Abstract

In the present study, the effect of ripe mango peel powder (MPP) at 0, 1, 3, and 5 % on rheological, physical, textural, color, antioxidant and sensory properties of whole wheat bread were evaluated. Rheological data of wheat flour incorporated with MPP showed an increase in viscoelastic property. However, the loaf height, weight loss percentage and specific volume were decreased with amount of incorporation. Bread density along with crumb moisture was increased after addition of MPP. The brownness index of bread samples were significantly different and whiteness index were also decremented. For textural analysis hardness, cohesiveness and springiness were also increased with level of addition of MPP. Breads incorporated with MPP exhibited an improvement in antioxidant properties as total phenolic content increased from (220.33 ± 8.5 to 757.8 ± 13.5) mg GAE/100 gm along with the highest value of 2,2-diphenyl-1-picrylhydrazyl (DPPH) inhibition and ferric reducing antioxidant power of 65.74 ± 0.51 % DPPH inhibition and 1436.25 ± 88 µM FeSO4,7H2O/100 g respectively. The MPP levels elevated the fruity aroma, crumb colour, fruity taste, after taste and score for oral texture descriptors in quantitative descriptive analysis. However, at 5 % level porosity and traditional bread aroma decreased significantly. Thus, at optimised level without affecting the sensory and physical properties 3 % MPP addition in whole wheat bread was regarded as best.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mango (Mangifera indica L.) is one of the most cultivated fruit which is consumed due to its delicious sweet taste. The world production of mango is more than 43 millions tons [1]. India is the largest producer of mangoes with 44.14 % of the total world production [2]. Mango consist of 33–85 % edible pulp, with 9–40 % inedible kernel and 7–24 % inedible peel [3]. Having high nutritional value with high range of polyphenols and specific enzyme contents, makes it a high potential candidate for nutraceutical use.

As a seasonal fruit, mango is highly perishable. Mango is processed and preserved in different forms like candy, leather, puree, nectar, jam, jelly, pickles and canned slices [4]. Because of this industrial processing, a huge amount of waste is being generated during production. Such by-products, which mainly consist of mango peel and kernels are a serious disposal problem. So, one should take actions towards either treatment or for sustainable techniques as a method for by-product utilisation in mango processing industry. This major step can lead to minimize the burden for appropriate waste treatment on local administrative bodies as well as industries.

It is known from literature that the peel contains different phytochemicals like polyphenols, carotenoids [5], vitamin E, dietary fibres [6] and vitamin C. It was proven that mango peel consists of good amount of antioxidant [7], anti proliferative [8] and antimicrobial properties [9]. Researchers have shown that the peel can be utilized as mango peel powder in biscuit [10], cookies [11], yoghurt [12], macaroni [13], muffin [14] and wine preparation [15] etc.

Thus, mango peel utilisation alone can lead to an effective way to not only for prevention of health and human hazards, but also have a commercial viability by the justified incorporation. As well as consumption of fruit polyphenols have health beneficial effects like preventing cardiovascular diseases, cancers, neurodegenerative diseases, Alzheimer’s disease and ageing etc. [16]. From ancient age due to its convenience of making, affordability and ease in consumption, bread becomes a staple processed food. For this aspect ripe mango peel can act as potential source of antioxidant in bread.

In our study, oven dried ripe mango peel powder (MPP), which was been incorporated at different levels (1, 3 and 5 %) in whole wheat bread to enhance its antioxidant properties. Thus, aim of our investigation is to study the improvement in antioxidant properties of whole wheat bread along with the sensory properties of the bread as well as the physical, rheological properties of dough and baking properties by addition of MPP powder at different level of enrichment.

Materials and methods

Materials

Ripe mangoes were procured from local market of Jadavpur, Kolkata, India. After that they were washed with water to remove dirt. Further the cleaned peels were blanched and spread in thin layers in trays and dried at 60 ± 2 °C using a Tray dryer (Reliance Enterprise, Kolkata, India) for 18 h till the weight became constant. The dried peel was powdered using a Grinder (GX7, Bajaj Electricals Ltd, India) and was stored in airtight packets. Whole wheat flour, granulated sugar, salt, refined oil (as shortening agent) were purchased from the local grocery stores of Jadavpur, Kolkata. Compressed Baker’s yeast (Saf Yeast Company Pvt. Ltd, Mumbai, India) was used as the leavening agent in bread preparation. Glycerol monostearate (GMS) (Loba Chemie Pvt. Ltd, Mumbai, India) and Potassium bromate (KBrO3) (Merck Specialities Pvt. Ltd, Mumbai, India) were used in bread formulation. 2,4,6-tripyridyl-s-triazine (TPTZ) (Himedia Laboratories Pvt., Ltd, Mumbai, India), anhydrous ferric chloride (Rankem, New Delhi, India), ferrous sulphate heptahydrate, ethanol, Folin–Ciocalteau reagent, sodium carbonate, sodium acetate, acetic acid (Merck Specialities Pvt., Ltd, Mumbai, India), gallic acid (SD Fine-Chem Ltd, Mumbai, India) and DPPH (Sigma-Aldrich, St. Louis, MO, USA) were used.

Dough and bread preparation

The different dough samples of wheat flour (g) were added with MPP at the 0, 1, 3 and 5 % level. Whole wheat bread formulated without MPP (0 %) was used as control.

Straight dough method was applied for preparation of the dough. The dough was prepared by mixing flour-100 g, sugar-6 g, shortening-2.0 g, salt/NaCl-1.5 g, KBrO3-1 ppm, GMS 1.5 g and water at optimum amount along with pre activated compressed yeast-3.0 g in 20 ml lukewarm water and 2 g sugar in a bowl. The prepared dough was firstly proofed for 30 min at 30 ± 2 °C and consecutive second proofing was done in greased moulds at 40 ± 2 °C for 1 h with a cover of wet cloth in both the fermentation steps to maintain the moisture content. In between the proofing, the dough was punched along with slight kneading for removal of excess gas CO2. Fermented dough was baked in a rotary oven (CM HS108; Chanmag Bakery Machine Co., Ltd, Taipei, Taiwan) at 215 ± 2 °C for 18–20 min. After baking, bread samples were cooled down for about 1 h at room temperature (22 ± 1 °C) and stored in airtight packages.

Rheological measurements of dough

Each sample represents a dough prepared with different levels of MPP. Small deformation rheological measurements were performed by using a controlled stress strain rheometer (MCR 300, manufactured by Physica/Anton Paar; Ostfildern, Germany), with parallel plate geometry of 49.986 mm with RheoPlus software package (version 2.65). The upper plate was lowered until the thickness of sample was adjusted to 2 mm where the dough was placed in between them and the excess dough was trimmed off carefully. The exposed surface was covered with a wet layer of filter paper to prevent moisture loss during the test. All samples were allowed to rest for 5 min before measurements to allow dough relaxation. A frequency sweep test, angular frequency ranging from 0.1 to 200 ω, at a constant strain of 1 % was used to study the dough rheological changes. All experiments were carried out at a constant temperature of 25 °C. The dynamic rheological properties of samples were measured by the storage modulus G′, loss modulus G″. Damping factor tan δ and complex viscosity η* [17].

Analysis of bread

Physical properties

The moisture content (dry basis) of samples was determined by AACC standard method where the initial weight (3 g) and final weight difference is measured by earlier drying the crumb of samples in a hot air oven (Reliance Enterprise, Kolkata, India) at 105 °C, shown in Eq. (1) [18].

Loaf height was measured using a scale. The average of the three readings was recorded.

Volumes of the loaves were measured by the seed displacement method. From these, the specific volume and loaf density was calculated as described in Eqs. (2) and (3) respectively [19, 20]

The dough and the baked loaf were weighed, and the percent weight loss was calculated as described in Eq. (4) [21]

Texture

Bread textural characteristics were evaluated with a Texture Analyser (TA.HD Plus Texture Analyzer, USA) equipped with a 35 mm diameter aluminium cylinder probe. Before performing the analysis, for each sample, slices were cut from the central portion of four different bread loaves of dimensions of 40 mm × 40 mm × 30 mm. Texture profile analysis (TPA) was performed with in 30–60 % deformation and 0.1–2 mm/s cross-head speed. The considered textural parameters were hardness, cohesiveness and springiness [22].

Colour

The colour parameters L* (lightness), a* (redness to bluishness), b* (yellowness to greenness) of the baked loaves crumbs were determined using a digital colorimeter (ColourTec PCM, Accuracy Micro Sensor Inc., USA).

To determine brownness index (BI) given in Eqs. (5) and (6), colour parameters L*, a*, b* were determined at each point of the top crust of bread. [23]

where, \(X = \frac{{\left( {{\text{a}} + 1.75{\text{L}}} \right)}}{{\left( {5.645 \times {\text{L}} + {\text{a}} - 3.012{\text{b}}} \right)}}\)

Whiteness index of breads given in Eq. (4) was measured on crumb [24].

Antioxidant activity

Sample extraction

The sample extraction procedure was used to determine the total phenolics content and the radical scavenging activity. The breads were sliced; crust and crumb were separated manually. 1 g of sample was weighed and mixed with 80 % ethanol. Then the mixture was sonicated to agitate the particle in sample. Then it was centrifuged at 8944×g for 15 min. Finally the supernatant was filtered and the extraction was completed by storing them in tubes at very low temperature or in refrigerator.

Total phenolics content

The extract amounting 0.5 ml was dissolved in 1.8 ml of distilled water and 0.2 ml of the Folin–Ciocalteau reagent was added. After 5 min, 2 ml of 7 % sodium carbonate was added and the contents mixed thoroughly by further addition of 0.8 ml distilled water again. Incubated at room temperature for 90 min, colour developed and the absorbance was observed at 750 nm by UV–Vis spectrophotometer (U 2800; Hitachi, Tokyo, Japan) using gallic acid as a standard. The results were expressed as mg GAE/100 g fresh material [25].

DPPH free radical scavenging activity

Radical scavenging activity was determined by using stable 2,2-diphenyl-1-picrylhydrazyl radical (DPPH) as the free radical. The extraction of antioxidants was conducted as reported above. The decrease in absorbance at 515 nm was determined at 25 °C by spectrophotometrically. The percentage of inhibition or the percentage of discolouration was calculated [26].

Ferric reducing antioxidant power (FRAP) assay

FRAP assay was based on the reduction of Fe3+-TPTZ to a blue coloured Fe2+-TPTZ. The FRAP reagent was freshly prepared by mixing acetate buffer (pH 3.6), TPTZ solution (10 mM TPTZ in 40 mM HCl) and 20 mM FeCl3 solution in 10:1:1 v/v ratio. 100 μl of sample was taken and 3 ml of the FRAP reagent added into it. The absorbance was taken at the interval of 0 and 30 min (after incubating at 37 °C) at 593 nm. The antioxidant potential of the extracts was determined against a standard curve plotted using µmol FeSO4,7H2O/l [27].

Sensory evaluation

The evaluation of the sensory attributes of the MPP fortified bread was done by the method of quantitative descriptive analysis (QDA). The first step which consists of section of judges was done by selecting members from faculty and students of Department of Food Technology and Biochemical Engineering, Jadavpur University, Kolkata. The panel constituted 50 judges aged between 20 and 55 years and 25 females and 25 males. To distinguish the descriptive feature for the bread, the panellists devised 8 descriptors for the bread and defined each of the feature of the sensory evaluation who covered the areas of appearance, taste, aroma and oral texture. Porosity, traditional bread aroma, fruity aroma, crumb colour, after taste, fruity flavour hardness and stickiness were the parameters on which the MPP incorporated bread were accessed. The panel members were trained in three training sessions of 1 h each to inculcate the ability to discriminate between the samples. Finally, the assessment was conducted in individual booths under white light at room temperature at Jadavpur University, Dept of Food Technology. For evaluation, approximately 1 cm thick slices including the crust and crumb, was presented to assessors. The assessors evaluated the samples on an unstructured 9 cm line scale labelled on the left by ‘none’ and on the right with the term ‘strong’. Ratings were registered on an evaluation form. The samples were kept in a 3-digit coded glass covered with a glass lid. Samples were assessed in triplicates in four sets [28].

Statistical analysis

The experimental design was completely randomized with three replicates and expressed as mean value ± SD. All experimental data were analyzed statistically for analysis of variance (ANOVA) using Microsoft Excel 2007. The scores for QDA was also analysed by analysis of variance (two-way ANOVA as factors). The comparisons between the mean values were tested using Duncan’s new multiple-range test at a level of p ≤ 0.05.

Results and discussion

Rheological measurements of dough

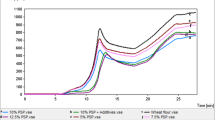

Frequency sweep tests were performed to investigate the effects of MPP on the rheological parameters such as storage modulus (G′), loss modulus (G″) and damping factor (tan δ) of bread dough. In case of MPP substituted samples of 1, 3 and 5 % as well as control both G′ and G″ showed frequency dependence behaviour i.e. both the modulus increased with the increase in angular frequency which is shown in Fig. 1. G′ was greater than G″ in all the angular frequencies studied, indicating viscoelastic soft solid nature of the dough. The frequency sweep data showed that the dough from all the samples displayed higher G′ and G″ at higher frequencies compared to those at low angular frequencies. Dough at lower frequencies showed lower tan δ values that increased with the increase in the angular frequency indicated in Table 1. A similar change in G′, G″ and tan δ of dough with the increasing frequency was observed due to incorporation of ginger powder, where active ginger components affected the dough structure due to cross-linking by the active sites [29]. The complex viscosity in frequency sweep profile was also showed as a linearly decreasing function with decreasing gradient of angular frequency which was earlier seen when hydrocolloids were added in dough [30]. However, as the percentage of incorporation increased η* also increased and tan δ showed a linear decrease with maximum and minimum at 5 % MPP bread respectively. This was likely due to interactions between the fibre structure and the gluten network leading to a denser dough structure.

Analysis of bread

Physical properties

For determining the moisture content (Table 2) of the bread samples, the crumb moisture of the samples was observed. The crumb moisture had a uniform linear relation with the amount of fortification which was highest at 5 %. The significant increase in moisture might be due to the presence of fibre in mango peel, which entrapped the moisture by increasing the water absorption activity of the dough [31].

There was a significant decrease in the specific volume of supplemented breads as compared to the control. In terms of loaf density, bread containing MPP at 1–5 % was found to be denser than control. This reflects that 5 % MPP incorporated bread had a tightly packed crumb structure. Possible explanation might be bread with less porous crumb structure representing increased density is inversely proportional to volume and subsequently low height [32]. The decrease in weight loss was significant at even 1 % addition and showed a range of 15.71 ± 0.70–7.16 ± 0.18 %. The same trend was followed in bread height also, where the decrease in height indicated a significant difference at (p ≤ 0.05).

Texture

Hardness, cohesiveness and springiness of bread crumb samples with different percentages of MPP in whole wheat bread are indicated in Table 3. The incorporation of MPP led to linear increase in crumb hardness compared to control. This is comprehended by earlier studies where incorporation of chestnut flour increased hardness [33] and may be due to the addition of fibre, which probably caused the thickening of the walls surrounding the air bubbles in the crumb. The higher amount of starch and sugars contained in MPP led the ability of a material to stick to itself. The cohesiveness of bread crumb ranged from 0.26 ± 0.02 to 0.82 ± 0.05 showed a linear increase, embarking that the 5 % MPP bread having the stickiest crumb. This increase was also studied earlier where subsequent addition elevated cohesiveness due to increase in stickiness [34]. In the very similar manner MPP addition, not only significantly affected the springiness but also showed a marked increment in compliance to the past studies.

Colour

Determination of bread crust’s and crumb’s colour is important to determine its acceptability. The whiteness index (WI) and the brownness index (BI) were evaluated as given in Table 4 as colour parameters for the sample prepared. The bread prepared by MPP showed a significant difference in WI compared to the supplemented samples. This may be due the effect of MPP imparting a brownish yellow colour in the bread crumb, which got dark at higher percentage of addition. This actually facilitates the acceptability by enhancing the brown colour of whole wheat bread, also observed in anka enriched bread [35].

However, the BI of the MPP incorporated sample increased as compared to the control. Nevertheless, the addition of mango peel gave a much desirable brown colour to the crust causing a darkening of brown colour of crust. This may be assumed due the sugar activity generated by Millard and caramelisation reaction, mentioned in earlier studies, the BI increase with the amount of incorporation in the bread formulation [36] [37]. This was obviously visible by linear decrease in L* and increase in b* values in case of BI and WI values. Fortification levels were inversely proportional with the L* value of the crust and crumb and increase in b* is due to the greenish colour intensification. This means that the crumb and crust stained towards darker colours, tending to brown and assuming a more vivid colour compared with the control bread.

Antioxidant activity

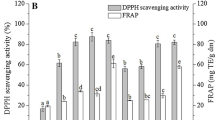

Total phenolics content (TPC) and total antioxidant activity of control bread and fortified bread samples with different percentages of MPP were observed and values were given in Table 5. There were significant differences in respect to total phenolic content between all breads prepared with MPP and control. 5 % incorporation of MPP showed the highest value of TPC 757.8 ± 13.5 mg GAE/100 gm compared to control. This led to the assumption, that inclusion of MPP may elevate the amount of polyphenol amount in bread and other products like biscuit [10]. Mango peel is enriched with phenols because of its dietary fibres, various phenolic compound and vitamins [38]. The same relation can be found in mango peel fortified biscuits.

The similar trend was seen in antioxidant activity by measuring the FRAP (Ferric Reducing Antioxidant Power) and DPPH scavenging property of the incorporated bread. The DPPH and FRAP values showed a linear increase with the amount of incorporation of MPP. In case of FRAP up to 3 % addition resulted in twice the amount of FRAP value. However a significant greater increment was also seen in 5 % incorporation indicating a value of 1436.25 ± 88 µM FeSO4,7H2O/100 g. The range for DPPH showed the value from 21.69 ± 0.72 % inhibition to 65.74 ± 0.51 % inhibition, resulting in a threefold increase till 5 % incorporation. Previous studies also revealed that mango peel incorporation in baked products increased antioxidant activity [39].

Sensory evaluation

The scores for the various descriptors for MPP fortified bread is shown in Table 6. Considering the crumb appearance depicted by porosity, the intensity decreased significantly when the level of addition was higher than 1 %. However, the traditional bread aroma also decreased the amount of fortification increased showing an inverse relationship with the fruity aroma. The fruity taste which should be somehow related to the sugar incorporation showed the highest value at 5 % MPP bread. These aromatic compounds found in peel might interfere and gave the characteristic bitter after taste, which was prevalent with the addition of MPP in bread. The crumb colour showed a linear increase and highest value at 5 % MPP in bread due to the increase in Millard reaction products by addition of sugar from peels [40]. Following the same trend for oral texture descriptors the hardness and stickiness also increased significantly than control. The 5 % MPP substituted bread was significantly different from the control with highest hardness, stickiness, crumb colour as well as lower porosity. Thus, the addition of 3 % MPP in bread would be a diligent decision as up to this level the scores were well acceptable.

Conclusion

According to the present research work ripe mango peel powder could be regarded as a potential health-promoting functional ingredient. Both quantitative and qualitative aspect of antioxidant activity in MPP fortified bread sample showed a linear increase with respect to fortification level. Viscoelasticity of dough sample like antioxidant activity also showed a linear result with increased level of fortification. Interference of dietary fibre and phenolic content also imparted a negative impact on other physical parameters like hardness, WI, specific volume at maximum fortification level. But at 3 % level it showed a close difference with control sample in all physical parameters. This trend was also supported by sensory evaluation, where 3 % MPP level gained favourable scores. Thus, it is important to choose appropriate amount of mango peel powder and processing parameters to obtain healthy bread.

References

S.V. Jawale, J.N. Ghulghule, Constraints and suggestions of Kesar mango production in export zone of Marathwada region. IJCBM 4(5), 713–721 (2015)

FAOSTAT, Food and Agriculture Organization of the United Nations Statistics Division (2014), http://faostat3.fao.org/browse/Q/QC/E. Accessed 14 April 2016

J. De La Cruz Medina, H.S. García, MANGO: Post-harvest Operations (FAO, Rome, 2002)

H.T. Chan Jr, Mango Processing and Products (Tropical Fruit and Vegetable Research Laboratory, USDA-Agricultural Research Service, Hilo, Hawaii)

H.E. Khoo, K.N. Prasad, A. Ismail, N. Mohd-Esa, Carotenoids from Mangifera pajang and their antioxidant capacity. Molecules 15, 6699–6712 (2010)

J.A. Larrauri, P. Rupérez, F. Saura-Calixto, Mango peel fibres with antioxidant activity. Z Lebensm Unters Forsch A 205(1), 39–42 (1997)

Z. Marina, A. Noriham, Quantification of total phenolic compound and in vitro antioxidant potential of fruit peel extracts. IFRJ 21(5), 1925–1929 (2014)

H.J.Y. Kim, H. Moon, D. Kim, M. Lee, H. Cho, Y.S. Choi, M.A. Kim, S.K. Cho, Antioxidant and antiproliferative activities of mango (Mangifera indica L.) flesh and peel. Food Chem. 121(2), 429–436 (2010)

S. Parashar, H. Sharma, M. Garg, Antimicrobial and antioxidant activities of fruits and vegetable peels: a review. J. Pharmacogn. Phytochem. 3(1), 160–164 (2014)

I.S. Ashoush, M.G.E. Gadallah, Utilization of mango peels and seed kernels powders as sources of phytochemicals in biscuit. World J. Dairy Food Sci. 6(1), 35–42 (2011)

K. Bandyopadhyay, C. Chakraborty, S. Bhattacharyya, Fortification of mango peel and kernel powder in cookies formulation. JAIR 2(12), 661–664 (2014)

O.I. El-Batawy, I.S. Ashoush, N.S. Mehanna, Impact of mango and pomegranate peels supplementation on quality characteristics of yoghurt with or without whey powder. World J. Dairy Food Sci. 9(1), 57–65 (2014)

C.M. Ajila, M. Aalami, K. Leelavathi, U.J.S.P. Rao, Mango peel powder: a potential source of antioxidant and dietary fiber in macaroni preparations. Innov. Food Sci. Emerg. Technol. 11(1), 219–224 (2010)

J. Ramirez-Maganda, F.J. Blancas-Benitez, V.M. Zamora-Gasga, M.L. García-Magaña, L.A. Bello-Pérez, J. Tovar, S.G. Sáyago-Ayerdi, Nutritional properties and phenolic content of a bakery product substituted with a mango (Mangifera indica) ‘Ataulfo’ processing by-product. Food Res. Int. 73, 117–123 (2015)

S. Varakumar, K. Naresh, O.V.S. Reddy, Preparation of mango (Mangifera indica L.) wine using a new yeast-mango-peel immobilised biocatalyst system. Czech J. Food Sci. 30(6), 557–566 (2012)

G. Pace, P. Lima, F. Vianello, C.R. Corrêa, R. Arnoux, M.G. Borguini, Polyphenols in fruits and vegetables and its effect on human health. Food Nutr. Sci. 5, 1065–1082 (2014)

L. Das, U. Raychaudhuri, R. Chakraborty, Role of hydrocolloids in improving the physical and textural characteristics of fennel bread. Int. Food Res. J. 20(5), 2253–2259 (2013)

Association of Official Agricultural Chemists (AOAC), Official Method of Analysis, vol. 14 (Association of Official Agricultural Chemists, Washington, DC, 1984)

C.L. Hsu, S.L. Hurang, W. Chen, Y.M. Weng, C.Y. Tseng, Qualities and antioxidant properties of bread as affected by the incorporation of yam flour in the formulation. Int. J. Food Sci. Technol. 39(2), 231–238 (2004)

B.A. Acosta-Estrada, M.A. Lazo-Vélez, Y. Nava-Valdez, J.A. Gutiérrez-Uribe, S.O. Serna-Saldívar, Improvement of dietary fiber, ferulic acid and calcium contents in pan bread enriched with nejayote food additive from white maize (Zea mays). J. Cereal Sci. 60, 264–269 (2014)

L.H. Ho, N.A.A. Aziz, B. Azahari, Physico-chemical characteristics and sensory evaluation of wheat bread partially substituted with banana (Musa acuminata X balbisiana cv. Awak) pseudo-stem flour. Food Chem. 139, 532–539 (2013)

M.C. Bouane, Texture profile analysis. Food Technol. 32(7), 62–66 (1978)

T.A. Shittu, A. Dixon, S.O. Awonorin, L.O. Sanni, B. Maziya-Dixon, Bread from composite cassava–wheat flour. II: effect of cassava genotype and nitrogen fertilizer on bread quality. Food Res. Int. 41, 569–578 (2008)

C. Collar, A. Angioloni, Nutritional and functional performance of barleyflours in breadmaking: mixed breads vs wheat breads. Eur. Food Res. Technol. 238, 459–469 (2014)

V.L. Singleton, R. Orthofer, R.M. Lamuela-Raventos, Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods Enzymol. 299, 152–178 (1999)

W. Brand-Williams, M.E. Cuveleir, C. Berset, Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 28(1), 25–30 (1995)

I.F. Benzie, J.J. Strain, The ferric reducing ability of plasma (FRAP) as a measure of ‘‘antioxidant power’’: the FRAP, assay. Anal. Biochem. 239, 70–76 (1996)

S.P. Heenan, J.P. Dufour, N. Hamid, W. Harvey, C.M. Delahunty, The sensory quality of fresh bread: descriptive attributes and consumer perceptions. Food Res. Int. 41(10), 989–997 (2008)

F. Balestra, E. Cocci, G. Pinnavaia, S. Romani, Evaluation of antioxidant, rheological and sensorial properties of wheat flour dough and bread containing ginger powder. LWT Food Sci. Technol. 44(3), 700–705 (2011)

L. Das, U. Raychaudhuri, R. Chakraborty, Effects of hydrocolloids as texture improver in coriander bread. J. Food Sci. Technol. 52(6), 3671–3680 (2015)

H. Erkan, S. Celik, B. Bilgi, H. Koskel, A new approach for the utilization of barley in food products: barley tarhana. Food Chem. 97, 12–18 (2006)

Y.S. Shyu, T.C. Lu, C.C. Lin, Functional analysis of unfermented and fermented citrus peels and physical properties of citrus peel-added doughs for bread making. J. Food Sci. Technol. 51(12), 3803–3811 (2013)

C. Dall’Asta, M. Cirlini, E. Morini, M. Rinaldi, T. Ganino, E. Chiavaro, Effect of chestnut flour supplementation on physico-chemical properties and volatiles in bread making. LWT Food Sci. Technol. 53, 233–239 (2013)

G.K. Dhillon, A. Kaur, Quality evaluation of bread incorporated with different levels of cinnamon powder. IJFS II(7), 1–6 (2013)

Y.H. Tseng, J.H.W.A. Yang, C.H. Chen, J.L. Mau, Quality and antioxidant properties of anka enriched bread. J. Food Process. Pres. 35(4), 518–523 (2010)

C. Collar, T. Jiméneza, P. Contea, C. Faddaba, Impact of ancient cereals, pseudocereals and legumes on starch hydrolysis and antiradical activity of technologically viable blended breads. Carbohydr. Polym. 113, 149–158 (2014)

T.A. Shittu, A.O. Raji, L.O. Sanni, Bread from composite cassava–wheat flour: I. Effect of baking time and temperature on some physical properties of bread loaf. Food Res. Int. 40, 280–290 (2007)

C.M. Ajila, S.G. Bhat, U.J.S.P. Rao, Valuable components of raw and ripe peels from two Indian mango varieties. Food Chem. 102(4), 1006–1011 (2007)

C.M. Ajila, K. Leelavathi, U.J.S.P. Rao, Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 48(2), 319–326 (2008)

A. Michalskaa, M. Amigo-Benaventb, H. Zielinskia, M.D. del Castillo, Effect of bread making on formation of Maillard reaction products contributing to the overall antioxidant activity of rye bread. J. Cereal Sci. 48, 123–132 (2008)

Acknowledgments

This research work is financially supported by the Basic Scientific Research (BSR) fellowship for meritorious student programme under University Grants Commission (UGC), India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pathak, D., Majumdar, J., Raychaudhuri, U. et al. Characterization of physicochemical properties in whole wheat bread after incorporation of ripe mango peel. Food Measure 10, 554–561 (2016). https://doi.org/10.1007/s11694-016-9335-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-016-9335-y