrically.

The available carbohydrate was calculated based on weight difference using crude protein, crude fat, crude fibre, and crude ash data as follows.

Determination of in-vitro protein digestibility

Digestibility of protein in the insects was determined by the method outlined by Mertz et al. [16]. Initial protein content of the samples was determined using micro-Kjeldahl nitrogen determination method. The second stage involved pepsin digestion, where 0.2 g of the sample was weighed into centrifuge tubes. Then 20 mL buffered pepsin was added and mixed. A blank was prepared in the same way but without a sample. The tubes were placed in a water bath at 37 °C for 2 h with gentle shaking after every 20 min.The tubes were then placed in an ice bath for 30 min to attain a temperature of 4 °C followed by centrifugation at 6000 rpm for 15 min. The supernatant was discarded and 10 mL of buffer solution added, then shaking and centrifugation was done again. The supernatant was discarded and the residue filtered using a filter paper. The filter paper was rolled and inserted into a Kjeldahl flask and dried for 15 min in the oven. 10 mL of Conc. Sulphuric acid, 1 g potassium sulphate and 1 mL of 10% copper sulphate solution were added to the Kjeldahl flask containing the dried filter paper and sample. Then digestion, distillation and titration were done according to the micro-Kjeldahl nitrogen determination.

Where A is % protein content in the sample before pepsin digestion, B is % protein in the sample after pepsin digestion.

Determination of protein fractions

The protein fractions were extracted based on a method by Agboola [17]. Albumin was determined by mixing 50 g of protein extract with 250 mL water, followed by stirring for 4 h, then centrifuging at 3000 rpm for 30 min. The supernatant was then freeze dried and then weighed.

Globulin was determined by mixing the residue after extracting albumin in 250 mL of 5% NaCl and stirred for 4 h. The supernatant was transferred to another flask, freeze dried and then weighed. Glutelin was determined by dissolving the residue after extraction of globulin in 250 mL of 0.1 M NaOH with continuous stirring for 1 h to extract glutelin. The supernatant was freeze dried and then weighed.

Prolamin was determined by dissolving the residue after extraction of glutelin in 250 mL of 70% ethanol, followed by stirring continuously for 1 h. The supernatant was freeze dried and then weighed.

Determination of functional properties

Emulsion capacity and stability

Emulsion capacity and emulsion stability were determined based on a method by Naczk et al. [18].

Emulsion capacity

One gram of protein concentrate was dissolved in 100 mL of distilled water. The suspension was homogenized for 10 min. At the 5th minute corn oil was added continuously and stirred. The emulsion was centrifuged at 3000 rpm for 10 min. Volume of the emulsified layer was then recorded.

Emulsion stability

One gram of protein concentrate was dissolved in 100 mL of distilled water. The suspension was homogenized for 10 min. At the 5th minute corn oil was added continuously and stirred. The emulsion was heated at 85 °C for 30 min then cooled back to room temperature. The samples were centrifuged at 3000 rpm for 10 min. The volume of the emulsified layer was then recorded.

Water holding capacity

Water holding capacity (WHC) was assessed by the approved AACC procedure [19]. One gram of the sample was put in a centrifuge tube followed by 3 mL of water. The samples in the centrifuge tubes were then put in a centrifuge (Beckman CS-6 centrifuge) and centrifuged to 2060 rpm for 10 min. The supernatant was then decanted and the volume of water in the supernatant determined.

Fat absorption capacity

Fat-absorption capacity (FAC) was determined using the procedure of Lin and Humbert [20]. A protein concentrate (0.3 g) was put in a pre-weighed 50 mL centrifuged tube and then mixed with corn oil (3 mL) for 1 min. After centrifugation at 2060 rpm for 30 min (Beckman CS-6 centrifuge), the supernatant was discarded and the tubes were re-weighed. The % FAC was expressed using the following equation:

Foam capacity and stability

The method described by Coffmann and Garcia [21] was used. Ten grams of protein concentrates were distributed in 100 mL of distilled water, the suspension was blended for 2 min using a blender (Signature SG-201) at speed 2. The initial solution volume (V1) and final volume after mixing (V2) were recorded. Foaming capacity (FC) was calculated as

Foaming stability (FS) was determined as the foam volume (V3) that persisted after 5 min.

Data analysis

Data was reported in means and standard deviations. To determine the effect of the extraction methods on the physic-chemical characteristics, data was analysed using one way analysis of variance (ANOVA) followed by determining differences among the mean values by Bonferroni’s method at P ≤ 0.05. Data analysis was performed using Stata, version 12.

Results and discussion

Yield and colour of protein concentrates

The yield of hexane and aqueous extraction procedures and colour characteristics of the protein concentrates is shown in (Table 2). Aqueous extraction gave two protein concentrates i.e. AE precipitate and AE residue. The yield of hexane extraction was the highest with HE recording (66.35%) while aqueous extraction had the least yield with AE Precipitate recording (32.72%).

Hexane extraction and aqueous extraction were aimed at removing fat and consequently the protein content of the concentrate could be higher. The higher yield in hexane extraction could be attributed to the fact that losses tend to occur during aqueous extraction [3]. The high yield shows the efficiency of the hexane extraction method. Other than hexane, ethanol and methanol are other organic solvents that have been utilized in deffating and consequently protein concentration. Ethanol has shown comparable defatting efficiency as hexane however methanol has proven to be a poor option [13]. There is a need to modify the protein extraction procedures for purposes of improving on the functionality of the protein extracts.

The hexane extraction procedures was dominant based on lightness and hue angle compared to aqueous extraction (P < 0.0001) with HE recording the highest value for lightness (L*) and hue angle while AE precipitate and AE residue the least. The brown colour of the protein concentrates is attributed to melanin [22] therefore the high L* recorded in HE could be due to higher removal of melanin during the defatting process [23]. Based on the hue angle all the protein concentrates were within the orange region [24]. There was significance difference in the chroma values however with slight numerical difference, the low values indicated lower saturation. Potentially positive visual appeal could result to a higher probability to taste and liking of a food product [25]. Colour is a major attribute that influences the acceptance or rejection of edible insects [26]. Evidently the protein extraction methods significantly affected the yield and colour characteristics of the protein concentrates.

Proximate composition of protein concentrate

Crude protein was the highest proximate component while crude ash was the least. HE recorded the highest crude protein content while AE precipitate and AE residue the least (Table 3). The protein content of the protein concentrates was similar to 64.38% reported by [8]. The protein content of AE precipitate and AE residue was within 65–75% and 58–69% reported in Precipitate and residue respectively from five different insects including Acheta domesticus [3].

Hexane extraction proves to be a suitable method for concentrating proteins to be used in the food industry. Soy proteins are highly utilized as non- meat ingredients in the meat industry. The protein content of concentrated soy protein is 62–69% [23], this shows that the protein concentrates obtained in this study matches well with soy protein concentrates. Therefore the protein concentrates in this study have the potential of being used as a supplement for soy protein in the food industry. In addition the proteins from the concentrates is highly digestible (Table 4) which further illustrates its suitability in utilization in food processing.

Hexane extraction proved to be a more proficient defatting method compared to aqueous extraction with the HE recording the least crude fat while residue recording the highest (P < 0.0001). Similarly high fat extraction yield was realized through solvent extraction compared to aqueous extraction [27]. The crude fat content of the protein concentrates was lower than 18.55–22.80% reported in crickets [8, 28]. Hexane extraction proves to be a more effective method and has been previously used in extraction of sweet lupin pea protein and soy proteins [13, 29]. Fat is the second most dominant proximate component in crickets therefore removing it results to an increase in other proximate components.

The ash content of HE was the highest while the least was recorded in AE precipitate and AE residue. Evidently hexane extraction resulted to a significantly higher ash content (P < 0.0001). The values obtained in this study were within 3.55–5.10% reported in adult Acheta domesticus [8]. From this study it is clear that the extraction methods used had significant effect on the ash content of the protein concentrates. The considerable good ash content of the protein concentrates signifies good mineral composition.

Hexane and aqueous extraction had no significant influence on the crude fibre content of the protein concentrates (P = 0.0467). The crude fiber content of the protein concentrates was close to 7.8% as reported by [30]. Studies have concluded that crude fibre in insects represents chitin since chitin has a linear structure to that of cellulose [28]. Chitin-chitosan has been extracted from insects for use as a supplement, this is due to it’s potential in reducing blood cholesterol and in the management of obesity [31]. New evidence have shown that humans have an enzyme that can breakdown chitin hence enhancing its utilization in the body.

AE residue had the highest available carbohydrate content while there was no significance difference in the other protein concentrates. The available carbohydrate was close to 3.55–9.10% reported by [9]. The variation observed in nutrient content could be attributed to differences in diets, environment and age of insect [32].

Protein digestibility and protein fractions

The protein digestibility and protein fractions of the protein concentrates are shown in Table 4. The hexane and aqueous extraction methods had no influence on the protein digestibility of the protein concentrates (P = 0.0822) however studies have shown that heat processing of edible insects may either decrease or increase the protein digestibility of edible insects [33].

There was no significance difference in protein digestibility of the protein concentrates (P = 0.0822). The protein digestibility of the protein concentrates was within 76–98% reported by [34]. Additionally the protein digestibility of the protein concentrates was close to 85% for salmon and 89% for beef [35]. Protein digestibility is a key parameter that shows the quality of cricket proteins [36]. The good protein digestibility of the cricket proteins proves the suitability of application of cricket protein concentrates in formulation of food products.

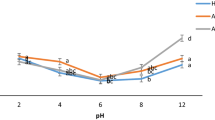

There was a general trend in protein fraction distribution with globulin being the highest component, followed by glutelin and albumin and prolamin being the least component. There was significance difference in protein fraction distribution, AE Precipitate recorded the highest amount of globulin while HE recorded the least (P < 0.0001). AE Precipitate had the highest amount of prolamin while HE and AE residue had the least. Globulin and albumin have been found in considerable amounts in inago [37]. According to Akpossan et al. [38] glutelin was the major component in defatted caterpillar flour, followed by albumin, prolamin and globulin was the least. Additionally glutelin has been recorded as the major protein component in edible insects [39]. The variation in distribution of protein fraction with other studies could be due to sex [37] species difference and method used in determination.

Functional properties

The extraction procedures had influence on the functional properties of the protein concentrates (Table 5). The aqueous extraction showed high values for emulsion capacity and emulsion stability with the AE Precipitate recording the highest value. There was no significance difference in emulsion and emulsion stability in HE and AE residue (P = 0.0053).

The emulsion capacities obtained in this study were lower than 46.8% while the emulsion stability were greater than 8.5% obtained in large African cricket (Gryllidae sp) [40]. Similarly the emulsion capacity of the protein concentrates was higher than 14.93% and the emulsion stability was lower than 74.22% obtained in defatted Imbrasia oyemensis Larvae flour [38]. The observed deviation in emulsion capacity and stability could be attributed to partial denaturation of proteins and change in the distribution of molecular charge that exposes hydrophobic aminoacids [41].The ability of the protein concentrates to form emulsions is of important specifically in communited meats, salad dressing and in cake production [40].

There was no significance difference in water holding capacity of the protein concentrates (P = 0.0371). The water holding capacity of the protein concentrates was close to 2.38 mL/g reported in Gryllidae sp [40]. However the protein concentrates exhibited higher water holding capacity than 1.87 mL/g obtained in yellow mealworm protein extract [42]. The good water holding capacity of the protein concentrates is desirable in processes where water retention is preferred such as in the meat and baking industry. The deviation observed could be attributed to differences in amino acid profile, conformation, hydrophilicity, protein concentration, charge characteristic and conformation of the protein concentrates [43].

Hexane and aqueous extraction had no significance effect on the oil adsorption capacity of the protein concentrates. The oil adsorption capacity of the protein concentrates was higher than 178.7% reported in Cirinia forda [44] and 233% reported in Yellow Mealworm protein extract [42]. The difference in the availability of the non- polar side chains to bind fat could potentially explain the observed difference in oil adsorption capacity [45]. The considerably high oil adsorption capacity exhibited by the protein concentrates shows the potential of protein concentrates in enhancing flavour characteristics of processed foods [44].

Aqueous extraction showed higher values for foaming capacity and foam stability with AE precipitate recording the highest values while HE recording the least values. The foaming capacity and foam stability of the protein concentrates were considerably lower than 61 and 21.2% respectively obtained in soy protein isolates [46]. This explains the undesirable foaming capacity and foam stability of the protein concentrates. The protein concentrates however exhibited considerably stable foams with a half time of about 5 min. Foam stability is highly influenced by protein structure, protein concentration and ionic strength [3] and this could explain the low foam stability. Additionally the protein concentrates had fat and this could also explain the low foaming capacity [47]. Clearly the protein concentrates are not suitable as foaming agents.

Conclusion

From the study it is clear that the extraction methods had an effect on the physio -chemical characteristics and functional properties of the protein concentrates. However hexane extraction method exhibited more desirable results for yield, colour, crude protein, crude ash and available carbohydrate. The hexane extraction was very effective in defatting the cricket meal which was a major focus in this study. Hexane extraction has been previously tested in concentration of plant proteins and could be potential utilized in the industry to concentrate insect proteins. On the other hand aqueous extraction demonstrated better emulsion capacity, emulsion stability, foaming capacity and foam stability. Therefore hexane extraction is suitable when the focus is acceptability and nutrition while aqueous extraction is desirable when the attention is functionality.

References

A. van Huis, Potential of insects as food and feed in assuring food security. Annu. Rev. Entomol. 58, 120928130709004 (2011). doi:10.1146/annurev-ento-120811-153704

FAO/WHO, Development of regional standard for Edible Crickets and their products:report of a joint FAO/WHO coordinating committee for Asia (Session 17) (2010)

L. Yi, C.M. Lakemond, L.M. Sagis, V. Eisner-Schadler, A. van Huis, M.A. van Boekel, Extraction and characterisation of protein fractions from five insect species. Food Chem. 141, 3341–3348 (2013). doi:10.1016/j.foodchem.2013.05.115

L. Capinera, Encyclopedia of Entomology, vol. 3 (Kluwer Academic Publishers, London, 2004)

D. Renault, A. Bouchereau, Y.R. Delettre, F. Hervant, P. Vernon, Changes in free amino acids in Alphitobius diaperinus (Coleoptera: Tenebrionidae) during thermal and food stress. Comp. Biochem. Physiol. 143, 279–285 (2006). doi:10.1016/j.cbpa.2005.11.012

D. Barker, M.P. Fitzpatrick, E.S. Dierenfeld, Nutrient composition of selected whole invertebrates. Zoo Biol. 134, 123–134 (1998)

Mark, D. Finke, Gene RDAJB Use of a four-Parameter logistic model to evaluate the quality of the protein from three insect species when Fed to Rats1. Entomol.-meat Anim. Sci. 119, 864–871 (1989)

B.A. Rumpold, O.K. Schlüter, Nutritional composition and safety aspects of edible insects. Mol. Nutr. Food Res. 57, 802–823 (2013). doi:10.1002/mnfr.201200735

B.A. Rumpold, O.K. Schl, Nutritional composition and safety aspects keywords. Mol. Nutr. Food Res. 57(5), 802–823 (2013). doi:10.1002/mnfr.201200735

A.L. Yen, Entomophagy and insect conservation: some thoughts for digestion. J. Insect Conserv. 13, 667–670 (2009). doi:10.1007/s10841-008-9208-8

F.R. Valle, M.H. Mena, H. Bourges, An investigation into insect protein. J. Food Process Preserv. 6, 99–110 (1982). doi:10.1111/j.1745-4549.1982.tb00645.x

E.E. Babiker, A.B. Hassan, M.M. Eltayeb, Solubility and functional properties of boiled and fried sudanese tree locust flour as a function of NaCl concentration. J. Food Technol. 5, 210–214 (2007)

L. L’hocine, J.I. Boye, Y. Arcand, Composition and functional properties of soy protein isolates prepared using alternative defatting and extraction procedures. J. Food Sci. 71, C137–C145 (2006). doi:10.1111/j.1365-2621.2006.tb15609.x

A.P. Gandhi, K.C. Joshi, K. Jha, V.S. Parihar, D.C. Srivastav, P. Raghunadh, J. Kawalkar, S.K. Jain, R.N. Tripathi, Studies on alternative solvents for the extraction of oil-l soybean. Int. J. Food Sci. Technol. 38, 369–375 (2003). doi:10.1046/j.1365-2621.2003.00683.x

P. Hernández-Muñoz, E. Almenar, V.V. Del, D. Velez, R. Gavara, Effect of chitosan coating combined with postharvest calcium treatment on strawberry (Fragaria × ananassa) quality during refrigerated storage. Food Chem. 110, 428–435 (2008). doi:10.1016/j.foodchem.2008.02.020

E.T. Mertz, M.M. Hassen, C. Cairns-Whittern, A.W. Kirleis, L. Tu, J.D. Axtell, Pepsin digestibility of proteins in sorghum and other major cereals. Proc. Natl. Acad. Sci. 81, 1–2 (1984). doi:10.1073/pnas.81.1.1

S. Agboola, D. Ng, D. Mills, Characterisation and functional properties of Australian rice protein isolates. J. Cereal Sci. 41, 283–290 (2005). doi:10.1016/j.jcs.2004.10.007

M. Naczk, L.J. Rubin, F. Shahidi, Functional properties and phytate content of pea protein preparations. J. Food Sci. 51, 1245–1247 (1986)

AACC, AACC method 56-30 water hydration capacity of protein materials AACC method 56-30 water hydration capacity of protein materials (continued) 3–4 (2000)

M.J.Y. Lin, E.S. Humbert, Certain functional properties of Sunflower meal products. J. Food Sci. 39, 5–7 (1974)

C.W. Coffmann, V.V. Garcia, Functional properties and amino acid content of a protein isolate from mung bean flour. J. Food Technol. 1, 473–484 (1977)

P.J. Wittkopp, P. Beldade, Development and evolution of insect pigmentation: genetic mechanisms and the potential consequences of pleiotropy. Semin. Cell Dev. Biol. 20, 65–71 (2009). doi:10.1016/j.semcdb.2008.10.002

H.W. Kim, D. Setyabrata, Y.J. Lee, O.G. Jones, Y.H.B. Kim, Pre-treated mealworm larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innov. Food Sci. Emerg. Technol. 38,116–123 (2016). doi:10.1016/j.ifset.2016.09.023

W.C. Stancil, D. Jordan, Color control from perception to instrumentation, in Precise Color Communication, (Minolta cop., New Jersey, 1985), pp 33–35

M.R. Yeomans, L. Chambers, H. Blumenthal, A. Blake, The role of expectancy in sensory and hedonic evaluation: the case of smoked salmon ice-cream. Food Qual. Prefer. 19, 565–573 (2008). doi:10.1016/j.foodqual.2008.02.009

HSG Tan, ARH Fischer, P. Tinchan, M. Stieger, LPA Steenbekkers, HCM van Trijp, Insects as food: exploring cultural exposure and individual experience as determinants of acceptance. Food Qual. Prefer. 42, 78–89 (2015). doi:10.1016/j.foodqual.2015.01.013

D.A. Tzompa-Sosa, L. Yi, HJF van Valenberg, MAJS van Boekel, CMM Lakemond, Insect lipid profile: aqueous versus organic solvent-based extraction methods. Food Res. Int. 62, 1087–1094 (2014). doi:10.1016/j.foodres.2014.05.052

M.D. Finke, Complete nutrient composition of commercially raised invertebrates used as food for insectivores. Zoo Biol. 21, 269–285 (2002). doi:10.1002/zoo.10031

V. Jayasena, H.J. Chih, S. Nasar-Abbas Functional properties of sweet lupin protein isolated and tested at various pH levels. Res. J. Agric. Biol. Sci. 6, 130–137 (2010)

E.N. Videan, J. Fritz, J. Murphy, Development of guidelines for assessing obesity in captive chimpanzees (Pan troglodytes). Zoo Biol. 26, 93–104 (2007). doi:10.1002/zoo

S. Koide, Chitin-chitosan properties, benefits and risks. Nutr. Res. 18, 1091–1101 (1998)

A.D. Banjo, O.A. Lawal, E.A. Songonuga, The nutritional value of fourteen species of edible insects in southwestern Nigeria. African. J. Biotechnol. 5, 298–301 (2006). doi:10.5897/AJB05.250

J.N. Kinyuru, G.M. Kenji, S.M. Njoroge, M. Ayieko, Effect of processing methods on the in vitro protein digestibility and vitamin content of edible winged termite (Macrotermes subhylanus) and grasshopper (Ruspolia differens). Food Bioprocess Technol. 3, 778–782 (2010). doi:10.1007/s11947-009-0264-1

J. Ramos-Elorduy, J.M.P. Moreno, E.E. Prado, M.A. Perez, J.L. Otero, O. Ladron De Guevara, Nutritional value of edible insects from the State of Oaxaca, Mexico. J. Food Compos. Anal. 10, 142–157 (1997). doi:10.1006/jfca.1997.0530

C.E. Bodwell, L.D. Satterlee, L.R. Hackler, Protein digestibility of the same protein preparations by human and rat assays and by in vitro enzymic digestion methods. Am. J. Clin. Nutr. 33, 677–686 (1980)

S. Belluco, C. Losasso, M. Maggioletti, C.C. Alonzi, M.G. Paoletti, A. Ricci, Edible insects in a food safety and nutritional perspective: a critical review. Compr. Rev. Food Sci. Food Saf. 12, 296–313 (2013). doi:10.1111/1541-4337.12014

J. Mitsuhashi, Insects as traditional foods in Japan. Ecol. Food Nutr. 36, 187–199 (1997). doi:10.1080/03670244.1997.9991514

R. Akpossan, Y. Digbeu, M. Koffi, J. Kouadio, E. Dué, P. Kouamé, Protein fractions and functional properties of dried Imbrasia oyemensis larvae full-fat and defatted flours. Int. J. Biochem. Res. Rev. 5, 116–126 (2015). doi:10.9734/IJBCRR/2015/12178

E.D. Aguilar-Miranda, M.G. Lopez, C. Escamilla-Santana, A.P. Barba de la Rosa, Characteristics of maize flour tortilla supplemented with ground Tenebrio molitor larvae. J. Agric. Food Chem. 50, 192–195 (2002). doi:10.1021/jf010691y

A. Yemisi, K.O.A. Adebowalea, MOO, Evaluation of nutritive properties of the large African Cricket (Gryllidae sp). Pak. J. Sci. Ind. Res. 48, 274–278 (2005)

S. Bußler, B.A. Rumpold, E. Jander, H.M. Rawel, O.K. Schlüter, Recovery and techno-functionality of flours and proteins from two edible insect species: meal worm (Tenebrio molitor) and black soldier fly (Hermetia illucens) larvae. Heliyon 2, e00218 (2016). doi:10.1016/j.heliyon.2016.e00218

X. Zhao, J.L. Vazquez-Gutierrez, D.P. Johansson, R. Landberg, M. Langton, Yellow mealworm protein for food purposes—extraction and functional properties. PLoS ONE 11, 1–17 (2016). doi:10.1371/journal.pone.0147791

A. Naik, S.N. Raghavendra, K.S.M.S. Raghavarao (2012) Production of coconut protein powder from coconut wet processing waste and its characterization. Appl. Biochem. Biotechnol. 167, 1290–1302. doi:10.1007/s12010-012-9632-9

A.I. Osasona, O. Olaofe, Nutritional and functional properties of Cirina forda larva from Ado-Ekiti, Nigeria. Afr. J. Food Sci. 4, 775–777 (2010)

H.A. Al-Kahtani, A.A. Abou-Arab, Comparison of physical, chemical and functional properties of Moringa peregrina and soybean proteins. Cereal Chem. 70, 619–626 (1993)

B.E. Chove, A.S. Grandison, M.J. Lewis, Some functional properties of fractionated soy protein isolates obtained by microfiltration. Food Hydrocoll. 21, 1379–1388 (2007). doi:10.1016/j.foodhyd.2006.10.018

K. Lomakina, K. Mikova, A Study of the factors affecting the foaming properties of egg white—a review. Czech. J. Food Sci. 24, 110–118 (2006)

Acknowledgements

I would like to thank Jomo Kenyatta University of Agriculture and Technology Research, Production and Extension department (JKUAT-RPE) for funding this project and the department of Food Science and Technology JKUAT for providing facilities and technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ndiritu, A.K., Kinyuru, J.N., Kenji, G.M. et al. Extraction technique influences the physico-chemical characteristics and functional properties of edible crickets (Acheta domesticus) protein concentrate. Food Measure 11, 2013–2021 (2017). https://doi.org/10.1007/s11694-017-9584-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9584-4