Abstract

A new electrochemical immunosensor for the determination of aflatoxin B1 (AFB1) based on bio-electrocatalytic reaction was proposed. An imidazolium cation room-temperature ionic liquid (RTIL), 1-ethyl-3-methyl imidazolium tetrafluoroborate ([EMIm][BF4]), was initially immobilized on the surface of a glassy carbon electrode (GCE) through titania sol and Nafion film, then nanogold particles were adsorbed onto the titania surface, and then horseradish peroxidase (HRP)-labeled anti-AFB1 antibodies (HRP-anti-AFB1) were attached on the nanogold surface. With a non-competitive immunoassay format, the formation of the antibody–antigen complex by a simple one-step immunoreaction between the immobilized HRP-anti-AFB1 and AFB1 in sample solution introduced a barrier of direct electrical communication between the immobilized HRP and the electrode surface, thus local current variations could be detected by the HRP bio-electrocatalytic reaction in 0.1 M PBS (pH 6.8) containing 0.28 M H2O2. Under optimal conditions, the electrochemical immunosensor exhibited a good current response relative to AFB1 concentration in a linear range from 0.1 to 12 ng/mL with a relatively low detection limit of 0.05 ng/mL at 3δ. The inter-assay coefficients of variation are 7.1% and 5.4% for 1.0 ng/mL and 8.0 AFB1, respectively. Naturally contaminated samples were screened with the developed immunosensor, and results were compared with those obtained by validated ELISA method. The assay was demonstrated to be accurate and reliable giving no false compliant and only a low percentage of false non-compliant results. The described method offers a simple, rapid and cost-effective screening tool, thus contributing to a better consumers’ health protection.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aflatoxins are toxic secondary metabolites produced by a number of different fungi, and can be present in a wide range of food and feed commodities including cereal grains, oil seeds, dried fruits, apple juice, wine and meat products from animals fed contaminated meal [1]. Many aflatoxins are highly resistant, and survive food processing, and therefore enter the food chain and provide a threat to human health. This has prompted adoption of regulatory limits in several countries, which, in turn, requires the development of validated official analytical methods for rapid and cost effective screening on a large scale. Special attention has been paid to aflatoxins B 1 (AFB1) because of their potential hazards for animal and human health. Thus, quantitative determination of AFB1 is very important in biochemistry, clinical chemistry, food processing and fermentation.

Many analytical techniques for AFB1 determination, such as synchronous spectrofluorimetry [2], ELISA [3], OWLS technique [4], immunochromatographic assay [5] have been reported. Most of these procedures, unfortunately, are often time-consuming, highly prone to interferences, and can be unreliable for some food and biological samples, due to the difficulty in obtaining a clear solution for final measurements. Hence, it is still a challenge to explore optimum determination methods for AFB1. Electrochemical immunoassay methods combining the specific antigen–antibody recognition can overcome above drawbacks for determination of AFB1 [6]. Especially, amperometric immunosensors are attractive because of its simplicity and high sensitivity [7, 8].

In the development of amperometric immunosensors, there are two basal issues to realize the application of electrochemical technique [9]. First, the key process is to retain the biologic activity of the immobilized biomolecules on the electrode surface in its native status. Gold and titania nanoparticles have been widely used to construct biosensor due to their excellent ability to immobilize biomolecules [10]. Moreover, they could provide an microenvironment similar to that of protein in native systems and give protein molecules more freedom in orientation [11–13]. They have been employed for synthesis of functional materials and electrochemical sensing by combining with sol–gel technique or opposite-charged adsorption technique to form composite structure. The layer-by-layer (LBL) assembly of these nanoparticles is based on electrostatic alternate adsorption of oppositely charged compounds regarded as one of the most convenient, simple and quite universal methods for the construction of ultrathin organized multilayers, and opens broad perspectives both in research and in practical applications [14]. Titania colloids are a positively charged species in the pH range of 2–5.5 as a result of the isoelectric point of rutile titania is 5.7 [15]. Thus, under a mildly acidic condition, the positively charged titania nanoparticles could be adsorbed to the negatively charged nanogold particles, which provides a facile microenvironment for the immobilization of proteins.

Another key factor is to provide a pathway of electron transfer between the redox center of proteins and the electrode surface [16]. The simplest method is direct adsorption of native proteins on the electrode surface, but only 40–50% of the biomolecules adsorbed remains active for transferring electron to the electrode [17]. Recently, work on the application of room-temperature ionic liquids (RTILs) in electrochemical fields has already attracted much attention. RTILs are air and water stable salts, composed of an organic cation and either an organic or an inorganic anion, and preserve in the liquid state over a wide temperature range [18]. They exhibit many unique advantages such as good chemical and thermal stability, negligible vapor pressure, good ionic conductivity, wide electrochemical windows, and are widely applied in organic synthesis, electrochemistry, lubrication, and solar cell etc. [19]. Recently, some reports on the application of RTILs in electrochemistry can be noted [20–22]. To the best of our knowledge, there was little report focusing on electrochemically studying the antigen–antibody interaction on RTILs and nanogold particles modified complex membranes for the determination of AFB1.

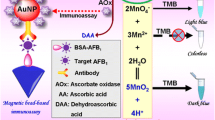

In this contribution, a new composite film coated on a glassy carbon electrode (GCE) is constructed, which comprises of HRP-anti-AFB1, nanogold particles, titania sol–gel, [EMIm][BF4] and Nafion. Nafion was used a binder to adhere [EMIm][BF4]. [EMIm][BF4] was incorporated into titania sol–gel film for the purpose of improving the ionic conductivity of the resulting composite. Titania sol–gel film preserved their functional characteristics and kept RTILs from leakage [23]. The presence of nanogold particles provided a good microenvironment for the immobilization for HRP-anti-AFB1. The experimental results indicate that the immobilized HRP-anti-AFB1 could efficiently exchange electron with the electrode. In addition, the performance and factors influencing the immunosensor were also discussed.

Materials and methods

Reagents

AFB1, AFB1-bovine serum albumin (BSA) conjugate, horseradish peroxidase (HRP)-labeled monoclonal antibodies against AFB1 (from goat) were purchased from Biocell Bioeng. Co. (China). The room-temperature ionic liquid, 1-ethyl-3-methyl imidazolium tetrafluoroborate (97%, [EMIm][BF4]), used in this study was obtained from Fluka (Buchs, Switzerland). Titania nanoparticle (TiO2, 5%, pH 2.0–3.0), Nafion-ethanol solution, bovine serum albumin (BSA, 96–99%) were obtained from Sigma. RTIL-ethanol solution (2%, v/v) and Nafion-ethanol solution (1%, v/v) were stored at 4 °C as stock solution. 0.1 M phosphate buffer solution (PBS) at various pH values was prepared by mixing the stock solutions of NaH2PO4 and Na2HPO4 and then adjusting the pH with NaOH. Hydrogen peroxide standardized by iodimetric titration, was freshly prepared in deionized water. Unless otherwise noted, all chemicals were reagent grade and were used without further treatment. For solution, doubly distilled and deionized water with a specific resistance over 18 MΩ cm−1 was used throughout the study. 20-nm gold nanoparticles are prepared according to the literature [24].

Fabrication of immunosensors

Prior to modification, a glassy carbon electrode (GCE, 4 mm in diameter) was polished with mirror smoothness with 0.3 and 0.05 μm Al2O3 slurry, rinsed with water, ultrasonicated in water bath for 3 min and dried in air. Initially, the Nafion modified electrodes were fabricated by placing 5 μL of 1% (v/v) Nafion-ethanol solution on the surface of the polished GCE electrode and removed to parch with an infrared light for 20 min. Then, 45 μL of 2% (v/v) RTIL-ethanol solution was dropped to the Nafion modified electrode. After drying, 10 μL of stock titania sol–gel solution was used to cover the RTIL/Nafion modified electrode. The stock sol–gel solution on the electrode surface was allowed to polymerize and later dried for 1 h at room temperature. After that, the TiO2/RTIL/Nafion modified electrode was immersed into colloidal gold nanoparticles for 4 h at 4 °C. Following that the nanogold/TiO2/RTIL/Nafion modified electrode was dipped in a pH 7.0 PBS containing HRP-anti-AFB1 for 12 h to form an HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion modified electrode. Finally, the modified electrode was incubated into HRP solution for 60 min at 37 °C to eliminate non-specific binding effect and block the remaining active groups. The finished immunosensor was stored at 4 °C when not in use. The fabricated process of the immunosensor is shown in Scheme 1. For comparison, HRP-anti-AFB1/nanogold/TiO2/RTIL, HRP-anti-AFB1/nanogold/TiO2/Nafion, HRP-anti-AFB1/TiO2/RTIL/Nafion, HRP-anti-AFB1/nanogold/RTIL/Nafion modified electrodes were prepared through the similar way.

Electrochemical measurement

Electrochemical measurements were performed with CHI 660 electrochemical analyzer (CHI, USA) with a conventional three-electrode cell. The modified GCE was used as a working electrode. An Ag/AgCl electrode and a platinum wire electrode were used as the reference and the auxiliary electrode, respectively.

The analytical procedure for immune-bioassay was based on detecting the inhibition of the access of the back-filled HRP active center, which resulted from the immunoreaction. Prior to the measurement, 5 μL AFB1 standard or sample solution was diluted with 45 μL dilute solution and 50 μL AFB1 zero buffer to a total volume of 100 μL, which used as the incubation solution. Measurements were carried out at room temperature (25 ± 1.0 °C) in a glass cell. The immunosensor was initially immersed in a measuring cell filled with 5 ml of magnetic stirred 0.1 M PBS (pH 6.8) containing 0.28 M H2O2, and the steady-state current response (i 0) was recorded. The proposed immunosensor was then incubated in the incubation solution at 35 °C for 50 min to obtain an antigen–antibody complex layer. The amount of the conjugated immunocomplex depended on the concentration of AFB1 in standard or sample solution. The incubation was followed by rinsing the sensor with 0.1 M PBS (pH 6.8) containing 0.2% of Tween-20 in order to remove non-specifically bound agents. After that, the sensor was transferred into 0.1 M PBS (pH 6.8) containing 0.28 M H2O2, and the steady-state current response (i n) was achieved. The detection is based on the current shift before and after the antigen–antibody interaction.

Statistical analysis

All measurements were carried out in triplicates. Statistical procedures were carried out with SPSS 10.1 (SPSS Inc., Chicago, IL) or SAS (SAS Institute, Cary, NC) software. For comparing two measurement systems that are supposed to be equivalent, results were tested by paired t-test and Bland–Altman model.

Results and discussion

Electrochemical characteristics of HRP-anti-AFB1 with the help of RTILs and nanogold

As shown in Fig. 1a, a pair of well-defined, quasi-reversible redox peaks could be obtained with HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion/GCE electrode in 0.1 M pH 6.8 PBS, where anodic and cathodic peak potentials are located at −340 and −390 mV, respectively. The separation of anodic and cathodic peak potentials (ΔE p) is 50 mV, indicating a fast electron transfer reaction. However, only a small pair of redox waves could be observed at the HRP-anti-AFB1/TiO2/RTIL/Nafion/GCE (Fig. 1b) and HRP-anti-AFB1/nanogold/TiO2/Nafion/GCE (Fig. 1c). And no peaks of interest were observed in this potential range with the HRP-anti-AFB1/TiO2/Nafion/GCE (Fig. 1d) and the HRP-anti-AFB1/GCE electrode (Fig. 1e). These results clearly suggested that the RTILs and nanogold modified complex membrane formed on the electrode surface provided desirable environments for the electron transfer process between the immobilized HRP-anti-AFB1 and the base electrode. Importantly, these two peaks could be improved with the aid of RTILs and nanogold. A likely explanation for this feasibility is that the RTILs have good conductivity, and the nanogold modified composite film conducts the proper orientation of HRP-anti-AFB1 on the electrode surface [25]. Thus, they facilitate electron transfer between HRP-anti-AFB1 and the base electrode.

Additionally, the HRP-anti-AFB1/nanogold/TiO2/RTIL/GCE and HRP-anti-AFB1/nanogold/RTIL/Nafion/GCE electrodes also display a couple of redox peaks of HRP-anti-AFB1 (data not shown). The peak currents, however, are much smaller than those at HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion/GCE. Moreover, the stability of the modified electrode was very bad in the absence of Nafion or titania sol–gel. The reason might be the fact that RTILs could be incorporated into Nafion film through a cation-exchange process, and the three-dimensional sol–gel network could prevent it leakage. Typical cyclic voltammograms of HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion/GCE in 0.1 M PBS (pH 6.8) at different scan rates are studied (Fig. 2). It is found that the peak current increases along with the rising of scan rate, while the ΔE p expands slowly. At low scan rate, the cathodic peak current rises linearly with the scan rate, v, not with v 1/2, as shown in inset of Fig. 2, indicating that the redox reaction is a surface process. When nΔE p < 200 mV, the electron transfer rate constant K s of HRP-anti-AFB1 on the HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion/GCE can be estimated by the following equation [26]:

Taking a charge transfer coefficient α of 0.5, and a scan rate of 100 mV/s, and then the electron transfer rate constant (ks) was 4.12 ± 0.11 s−1. In contrast with it, the electron transfer rate constants for HRP-anti-AFB1/nanogold/TiO2/Nafion/GCE and HRP-anti-AFB1/TiO2/RTIL/Nafion/GCE were 3.14 ± 0.13 s−1 and 3.76 ± 0.08 s−1, respectively. The results suggested that RTILs and nanogold could improve the electron transfer rate between the immobilized HRP-anti-AFB1 and the base electrode.

Elucidation on the enhanced faradic responses for HRP-anti-AFB1 with the help of RTILs and nanogold

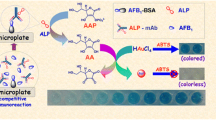

In this contribution, a non-competitive enzyme-linked assay format was employed to detect AFB1 with HRP-anti-AFB1 molecules as tracer and hydrogen peroxide as enzyme substrate. The principle of non-competitive immunoassay, which was described in this literature [27], is based on inhibition of the active center of HRP by forming antigen–antibody complexes as the following equations:

Immunoreaction:

Electrochemical measurement:

The electrochemical measurement attributes to the direct electron transfer of the immobilized HRP. Therefore, the formation of the antigen–antibody complex by a simple one-step immunoreaction introduces a local current change of the immobilized HRP towards the reduction of H2O2. The current change depends on the concentration of AFB1 in the samples. Therefore, a series of experiments were performed to investigate the antigen–antibody interaction at HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion/GCE (Fig. 3a), HRP-anti-AFB1/TiO2/RTIL/Nafion/GCE (Fig. 3b), and HRP-anti-AFB1/nanogold/TiO2/Nafion/GCE (Fig. 3c), respectively. Seen from Fig. 3, one can find that the sensor with RTILs and nanogold shows much greatest amperometric response than those obtained at the other sensors. Moreover, the sensors with RTILs and nanogold exhibited more rapid current response than the sensors without RTILs or nanogold in terms of steady-state current. Some possible explanations may contribute to these phenomena. Firstly, the high surface-to-volume area of assembled nanogold may greatly enhance the immobilization density of HRP-anti-AFB1 [28]. Secondly, the nanometric edges of gold nanoparticles could penetrate slightly into the protein, which could make the distance between the electrode and the biomolecules and promote the electron transfer [29, 30]. Thirdly, RTILs possess good conductivity [31]. The above results apparently suggest that the immunosensors can generate better performances for AFB1 detection, and exhibit direct fast electron transfer reactivity as a result of the synergetic effect of RTILs and nanogold. Thus, the HRP-anti-AFB1/nanogold/TiO2/RTIL/Nafion/GCE electrodes were used to the following experiments.

Optimization of experimental conditions

To achieve the effective catalytic capability of the immobilized HRP-anti-AFB1, the concentration of the injected H2O2 substrate was studied (Fig. 4a). Low H2O2 concentration affects the sensitivity of the immunosensor (i.e. the linear range and detection limit of the immunosensor to CEA). Higher H2O2 concentration is redundant. In this study, the injected H2O2 concentration was investigated via the immobilized HRP-anti-AFB1 towards the H2O2 reduction without AFB1. As shown in Fig. 4a, the reduction current increased with the increment of the H2O2 concentration, and reached a plateau at about 0.28 mM. Higher concentration did not improve the response. So, 0.28 mM H2O2 was selected for the detection of AFB1.

The influence of pH value of the detection solution is an important parameter, because the acidity of solution greatly affects the activity of the immobilized protein [32]. Fig. 4b shows the effect of pH value of the detection solution on the current responses of the immunosensors in 0.1 M PBS containing 0.28 mM H2O2 after incubation with 5 ng/mL AFB1 for 20 min at room temperature. The analytical signal is based on the catalytic effect of the immobilized HRP on the H2O2 system before and after the antigen–antibody interaction. The current change was increased with the increment of pH value from pH 3.0 to 6.8 and then decreased. The optimal amperometric response was achieved at pH 6.8. Highly acidic or alkaline surroundings would damage the electrode, especially in alkalinity [33]. So pH 6.8 was selected as the optimum pH value for AFB1 detection.

The factors that influenced the immunoreaction between the immobilized HRP-anti-AFB1 and AFB1 in the sample included incubation time and incubation temperature. To enhance the practical application of the developed immunosensor, we chose the room temperature (25 ± 0.5 °C) for the antigen–antibody interaction. At this temperature, 5 ng/mL AFB1 was incubated with the immobilized HRP-anti-AFB1 for different time intervals. Analyzed from the experimental results (Fig. 4c), the current shift increased with increasing pre-incubation time, and tended to an optimal value after a pre-incubation time of 20 min, indicating a maximum combination of AFB1 with HRP-anti-AFB1. Thus, a pre-incubation time of 20 min was chosen for the antigen–antibody interaction.

Response characteristics and calibration curve of the AFB1 immunosensor

To assess the sensitive and the quantitative range of the proposed immunosensor, a voltammetric measurement was applied under optimized conditions. An enzyme-linked assay format was employed to detect AFB1 with HRP-anti-AFB1 molecules as tracer and hydrogen peroxide as enzyme substrate. The peak currents of the proposed immunosensor showed a decrease with an increasing AFB1 concentration in the sample solution after the antigen–antibody reaction (Fig. 5). As shown in inset of Fig. 5, the decrease of anodic peak current was proportional to AFB1 concentration in the range of 0.1 to 12 ng/mL and the linear regression equation is i p (μA) = 0.0416 + 0.1164 × C [AFB1] (ng/mL) with a detection of 0.05 ng/mL at a signal to noise ratio of 3δ (where δ is the standard deviation of a blank solution, n = 10) (R 2 = 0.991). When the AFB1 concentration was higher than 12 ng/mL, an appropriate dilution of sample was necessary in the pre-incubation step.

Reproducibility, precision and stability of the AFB1 immunosensor

The reproducibility of the immunoassay system was evaluated by intra- and inter-assay coefficients of variation (CVs). The intra-assay precision of the analytical method was evaluated by analyzing four concentration levels 10 times per run in 3 h. The CVs of intra-assay with this method were 4.3%, 5.1%, 3.8% and 5.9% at 1.0, 3.0, 6.0, and 10 ng/mL of AFB1, respectively. Similarly, the inter-assay CV on five immunosensors used independently was 7.1% and 5.4% for 1.0 ng/mL and 8.0 AFB1, respectively. Thus, the precision and reproducibility of the proposed immunoassay was acceptable. Additionally, the stability of the immunoassay system was examined. When the proposed immunosensors were stored in pH 6.8 PBS at 4 °C, it retained 91.4% of its initial response after a storage period of 19 days. The reason for the slow decrease of response might be the fact that the electrode materials were leached from the base surface or it is due to the partial deactivation of the immobilized HRP-anti-AFB1 incorporated in the composite.

Specificity and preliminary application of the AFB1 immunosensor

Among 18 different types of aflatoxins identified, the major ones are aflatoxin B1 (AFB1), AFB2, AFG1 and AFG2. The International Agency for Research on Cancer (IARC) has classified all four aflatoxins as Group 1 carcinogens (in order of toxicity, AFB1 > AFG1 > AFB2 > AFG2) [34]. Therefore, the current responses of the proposed immunosensor to AFB1 and AFG1, AFB2, AFG2 were studied. According to “recommended definitions and classification for electrochemical biosensor” [33, 34], selectivity is expressed as a ratio of the output signal with the analyte alone and with the interfering substance alone at the same concentration as the analyte. The as-prepared immunosensor demonstrated a high selectivity to AFB1 alone with weak response to AFB2, AFG1 and AFG2 as single substrates (Δi < 0.1 μA).

The feasibility of applying the proposed immunosensor to measure AFB1 levels in a complex matrix was also studied. This experiment was performed by spiking various levels of AFB1 standards into normal human sera and grape samples. These specimens were examined by the developed immunoassay and the ELISA method. The toxin content was calculated on the basis of the calibration curve of spiking samples. To make sure, the paired t-test was used to evaluate these two immunoassay methods. Statistical analysis of these data was shown in Table 1 at the 95% confidence level. At the same time, AFB1 measurements for normal human serum or pure grape samples only were also carried out as a control experiment. These data shows that there is no significant difference between the results given by two methods, which are in accordance with the results obtained using the standard methods proposed by ELISA. Thus, the analyzed values of AFB1 in human serum and grape samples are acceptable.

Comparison with other electrochemical AFB1 immunosensors

To highlight the advantages of the developed immunosensor, we have compared the analytical properties of the proposed immunosensors with those of other AFB1 electrochemical immunosensors [35–37]. The results are summarized in Table 2. As can be seen, the linear range and detection limit of the developed immunosensor are acceptable. The reasons could include: (i) the [EMIm][BF4]/sol–gel-doped organic–inorganic hybrids composite membrane could represent crack-free morphology [22, 38], and (ii) the EMIm cation-based ionic liquid usually could exhibit high conductivities derived from relatively short but asymmetric side-chains [39]. Importantly, the system was capable of continuously carrying out all steps in less than 40 min for one sample, including incubation of 20 min, washing, enzymatic reaction, determination procedures, and regeneration of sensor.

Conclusions

This work describes an electrochemical immunosensor with nanoparticle amplification for the detection of AFB1 in food. To construct such an immunoassay format, HRP-labeled AFB1 antibodies were immobilized onto a RTILs and nanogold particles-doped organic–inorganic hybrid sol–gel composite membrane. The presence of RTILs and gold nanoparticles could improve the reversibility of the system and enhance the sensitivity of the developed immunosensor for the detection of AFB1. The proposed immunoassay system shows acceptable reproducibility, stability and accuracy. In comparison with conventional ELISA approaches, the method proposed here is rapid and easy to automate for high sample throughput. Thus, this strategy could be readily extended toward the preparation of other immunosensors and the detection of other antigens or biocompounds.

References

L. Monaci, F. Palmisano, Anal. Bioanal. Chem. 378, 96 (2004)

M. Aghamohammadi, J. Hashemi, G.A. Kram, N. Alizadeh, Anal. Chim. Acta 582, 288 (2007)

N. Ammida, L. Micheli, G. Palleschi, Anal. Chim. Acta 520, 159 (2004)

N. Adanyi, I. Levkovets, S. Rodriguez-Gil, A. Ronald, M. Varadi, I. Szendro, Biosens. Bioelectron. 22, 797 (2007)

X. Sun, X. Zhao, J. Tiang, X. Gu, J. Zhou, F. Chu, Food Control 17, 256 (2006)

J. Wang, A. Ibanez, M.P. Chatrathi, J. Am. Chem. Soc. 125, 8444 (2003)

J. Wang, Electroanalysis 4, 415 (2007)

J. Wang, M. Musameh, Y. Lin, J. Am. Chem. Soc. 125, 2408 (2003)

O. Loaiza, R. Laocharoensuk, J. Burdick, M.C. Rodriguez, J.M. Pingarron, M. Pedrero, J. Wang, Angew Chem. Int. Ed. 46, 1508 (2007)

C. Mirkin, C. Niemeyer, Nanoparticles for electrochemical assays, in Nanobiotechnology II (Wiley-VCH, Weiheim, 2007), p. 125

Z. Dai, A. Kawde, Y. Xiang, J.T. La Belle, J. Gerlach, V.P. Bhavanandan, L. Joshi, J. Wang, J. Am. Chem. Soc. 128, 100018 (2006)

J. Wang, M. Scamicchio, A. Blasco, A. Escarpa, Anal. Chem. 78, 2060 (2006)

J. Wang, M. Scampicchio, R. Laocharoensuk, F. Valentini, O. González-García, J. Burdick, J. Am. Chem. Soc. 128, 4562 (2006)

J. Wang, A. Kawde, M. Rodriguez, Chem. Commun. 42, 67 (2005)

M. Kosmulski, E. Maczka, J.B. Rosenholm, J. Phys. Chem. B 106, 2918 (2002)

J. Wang, Small 1, 1036 (2005)

J. Wang, Analyst 139, 421 (2005)

P. Yu, J. Yan, J. Zhang, L. Mao, Electrochem. Commun. 9, 1139 (2007)

M. Lopez, D. Mecerreyes, E. Lopez-Cabarcos, B. Lopex-Ruiz, Biosens. Bioelectron. 21, 2320 (2006)

S. Wang, T. Chen, Z. Zhang, D. Pan, Electrochem. Commun. 9, 1337 (2007)

Y. Jiang, A. Wang, J. Kan, Sens. Actuators B 124, 529 (2007)

L. Zhang, Q. Zhang, J. Li, J. Electroanal. Chem. 603, 243 (2007)

J. Wang, P. Pamidi, D. Zannette, J. Am. Chem. Soc. 120, 5852 (1998)

R. Yuan, D.P. Tang, Y.Q. Chai, X. Zhong, Y. Liu, J.Y. Dai, Langmuir 20, 7240 (2004)

G. Shi, Y. Qu, Y. Zhai, Y. Liu, Z. Sun, J. Yang, L. Jin, Electrochem. Commun. 9, 1719 (2007)

R. Murray, in Electroanalytical Chemistry, vol. 13, ed. by A.J. Bard (Marcel Dekker, New York, 1984), pp. 191–368

B.Y. Won, H. Chol, K. Kim, S. Byun, H. Kim, H. Yoon, Biotechnol. Bioeng. 89, 815 (2005)

D. Tang, R. Yuan, Y. Chai, L. Zhang, J. Dai, Y. Liu, X. Zhong, Electroanalysis 17, 155 (2005)

X.Y. Chen, J.R. Li, X.C. Li, L. Jiang, Biochem. Biophys. Res. Commun. 245, 352 (1998)

J. Wang, G. Liu, M. Jan, J. Am. Chem. Soc. 126, 3010 (2004)

M.C. Buzzeo, C. Hardacre, R.G. Compton, Anal. Chem. 76, 4583 (2004)

D. Tang, R. Yuan, Y. Chai, Electroanalysis 18, 259 (2006)

D. Tang, J. Ren, Electroanalysis 17, 2208 (2005)

D. Thevenot, K. Toth, R. Durst, G. Wilson, Biosens. Bioelectron. 16, 121 (2001)

S. Piermarini, L. Micheli, N.H.S. Ammida, G. Palleschi, D. Moscone, Biosens. Bioelectron. 22, 1434 (2007)

J. Owino, A. Ignaszak, A. Al-Ahmed, P. Baker, H. Alemu, J. Ngila, E. Iwuoha, Anal. Bioanal. Chem. 388, 1069 (2007)

Y. Liu, Z. Qin, X. Wu, H. Jiang, Biochem. Eng. J. 32, 211 (2006)

G. Zhao, M. Xu, J. Ma, X. Wei, Electrochem. Commun. 9, 920 (2007)

K. Matsumoto, R. Hagiwara, Z. Mazej, P. Benkic, B. Zemva, Solid State Sci. 8, 1250 (2006)

Acknowledgements

Financial aid from the NSFH of China and the Science Foundation of Henan to Sun is gratefully acknowledged. The authors would like to thank Prof. K. Liang for his help in food tests and discussion of nanoparticles and antibody immobilization.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, AL., Qi, QA., Dong, ZL. et al. An electrochemical enzyme immunoassay for aflatoxin B1 based on bio-electrocatalytic reaction with room-temperature ionic liquid and nanoparticle-modified electrodes. Sens. & Instrumen. Food Qual. 2, 43–50 (2008). https://doi.org/10.1007/s11694-008-9040-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-008-9040-6