Abstract

A method is described for construction of an amperometric biosensor for specific determination of tyramine, using black gram tyramine oxidase immobilized covalently on an epoxy resin membrane. The biosensor had optimum response within 10 s at pH 8.5 and 35 °C. A linear relationship was observed between tyramine concentrations and current (mA) in the range of 0.24 to 3.47 mg/dL. The biosensor was employed for determination of tyramine in beer and sauce. The detection limit of sensor was 0.24 mg/dL. The mean analytical recovery of added tyramine (0.5 and 1.0 mg/dL) was 97.3 ± 2.3 and 95.9 ± 3.4%. Within and between batch coefficient of variation were 5.1 and 5.34%, respectively. Enzyme electrode showed 35% loss in its initial activity after its regular use over a period of 2 months. The biosensor has the advantage that it does not suffer from leaching of enzyme and measures tyramine specifically.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tyramines (C8H11NO) are decarboxylation products of tyrosine and phenylalanine, which are associated with headaches, migraine, hypertension and hyperthyroidism [1]. Tyramines are found in high amount in certain foods such as chocolates, wine, beer, cheese, beans, banana peel, ketchup’s and soya products [2]. Tyramine also serves as possible indicators of defective food manufacturing processes related with poor sanitary condition [3]. Hence tyramine determination has become important in food industries. Various analytical methods are available for quantification of tyramine such as spectrophotometric [4], gas chromatographic [5], reversed phase high performance liquid chromatography [6] and ion-exchange chromatography with pulsed amperometry [7]. These methods suffer from certain drawbacks such as time consuming, sample preparation, expensive equipments and trained person to operate.

Therefore, a simple, rapid and sensitive method is required. Biosensors are considered as better option, because of their simplicity, rapidity and high sensitivity. The electrochemical biosensors/sensor for tyramine determination have been reported employing either monoamine oxidase or tyramine oxidase immobilized on different supports such as collagen membrane [8], gelatin [9], 2-[4,6-bis(aminoethylamine)-1,3,5-triazine]-Silasorb [10] and flurophore sol–gel containing aminopropyl 3-methoxycelane (APTMS) [3] or without enzyme [11]. Most of these immobilization methods provided poor stability due to leaching of enzymes from membrane/support, low conductivity, interference in electron communication and poor reproducibility of electrode, which limits the application of these biosensors. Therefore, there is demand for the development of a biosensor that is stable, reproducible, sensitive and specific for tyramine determination in real samples. We report herein immobilization of tyramine oxidase (purified from black gram seedlings) onto ‘Araldite’ epoxy resin membrane and its application in construction of a tyramine biosensor. ‘Araldite’ membrane, composed of epoxy resins having epoxy groups on both sides of singe epoxy resin, forming a highly crosslinked network, is long lasting and water-permeable. The membrane has advantages such as high affinity for enzyme, low cost, easy synthesis, high temperature stability, chemical resistance and porous nature that makes it an ideal support for an enzyme electrode [12].

Materials and methods

Chemical and reagents

Tris–HCl, tyramine, copper sulphate, and Folin-Ciocalteu’s reagent were from SISCO research Laboratory Pvt., Mumbai, India. All other chemicals used were of AR grade. ‘Araldite’ as a source of epoxy resins and polyamine cross linker, manufactured by Huntsman Advanced Material Pvt. Ltd., Mumbai, India, seeds of black gram (Vigna mungo L) and different beer and sauce samples were purchased from local market.

Extraction and purification of tyramine oxidase from black gram

Seven day old seedlings of black gram were raised in laboratory as described by Pundir and Nath, [13]. The seedlings were homogenized with Tris–HCl buffer (0.05 M, pH 8.0) in pestle and mortar in 1:5 ratio (w/v) at 4–10 °C and the homogenate was centrifuged at 10,000×g for 30 min. The supernatant was collected and treated as crude enzyme. It was purified by combination of 0–30% (NH4)2SO4 fractionation, gel filtration on Sephadex column (34 × 2 cm2) (height × diameter) using Tris–HCl as elution buffer and ion-exchange chromatography on DEAE-Sephacel column (17 × 2.5 cm2), (height × diameter) using a linear gradient of 0.1–0.6 M KCl in Tris–HCl buffer for its elution. The active DEAE-Sephacel fractions were pooled and treated as purified enzyme. The purity of enzyme was tested in simple PAGE using Coomassie blue as protein stain. The enzyme was purified by 55.5 fold with 23% yield and had an activity of 286.16 U/mL. One unit is defined as the amount of enzyme required to generate 1 μmol H2O2/min/mL under standard assay conditions.

Assay of tyramine oxidase

The assay of tyramine oxidase was carried out in dark as described with modification [14]. The reaction mixture containing 1.7 mL of 0.05 M Tris–HCl buffer pH 8.0, 0.1 mL of CuSO4 (10−2 M) and 0.1 mL crude enzyme was pre-incubated at 37 °C for 2 min. The reaction was started by adding 0.1 mL tyramine solution (10−2 M). After incubating it at 37 °C for 5 min, 1.0 mL color reagent was added and kept at room temperature for 15 min to develop the color. A520 was read in Spectronic 20D (Thermo USA) and the amount of H2O2 generated during the reaction was determined from a standard curve of H2O2. The color reagent consisted of 50 mg 4-aminophenazone, 100 mg solid phenol and 1.0 mg horseradish peroxidase (RZ = 1.0) per 100 mL of 0.4 M sodium phosphate buffer pH 7.0 and stored in amber colored bottle at 4 °C and prepared fresh after every 1 week.

The protein content in various enzyme preparations was measured by Lowry Method.

Immobilization of tyramine oxidase on epoxy resin membrane

It was done as described [12] with minor modifications. The epoxy resin and hardener of ‘Araldite’ were mixed on a plastic (polythene) piece in 85:15 ratio at room temperature for 5 min. The purified enzyme (3.0 mL) was added to this mixture and spread equally to polymerize and crosslinked for 48 h. Araldite membrane with entrapped tyramine oxidase was stripped off the plastic piece and washed with 0.05 M Tris–HCl buffer pH 8.0.

Scanning electron microscopy (SEM) of ‘Araldite’ membrane

The SEM of ‘Araldite’ membrane with and without enzyme was carried out at Chemistry Department, M.D. University Rohtak after gold coating.

Construction and response measurement of tyramine biosensor

Tyramine oxidase–epoxy resin biocomposite membrane was mounted over the sensing part of Pt electrode (1.5 cm × 0.1 mm) (length and diameter) with the help of parafilm. This working electrode along with Ag/AgCl as reference and Cu wire as counter electrode, were connected to a three terminal electrometer (Make: Keithley, model 6517A). To test the functioning of biosensor, the three electrode system was immersed into 10 mL 0.05 M Tris–HCl buffer pH 8.0 in a 50 mL beaker. The reaction was started by adding 0.2 mL tyramine solution (10−2 M) and reaction mixture was shaken gently. The working electrode was polarized at different volts ranging from 0.1 to 0.8 V at an interval of 0.1 V and the current (mA) generated, was recorded. The biosensor showed maximum current at 0.4 V, hence in subsequent experiments, the current was measured at 0.4 V.

Optimization of tyramine biosensor

To determine optimum working conditions of biosensor based on epoxy resin membrane bound tyramine oxidase, the pH of the reaction buffer was varied from 6.5 to 10.5 at an interval of 0.5 using 0.05 M Tris–HCl buffer at 37 °C. Similarly, the optimum temperature was studied by incubating reaction mixture at different temperature ranging from 20 to 50 °C at an interval of 5 °C at optimum pH (pH 8.5). To study the effect of substrate concentration, the tyramine concentration was varied from 0.01 to 1.5 mM. The apparent Michaelis–Menten constant (K m = [S] at ½ I max), which gives an indication of the enzyme–substrate kinetics for the biosensors, was calculated from the electrochemical version of the Lineweaver–Burk equation

where I is the steady state current after the addition of substrate, S is the bulk concentration of the tyramine, and I max is the maximum current measured under saturated tyramine condition.

Determination of tyramine content in beer and sauce

The sauce was homogenized in 5 mL Tris–HCl (0.05 M, pH 8.0) buffer solution in 1:3 ratio and centrifuged at 3,000 rpm for 5 min at 4 °C, and the supernatant was collected and analyzed for tyramine by the present biosensor. The beer was used as such without any pretreatment. The method of determination of tyramine was same as described for biosensor response measurement except that tyramine was replaced by food sample.

Results and discussion

Immobilization of tyramine oxidase onto epoxy resin membrane

Tyramine oxidase purified from 7 days old seedlings of black gram was immobilized onto ‘Araldite’ epoxy resin membrane with 85% retention of initial activity of free enzyme with a conjugation yield of 0.065 mg/cm2. The epoxy groups of epoxy resin membrane react with bifunctional polyamine and –NH2 groups of enzyme to form a network resulting into enzyme–epoxy amine resin composites. Scheme 1 represents the probable mechanism of immobilization of enzyme onto epoxy resin membrane which shows the covalent coupling of enzyme with the support.

SEM of epoxy resin membrane biocomposite

The SEM of tyramine oxidase epoxy resin membrane bioconjugate shows the distinct spots of aggregation of proteins throughout the surface of the epoxy membrane, (Fig. 1) which might be due to the both adsorption and covalent coupling of enzyme.

Construction of amperometric tyramine biosensor

A method is described for the construction of an amperometric tyramine biosensor using epoxy resin membrane bound tyramine oxidase (Fig. 2). The electrochemical reactions involved in response measurement of tyramine biosensor are given below, which is based on generation of H2O2 from tyramine by epoxy resin membrane bound tyramine oxidase and its splitting into 2H+ + O2 + 2e− at high potential (0.4 V). The flow of electrons to Pt electrode i.e., amount of current is directly proportional to tyramine concentration.

Optimization of tyramine biosensor

The optimum pH of biosensor/immobilized tyramine oxidase was pH 8.5 (Fig. 3), which is slightly higher than that of free enzyme pH (8.0) and higher than tyramine oxidase immobilized on microtiter plate using sol gel fluorophore (pH 7.0) [3]. The optimum temperature of the immobilized tyramine oxidase was 35 °C (Fig. 4) which is higher than tyramine oxidase immobilized on microtiter plate using sol gel fluorophore (23–25 °C) [3]. There was a hyperbolic relationship between biosensor response/Immobilized tyramine oxidase activity and tyramine concentration up to 0.35 mM thereafter it was constant. K m for tyramine was 0.24 mM, which is lower than that of free enzyme indicating the increased affinity of the enzyme after immobilization. The change in kinetics of tyramine oxidase after immobilization might be due to many factors like conformational changes due to chemical modification of the enzyme, steric hindrance, partitioning effects due to electrostatic or hydrophobic interactions between matrix and the low molecular weight species [12, 15].

Application of tyramine biosensor

The biosensor was employed to determine tyramine concentration in different beer and sauce samples. The tyramine level in different beer samples was in the range 0.37–2.53 mg/dL with a mean of 1.29 mg/dL while was in the range, 0.22–3.11 mg/dL with a mean of 1.22 mg/dL in sauce samples which is in agreement to those by spectrofluorometric method (Table 1) [16].

Specificity of tyramine biosensor

The substrates specificity of present biosensor was studied by using substrate analogs i.e., histamine, spermine, putrescine, serotonin and arginine at their physiological concentration in place of tyramine and found practically no response/negligible response (Table 2). These observations revels that, the present tyramine biosensor was specific for tyramine.

Evaluation of tyramine biosensor

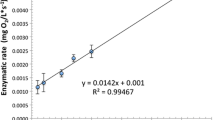

Figure 5 showed that working linear range of the biosensor was from 0.24 to 3.47 mg/dL which is better than tyramine oxidase immobilized on microtiter plate using sol gel fluorophore (6.30–8.73 mg/dL) [3] but lower than electrochemical sensor based on MWCNT-AuNPs composite and chitosan (1.88–174.63 mg/dL) [11]. Detection limit of biosensor is 0.24 mg/dL which is lower than that of tyramine oxidase immobilized on microtiter plate using sol gel fluorophore (6.30 mg/dL) [3] and electrochemical sensor based on MWCNT-AuNPs composite and chitosan (0.99 mg/dL) [11]. Mean analytical recovery of exogenously added tyramine in different beer samples (0.5 and 1.0 mg/dL) was 97.3 ± 2.3 and 95.9 ± 3.4, respectively showing the reliability of the method. To study the reproducibility and reliability of the present method, the tyramine value in five beer samples was determined six times a day (within batch) and after their one-week storage at −20 °C (between batch). The results showed that determinations were almost consistent and within and between batch coefficients of variation (CV) for tyramine determination were <5.1 and <5.34%, showing the good reproducibility and reliability of the method.

Reusability and storage stability

The enzyme electrode lost 35% of initial activity, after 100 uses over a period of 2 months after storing electrode at 4 °C (Fig. 6). This loss could be due to the leaching of enzyme during washing of the enzyme electrode.

Conclusion

A tyramine biosensor was constructed using an epoxy resin membrane bound tyramine oxidase purified from black gram seedlings. The biosensor was employed for determination of tyramine in beer and sauce items. The sensitivity and specificity of the biosensor towards tyramine make it more suitable for clinical and industrial applications, than earlier biosensors.

References

A. Guerrieri, V. Lattanzio, F. Palmisano, P.G. Zambonin, Biosens. Bioelectron. 21, 1710–1718 (2006)

A. Halasz, A. Barath, L.S. Sarkadi, W. Holzapfel, Trends Food Sci. Technol. 5, 42–49 (1994)

H.D. Duong, J. Rhee, Talanta 72, 1275–1282 (2007)

C.M.G. Silva, M.B.A. Gloria, Food Chem. 78, 241 (2002)

W.F. Staruszkiewiecz Jr, J.F. Bond, J. Assoc. Off. Anal. Chem. 64, 584–591 (1981)

F. Calbiani, N. Careri, L. Elviri, A. Mangia, L. Pistara, I. Zagnoni, J. Agricult. Food Chem. 53, 3779–3783 (2005)

J.C. Hoekstra, D.C. Johnson, Anal. Chem. 70, 83–88 (1998)

I. Karube, I. Satoh, Y. Araki, S. Suzuki, H. Yamada, Enz. Microb. Technol. 2, 117–120 (1980)

O.V. Yagodina, E.B. Nikolskaya, Sens. Actuators B 44, 566–570 (1997)

M. Wimmerova, L. Macholan, Biosens. Bioelectron. 14, 695–702 (1999)

J. Huanga, X. Xing, X. Zhang, X. Heb, Q. Linb, W. Lianc, H. Zhuc, Food Res. Internat. 44, 276–281 (2011)

J. Arora, S. Nandwani, M. Bhambi, C.S. Pundir, Anal. Chim. Acta 647, 195–201 (2009)

C.S. Pundir, R. Nath, Phytochemistry 23, 1871–1874 (1984)

Satyapal, C.S. Pundir, Biochim. Biophys. Acta 1161, 1–6 (1993)

J.F. Kennedy, A. Wiseman, Handbook of enzyme biotechnology (Wiley, New York, 1975), p. 147

M.L.I. Pulido, M.C.V. Carou, A.M. Font, J. Food Compos. Anal. 2, 219–227 (1989)

C.S. Solange, H.T. Karine, R.S. Élson, M. da Silvana, B.A.G. Maria, Braz. Arch. Bio. Technol. 48, 53–62 (2005)

L. Hua, L. Xinhong, F. Lidan, L. Yanlin, W. Hua, J. Food Drug Anal. 16, 53–58 (2008)

Acknowledgments

The authors are thankful to Head, Department of Chemistry, M.D.U. Rohtak, for providing Scanning Electron Microscope facility for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lata, S., Yadav, S., Bhardwaj, R. et al. Amperometric determination of tyramine in sauce and beer by epoxy resin biocomposite membrane bound tyramine oxidase. Sens. & Instrumen. Food Qual. 5, 104–110 (2011). https://doi.org/10.1007/s11694-011-9117-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-011-9117-5